Dtc On Code Reader, also known as Diagnostic Trouble Codes on scan tools, are essential for identifying vehicle malfunctions and ensuring efficient automotive repairs. CAR-TOOL.EDU.VN provides detailed information on DTCs, helping you understand their significance and application in vehicle diagnostics. Explore how to interpret these codes and use them effectively with our comprehensive guide and diagnostic equipment resources, ensuring you can quickly address vehicle issues and keep your fleet running smoothly.

Contents

- 1. Understanding DTCs: The Basics

- 1.1. The Role of OBD Systems in Generating DTCs

- 1.2. Key Components Monitored by DTCs

- 1.3. The Significance of Standardized DTCs

- 1.4. Types of DTC Standards: OBD-II and J1939

- 2. Decoding DTCs: A Step-by-Step Guide

- 2.1. Breaking Down the First Character

- 2.2. Understanding the Second Character

- 2.3. Deciphering the Third Character

- 2.4. Identifying the Fault Index: Fourth and Fifth Characters

- 2.5. Example: Decoding P0420

- 3. Interpreting J1939 DTCs for Heavy-Duty Vehicles

- 3.1. Understanding Suspect Parameter Number (SPN)

- 3.2. Decoding Failure Mode Identifier (FMI)

- 3.3. The Role of Occurrence Counter (OC)

- 3.4. SPN Conversion Method (CM): An Overview

- 3.5. Real-World Application of J1939 Codes

- 4. Clearing DTCs: Best Practices and Precautions

- 4.1. Using a Code Reader to Clear DTCs

- 4.2. When to Avoid Clearing DTCs

- 4.3. Understanding Permanent DTCs

- 4.4. The Importance of Addressing the Root Cause

- 4.5. Resetting the System After Clearing DTCs

- 5. Telematics Systems for DTC Monitoring in Fleets

- 5.1. Setting Up Real-Time DTC Alerts

- 5.2. Automating Fleet Maintenance with DTC Data

- 5.3. Generating DTC Reports for Fleet Analysis

- 5.4. Integrating Telematics with Maintenance Management Systems

- 5.5. Benefits of Proactive DTC Monitoring

- 6. Choosing the Right Code Reader for Your Needs

- 6.1. Basic vs. Advanced Code Readers

- 6.2. Compatibility with Vehicle Makes and Models

- 6.3. Essential Features to Look For

- 6.4. Budget Considerations

- 6.5. Top Code Reader Brands and Models

- 7. Troubleshooting Common DTC-Related Issues

- 7.1. Verifying DTC Accuracy

- 7.2. Checking for Related Symptoms

- 7.3. Common Sensor Problems

- 7.4. Diagnosing Wiring Issues

- 7.5. Control Module Malfunctions

- 8. Staying Updated with DTC Information

- 8.1. Industry Publications and Resources

- 8.2. Training Seminars and Workshops

- 8.3. Online Forums and Communities

- 8.4. Keeping Code Readers and Software Up-To-Date

- 8.5. Consulting Vehicle-Specific Service Information

- 9. FAQ: Decoding DTC on Code Reader

- 9.1. What Does DTC Stand For?

- 9.2. How Do I Read a DTC?

- 9.3. Can I Fix My Car With Just a DTC?

- 9.4. What Is an OBD-II Scanner?

- 9.5. Where Is the OBD-II Port Located?

- 9.6. Are All DTCs the Same?

- 9.7. Can I Clear DTCs Myself?

- 9.8. What Is a Permanent DTC?

1. Understanding DTCs: The Basics

What exactly are DTCs, and why are they crucial for modern vehicle maintenance?

Diagnostic Trouble Codes (DTCs) are alphanumeric codes generated by a vehicle’s onboard diagnostic (OBD) system to indicate specific malfunctions. According to the Society of Automotive Engineers (SAE), these codes provide a standardized way to identify and address issues within a vehicle’s various systems. DTCs are vital because they allow technicians and vehicle owners to quickly pinpoint problems, leading to faster and more accurate repairs. Understanding how DTCs work is the first step in effective vehicle diagnostics and maintenance.

1.1. The Role of OBD Systems in Generating DTCs

How do On-Board Diagnostic (OBD) systems function to produce Diagnostic Trouble Codes (DTCs)?

On-Board Diagnostic (OBD) systems monitor the performance of a vehicle’s engine, transmission, and other critical components. When the OBD system detects a problem, it stores a corresponding Diagnostic Trouble Code (DTC) in the vehicle’s computer memory. According to a study by the Environmental Protection Agency (EPA), OBD systems are designed to ensure vehicles meet emissions standards and to alert drivers to potential issues that could affect performance or safety. These systems continuously analyze data from various sensors, and when a reading falls outside the acceptable range, a DTC is triggered. This process enables early detection of malfunctions, preventing more severe damage and reducing repair costs.

1.2. Key Components Monitored by DTCs

Which specific vehicle parts are tracked by Diagnostic Trouble Codes (DTCs)?

