Camcammer technology integrates cameras into automotive tools, significantly improving diagnostics and repair efficiency. At CAR-TOOL.EDU.VN, we offer expert insights and resources to maximize the benefits of automotive camera systems, ensuring you stay ahead in the rapidly evolving field of automotive diagnostics. Exploring tools like borescopes and inspection cameras will enhance your repair capabilities, and you can find detailed information and comparisons on our site.

1. Understanding the Camcammer in Automotive Repair

A camcammer, in the context of automotive repair, refers to the integration of camera technology into diagnostic and repair tools. This includes devices like borescopes, inspection cameras, and advanced diagnostic systems that use visual data for assessing vehicle conditions. These tools allow technicians to see inside engines, transmissions, and other components without extensive disassembly.

- Definition: A camcammer is a tool equipped with a camera, typically a small, flexible device used for visual inspection in hard-to-reach areas of a vehicle.

- Application: Automotive technicians use camcammers to diagnose issues, assess wear and tear, and verify repairs.

- Benefits: Reduced disassembly time, improved diagnostic accuracy, and enhanced ability to show customers the problem.

2. Types of Camcammers Used in Automotive Repair

Several types of camcammers are available, each designed for specific tasks and offering different features to enhance diagnostic and repair processes.

-

Borescopes:

- Definition: Borescopes are flexible or rigid tubes with a camera and light source at the end, used to inspect internal components.

- Application: Inspecting cylinders, valves, and other engine parts through spark plug holes or injector ports.

- Key Features: High-resolution imaging, maneuverability, and durability.

-

Inspection Cameras:

- Definition: Inspection cameras, also known as endoscopes, feature a handheld unit with a flexible cable and camera for real-time viewing.

- Application: Examining exhaust systems, brake lines, and chassis components for corrosion, leaks, or damage.

- Key Features: Real-time video display, image capture, and adjustable lighting.

-

Wireless Inspection Cameras:

- Definition: Wireless inspection cameras transmit video to a separate display or mobile device via Wi-Fi or Bluetooth.

- Application: Inspecting hard-to-reach areas like inside door panels or under dashboards with greater flexibility.

- Key Features: Wireless connectivity, portability, and compatibility with smartphones and tablets.

-

Dual-Lens Inspection Cameras:

- Definition: These cameras feature both a forward-facing and a side-facing lens, providing comprehensive views without repositioning the camera.

- Application: Inspecting cylinder walls for scoring and wear, and examining valve seats and guides.

- Key Features: Dual perspectives, high-definition imaging, and easy switching between views.

-

Articulating Inspection Cameras:

- Definition: Articulating cameras allow the user to control the direction of the camera tip, providing a 360-degree view of the inspection area.

- Application: Detailed inspection of complex components such as transmissions and differentials.

- Key Features: Full directional control, durable construction, and high-resolution video.

Automotive technician using a borescope to inspect an engine cylinder

Automotive technician using a borescope to inspect an engine cylinder

3. Benefits of Using Camcammers in Automotive Repair

Integrating camcammers into automotive repair offers numerous advantages, enhancing both diagnostic accuracy and repair efficiency.

-

Improved Diagnostic Accuracy:

- Visual Confirmation: Camcammers provide visual confirmation of issues, reducing the reliance on guesswork and potentially flawed assumptions.

- Early Detection: They allow for early detection of problems like corrosion, cracks, and wear, preventing minor issues from becoming major repairs.

- Detailed Inspection: Technicians can examine components in detail, identifying the root cause of problems more effectively.

-

Reduced Disassembly Time:

- Non-Invasive Inspection: Camcammers enable inspection without extensive disassembly, saving time and labor costs.

- Targeted Repairs: By pinpointing the exact location and nature of the issue, repairs can be more targeted, reducing unnecessary work.

- Quick Assessment: A quick visual inspection can determine the extent of damage, helping to provide accurate estimates and timelines.

-

Enhanced Customer Communication:

- Visual Evidence: Camcammers allow technicians to show customers the exact problem, building trust and justifying repair recommendations.

- Clear Explanations: Visual aids help explain complex issues in an understandable way, improving customer satisfaction.

