Coolant Delete, the process of bypassing the rotor cooling system in Tesla Large Drive Units (LDU), is a potential solution to the persistent issue of coolant leaks, offering a more permanent fix for Model S, MB B250e, and RAV4 EV owners facing this problem, and CAR-TOOL.EDU.VN is here to provide the information you need to make an informed decision. Understanding the implications of coolant removal, alternative cooling strategies, and DIY modification options can help extend the life of your LDU and prevent costly repairs. Explore coolant bypass solutions and rotor cooling system modifications with CAR-TOOL.EDU.VN.

Contents

- 1. What is Coolant Delete and Why Is It Necessary?

- 2. What are the Primary Objectives of Performing a Coolant Delete?

- 3. How Do You Know If Your Tesla LDU Needs a Coolant Delete?

- 4. What are the Potential Drawbacks of Coolant Delete?

- 5. What are the Alternative Cooling Strategies to Coolant Delete?

- 6. How to Perform a DIY Coolant Delete on a Tesla LDU Manifold?

- 7. What Tools Do You Need for a Coolant Delete?

- 8. What are the Safety Precautions When Performing a Coolant Delete?

- 9. How Much Does a Coolant Delete Typically Cost?

- 10. What are the Most Reliable Coolant Delete Kits on the Market?

- FAQ: Coolant Delete on Tesla LDU

1. What is Coolant Delete and Why Is It Necessary?

Coolant delete refers to the process of bypassing the liquid cooling system for the rotor in Tesla Large Drive Units (LDUs). This modification is often considered as a solution to the persistent problem of coolant leaks that can lead to significant damage within the drive unit.

The necessity for coolant delete arises from the inherent design flaws in the original Tesla LDU cooling system, specifically the rotor seal. The rotor is cooled using a water-based glycol mixture that circulates through its hollow shaft. The design incorporates a lip seal on one end of the rotor shaft to prevent coolant leakage. However, these seals, despite multiple revisions, have proven unreliable, leading to coolant seeping into sealed chambers within the LDU. According to Johan from “DIY EV Guy” on YouTube, the absence of a weep hole, a standard engineering practice for water pump shaft seal designs, exacerbates this issue.

The ramifications of a leaking rotor seal are far-reaching:

- Bearing Damage: Coolant infiltrates the outer rotor bearing, eventually causing its destruction if the leak persists long enough.

- Stator Contamination: Coolant migrates into the stator cavity, compromising the electrical isolation resistance of the stator.

- Inverter Failure: If the LDU continues to operate with a compromised stator, coolant can travel through a tunnel at the bottom of the gearcase, where the high-voltage (HV) phase leads run, ultimately reaching and damaging the inverter electronics. This can lead to spurious alert codes or, in severe cases, complete inverter failure, rendering the LDU irreparable.

Given these potential consequences and the unreliability of Tesla’s remanufactured LDUs, where leaks often reappear after only a short period, coolant delete has emerged as a viable alternative. By eliminating the liquid cooling of the rotor, this modification removes the source of potential leaks, providing a more permanent solution for owners of Model S, MB B250e, and RAV4 EV vehicles. While Tesla has seemingly adopted a version of coolant delete in their remanufactured units, aftermarket solutions and DIY approaches have also gained traction as cost-effective ways to address this well-known issue. These methods aim to prevent coolant from leaking and causing extensive damage to the LDU’s critical components.

2. What are the Primary Objectives of Performing a Coolant Delete?

The primary objective of performing a coolant delete is to eliminate the risk of coolant leaks within the Tesla Large Drive Unit (LDU) and prevent consequential damage to its critical components. Coolant leaks in LDUs are a well-documented issue, stemming from the failure of the rotor seal, which is responsible for containing the water-based glycol coolant within the rotor’s hollow shaft.

