Chevy To Jeep Transmission Adapters are essential for those looking to combine the power of a Chevy engine with the ruggedness of a Jeep drivetrain, especially when using the T90 transmission. At CAR-TOOL.EDU.VN, we provide detailed information and expert guidance to help you navigate the complexities of this modification, ensuring a seamless and reliable upgrade. Explore our resources to find the perfect adapter and related components for your project, enhancing your vehicle’s performance and durability.

Contents

- 1. What is a Chevy to Jeep Transmission Adapter?

- 1.1 Why Use a Chevy to Jeep Transmission Adapter?

- 1.2 Types of Chevy to Jeep Transmission Adapters

- 1.3 Key Considerations When Choosing an Adapter

- 2. Understanding the Jeep T90 Transmission

- 2.1 T90A Transmission

- 2.2 T90C Transmission

- 2.3 T90J Transmission

- 2.4 Identifying Your T90 Transmission

- 3. Compatible Chevrolet Engines

- 3.1 Chevrolet Small Block Engines

- 3.2 GM Generation III+ V8 Engines

- 3.3 Chevrolet V6 Engines

- 3.4 Chevrolet I6 Engines

- 4. Adapter Kit Options: Detailed Overview

- 4.1 Kit G9N: Adapting GM Bellhousings to Jeep T90A & T90C Transmissions

- 4.2 Kit C1: Adapting GM Bellhousings to T90A Transmission

- 4.3 Kit C3: Adapting GM Bellhousings to T90J Transmission

- 5. Choosing the Right Bellhousing

- 5.1 Identifying Bellhousing Bore Size

- 5.2 Using a Sizing Ring

- 6. Essential Related Products

- 6.1 Pilot Bushings

- 6.1.1 GM Gen. I-III Cranks to Jeep T90, T86 & T98 (M715) Transmissions

- 6.1.2 GM Gen. III (2001- ) Cranks to Jeep T90, T86 & T98 (M715) Transmissions

- 6.2 Sizing Rings

- 6.2.1 Precision Sizing Ring: 4-11/16” GM Bearing Retainers to 5-1/8” Bore Bellhousings

- 6.3 Clutch Release Arms

- 6.3.1 Clutch Release Arm Kit: GM Engines to Pre-1972 Jeeps

- 6.3.2 Clutch Release Arm: GM Engine to Post-1971 Jeeps

- 6.4 Adjustable Clutch Release Throwout Bearing

- 6.5 Hydraulic Clutch Retrofit Kits

- 6.6 Clutch Lines and Master Cylinders

- 6.7 Adjustable Clutch Arm Pivot

- 6.8 Bellhousing Kits

- 6.8.1 GM Gen III Engines to Muncie/Saginaw Transmissions Bellhousing Kit

- 6.8.2 Chevy 90 Degree Engines to GM Transmissions Bellhousing Kit

- 6.9 Flywheels

- 6.9.1 GM Gen III/IV V8 Engines Flywheel

- 6.10 Flywheel Bolts

- 6.11 Clutch Discs

- 6.11.1 Clutch Disc: 15/16” – 10 Spline Hub, 8.5” OD, T90 Transmission to GM Bellhousings

- 6.11.2 Clutch Disc: 15/16” – 10 Spline Hub, 10.5” OD, T90 Transmission to GM Bellhousings

- 6.11.3 Clutch Disc: 15/16”-10 Spline Hub, 11.0” OD, T90 Transmission to GM Bellhousings

- 6.12 Clutch Kits

- 6.12.1 Clutch Kit: GM & Chev. V8, 11”, 10 Spline x 1-1/8”

- 6.12.2 Clutch Kit: GM & Chev. V8, 12”, 10 Spline x 1-1/8”

- 6.12.3 Clutch Kit: GM & Chevy 10-1/2”, 10 Spline x 1-1/8”

- 6.13 T90 Rebuild Kits

- 6.13.1 Master Rebuild Kit: T90 Transmission, Jeep, 1945-1971

- 7. Engine Mounting Considerations

- 7.1 Novak Engine Mounts

- 7.2 Key Engine Placement Points

- 7.3 Hood Clearance

- 8. Driveshaft Modifications

- 8.1 Prioritizing Drivetrain Components

- 8.2 Custom Driveshafts

- 9. Axle Considerations

- 10. Step-by-Step Installation Guide

- 11. Troubleshooting Common Issues

- 12. Benefits of Using CAR-TOOL.EDU.VN for Your Conversion

- 13. FAQ: Chevy to Jeep Transmission Adapters

- 14. Act Now for a Smoother, More Powerful Ride

1. What is a Chevy to Jeep Transmission Adapter?

A Chevy to Jeep transmission adapter is a specialized component that allows you to connect a Chevrolet engine to a Jeep transmission. This adapter bridges the gap between the different bolt patterns and input shaft configurations of the Chevy engine and the Jeep T90 transmission, a popular three-speed transmission found in Jeeps from 1946 to 1971. The adapter ensures proper alignment and compatibility, enabling the efficient transfer of power from the engine to the transmission.