Diagnostic Trouble Codes (DTCs) monitor a broad spectrum of vehicle components, encompassing the engine, transmission, fuel system, emissions control, and electrical systems. The powertrain, which includes the engine and transmission, is frequently monitored for issues like misfires, fuel delivery problems, and transmission malfunctions. Emissions control systems, such as catalytic converters and oxygen sensors, are also closely tracked to ensure compliance with environmental regulations. Electrical systems, including sensors and wiring, are monitored for shorts, open circuits, and other faults. According to a report by the National Institute for Automotive Service Excellence (ASE), knowing which components DTCs monitor helps technicians focus their diagnostic efforts, leading to more efficient and accurate repairs.

1.3. The Significance of Standardized DTCs

Why is it vital for Diagnostic Trouble Codes (DTCs) to be consistent across different vehicle brands?

Standardized Diagnostic Trouble Codes (DTCs) ensure that regardless of the vehicle’s make or model, a specific code indicates the same general problem. This standardization is crucial for technicians who work on various vehicles, as it allows them to quickly understand the nature of the issue without needing to learn different code systems for each brand. According to SAE International, standardized DTCs streamline the diagnostic process, reduce the likelihood of misdiagnosis, and improve the overall efficiency of automotive repairs. This consistency also benefits vehicle owners, as they can receive more reliable information about their vehicle’s condition from any qualified mechanic.

OBD-II scanner displaying DTC code

OBD-II scanner displaying DTC code

1.4. Types of DTC Standards: OBD-II and J1939

What distinguishes OBD-II and J1939 Diagnostic Trouble Code (DTC) standards, and where are they utilized?

OBD-II and J1939 are distinct Diagnostic Trouble Code (DTC) standards tailored for different vehicle categories. OBD-II is predominantly used in light and medium-duty vehicles, typically those under 10,000 pounds, and has been mandatory in the United States since 1996, as mandated by the EPA. Conversely, J1939 is designed for heavy-duty vehicles like buses, trucks, and construction equipment, which often exceed 26,000 pounds. The main difference lies in their communication protocols and the specific data they monitor. OBD-II focuses on emissions-related issues, while J1939 offers more comprehensive diagnostics for complex systems in heavy-duty vehicles. Technicians need to understand these differences to accurately diagnose and repair vehicles across various weight classes.

2. Decoding DTCs: A Step-by-Step Guide

How can you effectively interpret DTCs to diagnose vehicle issues?

Decoding DTCs involves understanding the structure of the code and using that information to pinpoint the source of the problem. Each character in a DTC provides specific information about the nature and location of the fault. By systematically breaking down the code, you can narrow down the potential causes and focus your diagnostic efforts. This step-by-step approach ensures a more efficient and accurate diagnosis, saving time and reducing the risk of unnecessary repairs. CAR-TOOL.EDU.VN offers resources and tools to help you decode DTCs effectively.

2.1. Breaking Down the First Character

What does the initial character of a Diagnostic Trouble Code (DTC) signify?

The first character of a Diagnostic Trouble Code (DTC) indicates the system where the fault originated. There are four main categories:

- P (Powertrain): Relates to the engine, transmission, and related components.

- C (Chassis): Pertains to systems like brakes, suspension, and steering.

- B (Body): Involves components within the passenger compartment, such as airbags and power windows.

- U (Network): Indicates issues with the vehicle’s computer network.

According to Automotive Engineering International, knowing this first character helps technicians quickly identify the general area of the problem, streamlining the diagnostic process.

2.2. Understanding the Second Character

What does the second character in a Diagnostic Trouble Code (DTC) indicate?

The second character of a Diagnostic Trouble Code (DTC) specifies whether the code is standardized or manufacturer-specific. A “0” indicates a generic code, meaning it applies to all vehicles that comply with OBD-II standards. A “1” signifies an enhanced or manufacturer-specific code, which is unique to the particular make and model of the vehicle. According to a technical bulletin from Bosch Automotive, understanding this distinction is crucial because manufacturer-specific codes may require access to specialized diagnostic information from the vehicle manufacturer.

2.3. Deciphering the Third Character

What information does the third character in a Diagnostic Trouble Code (DTC) provide?

The third character in a Diagnostic Trouble Code (DTC) pinpoints the specific subsystem experiencing the malfunction. This character can be a number from 0 to 7, each representing a different subsystem:

- 0: Fuel and air metering and auxiliary emission controls.

- 1: Fuel and air metering injection system.

- 2: Fuel and air metering (injection system).

- 3: Ignition systems or misfires.

- 4: Auxiliary emission controls.

- 5: Vehicle speed control, idle control systems, and auxiliary inputs.

- 6: Computer output circuit.

- 7-8: Transmission.

According to a guide by the National Automotive Service Task Force (NASTF), this character helps narrow down the diagnostic focus to the relevant subsystem, improving efficiency.

2.4. Identifying the Fault Index: Fourth and Fifth Characters

What do the fourth and fifth characters of a Diagnostic Trouble Code (DTC) represent?

The fourth and fifth characters of a Diagnostic Trouble Code (DTC) form a two-digit number, ranging from 0 to 99, known as the “Specific Fault Index.” This index identifies the precise nature of the malfunction within the subsystem indicated by the third character. For example, in the code P0420, the “20” specifies a problem with the catalytic converter. According to a study by the University of California, Berkeley, these characters provide the most detailed information about the fault, enabling technicians to accurately diagnose and address the issue.