Specifically, the key objectives are as follows:

- Eliminate Coolant Leaks: The most immediate goal is to prevent coolant from leaking out of the rotor cooling system. These leaks can lead to a cascade of problems, including bearing failure, stator contamination, and inverter damage. By bypassing the rotor cooling system, the source of the leak is effectively removed.

- Prevent Bearing Damage: Coolant leaks often find their way into the outer rotor bearing, leading to corrosion and eventual failure. Coolant delete aims to protect the bearing by eliminating the coolant’s presence in this area.

- Protect the Stator and Inverter: Coolant contamination of the stator can compromise its electrical isolation resistance, while coolant reaching the inverter can cause severe electrical damage. Coolant delete aims to safeguard these critical components by preventing coolant from entering these areas.

- Extend LDU Lifespan: By addressing the root cause of coolant-related issues, coolant delete can significantly extend the lifespan of the LDU. This is particularly important for owners of older Tesla Model S, MB B250e, and RAV4 EV vehicles, where LDU replacements can be costly and difficult to source.

- Reduce Maintenance and Repair Costs: Coolant leaks can lead to a cycle of repairs, including seal replacements, bearing replacements, and even complete LDU replacements. By implementing coolant delete, owners can avoid these recurring expenses.

- Improve Reliability: By eliminating a known failure point, coolant delete enhances the overall reliability of the LDU, reducing the risk of unexpected breakdowns and downtime.

The implementation of coolant delete is often seen as a proactive measure to address a known vulnerability in the LDU design. While alternative solutions, such as improved seals and weep holes, have been explored, they have not proven to be as reliable as completely bypassing the rotor cooling system. Coolant delete offers a more permanent solution for those seeking to mitigate the risks associated with coolant leaks in their Tesla LDUs.

3. How Do You Know If Your Tesla LDU Needs a Coolant Delete?

Determining whether your Tesla Large Drive Unit (LDU) requires a coolant delete involves recognizing the signs of coolant leakage and assessing the potential damage it can cause. Here’s how you can identify if your LDU might benefit from this modification:

-

Visual Inspection for Coolant Leaks:

- Regularly inspect the speed sensor chamber for the presence of blue coolant. As mentioned by “DIY EV Guy“, this is a common indicator of a leaking rotor seal.

- Check for coolant stains or drips around the LDU housing, particularly near the rotor case cap and coolant manifold.

-

Monitoring for “Check EV System” Alerts:

- Pay attention to any “Check EV System” alerts on your dashboard, as these can sometimes be triggered by coolant-related issues within the LDU.

-

Assessing Coolant Loss:

- Monitor the coolant level in your vehicle’s coolant reservoir. A significant and unexplained drop in coolant level could indicate a leak within the LDU.

-

Inspecting the Rotor Bearing:

- If you suspect a leak, consider inspecting the rotor bearing for signs of corrosion or damage caused by coolant infiltration. This may require partial disassembly of the LDU.

-

Checking Stator Isolation Resistance:

- A drop in stator isolation resistance can indicate coolant contamination. This requires specialized equipment to measure and should be performed by a qualified technician.

Coolant Leak

Coolant Leak

-

Considering Mileage and Age:

- LDUs in older vehicles, particularly those with higher mileage, are more prone to coolant leaks due to the degradation of the rotor seal over time.

-

Evaluating LDU History:

- If your LDU has been previously remanufactured, be aware that these units have a history of recurring leaks. Coolant delete may be a proactive solution to prevent future issues.

If you observe any of these symptoms, it’s crucial to take action to prevent further damage. While adding a weep hole or installing a water monitor can provide early warnings of coolant leaks, they do not address the root cause of the problem. Coolant delete, on the other hand, offers a more permanent solution by eliminating the risk of coolant leakage altogether. Consulting with a qualified mechanic experienced in EV repair is highly recommended to assess the condition of your LDU and determine if coolant delete is the appropriate course of action. CAR-TOOL.EDU.VN can help you find the right professionals and resources to make an informed decision.