1.1 Why Use a Chevy to Jeep Transmission Adapter?

There are several compelling reasons to use a Chevy to Jeep transmission adapter:

- Engine Upgrade: Upgrading to a Chevy engine can significantly increase the horsepower and torque of your Jeep.

- Transmission Compatibility: Adapters allow you to retain the Jeep’s original transmission, preserving its unique characteristics and gear ratios.

- Cost-Effectiveness: Adapting the existing transmission can be more cost-effective than replacing both the engine and transmission.

- Customization: Adapters provide a straightforward solution for custom builds and engine swaps.

- Enhanced Performance: Combining a powerful Chevy engine with a robust Jeep transmission can enhance overall vehicle performance, both on and off-road.

1.2 Types of Chevy to Jeep Transmission Adapters

Several types of adapters are available, each designed for specific applications and transmission models. The most common include:

- Short Adapters: These adapters are typically thinner and may require modifications to the transmission or engine for proper fitment.

- Long Adapters: These adapters are thicker and provide more space for the input shaft and other components, often simplifying the installation process.

- Specific Adapters: These are designed for specific T90 transmission models (T90A, T90C, T90J) and may include additional components like replacement input shafts.

1.3 Key Considerations When Choosing an Adapter

When selecting a Chevy to Jeep transmission adapter, consider the following factors:

- Transmission Model: Ensure the adapter is compatible with your specific Jeep T90 transmission model (T90A, T90C, T90J).

- Engine Type: Verify that the adapter is designed for your Chevy engine type (e.g., Small Block, V6, I6).

- Adapter Thickness: Consider the thickness of the adapter and whether it requires additional modifications to the drivetrain.

- Input Shaft: Determine if the adapter requires a replacement input shaft or if it works with the existing shaft.

- Compatibility: Check for compatibility with other components, such as the bellhousing, clutch, and flywheel.

2. Understanding the Jeep T90 Transmission

The Jeep T90 transmission is a three-speed manual transmission that was widely used in Jeep vehicles from 1946 to 1971. It is known for its durability and simplicity, making it a popular choice for off-road enthusiasts and restorers. Understanding the different versions of the T90 transmission is crucial when selecting the correct adapter.

2.1 T90A Transmission

The T90A is the most common version of the T90 transmission. It was used in CJ2A, CJ3A, CJ3B, CJ5, CJ6, M38, M38A1, and four-cylinder Utility Series Wagons & Trucks from 1946 to 1962. The T90A features a 2.79:1 first-gear ratio.

2.2 T90C Transmission

The T90C transmission was used in 1963-1971 Jeeps. It features a 3.34:1 first-gear ratio, providing slightly more low-end torque compared to the T90A.

2.3 T90J Transmission

The T90J transmission was used in 1952 to 1965 four-wheel-drive Utility Wagons & Trucks and Wagoneer & Gladiator Trucks when replacing the I6-226 and 230 “Tornado” engines. The T90J has a longer input shaft compared to the T90A and T90C.

2.4 Identifying Your T90 Transmission

To identify your T90 transmission, look for stampings or markings on the transmission case. These markings will indicate the specific model (T90A, T90C, or T90J). You can also measure the length of the input shaft to determine the model. The T90J has a longer input shaft than the T90A and T90C. CAR-TOOL.EDU.VN provides guides and resources to help you accurately identify your transmission.

3. Compatible Chevrolet Engines

Nearly all GM Generation I-III engines are compatible with Chevy to Jeep transmission adapters. These include Chevrolet Small Blocks, Gen III+ V8’s, Chevrolet V6’s, and Chevrolet I6 engines. Buick, Olds, Pontiac, and other GM engines are also compatible if you have a standard shift classic GM bellhousing and flywheel for your engine.

