Injector Coding is the process of calibrating fuel injectors to optimize engine performance, and CAR-TOOL.EDU.VN provides comprehensive information to help you understand and implement this crucial procedure. By precisely matching injector characteristics to your engine’s ECU, injector programming enhances fuel efficiency, reduces emissions, and prevents potential injector failures. Explore CAR-TOOL.EDU.VN for expert insights into injector calibration, fuel injection systems, and engine management to unlock your vehicle’s full potential.

Contents

- 1. Understanding Injector Coding: The Basics

- 2. Why Is Injector Coding So Important for Your Vehicle?

- 3. Decoding the Benefits: What Injector Coding Achieves

- 4. The Injector Coding Process: A Step-by-Step Guide

- 5. Decoding Tools: Essential Equipment for Injector Coding

- 6. DIY vs. Professional Coding: Which Path Is Right for You?

- 7. Common Misconceptions About Injector Coding

- 8. Symptoms of Incorrect Injector Coding: Recognizing the Signs

- 9. Injector Coding vs. Injector Cleaning: What’s the Difference?

- 10. Maintaining Your Fuel Injectors: Best Practices for Longevity

- 11. Choosing the Right Fuel Injectors: A Buyer’s Guide

- 12. The Future of Injector Coding: Emerging Technologies

- 13. Understanding Fuel Trim and Its Relation to Injector Coding

- 14. Ethanol and Injector Coding: Considerations for Flex-Fuel Vehicles

- 15. Injector Coding and Engine Swaps: What You Need to Know

- 16. Injector Coding and Performance Tuning: Optimizing for Power

- 17. Troubleshooting Injector Coding Problems: A Diagnostic Approach

- 18. The Role of Sensors in Injector Coding Accuracy

- 19. Finding Reliable Injector Coding Services: What to Look For

- 20. Injector Coding and Vehicle Resale Value: An Investment in the Future

- FAQ: Frequently Asked Questions About Injector Coding

1. Understanding Injector Coding: The Basics

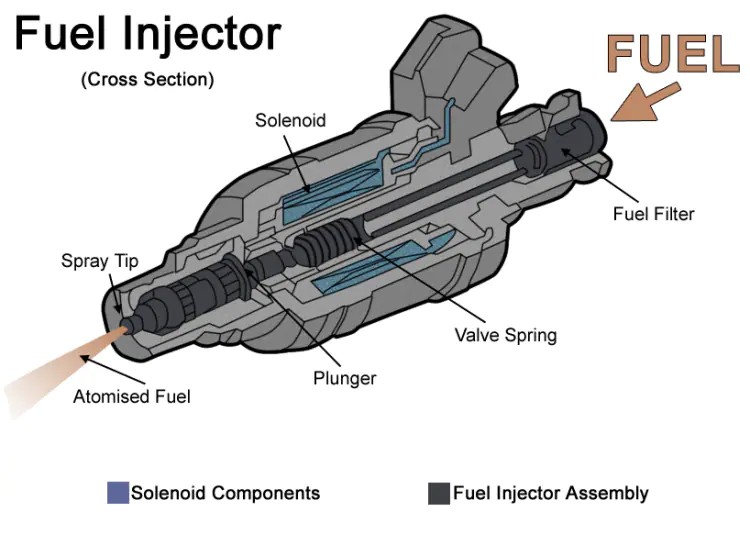

What exactly is injector coding, and why is it a necessary procedure for modern vehicles? Injector coding, also known as injector programming or calibration, is the process of assigning specific correction values to each fuel injector in an engine, enabling the engine control unit (ECU) to precisely manage fuel delivery. This is crucial because fuel injectors, even within the same production batch, exhibit slight variations in their performance characteristics. According to a study by the Society of Automotive Engineers (SAE), injector-to-injector variations can lead to imbalances in fuel distribution, negatively impacting engine performance and emissions. Coding allows the ECU to compensate for these individual differences, ensuring optimal combustion in each cylinder.

- Fuel Injector Variation: Even injectors from the same manufacturer have slight differences in flow rates and response times.

- ECU Compensation: Coding enables the ECU to adjust fuel delivery for each injector to account for these variations.

- Optimized Combustion: Proper coding leads to more efficient and complete combustion, improving performance and reducing emissions.

Fuel Injector

Fuel Injector

2. Why Is Injector Coding So Important for Your Vehicle?

Why should you care about injector coding, and what are the tangible benefits it offers? Injector coding is essential for maintaining optimal engine performance, fuel efficiency, and emissions control. When injectors are not properly coded, the ECU cannot accurately compensate for their individual variations. This can lead to a range of problems, including:

- Poor Fuel Economy: Inaccurate fuel delivery results in inefficient combustion, wasting fuel and increasing operating costs.