4. What are the Potential Drawbacks of Coolant Delete?

While coolant delete offers a promising solution to the persistent problem of coolant leaks in Tesla Large Drive Units (LDUs), it’s essential to consider the potential drawbacks before implementing this modification. Bypassing the rotor cooling system can have implications for the LDU’s thermal management and overall performance.

The primary concerns associated with coolant delete include:

-

Reduced Rotor Cooling Efficiency:

- The most obvious drawback is the reduction in rotor cooling efficiency. The liquid cooling system is designed to dissipate heat generated within the rotor, particularly during high-performance driving or towing. Removing this cooling mechanism can lead to higher rotor temperatures.

-

Potential for Overheating:

- In demanding driving conditions, such as sustained high speeds, uphill climbs, or towing heavy loads, the rotor may overheat without adequate cooling. Overheating can lead to decreased performance, accelerated wear, and potentially even damage to the rotor and other LDU components.

-

Impact on Longevity:

- The long-term effects of running the LDU without rotor cooling are not fully understood. It’s possible that higher operating temperatures could shorten the lifespan of the rotor, bearings, and other internal components.

-

Firmware Compatibility:

- It’s unclear whether Tesla firmware is designed to accommodate LDUs without rotor cooling. There may be potential compatibility issues or error codes that could arise after implementing coolant delete.

Tesla Drive Unit

Tesla Drive Unit

-

Warranty Implications:

- Performing coolant delete will likely void any remaining warranty on the LDU or other related components. This is an important consideration for owners of newer vehicles.

Despite these potential drawbacks, many owners have successfully implemented coolant delete without experiencing significant issues. The suitability of this modification depends on several factors, including driving habits, climate, and vehicle usage. If you primarily use your vehicle for commuting or light driving and live in a temperate climate, the risks associated with coolant delete may be minimal. However, if you frequently engage in high-performance driving, towing, or live in a hot climate, the potential for overheating and reduced longevity may be more significant.

Before proceeding with coolant delete, it’s essential to weigh the risks and benefits carefully and consult with a qualified mechanic experienced in EV repair. Alternative cooling strategies, such as improved air cooling or the use of alternative coolants, may also be worth exploring. CAR-TOOL.EDU.VN offers a wealth of information and resources to help you make an informed decision.

5. What are the Alternative Cooling Strategies to Coolant Delete?

While coolant delete offers a straightforward solution to prevent coolant leaks in Tesla Large Drive Units (LDUs), alternative cooling strategies can help mitigate the potential drawbacks of removing the rotor’s liquid cooling system. These strategies aim to enhance heat dissipation and maintain optimal operating temperatures, even without liquid cooling.

Here are some alternative cooling strategies to consider:

-

Improved Air Cooling:

- Enhancing air cooling can help compensate for the loss of liquid cooling. This can involve modifications to the LDU housing to improve airflow, such as adding vents or scoops to direct air towards the rotor.

- Installing a larger or more efficient fan can also increase airflow and improve heat dissipation.

-

Heat Sink Addition:

- Adding a heat sink to the rotor or LDU housing can provide additional surface area for heat to dissipate into the surrounding air. The heat sink should be made of a thermally conductive material, such as aluminum or copper, and properly attached to the rotor or housing.

-

Alternative Coolants:

- Instead of completely removing the liquid cooling system, consider replacing the water-based glycol coolant with a non-water-based coolant, such as a waterless coolant or a light oil. These coolants have higher boiling points and better thermal conductivity, which can improve cooling efficiency.

-

Reduced Power Output:

- Limiting the power output of the LDU can reduce the amount of heat generated within the rotor. This can be achieved through software modifications or by adjusting driving habits to avoid sustained high-performance driving.

-

Temperature Monitoring:

- Installing temperature sensors on the rotor and LDU housing can provide real-time data on operating temperatures. This allows you to monitor the effectiveness of your cooling strategy and make adjustments as needed.