- Transparent Service: Providing visual evidence of the work done enhances transparency, assuring customers of the value of the service.

-

Increased Efficiency:

- Faster Diagnostics: Quicker identification of problems leads to faster repair times and increased shop throughput.

- Minimized Errors: Accurate diagnostics reduce the likelihood of misdiagnosis and incorrect repairs, saving time and resources.

- Optimized Workflow: Streamlined inspection processes allow technicians to focus on repairs, improving overall efficiency.

-

Safety Improvements:

- Reduced Exposure to Hazards: Inspecting components without disassembly minimizes exposure to potentially harmful substances and conditions.

- Ergonomic Benefits: Using flexible camcammers reduces strain and awkward positions, improving technician comfort and safety.

- Preventative Measures: Early detection of wear and damage helps prevent breakdowns and accidents caused by component failure.

-

Cost Savings:

- Reduced Labor Costs: Faster diagnostics and targeted repairs lower labor expenses.

- Minimized Parts Waste: Accurate assessments prevent unnecessary part replacements.

- Preventative Maintenance: Early detection and repair of minor issues prevent costly major repairs down the line.

4. Key Features to Look for in a Camcammer

When selecting a camcammer for automotive repair, several key features can significantly impact its effectiveness and usability.

-

Image Resolution:

- Importance: High image resolution ensures clear, detailed images for accurate diagnostics.

- Specifications: Look for cameras with at least 720p resolution, with 1080p or higher for more detailed inspections.

- Benefits: Better visibility of small cracks, corrosion, and wear patterns.

-

Cable Flexibility and Length:

- Importance: Flexible and adequately long cables allow access to hard-to-reach areas.

- Specifications: Choose cables made of durable, flexible materials and lengths appropriate for common automotive applications (e.g., 1 to 3 meters).

- Benefits: Easier navigation through tight spaces and complex engine compartments.

-

Lighting:

- Importance: Adequate lighting is crucial for clear visibility in dark areas.

- Specifications: Look for cameras with adjustable LED lighting and high light intensity.

- Benefits: Improved visibility in cylinders, exhaust systems, and other dark areas.

-

Display Size and Type:

- Importance: A clear, appropriately sized display ensures comfortable viewing during inspections.

- Specifications: Opt for displays with at least 4.3-inch screens and high brightness for outdoor visibility.

- Benefits: Reduced eye strain and improved overall viewing experience.

-

Durability and Water Resistance:

- Importance: Automotive environments can be harsh, so durability and water resistance are essential.

- Specifications: Choose cameras with rugged housings and IP67-rated water resistance for use in wet or oily conditions.

- Benefits: Longer lifespan and reliable performance in demanding conditions.

-

Recording and Storage:

- Importance: The ability to record images and videos is crucial for documentation and customer communication.

- Specifications: Look for cameras with built-in storage or SD card slots, and the ability to record in high definition.

- Benefits: Easy documentation of findings, sharing with colleagues, and providing visual evidence to customers.

-

Battery Life:

- Importance: Longer battery life ensures uninterrupted use during extended diagnostic sessions.

- Specifications: Choose cameras with at least 4 hours of battery life, and consider models with replaceable batteries.

- Benefits: Reduced downtime and improved productivity.

-

Articulating Capabilities:

- Importance: Articulating cameras provide greater control over the viewing angle, essential for complex inspections.

- Specifications: Look for cameras with 360-degree articulation and responsive controls.

- Benefits: Comprehensive views of internal components without repositioning the camera.