- Increased Emissions: Imbalances in air-fuel ratios lead to higher levels of harmful pollutants being released into the atmosphere.

- Rough Engine Running: Uneven combustion can cause engine misfires, vibrations, and a decrease in overall smoothness.

- Reduced Power Output: Suboptimal fuel delivery limits the engine’s ability to generate power, resulting in sluggish acceleration and decreased performance.

- Potential Engine Damage: In extreme cases, improperly coded injectors can cause localized overheating and damage to engine components.

Injector coding, therefore, is not just a minor adjustment; it’s a critical step in ensuring the longevity and optimal performance of your engine.

3. Decoding the Benefits: What Injector Coding Achieves

What specific advantages can you expect from properly coded fuel injectors? The benefits of injector coding are numerous and directly impact your vehicle’s performance and lifespan. Here’s a detailed look:

- Enhanced Fuel Efficiency: By ensuring precise fuel delivery, injector coding optimizes combustion, leading to significant improvements in fuel economy.

- Reduced Exhaust Emissions: Proper air-fuel ratios minimize the production of harmful pollutants, helping your vehicle meet emission standards.

- Smoother Engine Operation: Balanced fuel delivery eliminates misfires and vibrations, resulting in a smoother and more refined driving experience.

- Optimized Power Delivery: Accurate fuel metering allows the engine to generate its maximum power output, improving acceleration and overall performance.

- Extended Injector Lifespan: By reducing stress on individual injectors, coding helps to prolong their lifespan and prevent premature failures.

- Cost Savings: The combined benefits of improved fuel economy and reduced maintenance costs translate into significant savings over the long term.

According to a report by the Environmental Protection Agency (EPA), properly maintained fuel injection systems can improve fuel economy by as much as 15% and reduce emissions by up to 25%. Injector coding is a vital part of maintaining such a system.

4. The Injector Coding Process: A Step-by-Step Guide

How is injector coding actually performed, and what tools are required? The injector coding process typically involves these steps:

- Diagnostic Scan: The process begins with a diagnostic scan of the vehicle’s ECU to identify any existing fault codes related to the fuel injection system.

- Injector Identification: Each injector is identified, and its unique coding value is retrieved. This value is usually printed on the injector body or stored in the ECU.

- Hydraulic Parameter Measurement: Specialized diagnostic tools are used to measure the hydraulic parameters of each injector, such as its flow rate and response time.

- Correction Code Generation: Based on the measured parameters, the diagnostic tool generates a correction code for each injector.

- Code Input: The correction codes are then entered into the ECU using the diagnostic tool.

- Verification: After coding, the ECU is scanned again to ensure that the new codes have been successfully programmed and that no new fault codes have been generated.

- Test Drive: Finally, a test drive is performed to verify that the engine is running smoothly and that the benefits of coding are noticeable.

Tools required for injector coding include a professional-grade diagnostic scanner with injector coding capabilities, a laptop with appropriate software, and potentially a multimeter for electrical testing.

Fuel Injector diagram

Fuel Injector diagram

5. Decoding Tools: Essential Equipment for Injector Coding

What types of diagnostic tools are best suited for injector coding, and what features should you look for? Several diagnostic tools on the market are capable of performing injector coding. Here are some key features to consider when choosing a tool:

- Coverage: Ensure that the tool supports the make and model of your vehicle.

- Functionality: Look for a tool that can not only code injectors but also perform other diagnostic functions, such as reading fault codes, monitoring live data, and performing component testing.

- User-Friendliness: Choose a tool with an intuitive interface and clear instructions.

- Updates: Make sure that the tool receives regular software updates to stay compatible with new vehicle models and coding protocols.

- Accuracy: The tool should be able to accurately measure injector parameters and generate reliable correction codes.

Popular diagnostic tools for injector coding include those from manufacturers like Autel, Launch, Snap-on, and Bosch. These tools offer a range of features and price points to suit different needs and budgets.

6. DIY vs. Professional Coding: Which Path Is Right for You?

Should you attempt injector coding yourself, or is it best left to a professional mechanic? While it’s possible to perform injector coding yourself with the right tools and knowledge, there are several factors to consider:

- Expertise: Injector coding requires a thorough understanding of engine management systems and diagnostic procedures.

- Equipment: Professional-grade diagnostic tools can be expensive, and cheaper alternatives may not be reliable.

- Risk: Incorrect coding can lead to serious engine problems, potentially costing you more in the long run.