2.5. Example: Decoding P0420

What does the Diagnostic Trouble Code (DTC) P0420 indicate about a vehicle’s condition?

The Diagnostic Trouble Code (DTC) P0420 indicates a problem with the vehicle’s catalytic converter.

- P: Indicates a powertrain issue, specifically related to the engine or transmission.

- 0: Signifies a generic OBD-II code, applicable to all compliant vehicles.

- 4: Points to a problem with auxiliary emission controls.

- 20: Specifically identifies the catalytic converter as the source of the issue.

This code suggests that the catalytic converter’s efficiency is below the required threshold, possibly due to a malfunctioning oxygen sensor or a damaged converter. Addressing this issue promptly is important for maintaining emissions compliance and preventing further damage.

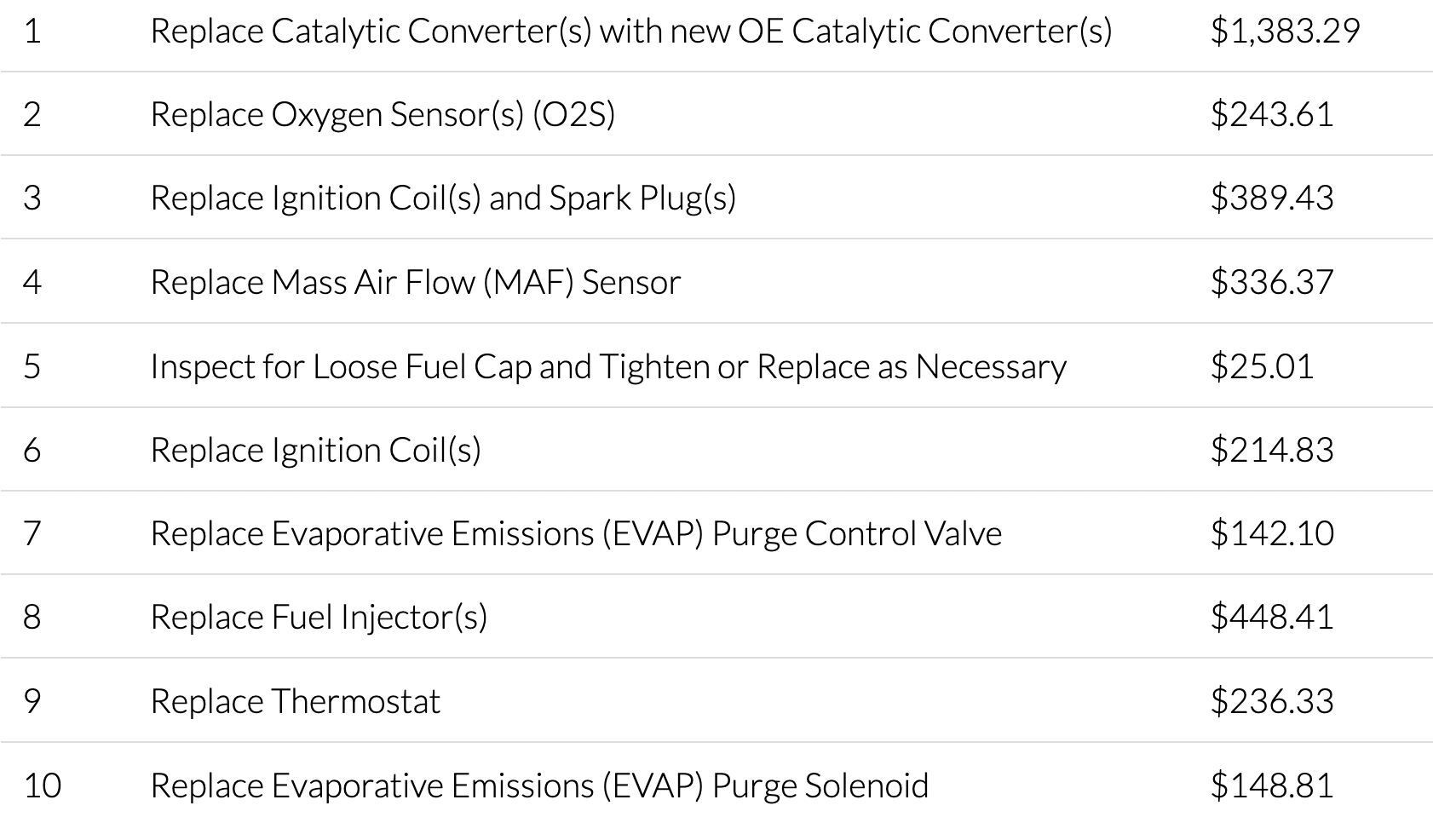

Common check engine vehicle repairs in the US

Common check engine vehicle repairs in the US

3. Interpreting J1939 DTCs for Heavy-Duty Vehicles

How are Diagnostic Trouble Codes (DTCs) interpreted under the J1939 standard for heavy-duty vehicles?