5. Top Camcammer Brands and Models in the Market

Several brands offer high-quality camcammers tailored for automotive repair. Here are some of the top brands and models:

| Brand | Model | Key Features | Application | Price Range |

|---|---|---|---|---|

| Snap-on | BK8000 | High-resolution imaging, durable construction, wireless connectivity, advanced articulation | Engine diagnostics, transmission inspections, detailed component analysis | $1,500 – $2,500 |

| Matco Tools | MDSCAM2 | Dual-lens camera, 1080p resolution, long battery life, rugged design | Cylinder inspections, valve seat analysis, exhaust system examination | $800 – $1,200 |

| Bosch | Endoscope 1600A009C6 | Flexible cable, adjustable LED lighting, image and video recording, water resistance | General inspections, brake lines, chassis components | $300 – $500 |

| Milwaukee | 2314-21 M-Spector M12 | Compact design, high-resolution display, durable cable, enhanced lighting | Tight spaces, door panels, under dashboards | $250 – $400 |

| Innova | 3630 Automotive Digital Inspection Camera | Large color display, zoom function, LED brightness control, wide-angle lens | Engine compartments, undercarriage, electrical systems | $150 – $300 |

| Flir | VS70 | High-resolution thermal imaging, visual camera, flexible probe, ergonomic design | Thermal diagnostics, leak detection, electrical fault finding | $1,200 – $2,000 |

| Autel | MaxiVideo MV480 | Dual-camera, articulating probe, 1080p resolution, 8.5mm camera head | Engine diagnostics, transmission inspections, detailed component analysis | $900 – $1,500 |

| Ridgid | MicroReel CA-300 | Durable construction, long cable length, self-leveling camera head, digital zoom | Drain lines, exhaust systems, long-reach inspections | $700 – $1,100 |

| Depstech | DS450 | Wireless connectivity, 1080p resolution, adjustable LED lights, waterproof probe | General inspections, hard-to-reach areas, smartphone compatibility | $80 – $150 |

| Teslong | MS450 | Dual-lens camera, 5-inch IPS screen, one-button photo and video, 32GB memory card | Cylinder inspections, valve seat analysis, exhaust system examination | $100 – $200 |

Note: Prices are approximate and may vary.

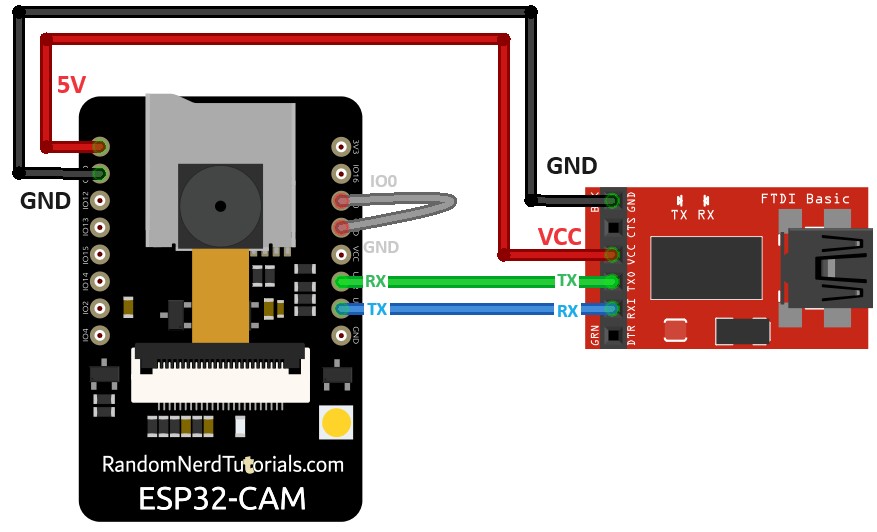

Close-up of a dual-lens inspection camera, highlighting its versatility for detailed automotive inspections

Close-up of a dual-lens inspection camera, highlighting its versatility for detailed automotive inspections

6. How to Effectively Use a Camcammer for Automotive Diagnostics

To maximize the benefits of a camcammer, follow these best practices for effective use:

-

Preparation:

- Clean the Area: Ensure the inspection area is clean to provide the best possible visibility.

- Proper Lighting: Use additional lighting if needed to supplement the camera’s built-in LEDs.

- Plan Your Route: Plan the inspection route to ensure you cover all critical areas efficiently.

-

Inspection Techniques:

- Slow and Steady: Move the camera slowly and steadily to capture clear images and video.

- Adjust Lighting: Adjust the LED brightness to optimize visibility in different environments.

- Use Articulation: Utilize articulating capabilities to view components from multiple angles.