- Warranty: Attempting to code injectors yourself may void your vehicle’s warranty.

If you are an experienced mechanic with a solid understanding of engine diagnostics, DIY coding may be an option. However, for most vehicle owners, it’s best to entrust injector coding to a qualified professional.

7. Common Misconceptions About Injector Coding

What are some common myths and misunderstandings surrounding injector coding that you should be aware of? Here are a few misconceptions to clear up:

- Myth: Injector coding is only necessary for diesel engines.

- Fact: While more common in diesel engines, injector coding is also important for many modern gasoline engines with direct injection.

- Myth: All injectors of the same type have identical performance characteristics.

- Fact: Even injectors from the same production batch exhibit slight variations in their flow rates and response times.

- Myth: Injector coding is a one-time procedure that never needs to be repeated.

- Fact: Injectors can wear out over time, and their coding values may need to be adjusted or re-entered.

- Myth: Any diagnostic tool can perform injector coding.

- Fact: Injector coding requires a specialized diagnostic tool with the appropriate software and capabilities.

8. Symptoms of Incorrect Injector Coding: Recognizing the Signs

How can you tell if your fuel injectors are not properly coded, and what symptoms should you watch out for? The symptoms of incorrect injector coding can vary depending on the severity of the problem, but some common signs include:

- Reduced Fuel Economy: A noticeable decrease in gas mileage.

- Increased Emissions: Failing an emissions test or noticing excessive smoke from the exhaust.

- Rough Engine Running: Misfires, vibrations, or a lumpy idle.

- Reduced Power Output: Sluggish acceleration or a decrease in overall performance.

- Difficulty Starting: Hard starting or extended cranking times.

- Engine Knocking or Pinging: Abnormal noises from the engine.

- Check Engine Light: Illumination of the check engine light on the dashboard.

If you experience any of these symptoms, it’s important to have your fuel injectors inspected and coded by a qualified mechanic.

9. Injector Coding vs. Injector Cleaning: What’s the Difference?

Are injector coding and injector cleaning the same thing, and when is each procedure necessary? Injector coding and injector cleaning are two distinct procedures that address different aspects of fuel injector maintenance.

- Injector Coding: As previously explained, injector coding is the process of calibrating fuel injectors to optimize engine performance. It involves assigning specific correction values to each injector based on its individual characteristics.

- Injector Cleaning: Injector cleaning is the process of removing deposits and contaminants from the fuel injectors to restore their proper flow rate and spray pattern. Over time, fuel injectors can become clogged with carbon deposits, varnish, and other debris, which can restrict fuel flow and negatively impact engine performance.

Injector cleaning is typically recommended as a preventative maintenance measure, while injector coding is usually performed when injectors are replaced or when engine performance issues arise. In some cases, both procedures may be necessary to restore optimal engine operation.

10. Maintaining Your Fuel Injectors: Best Practices for Longevity

How can you prolong the lifespan of your fuel injectors and prevent the need for frequent coding or replacement? Here are some best practices for maintaining your fuel injectors:

- Use High-Quality Fuel: Using high-quality fuel from reputable sources can help to minimize the buildup of deposits in your fuel injectors.

- Regular Fuel Injector Cleaning: Consider using a fuel injector cleaner additive periodically to help keep your injectors clean.

- Replace Fuel Filter Regularly: A clogged fuel filter can restrict fuel flow and put extra strain on your fuel injectors.

- Avoid Running on Empty: Running your fuel tank consistently low can draw sediment and debris into the fuel injectors.

- Address Engine Problems Promptly: Issues like misfires or rough running can put extra stress on your fuel injectors.

By following these simple tips, you can help to prolong the lifespan of your fuel injectors and maintain optimal engine performance.

11. Choosing the Right Fuel Injectors: A Buyer’s Guide

If you need to replace your fuel injectors, how do you choose the right ones for your vehicle? Here are some factors to consider when selecting replacement fuel injectors:

- Compatibility: Ensure that the injectors are compatible with the make, model, and year of your vehicle.

- Flow Rate: Choose injectors with the correct flow rate for your engine’s horsepower and fuel requirements.

- Spray Pattern: Select injectors with a spray pattern that is optimized for your engine’s combustion chamber design.

- Quality: Choose injectors from reputable manufacturers known for their quality and reliability.

- Warranty: Look for injectors that come with a warranty to protect against defects.

Popular fuel injector brands include Bosch, Delphi, Denso, and Siemens. It’s always a good idea to consult with a qualified mechanic to determine the best fuel injectors for your specific needs.