Interpreting J1939 Diagnostic Trouble Codes (DTCs) for heavy-duty vehicles involves understanding the four key fields that comprise the code: Suspect Parameter Number (SPN), Failure Mode Identifier (FMI), Occurrence Counter (OC), and SPN Conversion Method (CM). Unlike OBD-II codes, J1939 codes provide more detailed information about the specific component and type of failure. Properly interpreting these codes enables technicians to quickly identify and address issues in heavy-duty vehicles, minimizing downtime and repair costs. CAR-TOOL.EDU.VN offers specialized tools and resources for diagnosing J1939 DTCs.

3.1. Understanding Suspect Parameter Number (SPN)

What does the Suspect Parameter Number (SPN) signify within a J1939 Diagnostic Trouble Code (DTC)?

The Suspect Parameter Number (SPN) in a J1939 Diagnostic Trouble Code (DTC) is a unique diagnostic fault code assigned by the SAE to a specific part or electrical subsystem. It helps technicians pinpoint the exact location of the problem within the vehicle. For instance, an SPN might indicate an issue with a particular sensor, actuator, or electronic control unit (ECU). According to the SAE J1939 standards, the SPN is crucial for directing diagnostic efforts to the relevant component, ensuring a more efficient and accurate repair process.

3.2. Decoding Failure Mode Identifier (FMI)

What does the Failure Mode Identifier (FMI) indicate in a J1939 Diagnostic Trouble Code (DTC)?

The Failure Mode Identifier (FMI) in a J1939 Diagnostic Trouble Code (DTC) specifies the type of error that has occurred. Examples of FMIs include short circuits, open circuits, calibration errors, and abnormal update rates. According to a technical guide from Cummins, the FMI provides critical information about the nature of the fault, helping technicians understand how the component has failed. For instance, an FMI might indicate that a sensor is providing an out-of-range signal or that a circuit is experiencing an interruption. This level of detail enables a more targeted and effective diagnostic approach.

3.3. The Role of Occurrence Counter (OC)

What is the purpose of the Occurrence Counter (OC) in a J1939 Diagnostic Trouble Code (DTC)?

The Occurrence Counter (OC) in a J1939 Diagnostic Trouble Code (DTC) tracks the number of times a specific error or failure has been detected. Each time the error is detected, the OC number increases by one. This counter helps technicians understand the frequency and consistency of the problem. According to a report by the Diesel Technology Forum, a high OC value may indicate an intermittent issue or a recurring problem that needs immediate attention. Monitoring the OC can also assist in identifying whether a fault is becoming more frequent, which can be a sign of a deteriorating component.

3.4. SPN Conversion Method (CM): An Overview

What is the SPN Conversion Method (CM) in J1939 Diagnostic Trouble Codes (DTCs), and why is it important?

The SPN Conversion Method (CM) in J1939 Diagnostic Trouble Codes (DTCs) defines the byte alignment within the DTC and indicates how the SPN and FMI should be handled or translated. It is primarily used for older versions of the diagnostic protocols. According to the Truck and Engine Manufacturers Association (TEMA), the CM ensures that diagnostic tools can correctly interpret the SPN and FMI, even if they are using different communication protocols. This is particularly important for backward compatibility and for ensuring that a wide range of diagnostic equipment can effectively communicate with the vehicle’s electronic control units (ECUs).

3.5. Real-World Application of J1939 Codes

How can understanding J1939 Diagnostic Trouble Codes (DTCs) benefit fleet managers and technicians in practical scenarios?

Understanding J1939 Diagnostic Trouble Codes (DTCs) provides significant benefits for fleet managers and technicians by enabling more efficient diagnostics and maintenance. For example, a fleet manager using a telematics system can receive real-time alerts when a J1939 code is triggered, allowing them to address issues proactively. According to a case study by the American Trucking Associations (ATA), technicians can use the SPN and FMI to quickly identify the faulty component and the nature of the failure, reducing diagnostic time and minimizing vehicle downtime. This leads to cost savings and improved operational efficiency for the fleet.

4. Clearing DTCs: Best Practices and Precautions

What are the recommended procedures for clearing Diagnostic Trouble Codes (DTCs) and what precautions should be taken?

Clearing Diagnostic Trouble Codes (DTCs) should only be done after the underlying issue has been properly diagnosed and resolved. Using a code reader to clear DTCs without fixing the problem will only result in the check engine light turning back on. Best practices include using a reliable OBD-II scanner, following the manufacturer’s instructions, and verifying that the issue is resolved before clearing the code. Additionally, be aware of permanent DTCs that cannot be cleared until the vehicle’s system confirms the problem is fixed. CAR-TOOL.EDU.VN provides resources and tools to help you clear DTCs safely and effectively.

4.1. Using a Code Reader to Clear DTCs

How can a code reader be used to clear Diagnostic Trouble Codes (DTCs) from a vehicle’s computer?

A code reader can clear Diagnostic Trouble Codes (DTCs) by connecting to the vehicle’s OBD-II port, typically located under the dashboard. Once connected, turn on the ignition without starting the engine and follow the code reader’s instructions to access the DTCs. Most code readers have an option to clear the codes, which will reset the check engine light. According to a guide by Popular Mechanics, it’s essential to record the DTCs before clearing them, as this information can be useful if the problem recurs. Also, ensure that the underlying issue has been resolved to prevent the codes from reappearing.