-

Combination of Strategies:

- Combining multiple cooling strategies can provide the most effective solution. For example, you could enhance air cooling with a heat sink and use an alternative coolant for improved thermal conductivity.

Tesla Drive Unit Modification

Tesla Drive Unit Modification

When selecting an alternative cooling strategy, consider your driving habits, climate, and vehicle usage. If you frequently engage in high-performance driving or live in a hot climate, you’ll need a more robust cooling solution than someone who primarily uses their vehicle for commuting in a temperate climate. Consulting with a qualified mechanic experienced in EV repair is highly recommended to determine the most appropriate cooling strategy for your specific needs. CAR-TOOL.EDU.VN offers a wealth of information and resources to help you make an informed decision and find the right products and services for your vehicle.

6. How to Perform a DIY Coolant Delete on a Tesla LDU Manifold?

Performing a DIY coolant delete on a Tesla LDU manifold involves modifying the existing manifold to bypass the rotor cooling system. This requires careful planning, precision, and a good understanding of the LDU’s cooling system. It is essential to emphasize that this modification carries inherent risks, and improper execution can lead to damage to the LDU. If you are not comfortable with this level of complexity, it is best to seek professional assistance.

Here’s a step-by-step guide to performing a DIY coolant delete on a Tesla LDU manifold:

1. Preparation:

- Gather Necessary Tools and Materials:

- Socket set and wrenches

- Coolant drain pan

- Safety glasses and gloves

- Aluminum plug or cup

- Drill with various bits

- Taps

- Epoxy or welding equipment (depending on the chosen method)

- Gaskets and sealants

- Disconnect the High Voltage System: Ensure the vehicle is completely powered down and the high voltage system is disconnected before starting any work on the LDU.

- Drain the Coolant: Properly drain the coolant from the LDU’s cooling system into a drain pan. Dispose of the coolant responsibly.

- Remove the Coolant Manifold: Carefully remove the coolant manifold from the LDU. This typically involves removing several bolts and disconnecting coolant hoses.

2. Modification:

There are several approaches to modifying the coolant manifold to bypass the rotor cooling system. Here are a few common methods:

- Aluminum Cup Method:

- Machine or purchase an aluminum cup that fits snugly into the rotor seal cavity in the manifold.

- Press the aluminum cup into the cavity, effectively blocking coolant flow to the rotor.

- Ensure the cup is securely in place and sealed to prevent leaks.

- Drilling and Tubing Method:

- Drill a hole from the flyover tube down to below the reluctor chamber in the manifold.

- Run a metal tube from the top to the bottom of the hole, creating a bypass for coolant flow.

- Ensure the tube is securely in place and sealed to prevent leaks.

- Welding or Epoxy Method:

- Weld or epoxy the internal passage to the rotor, blocking coolant flow.

- This can be done with or without retaining the flyover tube flow.

- Ensure the weld or epoxy is strong and completely seals the passage.

3. Reassembly:

- Clean the Manifold: Thoroughly clean the modified coolant manifold to remove any debris or contaminants.

- Install New Gaskets and Sealants: Use new gaskets and sealants to ensure a proper seal between the manifold and the LDU.

- Reinstall the Manifold: Carefully reinstall the modified coolant manifold onto the LDU, tightening the bolts to the specified torque.

- Reconnect Coolant Hoses: Reconnect the coolant hoses to the manifold, ensuring they are securely attached and properly sealed.

- Refill the Coolant System: Refill the LDU’s cooling system with fresh coolant.

Tesla Drive Unit Manifold

Tesla Drive Unit Manifold

4. Testing:

- Check for Leaks: Carefully inspect the modified coolant manifold and coolant hoses for any signs of leaks.

- Monitor Temperature: Monitor the temperature of the LDU during operation to ensure it is not overheating.

- Test Drive: Perform a test drive to verify that the LDU is functioning properly and there are no warning lights or error codes.