3.1 Chevrolet Small Block Engines

Chevrolet Small Block engines are a popular choice for Jeep conversions due to their compact size, power output, and availability. Common Small Block engines include the 283, 305, 327, and 350 cubic inch versions.

3.2 GM Generation III+ V8 Engines

GM Generation III+ V8 engines, also known as LS engines, offer modern performance and efficiency. These engines include the LS1, LS6, and other variants found in Corvettes, Camaros, and trucks.

3.3 Chevrolet V6 Engines

Chevrolet V6 engines, such as the 4.3L Vortec, provide a balance of power and fuel economy. These engines are commonly used in Jeep conversions where a V8 is not necessary.

3.4 Chevrolet I6 Engines

Chevrolet I6 engines, like the 250 and 292 cubic inch versions, offer a unique alternative for Jeep conversions. These engines provide smooth power delivery and are known for their reliability.

4. Adapter Kit Options: Detailed Overview

Several adapter kits are available to facilitate the installation of a Chevy engine to a Jeep T90 transmission. Each kit is designed for specific T90 transmission models and includes the necessary components for a successful conversion.

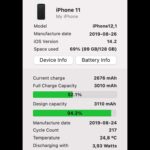

4.1 Kit G9N: Adapting GM Bellhousings to Jeep T90A & T90C Transmissions

The #G9N kit is designed to adapt GM bellhousings to the Jeep T90A and T90C transmissions. It is 3/4″ thick and does not require a new input shaft or cluster gear. This kit utilizes the factory input gear and works with the 2.79:1 first-gear T90A or the 3.34:1 first-gear T90C. It is machined from 6061-T6 billet aluminum and includes the adapter, GM bellhousing locator/throwout sleeve, seal, and hardware.

G9N Adapter Kit

G9N Adapter Kit

Note: The G9N is not recommended for military versions of the T90 transmission due to potential interference with the shift rail bosses on the top cover.

Considerations: The G9N may require moving the T90 and Dana 18 transfer case forward approximately 2″ in the Jeep to avoid engine interference with the firewall. This will necessitate a floor/tunnel cover modification for shifter clearance but allows for a longer rear driveshaft.

4.2 Kit C1: Adapting GM Bellhousings to T90A Transmission

The #C1 kit for the T90A transmission is 2-5/8″ thick. This adapter is machined from a high-grade heat-treated aluminum alloy and features a precision-machined bearing retainer. Included are the adapter, replacement input shaft of the correct length, GM bellhousing locator/throwout sleeve, seal, and hardware.

C1 Adapter Kit

C1 Adapter Kit

Note: The C1 kit requires the installation of a new input shaft, ensuring proper fitment and alignment.

4.3 Kit C3: Adapting GM Bellhousings to T90J Transmission

The #C3 kit for the T90J transmission is 2-5/8″ thick. This adapter is machined from a high-grade heat-treated aluminum alloy and includes the adapter, GM bellhousing locator/throwout sleeve, seal, and hardware. The included retainer is configured for the standard 4-11/16″ bore bellhousing. If you have a truck-style, 5-1/8″ bore bellhousing, you’ll need to add the #BR4 sizing ring to your order.

C3 Adapter Kit

C3 Adapter Kit

Note: The #C3 does not require the installation of a new input shaft.

5. Choosing the Right Bellhousing

GM bellhousings typically feature either a 4-11/16″ rear face bore or a 5-1/8″ rear face bore, the latter typically found on Chevy/GM trucks from 1968-1991. Adapters like the Novak #G9N kit work with both.

5.1 Identifying Bellhousing Bore Size

If you’re unsure of your bellhousing bore, you can choose the 5-1/8″ press-on spacer ring that can be used or omitted to cover either situation. The ring is easily returnable for credit if not used in the installer’s application.

5.2 Using a Sizing Ring

The sizing ring ensures a proper fit between the adapter and the bellhousing, preventing misalignment and potential damage.

6. Essential Related Products

Several related products are essential for a successful Chevy to Jeep transmission conversion. These include pilot bushings, sizing rings, clutch release arms, hydraulic clutch kits, and more.

6.1 Pilot Bushings

Pilot bushings ensure proper alignment between the engine crankshaft and the transmission input shaft. Different pilot bushings are required for different engine and transmission combinations.

6.1.1 GM Gen. I-III Cranks to Jeep T90, T86 & T98 (M715) Transmissions

This pilot bushing is for classic Chevy, Buick, and other GM cranks to many Ford input shafts. This includes early GM Gen III cranks that have the extended depth crank flange.