4.2. When to Avoid Clearing DTCs

In which situations should you refrain from clearing Diagnostic Trouble Codes (DTCs) in a vehicle?

You should avoid clearing Diagnostic Trouble Codes (DTCs) if the underlying problem has not been identified and fixed. Clearing the codes without addressing the issue will only temporarily turn off the check engine light, and the problem will likely return, potentially causing further damage. According to a recommendation by the National Highway Traffic Safety Administration (NHTSA), it’s also important to avoid clearing DTCs immediately before an emissions test, as the vehicle’s system may not have enough time to reset, leading to a failed test. Always diagnose and repair the issue before clearing the codes.

4.3. Understanding Permanent DTCs

What are permanent Diagnostic Trouble Codes (DTCs), and how do they differ from regular DTCs?

Permanent Diagnostic Trouble Codes (DTCs) are a specific type of code that cannot be cleared using a standard OBD-II scanner or by disconnecting the vehicle’s battery. These codes are stored in the vehicle’s computer until the system verifies that the underlying issue has been resolved through multiple drive cycles. According to the EPA, permanent DTCs were introduced to prevent drivers from clearing codes just before an emissions test, ensuring accurate testing results. The only way to clear a permanent DTC is to fix the problem and allow the vehicle’s system to clear the code automatically.

4.4. The Importance of Addressing the Root Cause

Why is it crucial to address the underlying cause of a Diagnostic Trouble Code (DTC) rather than just clearing the code?

Addressing the root cause of a Diagnostic Trouble Code (DTC) is crucial because merely clearing the code only provides a temporary solution. The underlying problem will persist, potentially leading to further damage and more costly repairs. According to a study by AAA, ignoring DTCs can result in decreased fuel efficiency, reduced engine performance, and increased emissions. By properly diagnosing and fixing the issue, you ensure the vehicle operates efficiently and safely, preventing future problems.

4.5. Resetting the System After Clearing DTCs

What steps should be taken to reset a vehicle’s system after clearing Diagnostic Trouble Codes (DTCs)?

After clearing Diagnostic Trouble Codes (DTCs), it’s important to perform a drive cycle to allow the vehicle’s system to reset and recalibrate. A drive cycle involves driving the vehicle under specific conditions, such as maintaining a steady speed for a certain period or performing a series of accelerations and decelerations. According to a guide by the California Bureau of Automotive Repair, completing a drive cycle ensures that all the vehicle’s systems are functioning correctly and that the diagnostic monitors are ready for an emissions test. Consult your vehicle’s service manual for the specific drive cycle requirements.

5. Telematics Systems for DTC Monitoring in Fleets

How can telematics systems be utilized to monitor Diagnostic Trouble Codes (DTCs) in a fleet of vehicles?

Telematics systems offer a comprehensive solution for monitoring Diagnostic Trouble Codes (DTCs) across an entire fleet. These systems provide real-time alerts when a DTC is triggered, allowing fleet managers to quickly identify and address issues. Additionally, telematics systems can automate maintenance schedules, track vehicle performance, and generate reports on DTC trends. This proactive approach helps reduce downtime, lower repair costs, and improve overall fleet efficiency. CAR-TOOL.EDU.VN offers advanced telematics solutions for effective fleet management.

5.1. Setting Up Real-Time DTC Alerts

How can real-time alerts for Diagnostic Trouble Codes (DTCs) be set up in a telematics system?

Real-time alerts for Diagnostic Trouble Codes (DTCs) can be set up in a telematics system by configuring the system to monitor the vehicle’s OBD-II port continuously. When a DTC is detected, the system automatically sends an alert to the fleet manager or designated personnel via email, SMS, or a dashboard notification. According to a whitepaper by Verizon Connect, these alerts typically include the DTC code, a brief description of the issue, and the vehicle’s location. Setting up these alerts allows for immediate action, reducing the risk of further damage and minimizing downtime.

5.2. Automating Fleet Maintenance with DTC Data

How can Diagnostic Trouble Code (DTC) data be used to automate and improve fleet maintenance schedules?

Diagnostic Trouble Code (DTC) data can automate and improve fleet maintenance schedules by providing insights into the health and performance of each vehicle. Telematics systems can analyze DTC trends to predict when maintenance is needed, scheduling service based on actual vehicle condition rather than fixed intervals. According to a case study by Teletrac Navman, this proactive approach helps prevent breakdowns, extend vehicle lifespan, and optimize maintenance costs. For example, if a specific DTC related to engine performance is frequently triggered, the system can schedule an engine tune-up to address the issue before it escalates.

5.3. Generating DTC Reports for Fleet Analysis

How can Diagnostic Trouble Code (DTC) reports be generated and used for analyzing fleet performance and identifying trends?

Diagnostic Trouble Code (DTC) reports can be generated through telematics systems to analyze fleet performance and identify trends. These reports provide a comprehensive overview of the DTCs triggered across the fleet over a specific period. Fleet managers can use this data to identify common issues, track the frequency of specific DTCs, and assess the overall health of their vehicles. According to a study by Frost & Sullivan, this analysis can help optimize maintenance schedules, improve driver behavior, and reduce downtime. For example, if a particular vehicle model consistently triggers DTCs related to brake issues, the fleet manager can investigate whether there is a manufacturing defect or a need for more frequent brake inspections.