Remember, this is a complex modification, and it’s crucial to proceed with caution and consult with experienced professionals if you have any doubts. CAR-TOOL.EDU.VN provides access to a network of experts and resources to help you navigate this process safely and effectively.

7. What Tools Do You Need for a Coolant Delete?

Performing a coolant delete on a Tesla LDU requires a specific set of tools to ensure the job is done correctly and safely. Having the right tools not only makes the process easier but also minimizes the risk of damaging the LDU or injuring yourself.

Here’s a list of essential tools you’ll need for a coolant delete:

-

Safety Gear:

- Safety glasses: To protect your eyes from debris and coolant splashes.

- Gloves: To protect your hands from chemicals and sharp edges.

-

Basic Hand Tools:

- Socket set: A comprehensive set of sockets in various sizes to remove and install bolts and nuts.

- Wrenches: A set of open-end and box-end wrenches for accessing hard-to-reach fasteners.

- Screwdrivers: Both flathead and Phillips head screwdrivers for removing screws and clips.

- Pliers: A set of pliers, including needle-nose and regular pliers, for gripping and manipulating parts.

-

Coolant System Tools:

- Coolant drain pan: To collect the coolant when draining the system.

- Hose clamp pliers: To safely remove and install hose clamps without damaging the hoses.

- Funnel: To refill the coolant system without spills.

-

Modification Tools:

- Drill: For drilling holes in the coolant manifold (if necessary for your chosen method).

- Drill bits: A set of drill bits in various sizes for drilling precise holes.

- Tap and die set: For threading holes in the coolant manifold (if necessary).

- Grinder or file: For smoothing rough edges or removing material from the coolant manifold.

-

Sealing and Fastening:

- Torque wrench: To ensure bolts and nuts are tightened to the correct specifications.

- Gasket scraper: To remove old gaskets and sealant from mating surfaces.

- Sealant applicator: For applying new sealant to mating surfaces.

-

Optional Tools:

- Impact wrench: To quickly remove stubborn bolts and nuts.

- Multimeter: To check electrical connections and ensure proper grounding.

- Diagnostic scanner: To check for error codes after the modification is complete.

Having access to these tools will streamline the coolant delete process and increase the likelihood of a successful outcome. Remember to use high-quality tools and follow proper safety procedures to avoid injury or damage to the LDU. CAR-TOOL.EDU.VN offers a wide selection of automotive tools and equipment to help you tackle this and other maintenance tasks with confidence.

8. What are the Safety Precautions When Performing a Coolant Delete?

Performing a coolant delete on a Tesla LDU involves working with potentially hazardous materials and high-voltage components. Prioritizing safety is paramount to prevent injury and ensure the successful completion of the project.

Here are essential safety precautions to follow when performing a coolant delete:

-

High Voltage Disconnection:

- Disconnect the High Voltage System: This is the most critical safety precaution. Ensure the vehicle is completely powered down and the high voltage system is disconnected before starting any work on the LDU. Follow Tesla’s official procedures for disconnecting the high voltage system, which typically involves removing the service disconnect and waiting for a specified period to allow the capacitors to discharge.

- Verify Disconnection: Use a high-voltage multimeter to verify that the high voltage system is indeed disconnected and that there is no residual voltage present.

-

Personal Protective Equipment (PPE):

- Safety Glasses: Always wear safety glasses to protect your eyes from coolant splashes, debris, and other hazards.

- Gloves: Wear chemical-resistant gloves to protect your hands from contact with coolant and other fluids.

- Protective Clothing: Wear appropriate clothing to protect your skin from contact with coolant and sharp edges.

-

Coolant Handling:

- Proper Drainage: Use a coolant drain pan to collect the coolant when draining the system. Avoid spilling coolant on the ground.

- Responsible Disposal: Dispose of used coolant properly according to local regulations. Coolant is toxic and should not be poured down the drain or into the environment.