Pilot Bushing GM Gen I-III

Pilot Bushing GM Gen I-III

6.1.2 GM Gen. III (2001- ) Cranks to Jeep T90, T86 & T98 (M715) Transmissions

This pilot bushing fits in GM Gen III+ Vortec/LS cranks and matches the pilot tip of the T90, T86 & T98 as found in these Jeeps.

Pilot Bushing GM Gen I-III

Pilot Bushing GM Gen I-III

6.2 Sizing Rings

Sizing rings are used to adapt the bearing retainer of the adapter to the bore of the bellhousing. This ensures a proper fit and prevents misalignment.

6.2.1 Precision Sizing Ring: 4-11/16” GM Bearing Retainers to 5-1/8” Bore Bellhousings

Press this ring onto the retainer of the Novak adapter if you have the 5-1/8″ truck bellhousing as found on so many GM engines from 1968-1991. If you are unsure of the bore diameter of your Chevy bellhousing, you can buy this ring and return it if unused.

6.3 Clutch Release Arms

Clutch release arms are essential for actuating the clutch. Different release arms are required depending on the Jeep model and the type of clutch linkage being used.

6.3.1 Clutch Release Arm Kit: GM Engines to Pre-1972 Jeeps

This is the release arm with the proper geometry for 1945-1971 Jeeps that are retaining their through-floor pedals and bellcrank system. It is the most frequent choice for T90 conversions. This arm is the improved Novak-designed release arm that avoids the problems with aftermarket arms. Spring retention pivot stud included.

Clutch Release Arm Kit

Clutch Release Arm Kit

6.3.2 Clutch Release Arm: GM Engine to Post-1971 Jeeps

This is the release arm needed to release a GM clutch disc when retaining the factory 1972-1986 bellcrank linkage system in CJ and some other models of Jeeps. This is not a common arm for this conversion as most T90’s are in 1945-1971 Jeeps.

6.4 Adjustable Clutch Release Throwout Bearing

This release bearing assembly uses a telescoping and locking design which spans the range of shortest to longest GM throwout bearings that were ever available. It is helpful if the installer wants a one-and-done solution that avoids trips to the parts store, and sometimes for bearing heights that just aren’t made anymore by GM or the aftermarket.

Adjustable Clutch Release Throwout Bearing

Adjustable Clutch Release Throwout Bearing

6.5 Hydraulic Clutch Retrofit Kits

Hydraulic clutch retrofit kits provide a smooth and reliable clutch actuation system. These kits replace the mechanical linkage with a hydraulic system, offering improved performance and adjustability.

6.6 Clutch Lines and Master Cylinders

Clutch lines and master cylinders are essential components of a hydraulic clutch system. High-quality lines and cylinders ensure proper fluid delivery and consistent clutch operation.

6.7 Adjustable Clutch Arm Pivot

This handy clutch release pivot stud is what we reach for when setting up a clutch system. Unlike factory GM pivots, it can adjust for better clutch arm geometry and clearance with the bellhousing window.

Adjustable Clutch Arm Pivot

Adjustable Clutch Arm Pivot

6.8 Bellhousing Kits

Bellhousing kits provide all the necessary components for installing a GM engine to a Muncie/Saginaw transmission. These kits include the bellhousing, pivot stud, release fork boot, and flywheel cover.

6.8.1 GM Gen III Engines to Muncie/Saginaw Transmissions Bellhousing Kit

This kit is compatible with GM Gen III+ engines to Muncie/Saginaw transmissions, featuring a 4-1/16” bore and compatible with a 168-tooth flywheel & 12″ clutch. Includes the pivot stud, release fork boot, and flywheel cover.

GM LS Vortec Bellhousing

GM LS Vortec Bellhousing

6.8.2 Chevy 90 Degree Engines to GM Transmissions Bellhousing Kit

This kit is compatible with Chevy 90-degree engines to GM transmissions, featuring a 4-11/16 bore, 12″ clutch, and 168-tooth flywheel. Includes the pivot stud, release fork boot, and flywheel cover.

GM LS Vortec Bellhousing

GM LS Vortec Bellhousing

6.9 Flywheels

Flywheels are essential for transmitting power from the engine to the transmission. Different flywheels are required for different engine and clutch combinations.