5.4. Integrating Telematics with Maintenance Management Systems

How can telematics systems be integrated with maintenance management systems for streamlined operations?

Integrating telematics systems with maintenance management systems streamlines operations by automating the transfer of Diagnostic Trouble Code (DTC) data and maintenance schedules. When a DTC is triggered, the telematics system automatically creates a work order in the maintenance management system, assigning it to a technician and scheduling the necessary repairs. According to a report by the Technology & Maintenance Council (TMC), this integration reduces administrative overhead, improves communication between fleet managers and technicians, and ensures that maintenance tasks are completed promptly. This leads to increased efficiency and reduced downtime for the fleet.

5.5. Benefits of Proactive DTC Monitoring

What are the key advantages of proactively monitoring Diagnostic Trouble Codes (DTCs) in a fleet using telematics systems?

The key advantages of proactively monitoring Diagnostic Trouble Codes (DTCs) in a fleet using telematics systems include reduced downtime, lower repair costs, improved vehicle performance, and enhanced safety. By receiving real-time alerts and addressing issues promptly, fleet managers can prevent minor problems from escalating into major breakdowns. According to a study by Aberdeen Group, proactive DTC monitoring can reduce maintenance costs by up to 20% and increase vehicle uptime by 15%. Additionally, it helps ensure that vehicles are operating efficiently, reducing fuel consumption and emissions, and improving overall fleet sustainability.

6. Choosing the Right Code Reader for Your Needs

How can you select the most suitable code reader for your particular automotive diagnostic needs?

Selecting the right code reader involves considering factors such as the types of vehicles you work on, the level of diagnostic information you need, and your budget. Basic code readers are suitable for reading and clearing DTCs, while advanced scan tools offer features like live data streaming, bidirectional controls, and access to manufacturer-specific codes. It’s also important to choose a code reader that is compatible with the vehicles you service and that comes with reliable software updates. CAR-TOOL.EDU.VN offers a wide range of code readers to meet various needs.

6.1. Basic vs. Advanced Code Readers

What are the primary distinctions between basic and advanced code readers in terms of functionality and features?

Basic code readers primarily read and clear Diagnostic Trouble Codes (DTCs), offering a simple and cost-effective solution for identifying common vehicle issues. Advanced code readers, also known as scan tools, provide a wider range of functionalities, including live data streaming, bidirectional controls, access to manufacturer-specific codes, and advanced diagnostic tests. According to a comparison by Consumer Reports, advanced code readers are better suited for professional technicians and serious DIY enthusiasts who need more in-depth diagnostic capabilities. While basic code readers are sufficient for simple tasks, advanced tools offer more comprehensive diagnostic insights.

6.2. Compatibility with Vehicle Makes and Models

Why is it crucial to ensure that a code reader is compatible with the specific makes and models of vehicles you service?

Ensuring that a code reader is compatible with the specific makes and models of vehicles you service is crucial because different vehicles use different communication protocols and Diagnostic Trouble Codes (DTCs). A code reader that is not compatible may not be able to accurately read the DTCs or access the vehicle’s diagnostic system. According to a technical bulletin by Snap-on, using an incompatible code reader can lead to inaccurate diagnoses, wasted time, and potential damage to the vehicle’s electronic control units (ECUs). Always verify compatibility before purchasing a code reader.

6.3. Essential Features to Look For

What key features should you consider when selecting a code reader for automotive diagnostics?

When selecting a code reader, consider essential features such as OBD-II compatibility, DTC definitions, live data streaming, bidirectional controls, and software updates. OBD-II compatibility ensures the reader can communicate with most modern vehicles. DTC definitions provide clear explanations of the codes, helping with diagnosis. Live data streaming allows you to monitor sensor values in real-time, and bidirectional controls enable you to command the vehicle’s systems for testing purposes. According to a guide by AutoZone, regular software updates ensure the code reader stays current with new vehicle models and diagnostic protocols.

6.4. Budget Considerations

How should you balance your budget with the features and capabilities you need in a code reader?

Balancing your budget with the features and capabilities you need in a code reader involves assessing your diagnostic requirements and prioritizing the functions that are most important to you. Basic code readers are generally more affordable but offer limited features, while advanced scan tools come with a higher price tag but provide more comprehensive diagnostic capabilities. According to a review by Car and Driver, consider the types of vehicles you work on, the complexity of the repairs you typically perform, and your long-term diagnostic needs. Investing in a mid-range code reader that offers a good balance of features and affordability may be the best option for many users.

6.5. Top Code Reader Brands and Models

Which brands and models of code readers are highly recommended in the automotive industry?

Several brands and models of code readers are highly recommended in the automotive industry, including those from Snap-on, Bosch, Autel, and Innova. Snap-on and Bosch are known for their professional-grade scan tools that offer advanced features and comprehensive coverage. Autel provides a range of code readers that cater to both professional technicians and DIY enthusiasts. Innova offers affordable and user-friendly options that are ideal for basic diagnostic tasks. According to a survey by the Professional Tool & Equipment News (PTEN), these brands consistently receive high ratings for their performance, reliability, and customer support.