12. The Future of Injector Coding: Emerging Technologies

How is injector coding technology evolving, and what new developments can you expect to see in the future? The field of injector coding is constantly evolving, with new technologies and techniques being developed to improve accuracy and efficiency. Some emerging trends include:

- Adaptive Coding: Systems that automatically adjust injector coding values in real-time based on engine operating conditions.

- Cloud-Based Coding: Diagnostic tools that utilize cloud-based databases to access the latest coding information and calibration data.

- AI-Powered Coding: Diagnostic tools that use artificial intelligence to analyze injector performance and generate optimal coding values.

- Remote Coding: The ability to perform injector coding remotely via the internet.

These advancements promise to make injector coding more accurate, efficient, and accessible in the years to come.

13. Understanding Fuel Trim and Its Relation to Injector Coding

What is fuel trim, and how does it relate to injector coding? Fuel trim refers to the adjustments that the ECU makes to the air-fuel ratio in order to maintain optimal combustion. There are two types of fuel trim:

- Short-Term Fuel Trim (STFT): Instantaneous adjustments made by the ECU based on sensor readings.

- Long-Term Fuel Trim (LTFT): Gradual adjustments made by the ECU over time to compensate for long-term changes in engine performance.

Incorrect injector coding can cause fuel trim values to deviate significantly from their normal range. For example, if an injector is delivering too much fuel, the ECU will reduce the fuel trim to compensate. Conversely, if an injector is delivering too little fuel, the ECU will increase the fuel trim. Monitoring fuel trim values can be a useful diagnostic tool for identifying injector-related problems.

14. Ethanol and Injector Coding: Considerations for Flex-Fuel Vehicles

If you own a flex-fuel vehicle that can run on gasoline or ethanol, are there any special considerations for injector coding? Ethanol can have different effects on fuel injectors compared to gasoline. Ethanol is more corrosive than gasoline and can also absorb water, which can lead to fuel injector problems. When coding injectors in a flex-fuel vehicle, it’s important to:

- Use Compatible Injectors: Ensure that the injectors are designed to be compatible with ethanol.

- Use the Correct Coding Values: Flex-fuel vehicles may require different coding values depending on the percentage of ethanol in the fuel.

- Monitor Fuel System Components: Keep a close eye on fuel system components for signs of corrosion or degradation.

15. Injector Coding and Engine Swaps: What You Need to Know

If you’re performing an engine swap, what considerations should you keep in mind regarding injector coding? When swapping an engine, it’s essential to ensure that the fuel injectors are properly matched to the new engine’s specifications. This may involve:

- Using Injectors from the New Engine: Ideally, you should use the fuel injectors that came with the new engine.

- Checking Injector Compatibility: If you’re using different injectors, make sure they are compatible with the new engine’s ECU and fuel requirements.

- Coding the Injectors: After installing the injectors, you’ll need to code them to the new engine’s ECU.

- Verifying Fuel Trim: Monitor fuel trim values to ensure that the injectors are delivering the correct amount of fuel.

Failing to properly address injector coding during an engine swap can lead to a range of performance problems and potentially damage the engine.

16. Injector Coding and Performance Tuning: Optimizing for Power

Can injector coding be used to enhance engine performance in modified vehicles? Injector coding can play a crucial role in performance tuning, especially in vehicles with modified engines. By carefully selecting and coding fuel injectors, tuners can:

- Increase Fuel Flow: Use injectors with a higher flow rate to provide more fuel to the engine.

- Optimize Spray Pattern: Select injectors with a spray pattern that is optimized for the engine’s combustion chamber design.

- Fine-Tune Fuel Delivery: Precisely adjust fuel delivery to maximize power output.

However, it’s important to note that increasing fuel flow without making other necessary modifications can lead to engine damage. Injector coding should always be performed in conjunction with other tuning adjustments to ensure that the engine is operating safely and efficiently.

17. Troubleshooting Injector Coding Problems: A Diagnostic Approach

What steps should you take to troubleshoot injector coding problems, and how can you identify the root cause of the issue? When troubleshooting injector coding problems, it’s important to follow a systematic diagnostic approach:

- Scan the ECU: Check for any fault codes related to the fuel injection system.

- Verify Injector Coding: Make sure that the injectors are properly coded to the ECU.

- Check Injector Parameters: Use a diagnostic tool to monitor injector parameters, such as flow rate and response time.

- Inspect Injectors: Visually inspect the injectors for signs of damage or contamination.

- Perform Injector Testing: Use a specialized injector tester to evaluate injector performance.

- Check Fuel System Components: Inspect the fuel pump, fuel filter, and fuel pressure regulator for any issues.

By following these steps, you can systematically narrow down the possible causes of the problem and identify the appropriate solution.