- Ventilation: Work in a well-ventilated area to avoid inhaling coolant fumes.

-

Tool Safety:

- Use Correct Tools: Use the correct tools for the job and ensure they are in good working condition.

- Torque Specifications: Use a torque wrench to tighten bolts and nuts to the specified torque. Over-tightening or under-tightening can damage components.

-

Workspace Safety:

- Clean Workspace: Keep your workspace clean and free of clutter to prevent accidents.

- Proper Lighting: Ensure adequate lighting to see what you are doing clearly.

-

Emergency Preparedness:

- First Aid Kit: Keep a well-stocked first aid kit nearby in case of injury.

- Emergency Contact Information: Have emergency contact information readily available.

By adhering to these safety precautions, you can significantly reduce the risk of injury and ensure a safe and successful coolant delete. Remember, if you are not comfortable with any aspect of the procedure, it is best to seek professional assistance. CAR-TOOL.EDU.VN emphasizes the importance of safety and encourages all DIYers to prioritize their well-being when working on their vehicles.

9. How Much Does a Coolant Delete Typically Cost?

The cost of a coolant delete on a Tesla LDU can vary significantly depending on whether you choose to perform the modification yourself (DIY) or have it done by a professional. Here’s a breakdown of the typical costs associated with each approach:

1. DIY Coolant Delete:

- Parts and Materials: The cost of parts and materials for a DIY coolant delete can range from $50 to $200, depending on the chosen method and the quality of the components. This includes items such as:

- Aluminum plug or cup: $20 – $50

- Gaskets and sealants: $10 – $30

- Coolant: $20 – $40

- Drill bits and taps (if needed): $0 – $80 (if you don’t already own them)

- Tools: If you don’t already have the necessary tools, you may need to invest in some basic hand tools, such as sockets, wrenches, and screwdrivers. The cost of these tools can range from $50 to $200, depending on the quality and brand.

- Time: Performing a DIY coolant delete can take anywhere from 4 to 8 hours, depending on your experience and the complexity of the chosen method.

Total Cost (DIY): $100 – $400 (excluding labor)

2. Professional Coolant Delete:

- Labor: The labor cost for a professional coolant delete can range from $500 to $1500, depending on the shop’s hourly rate and the complexity of the job.

- Parts and Materials: The cost of parts and materials is typically included in the labor cost.

- Shop Fees: Some shops may charge additional fees for shop supplies or disposal of used coolant.

Total Cost (Professional): $500 – $1500+

Factors Affecting Cost:

- Chosen Method: The method used for the coolant delete can affect the cost. Some methods, such as the aluminum cup method, may require specialized machining, which can increase the cost.

- Vehicle Model: The cost can also vary depending on the specific Tesla model and the complexity of accessing the LDU.

- Shop Rates: Labor rates vary from shop to shop, so it’s essential to get quotes from multiple shops before making a decision.

It’s important to note that the cost of a coolant delete is just one factor to consider. The potential benefits of preventing coolant leaks and extending the lifespan of the LDU should also be taken into account. CAR-TOOL.EDU.VN can help you find qualified mechanics and suppliers to get the best value for your coolant delete project.

10. What are the Most Reliable Coolant Delete Kits on the Market?

As coolant delete becomes an increasingly popular solution for addressing coolant leaks in Tesla LDUs, several aftermarket kits have emerged on the market. While DIY modifications are possible, using a pre-engineered kit can offer a more convenient and reliable solution.

Here are some of the most reliable coolant delete kits currently available:

-

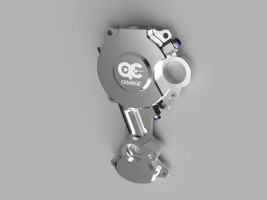

QC Charge Coolant Delete Manifold:

- Description: The QC Charge coolant delete manifold is a bespoke replacement for the OEM coolant manifold. It eliminates the rotor cooling circuit while maintaining coolant flow to the stator and inverter.