-

Documentation:

- Record Findings: Record images and videos of all relevant findings for documentation and customer communication.

- Annotate Images: Use annotation tools to highlight specific areas of concern.

- Organize Files: Keep files organized with clear naming conventions for easy retrieval.

-

Maintenance:

- Clean the Camera: Regularly clean the camera lens and cable to maintain image quality.

- Store Properly: Store the camcammer in a protective case to prevent damage.

- Check Cables: Inspect cables for wear and tear, and replace if necessary.

7. Advanced Techniques and Applications

Advanced camcammer techniques can further enhance diagnostic capabilities, including:

-

Thermal Imaging:

- Application: Detecting overheating components, electrical faults, and exhaust leaks using thermal imaging cameras.

- Benefits: Non-contact temperature measurement, quick identification of thermal anomalies, and improved safety.

-

3D Modeling:

- Application: Creating 3D models of internal components using advanced imaging software for detailed analysis.

- Benefits: Precise measurements, enhanced visualization, and improved repair planning.

-

Remote Collaboration:

- Application: Sharing real-time video feeds with remote experts for collaborative diagnostics.

- Benefits: Access to specialized knowledge, faster problem-solving, and reduced downtime.

8. Case Studies: Successful Camcammer Implementations

Several case studies illustrate the effectiveness of camcammers in automotive repair:

-

Case Study 1: Cylinder Inspection

- Problem: A vehicle was experiencing unexplained engine misfires.

- Solution: Using a borescope, the technician discovered scoring on the cylinder walls, indicating excessive wear.

- Outcome: The engine was rebuilt, resolving the misfire issue and preventing further damage.

-

Case Study 2: Exhaust Leak Detection

- Problem: A vehicle failed an emissions test due to high levels of pollutants.

- Solution: A thermal imaging camera quickly identified a small exhaust leak near the manifold.

- Outcome: The exhaust manifold was repaired, allowing the vehicle to pass the emissions test.

-

Case Study 3: Transmission Inspection

- Problem: A vehicle was experiencing erratic shifting and slipping.

- Solution: An articulating inspection camera was used to examine the transmission internals, revealing damaged clutch plates.

- Outcome: The transmission was rebuilt with new clutch plates, restoring smooth and reliable shifting.

9. Integrating Camcammers with Other Diagnostic Tools

Camcammers can be effectively integrated with other diagnostic tools to provide a comprehensive approach to automotive repair.

- Scan Tools: Combine camcammer inspections with scan tool data to correlate visual findings with diagnostic trouble codes (DTCs).

- Multimeters: Use camcammers to visually inspect electrical connections and wiring harnesses, complementing multimeter readings.

- Smoke Machines: Integrate camcammer inspections with smoke testing to pinpoint the exact location of leaks in vacuum and exhaust systems.

- Pressure Testers: Use camcammers to visually inspect components while pressure testing cooling and fuel systems.

10. Future Trends in Camcammer Technology

The future of camcammer technology promises even more advanced capabilities and applications:

-

AI-Powered Diagnostics:

- Trend: Integrating artificial intelligence (AI) to automatically analyze images and videos, identifying potential issues and recommending repairs.

- Benefits: Faster diagnostics, reduced reliance on technician expertise, and improved accuracy.

-

Augmented Reality (AR) Integration:

- Trend: Using augmented reality to overlay diagnostic information and repair instructions onto the camcammer’s video feed.

- Benefits: Hands-free operation, real-time guidance, and improved training.

-

Miniaturization:

- Trend: Developing smaller, more flexible camcammers that can access even tighter spaces.

- Benefits: Improved access to complex components, reduced disassembly, and enhanced diagnostic capabilities.

-

Wireless Charging:

- Trend: Implementing wireless charging to ensure camcammers are always ready for use.

- Benefits: Reduced downtime, simplified charging, and improved convenience.

11. Maintenance Tips for Camcammers

To extend the life and performance of your camcammer, follow these maintenance tips:

-

Regular Cleaning:

- Tip: Clean the camera lens and cable after each use with a soft, lint-free cloth.

- Benefits: Maintains image quality and prevents debris from damaging the camera.