18. The Role of Sensors in Injector Coding Accuracy

How do various sensors in your vehicle contribute to the accuracy of injector coding and overall engine performance? Several sensors play a crucial role in ensuring the accuracy of injector coding and the optimal performance of the fuel injection system:

- Oxygen Sensors: These sensors measure the amount of oxygen in the exhaust gas and provide feedback to the ECU, allowing it to adjust the air-fuel ratio.

- Mass Airflow (MAF) Sensor: This sensor measures the amount of air entering the engine, providing the ECU with information needed to calculate the correct amount of fuel to inject.

- Crankshaft Position Sensor (CKP): This sensor monitors the position of the crankshaft, providing the ECU with timing information needed to control fuel injection and ignition.

- Camshaft Position Sensor (CMP): This sensor monitors the position of the camshaft, providing the ECU with information needed to synchronize fuel injection and ignition.

- Throttle Position Sensor (TPS): This sensor monitors the position of the throttle, providing the ECU with information needed to adjust fuel delivery based on driver demand.

Properly functioning sensors are essential for accurate injector coding and optimal engine performance.

19. Finding Reliable Injector Coding Services: What to Look For

How do you find a reputable and qualified mechanic to perform injector coding services? When choosing a mechanic to perform injector coding, consider the following factors:

- Experience: Look for a mechanic with extensive experience in diagnosing and repairing fuel injection systems.

- Certifications: Check if the mechanic is certified by reputable organizations, such as the National Institute for Automotive Service Excellence (ASE).

- Equipment: Ensure that the mechanic has the necessary diagnostic tools and equipment to perform injector coding accurately.

- Reputation: Read online reviews and ask for recommendations from friends and family.

- Warranty: Inquire about the mechanic’s warranty policy on their services.

Choosing a qualified and experienced mechanic can help to ensure that your injector coding is performed correctly and that your vehicle’s engine is running optimally.

20. Injector Coding and Vehicle Resale Value: An Investment in the Future

Does injector coding have any impact on your vehicle’s resale value? While injector coding may not be a direct selling point, maintaining your vehicle’s engine in optimal condition can certainly enhance its resale value. Potential buyers are more likely to pay a premium for a vehicle that has been well-maintained and runs smoothly. By ensuring that your fuel injectors are properly coded and that your engine is running efficiently, you’re investing in the long-term value of your vehicle.

To find the perfect tools for your car, visit CAR-TOOL.EDU.VN at 456 Elm Street, Dallas, TX 75201, United States or contact us via Whatsapp at +1 (641) 206-8880. Our team of experts is ready to assist you.

Don’t let your vehicle suffer from poorly coded injectors! Contact CAR-TOOL.EDU.VN today and experience the difference that professional injector coding can make. Our skilled technicians use state-of-the-art equipment to ensure your engine runs at peak performance. Call us now or visit our website at CAR-TOOL.EDU.VN to schedule your appointment. Your car will thank you.

FAQ: Frequently Asked Questions About Injector Coding

-

What is the purpose of injector coding?

Injector coding allows the ECU to compensate for individual variations in fuel injector performance, ensuring optimal fuel delivery and engine performance. -

How often should I have my fuel injectors coded?

Injector coding is typically recommended when injectors are replaced or when engine performance issues arise. -

Can I perform injector coding myself?

While possible with the right tools and knowledge, it’s generally best to leave injector coding to a qualified professional. -

What are the symptoms of incorrect injector coding?

Symptoms can include reduced fuel economy, increased emissions, rough engine running, and reduced power output. -

How much does injector coding cost?

The cost of injector coding can vary depending on the mechanic and the type of vehicle. -

What tools are needed for injector coding?

Injector coding requires a specialized diagnostic tool with injector coding capabilities. -

Is injector coding the same as injector cleaning?

No, injector coding and injector cleaning are two distinct procedures that address different aspects of fuel injector maintenance. -

Can injector coding improve my gas mileage?

Yes, proper injector coding can optimize combustion and improve fuel economy. -

Does injector coding affect emissions?

Yes, proper injector coding can minimize the production of harmful pollutants and help your vehicle meet emission standards. -

Where can I find reliable injector coding services?

Look for a mechanic with experience, certifications, and a good reputation.

Remember, for all your automotive tool and diagnostic needs, CAR-TOOL.EDU.VN is your trusted partner. Our expert team is dedicated to providing you with the highest quality products and services to keep your vehicle running smoothly. Visit us at 456 Elm Street, Dallas, TX 75201, United States, or reach out via Whatsapp at +1 (641) 206-8880. Let us help you unlock the full potential of your vehicle!