7. Troubleshooting Common DTC-Related Issues

How can you effectively troubleshoot common issues related to Diagnostic Trouble Codes (DTCs) to ensure accurate diagnoses and repairs?

Troubleshooting common issues related to Diagnostic Trouble Codes (DTCs) involves verifying the accuracy of the code, checking for related symptoms, and systematically testing the affected components. It’s important to use a reliable code reader, consult vehicle-specific service information, and follow a logical diagnostic process. Common issues include faulty sensors, wiring problems, and malfunctioning control modules. By addressing these issues methodically, you can ensure accurate diagnoses and effective repairs. CAR-TOOL.EDU.VN provides resources and tools to support your troubleshooting efforts.

7.1. Verifying DTC Accuracy

Why is it crucial to verify the accuracy of a Diagnostic Trouble Code (DTC) before proceeding with repairs?

Verifying the accuracy of a Diagnostic Trouble Code (DTC) is crucial because misinterpreting or relying on a faulty code can lead to unnecessary repairs and wasted time. Sometimes, a DTC may be triggered by a temporary issue or a malfunctioning sensor, rather than a genuine problem. According to a technical article by Motor Age, it’s important to confirm the code by checking for related symptoms, consulting vehicle-specific service information, and using a reliable code reader. Verifying the accuracy of the DTC ensures that you are addressing the actual problem and not chasing a ghost.

7.2. Checking for Related Symptoms

How can checking for related symptoms help in diagnosing issues associated with Diagnostic Trouble Codes (DTCs)?

Checking for related symptoms helps in diagnosing issues associated with Diagnostic Trouble Codes (DTCs) by providing additional clues about the nature and location of the problem. Symptoms such as decreased engine performance, unusual noises, or abnormal readings on the dashboard can indicate which components are affected. According to a guide by the Automotive Service Association (ASA), correlating the DTC with the symptoms helps narrow down the potential causes and focus your diagnostic efforts. For example, if a DTC indicates a problem with the oxygen sensor, checking for symptoms like poor fuel economy or a rough-running engine can confirm the diagnosis.

7.3. Common Sensor Problems

What are some of the most frequent issues encountered with sensors that can trigger Diagnostic Trouble Codes (DTCs)?

Some of the most frequent issues encountered with sensors that can trigger Diagnostic Trouble Codes (DTCs) include contamination, electrical faults, and physical damage. Contamination from oil, coolant, or other fluids can affect sensor readings, leading to inaccurate data. Electrical faults, such as short circuits or open circuits, can disrupt the sensor’s signal. Physical damage from impacts or vibrations can also cause sensor malfunction. According to a technical bulletin by Standard Motor Products, regularly inspecting and testing sensors can help identify these issues early, preventing more serious problems.

7.4. Diagnosing Wiring Issues

What methods and tools can be used to effectively diagnose wiring issues that may be causing Diagnostic Trouble Codes (DTCs)?

Effective diagnosis of wiring issues causing Diagnostic Trouble Codes (DTCs) involves visual inspection, testing continuity, and checking for voltage drops. Visual inspection can reveal obvious problems like frayed wires, corroded connectors, or damaged insulation. Testing continuity with a multimeter ensures that the wire is not broken or disconnected. Checking for voltage drops can identify areas of high resistance that are impeding the flow of electricity. According to a guide by Fluke Corporation, using a wiring diagram and a systematic approach can help you trace the circuit and locate the source of the problem.

7.5. Control Module Malfunctions

How can control module malfunctions be identified and addressed when troubleshooting Diagnostic Trouble Codes (DTCs)?

Control module malfunctions can be identified and addressed by checking for consistent DTCs, testing the module’s inputs and outputs, and performing a module reset or reprogramming. Consistent DTCs that cannot be cleared or that reappear immediately often indicate a problem with the control module itself. Testing the module’s inputs and outputs with a scan tool or multimeter can verify whether it is receiving and sending signals correctly. According to a technical article by Delphi Technologies, if the module is not functioning properly, a reset or reprogramming may be necessary. In some cases, the module may need to be replaced.

8. Staying Updated with DTC Information

How can you stay informed about the latest updates and changes related to Diagnostic Trouble Codes (DTCs) and automotive diagnostic technology?

Staying updated with DTC information requires continuous learning and access to reliable resources. Subscribing to industry publications, attending training seminars, and participating in online forums can provide valuable insights into the latest DTC updates and diagnostic techniques. Additionally, using up-to-date code readers and diagnostic software ensures you have access to the most current information. CAR-TOOL.EDU.VN is committed to providing the latest resources and information to help you stay ahead in automotive diagnostics.

8.1. Industry Publications and Resources

Which industry publications and resources are most valuable for staying informed about Diagnostic Trouble Codes (DTCs)?

Valuable industry publications and resources for staying informed about Diagnostic Trouble Codes (DTCs) include Motor Age, Automotive Engineering International, and the websites of organizations like SAE International and ASE. Motor Age provides practical articles and technical tips for diagnosing and repairing vehicles. Automotive Engineering International offers in-depth coverage of automotive technology and standards. SAE International publishes the J1939 and OBD-II standards, and ASE provides certification and training for automotive technicians. According to a survey by the National Automotive Service Task Force (NASTF), these resources are essential for staying current with the latest DTC information and diagnostic techniques.