-

Proper Storage:

- Tip: Store the camcammer in a protective case in a clean, dry environment.

- Benefits: Protects the camera from physical damage, dust, and moisture.

-

Cable Inspection:

- Tip: Regularly inspect the cable for cuts, kinks, or other damage.

- Benefits: Prevents electrical shorts and ensures reliable performance.

-

Battery Care:

- Tip: Follow the manufacturer’s recommendations for battery charging and storage.

- Benefits: Extends battery life and prevents damage.

-

Software Updates:

- Tip: Keep the camcammer’s software up to date to ensure optimal performance and access to new features.

- Benefits: Improved functionality, bug fixes, and enhanced compatibility.

12. How to Choose the Right Camcammer for Your Needs

Selecting the right camcammer depends on your specific needs and applications. Consider these factors:

-

Frequency of Use:

- Consideration: If you use a camcammer frequently, invest in a higher-quality model with durable construction and advanced features.

- Recommendation: For occasional use, a more basic model may suffice.

-

Types of Inspections:

- Consideration: Choose a camcammer with features tailored to the types of inspections you perform most often.

- Recommendation: For engine work, prioritize high-resolution imaging and articulating capabilities. For general inspections, focus on cable length and durability.

-

Budget:

- Consideration: Camcammers range in price from a few hundred to several thousand dollars.

- Recommendation: Set a budget and compare models within that range, balancing features and cost.

-

User Reviews:

- Consideration: Read user reviews and ratings to get real-world feedback on performance and reliability.

- Recommendation: Look for models with consistently high ratings and positive comments.

-

Warranty:

- Consideration: A good warranty provides peace of mind and protection against defects.

- Recommendation: Choose a camcammer with a comprehensive warranty from a reputable manufacturer.

13. Safety Precautions When Using Camcammers

Safety should always be a priority when using camcammers. Follow these precautions:

-

Wear Protective Gear:

- Precaution: Wear safety glasses and gloves to protect against debris and hazardous substances.

- Reason: Prevents eye injuries and skin irritation.

-

Disconnect Power:

- Precaution: Disconnect the vehicle’s battery before performing inspections on electrical components.

- Reason: Prevents electrical shock and damage to the vehicle.

-

Avoid Contact with Moving Parts:

- Precaution: Ensure the engine is off and all moving parts are stationary before inserting the camcammer.

- Reason: Prevents injury and damage to the camera.

-

Use Proper Lighting:

- Precaution: Use adequate lighting to avoid eye strain and improve visibility.

- Reason: Reduces the risk of accidents and improves diagnostic accuracy.

-

Follow Manufacturer’s Instructions:

- Precaution: Always follow the manufacturer’s instructions for safe operation and maintenance.

- Reason: Ensures proper use and prevents damage to the camcammer.

14. Common Problems and Solutions When Using Camcammers

Even with proper use, some common problems may arise. Here are some solutions:

-

Problem: Poor Image Quality

- Solution: Clean the camera lens, adjust the lighting, and ensure the inspection area is clean.

- Reason: Improves visibility and clarity.

-

Problem: Cable Getting Stuck

- Solution: Gently rotate and maneuver the cable, avoiding sharp bends or excessive force.

- Reason: Prevents damage to the cable and ensures smooth movement.

-

Problem: No Power

- Solution: Check the battery, connections, and power switch. Replace the battery if necessary.

- Reason: Restores power to the camcammer.

-

Problem: Software Issues

- Solution: Update the software, restart the device, or contact technical support.

- Reason: Resolves bugs and ensures optimal performance.

-

Problem: Overheating

- Solution: Allow the camcammer to cool down before continuing use.

- Reason: Prevents damage to the camera and ensures safe operation.

15. Resources for Learning More About Camcammers

To expand your knowledge and skills, consider these resources:

- Online Courses: Platforms like Coursera, Udemy, and Skillshare offer courses on automotive diagnostics and camcammer techniques.

- Technical Manuals: Consult the manufacturer’s manuals for detailed information on specific camcammer models.

- Industry Forums: Participate in online forums and communities to share knowledge and learn from other technicians.