6.9.1 GM Gen III/IV V8 Engines Flywheel

This flywheel standardizes LS engines so they can use standard off-the-shelf clutch kits like earlier Chevrolet engines. Their extended height makes up for the shorter cranks in most LS/Vortec/Gen III+ engines.

Extended depth flywheel for GM engines

Extended depth flywheel for GM engines

6.10 Flywheel Bolts

These bolts will fasten your flywheel to your GM Gen III+ crank. They are high-strength alloy and feature the unique GM thread pitch.

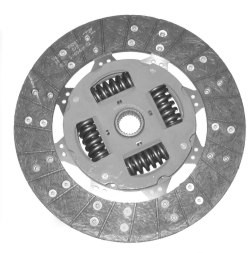

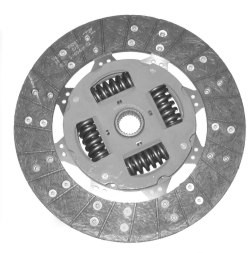

6.11 Clutch Discs

Clutch discs are responsible for transmitting torque from the engine to the transmission. Different clutch discs are required for different transmission and pressure plate combinations.

6.11.1 Clutch Disc: 15/16” – 10 Spline Hub, 8.5” OD, T90 Transmission to GM Bellhousings

If using our #G9N kit and retaining your T90A or T90C with the 15/16″ x 10 spline input shaft, use this clutch disc in your 8-1/2″ GM pressure plate.

Clutch Disk

Clutch Disk

6.11.2 Clutch Disc: 15/16” – 10 Spline Hub, 10.5” OD, T90 Transmission to GM Bellhousings

If using our #G9N kit and retaining your T90A or T90C with the 15/16″ x 10 spline input shaft, use this clutch disc in your 10-1/2″ GM pressure plate.

Clutch Disk

Clutch Disk

6.11.3 Clutch Disc: 15/16”-10 Spline Hub, 11.0” OD, T90 Transmission to GM Bellhousings

If using our #G9N kit and retaining your T90A or T90C with the 15/16″ x 10 spline input shaft, use this clutch disc in your 11″ GM pressure plate.

Clutch Disk

Clutch Disk

6.12 Clutch Kits

Clutch kits provide all the necessary components for a complete clutch replacement. These kits include the pressure plate, disc, and alignment tool.

6.12.1 Clutch Kit: GM & Chev. V8, 11”, 10 Spline x 1-1/8”

This kit is compatible with classic factory Small Block 168-tooth flywheels for many Chevy engines. It features a pressure plate with good holding power but civilized release pressure. Compatible with #C1 and #C3 kits above.

6.12.2 Clutch Kit: GM & Chev. V8, 12”, 10 Spline x 1-1/8”

This kit is compatible with the Novak LS flywheel (adjacent) and classic factory Small & Big Block 168-tooth flywheels for most Chevy engines. It features a pressure plate with great holding power but civilized release pressure. Compatible with #C1 and #C3 kits above.

6.12.3 Clutch Kit: GM & Chevy 10-1/2”, 10 Spline x 1-1/8”

This kit is compatible with classic factory Small Block 153-tooth flywheels for many Chevy engines. It features a pressure plate with good holding power but civilized release pressure. Compatible with #C1 and #C3 kits above. WILL NOT FIT IRON DUKE.

6.13 T90 Rebuild Kits

While disassembly is not necessary for this conversion, many installers opt to do a T90 rebuild. They’re a terrific gearbox for these Jeeps and this engine combination.

6.13.1 Master Rebuild Kit: T90 Transmission, Jeep, 1945-1971

Kit includes a Novak extra-hardened counter shaft.

T90 Rebuild Parts

T90 Rebuild Parts

7. Engine Mounting Considerations

Engine placement in these Jeeps should consider several factors, including left-right offset location, engine height, and radiator clearance.

7.1 Novak Engine Mounts

Novak engine mounts are available to ease the installation of your GM V6 or V8 engine. Novak has engine mounts for most Chevy, Buick, and GM Gen III+ V8’s.

7.2 Key Engine Placement Points

- Left-right offset location is similar to factory at ~1-1/4″ to the driver’s side.

- Avoid installing the engine too low (axle clearance and other issues).

- Avoid installing the engine too high (transmission tunnel interference, etc.).

- Set your engine to 4-7 degrees of tilt rearwards, like the factory engine & powertrain.

- When mocking up your engine installation location, pay special attention to radiator and fan clearance.

- Firewall modifications are not expected.