- Features:

- CNC-machined aluminum construction

- Direct replacement for the OEM manifold

- Maintains coolant flow to the stator and inverter

- Includes all necessary hardware for installation

- Price: Approximately $770 (with tax)

- Pros: High-quality construction, easy installation, maintains cooling to other critical components.

- Cons: Relatively expensive.

QC Charge Coolant Delete

QC Charge Coolant Delete

-

Revolt Coolant Delete Kit:

- Description: The Revolt coolant delete kit is another aftermarket solution that bypasses the rotor cooling system. It also eliminates the flyover tube to the gearcase heat exchanger.

- Features:

- Bypasses rotor cooling system

- Eliminates flyover tube

- Includes necessary hardware for installation

- Price: Approximately $550 (after tax)

- Pros: More affordable than the QC Charge manifold, simplifies the cooling system.

- Cons: Eliminates the gearcase heat exchanger, which may be a concern for some users.

-

DIY Modification Parts:

- Description: For those who prefer a DIY approach, various parts and materials can be sourced to create a custom coolant delete solution.

- Components:

- Aluminum plug or cup

- Gaskets and sealants

- Hoses and fittings

- Price: Varies depending on the chosen components and materials.

- Pros: Most affordable option, allows for customization.

- Cons: Requires more technical skill and effort, may not be as reliable as pre-engineered kits.

When choosing a coolant delete kit, consider your budget, technical skill, and desired level of cooling performance. Pre-engineered kits, such as the QC Charge manifold and the Revolt kit, offer a more convenient and reliable solution, while DIY modifications can be more affordable but require more effort and expertise. CAR-TOOL.EDU.VN provides access to a network of suppliers and experts to help you find the best coolant delete solution for your specific needs.

FAQ: Coolant Delete on Tesla LDU

-

Is coolant delete safe for my Tesla LDU?

Coolant delete can be safe if done correctly, but it’s crucial to understand the potential risks and ensure proper execution. Overheating can occur if alternative cooling measures are not implemented.

-

Will coolant delete void my Tesla warranty?

Yes, performing a coolant delete will likely void any remaining warranty on the LDU or related components.

-

Can I perform a coolant delete myself?

Yes, you can perform a coolant delete yourself if you have the necessary skills and tools. However, it’s a complex modification that requires caution and precision.

-

How much does it cost to have a professional perform a coolant delete?

The cost of a professional coolant delete can range from $500 to $1500 or more, depending on the shop’s hourly rate and the complexity of the job.

-

What are the benefits of coolant delete?

The main benefit of coolant delete is the elimination of coolant leaks, which can prevent bearing damage, stator contamination, and inverter failure.

-

Are there any alternatives to coolant delete?

Yes, alternatives to coolant delete include improved air cooling, heat sink addition, and the use of alternative coolants.

-

What happens if my LDU overheats after performing a coolant delete?

If your LDU overheats after performing a coolant delete, it can lead to decreased performance, accelerated wear, and potentially even damage to the rotor and other components.

-

Do I need to make any firmware modifications after performing a coolant delete?

It’s unclear whether firmware modifications are necessary after performing a coolant delete. Some users have reported no issues, while others have recommended adjusting the firmware to account for the reduced cooling capacity.

-

Where can I find reliable coolant delete kits?

You can find reliable coolant delete kits from aftermarket suppliers such as QC Charge and Revolt.

-

How can I ensure that my coolant delete is done safely and effectively?

To ensure a safe and effective coolant delete, follow proper safety procedures, use the correct tools, and consult with experienced professionals if you have any doubts.

Seeking expert advice and guidance can significantly improve your experience. Contact us via Whatsapp at +1 (641) 206-8880 or visit us at 456 Elm Street, Dallas, TX 75201, United States. Alternatively, explore our website at CAR-TOOL.EDU.VN for additional resources.