- Trade Shows: Attend automotive trade shows and conferences to see the latest camcammer technology and network with industry experts.

- Websites and Blogs: Visit websites and blogs dedicated to automotive repair for tips, tutorials, and product reviews. CAR-TOOL.EDU.VN is your go-to resource for detailed information and comparisons.

- Professional Certifications: Obtain professional certifications from organizations like ASE (Automotive Service Excellence) to demonstrate your expertise.

16. The Impact of Camcammers on Automotive Training

Camcammers are transforming automotive training by providing students with hands-on experience and realistic scenarios.

-

Enhanced Learning:

- Impact: Students can visually inspect components and diagnose issues, improving their understanding and retention of concepts.

- Benefit: More effective learning and better preparation for real-world scenarios.

-

Realistic Simulations:

- Impact: Camcammers allow instructors to simulate common automotive problems and guide students through the diagnostic process.

- Benefit: Development of critical thinking and problem-solving skills.

-

Improved Skill Development:

- Impact: Students gain practical experience using camcammers, developing the skills needed to perform accurate diagnostics and repairs.

- Benefit: Increased confidence and competence in automotive repair.

-

Modernized Curriculum:

- Impact: Incorporating camcammers into the curriculum ensures students are trained on the latest technology and techniques.

- Benefit: Staying current with industry trends and preparing students for future challenges.

-

Accessibility:

- Impact: Camcammers make it easier for students to access and inspect internal components without extensive disassembly.

- Benefit: More efficient use of time and resources.

17. Camcammers in Preventative Maintenance

Camcammers are invaluable tools for preventative maintenance, helping to identify potential issues before they lead to breakdowns.

-

Early Detection of Wear:

- Application: Inspecting brake components, belts, and hoses for signs of wear and tear.

- Benefit: Prevents component failure and reduces the risk of accidents.

-

Fluid Leak Detection:

- Application: Examining engine, transmission, and brake systems for fluid leaks.

- Benefit: Prevents fluid loss and component damage.

-

Corrosion Inspection:

- Application: Inspecting chassis components and electrical connections for corrosion.

- Benefit: Prevents structural damage and electrical problems.

-

Internal Engine Inspection:

- Application: Using borescopes to inspect cylinders, valves, and pistons for carbon buildup and wear.

- Benefit: Optimizes engine performance and extends engine life.

-

Exhaust System Inspection:

- Application: Examining exhaust systems for leaks and damage.

- Benefit: Prevents emissions problems and ensures proper engine operation.

18. Real-World Applications of Camcammers

Camcammers are used in a wide range of automotive applications, including:

-

Engine Diagnostics:

- Application: Inspecting cylinders, pistons, valves, and spark plugs for wear, damage, and carbon buildup.

- Benefit: Accurate diagnosis of engine problems and improved performance.

-

Transmission Inspections:

- Application: Examining gears, clutch plates, and fluid levels in transmissions.

- Benefit: Identification of transmission problems and prevention of major failures.

-

Brake System Inspections:

- Application: Inspecting brake pads, rotors, calipers, and brake lines for wear, damage, and leaks.

- Benefit: Ensuring safe and reliable braking performance.

-

Electrical System Diagnostics:

- Application: Inspecting wiring harnesses, connectors, and components for corrosion, damage, and loose connections.

- Benefit: Troubleshooting electrical problems and ensuring proper operation of vehicle systems.

-

HVAC System Inspections:

- Application: Examining evaporator cores, heater cores, and ductwork for leaks and blockages.

- Benefit: Diagnosing HVAC problems and maintaining comfortable cabin temperatures.

-

Body and Chassis Inspections:

- Application: Inspecting chassis components, frame rails, and body panels for corrosion, damage, and structural issues.

- Benefit: Ensuring vehicle safety and preventing costly repairs.

19. Maximizing ROI with Camcammer Investments

To maximize your return on investment (ROI) with camcammer technology, consider these strategies:

-

Training and Education:

- Strategy: Invest in training and education for technicians to ensure they can effectively use camcammers.