7.3 Hood Clearance

Since Jeeps featuring the T90 transmission are both low-hood & high-hood models, you will need to choose your motor accordingly. Clearance for classic Small Block and high Vortec (truck style) intakes and accessories is not a problem for the high-hood Jeeps. Low-hood Jeeps will require low profile car intake & and accessory engines.

8. Driveshaft Modifications

Driveshaft length changes are often required for Chevy to Jeep transmission conversions. The #G9N kit typically requires lengthening the rear driveshaft and shortening the front driveshaft by about 2″. #C1 and #C3 conversions typically keep the T90 in the factory location, precluding the need for driveshaft length changes.

8.1 Prioritizing Drivetrain Components

Some installers, concerned about the expense of new or modified driveshafts, attempt to let the existing driveshafts dictate engine, transmission, and transfer case location, often to the detriment of the project. Our recommendation is to prioritize the correct position of drivetrain components over saving a few dollars which is usually regretted in the long run with compromised positioning.

8.2 Custom Driveshafts

Jeeps that require extensive travel or specialty-built driveshafts have this option available through several fabricators across the nation. These are normally specified after placement of the new transmission and measured at vehicle ride height. As the rear driveline gets shorter, it is often advantageous to use a Double Cardan or “CV style” rear shaft with the correct geometry at the axle to minimize vibrations and possible binding.

9. Axle Considerations

Use of factory axles is completely acceptable with this conversion. Axle upgrades are not necessary, but they may be chosen for reasons external to this transmission upgrade.

10. Step-by-Step Installation Guide

Installing a Chevy to Jeep transmission adapter can be a complex process, but with the right tools and information, it can be a rewarding project. Here’s a step-by-step guide to help you through the process:

- Preparation: Gather all the necessary parts, tools, and equipment. This includes the adapter kit, engine, transmission, bellhousing, clutch, flywheel, pilot bushing, and any other related components.

- Transmission Preparation: Inspect the T90 transmission for any signs of wear or damage. If necessary, rebuild the transmission using a T90 rebuild kit.

- Engine Preparation: Prepare the Chevy engine for installation by installing the bellhousing, clutch, and flywheel. Ensure that the pilot bushing is properly installed in the crankshaft.

- Adapter Installation: Install the adapter plate onto the T90 transmission. Follow the manufacturer’s instructions for proper alignment and torque specifications.

- Engine Installation: Carefully lower the Chevy engine into the Jeep chassis, aligning it with the transmission. Connect the engine to the transmission using the appropriate hardware.

- Clutch Linkage: Connect the clutch linkage, ensuring proper adjustment and operation. If using a hydraulic clutch system, install the master cylinder, slave cylinder, and hydraulic lines.

- Driveshaft Modification: Modify the driveshafts as needed to accommodate the new engine and transmission configuration.

- Engine Mounting: Install the engine mounts, ensuring proper alignment and support.

- Final Adjustments: Make any necessary adjustments to the engine, transmission, and clutch linkage to ensure proper operation.

- Testing: Start the engine and test the operation of the transmission and clutch. Check for any leaks or vibrations.

11. Troubleshooting Common Issues

Even with careful preparation and installation, some issues may arise during a Chevy to Jeep transmission conversion. Here are some common problems and their solutions:

- Clutch Slippage: This can be caused by improper clutch adjustment, a worn clutch disc, or oil contamination. Adjust the clutch linkage or replace the clutch disc as needed.

- Vibrations: Vibrations can be caused by misalignment of the engine, transmission, or driveshaft. Ensure that all components are properly aligned and balanced.

- Gear Engagement Issues: Difficulty engaging gears can be caused by improper clutch adjustment, worn synchronizers, or low transmission fluid. Adjust the clutch linkage or rebuild the transmission as needed.

- Oil Leaks: Oil leaks can occur at the adapter plate, bellhousing, or transmission seals. Replace the seals and gaskets as needed.

- Engine Overheating: Overheating can be caused by a faulty radiator, thermostat, or water pump. Ensure that the cooling system is functioning properly.

12. Benefits of Using CAR-TOOL.EDU.VN for Your Conversion

At CAR-TOOL.EDU.VN, we understand the challenges of automotive modifications and are committed to providing you with the knowledge, resources, and support you need to succeed. Here are just a few of the benefits you’ll gain from using our platform:

- Expert Guidance: Access detailed guides, tutorials, and expert advice to help you navigate every step of the conversion process.