8.2. Training Seminars and Workshops

What are the benefits of attending training seminars and workshops focused on Diagnostic Trouble Codes (DTCs) and automotive diagnostics?

Attending training seminars and workshops focused on Diagnostic Trouble Codes (DTCs) offers several benefits, including hands-on experience, expert instruction, and networking opportunities. These events provide a structured learning environment where you can deepen your understanding of DTCs, learn new diagnostic techniques, and practice using advanced scan tools. According to a report by the TechForce Foundation, training seminars can also help you stay current with the latest automotive technology and meet continuing education requirements for certifications.

8.3. Online Forums and Communities

How can participating in online forums and communities enhance your knowledge of Diagnostic Trouble Codes (DTCs)?

Participating in online forums and communities can enhance your knowledge of Diagnostic Trouble Codes (DTCs) by providing access to a wealth of collective knowledge and real-world experiences. These platforms allow you to ask questions, share insights, and learn from other technicians and enthusiasts. According to a survey by the Automotive Management Institute (AMI), online forums are a valuable resource for troubleshooting complex diagnostic problems and staying informed about the latest DTC trends.

8.4. Keeping Code Readers and Software Up-To-Date

Why is it important to keep your code readers and diagnostic software updated with the latest information?

Keeping your code readers and diagnostic software updated is important because automotive technology is constantly evolving, and new vehicles and systems are introduced regularly. Updates often include new Diagnostic Trouble Code (DTC) definitions, enhanced diagnostic capabilities, and bug fixes. According to a technical bulletin by Autel, using outdated code readers and software can lead to inaccurate diagnoses and missed opportunities to identify and resolve vehicle issues effectively.

8.5. Consulting Vehicle-Specific Service Information

Why is it essential to consult vehicle-specific service information when diagnosing Diagnostic Trouble Codes (DTCs)?

Consulting vehicle-specific service information is essential because it provides detailed guidance on diagnosing and repairing issues related to Diagnostic Trouble Codes (DTCs). This information includes wiring diagrams, component locations, diagnostic procedures, and troubleshooting tips that are specific to the vehicle’s make, model, and year. According to a recommendation by Mitchell 1, using vehicle-specific service information ensures that you are following the correct procedures and avoiding potential damage to the vehicle.

9. FAQ: Decoding DTC on Code Reader

Do you have questions about DTC on code reader? We’ve compiled a list of frequently asked questions to help you understand the topic better.

9.1. What Does DTC Stand For?

What is the full meaning of the acronym DTC in the context of automotive diagnostics?

DTC stands for Diagnostic Trouble Code. It is an alphanumeric code used in vehicle onboard diagnostic systems to indicate a specific malfunction or issue detected by the system.

9.2. How Do I Read a DTC?

What steps are involved in reading a Diagnostic Trouble Code (DTC) from a vehicle’s computer system?

To read a Diagnostic Trouble Code (DTC), you need to use an OBD-II scanner or code reader. Connect the scanner to the vehicle’s OBD-II port, turn on the ignition, and follow the scanner’s instructions to retrieve the DTCs stored in the vehicle’s computer.

9.3. Can I Fix My Car With Just a DTC?

Is it possible to diagnose and repair a vehicle solely based on the information provided by a Diagnostic Trouble Code (DTC)?

No, you cannot reliably fix your car with just a Diagnostic Trouble Code (DTC). While the DTC provides a starting point, you need to perform further diagnostics to identify the root cause of the issue.

9.4. What Is an OBD-II Scanner?

What is the function and purpose of an OBD-II scanner in automotive diagnostics?

An OBD-II scanner is a diagnostic tool used to read and interpret Diagnostic Trouble Codes (DTCs) from a vehicle’s onboard diagnostic system. It connects to the vehicle’s OBD-II port and provides information about the vehicle’s condition.

9.5. Where Is the OBD-II Port Located?

Where can I typically find the OBD-II port in a passenger vehicle for connecting a diagnostic scanner?

The OBD-II port is typically located under the dashboard on the driver’s side of the vehicle. It is often near the steering column or in the center console area.

9.6. Are All DTCs the Same?

Do all Diagnostic Trouble Codes (DTCs) indicate the same type or severity of issue across different vehicles?

No, all Diagnostic Trouble Codes (DTCs) are not the same. Some DTCs are generic and apply to all OBD-II compliant vehicles, while others are manufacturer-specific and unique to certain makes and models.

9.7. Can I Clear DTCs Myself?

Is it advisable for vehicle owners to clear Diagnostic Trouble Codes (DTCs) on their own, and what precautions should they take?

Yes, you can clear Diagnostic Trouble Codes (DTCs) yourself using an OBD-II scanner. However, it is important to diagnose and fix the underlying issue first to prevent the code from reappearing.

9.8. What Is a Permanent DTC?

What distinguishes a permanent Diagnostic Trouble Code (DTC) from a regular DTC, and how is it cleared?

A permanent Diagnostic Trouble Code (DTC) cannot be cleared using a standard OBD-II scanner. It is stored in the vehicle’s computer until the system verifies that the issue has been resolved