- Benefit: Improves diagnostic accuracy, reduces repair times, and increases customer satisfaction.

-

Marketing and Promotion:

- Strategy: Promote your use of camcammers to customers, highlighting the benefits of accurate diagnostics and transparent service.

- Benefit: Attracts new customers and builds trust.

-

Workflow Integration:

- Strategy: Integrate camcammer inspections into your standard workflow to streamline diagnostic processes.

- Benefit: Reduces diagnostic times and increases shop throughput.

-

Preventative Maintenance Programs:

- Strategy: Offer preventative maintenance programs that include camcammer inspections to identify potential issues before they become major problems.

- Benefit: Generates recurring revenue and builds customer loyalty.

-

Data Analysis:

- Strategy: Analyze data from camcammer inspections to identify common issues and trends.

- Benefit: Improves diagnostic accuracy and informs preventative maintenance strategies.

20. Frequently Asked Questions (FAQs) About Camcammers

-

Q: What is a camcammer and how does it work?

- A: A camcammer is a tool equipped with a camera, typically used for visual inspection in hard-to-reach areas. It works by providing a live video feed of the inspection area, allowing technicians to diagnose issues without extensive disassembly.

-

Q: What are the different types of camcammers available?

- A: The main types include borescopes, inspection cameras, wireless inspection cameras, dual-lens inspection cameras, and articulating inspection cameras, each designed for specific applications and offering different features.

-

Q: How can a camcammer improve diagnostic accuracy?

- A: Camcammers provide visual confirmation of issues, allowing for early detection of problems like corrosion, cracks, and wear. This detailed inspection helps technicians identify the root cause more effectively.

-

Q: What are the key features to look for when choosing a camcammer?

- A: Key features include image resolution, cable flexibility and length, lighting, display size and type, durability and water resistance, recording and storage, battery life, and articulating capabilities.

-

Q: How do I properly maintain a camcammer?

- A: Regular maintenance includes cleaning the camera lens and cable after each use, storing the camcammer in a protective case, inspecting the cable for damage, following manufacturer’s recommendations for battery care, and keeping the software up to date.

-

Q: Can camcammers be used for preventative maintenance?

- A: Yes, camcammers are invaluable tools for preventative maintenance. They help identify potential issues before they lead to breakdowns by detecting wear, fluid leaks, and corrosion.

-

Q: What are the safety precautions when using camcammers?

- A: Safety precautions include wearing protective gear, disconnecting power before inspecting electrical components, avoiding contact with moving parts, using proper lighting, and following the manufacturer’s instructions.

-

Q: How can I integrate camcammers with other diagnostic tools?

- A: Camcammers can be combined with scan tools, multimeters, smoke machines, and pressure testers to provide a comprehensive approach to automotive repair.

-

Q: What are the future trends in camcammer technology?

- A: Future trends include AI-powered diagnostics, augmented reality (AR) integration, miniaturization, and wireless charging.

-

Q: Where can I learn more about camcammers and automotive diagnostics?

- A: You can learn more through online courses, technical manuals, industry forums, trade shows, websites and blogs, and professional certifications.

Conclusion

Camcammers are indispensable tools for modern automotive repair, offering enhanced diagnostic accuracy, reduced disassembly time, and improved customer communication. By understanding the different types of camcammers, key features, best practices, and future trends, you can maximize the benefits of this technology and stay ahead in the rapidly evolving automotive industry. For more detailed information and expert guidance, contact CAR-TOOL.EDU.VN at 456 Elm Street, Dallas, TX 75201, United States, or call us on Whatsapp: +1 (641) 206-8880. Visit our website at CAR-TOOL.EDU.VN for the latest tools and resources.

Ready to elevate your automotive repair capabilities? Contact CAR-TOOL.EDU.VN today for expert advice and the best camcammer solutions. Reach us at 456 Elm Street, Dallas, TX 75201, United States, call us on Whatsapp: +1 (641) 206-8880, or visit our website at CAR-TOOL.EDU.VN. Let us help you transform your diagnostic process.

Technician utilizing a camcammer for detailed automotive inspection

Technician utilizing a camcammer for detailed automotive inspection