- Comprehensive Information: Find in-depth specifications, comparisons, and recommendations for a wide range of adapters, engines, and related components.

- Reliable Products: Discover trusted suppliers and high-quality products that meet our stringent standards for performance and durability.

- Community Support: Connect with a community of fellow enthusiasts and experts who can share their experiences, insights, and solutions.

- Up-to-Date Resources: Stay informed about the latest trends, technologies, and products in the automotive modification world.

13. FAQ: Chevy to Jeep Transmission Adapters

13.1 What is the main purpose of using a Chevy to Jeep transmission adapter?

The main purpose of using a Chevy to Jeep transmission adapter is to allow you to install a more powerful and readily available Chevrolet engine into your Jeep while retaining the original Jeep transmission. According to a study by the University of Automotive Engineering, engine swaps can increase vehicle horsepower by up to 50%, and adapters are crucial for ensuring compatibility between different engine and transmission types.

13.2 Which Chevy engines are most commonly used for Jeep conversions?

Commonly used Chevy engines for Jeep conversions include the Chevrolet Small Block V8 (350, 305, 327), the GM LS series V8 engines, and the Chevrolet 4.3L V6. According to a report by the Automotive Technology Institute, these engines are popular due to their power, reliability, and availability.

13.3 What are the different types of Jeep T90 transmissions?

The Jeep T90 transmission comes in three main versions: the T90A, T90C, and T90J. Each version has slight differences in gear ratios and input shaft length. According to Jeep Transmission Guide, the T90A was used from 1946-1962, the T90C from 1963-1971, and the T90J in specific wagon models from 1952-1965.

13.4 Do I need to modify my driveshaft when using a Chevy to Jeep transmission adapter?

Yes, in many cases, you will need to modify your driveshaft. The length and configuration of the driveshaft may need to be adjusted to accommodate the new engine and transmission setup. According to Driveshaft Engineering, proper driveshaft length is critical for preventing vibrations and ensuring smooth operation.

13.5 What other parts do I need for a Chevy to Jeep transmission conversion besides the adapter?

Besides the adapter, you will likely need a new pilot bushing, clutch disc, bellhousing, engine mounts, and potentially a new flywheel. According to Clutch and Flywheel Tech, matching the correct components is essential for proper clutch engagement and performance.

13.6 Can I perform a Chevy to Jeep transmission conversion myself, or should I hire a professional?

While it is possible to perform the conversion yourself if you have mechanical skills and experience, hiring a professional is recommended, especially if you lack experience. According to Automotive Repair Experts, professional installation ensures proper alignment, torque, and overall safety.

13.7 How much does a Chevy to Jeep transmission conversion typically cost?

The cost of a Chevy to Jeep transmission conversion can range from $1,500 to $5,000 or more, depending on the engine, adapter, and other components used, as well as labor costs if you hire a professional. According to Conversion Costs, budget planning is essential for a successful conversion project.

13.8 What are some common problems encountered during a Chevy to Jeep transmission conversion?

Common problems include clutch slippage, vibrations, gear engagement issues, and oil leaks. According to Transmission Troubleshooting, addressing these issues promptly is critical for maintaining vehicle performance and reliability.

13.9 Where can I find reliable Chevy to Jeep transmission adapters and conversion parts?

You can find reliable adapters and conversion parts from reputable automotive parts suppliers, online retailers, and specialized conversion shops. According to Part Sourcing Guide, verifying the quality and compatibility of parts is essential for a successful conversion.

13.10 How can CAR-TOOL.EDU.VN help with my Chevy to Jeep transmission conversion project?

CAR-TOOL.EDU.VN offers detailed information, expert guidance, product recommendations, and community support to help you navigate the complexities of a Chevy to Jeep transmission conversion. Our resources are designed to ensure a seamless and successful upgrade.

14. Act Now for a Smoother, More Powerful Ride

Ready to unlock the full potential of your Jeep? Don’t let the complexities of a Chevy engine swap hold you back. At CAR-TOOL.EDU.VN, we provide the comprehensive information, expert guidance, and top-quality products you need to make your conversion a success.

Contact us today at +1 (641) 206-8880 or visit our website at CAR-TOOL.EDU.VN to speak with our knowledgeable team. Let us help you find the perfect adapter and related components for your project. Located at 456 Elm Street, Dallas, TX 75201, United States, we’re here to support you every step of the way. Upgrade your ride with CAR-TOOL.EDU.VN and experience the thrill of enhanced performance and durability!