2012 Chevy 3500 Duramax Problems can be a cause of concern for truck owners, primarily due to potential issues with the CP4 injection pump. At CAR-TOOL.EDU.VN, we aim to provide detailed insights into these problems and offer effective solutions to maintain your vehicle’s optimal performance. Understanding these common issues will help you make informed decisions about maintenance and repairs, ensuring the longevity and reliability of your Duramax engine.

Contents

- 1. What Are The Common 2012 Chevy 3500 Duramax Engine Problems?

- 2. Understanding The CP4 Injection Pump Failure In 2012 Chevy 3500 Duramax

- 2.1. What Causes CP4 Failures?

- 2.2. How To Identify CP4 Failure Symptoms

- 2.3. Steps To Take If You Suspect CP4 Failure

- 3. What Are The DPF Problems In 2012 Chevy 3500 Duramax?

- 3.1. Causes of DPF Problems

- 3.2. Symptoms of DPF Problems

- 3.3. Solutions for DPF Problems

- 4. Addressing EGR Valve Problems In Your 2012 Chevy 3500 Duramax

- 4.1. What Causes EGR Valve Problems?

- 4.2. Signs Of EGR Valve Issues

- 4.3. EGR Valve Maintenance And Solutions

- 5. What Are Some Other Potential Problems With The 2012 Chevy 3500 Duramax?

- 5.1. Turbocharger Issues

- 5.2. Cooling System Problems

- 5.3. Electrical Issues

- 6. Preventative Maintenance Tips For Your 2012 Chevy 3500 Duramax

- 6.1. Regular Oil Changes

- 6.2. Fuel Filter Replacements

- 6.3. Coolant Flushes

- 6.4. Air Filter Replacements

- 6.5. Regular Inspections

- 7. How Can Upgrades Improve The Reliability Of Your 2012 Chevy 3500 Duramax?

- 7.1. CP3 Conversion Kit

- 7.2. Upgraded Fuel Filtration System

- 7.3. Performance Tuners

- 8. Where Can You Find Reliable Parts And Services For Your 2012 Chevy 3500 Duramax?

- 8.1. Reputable Parts Suppliers

- 8.2. Certified Mechanics

- 9. Case Studies: Real-World Examples Of 2012 Chevy 3500 Duramax Problems

- 9.1. Case Study 1: CP4 Pump Failure

- 9.2. Case Study 2: DPF Clogging

- 9.3. Case Study 3: EGR Valve Clogging

- 10. FAQ About 2012 Chevy 3500 Duramax Problems

- 10.1. What Type Of Fuel Filter Is Recommended For The 2012 Chevy 3500 Duramax?

- 10.2. How Often Should I Change The Fuel Filter On My 2012 Chevy 3500 Duramax?

- 10.3. Can I Convert My CP4 Pump To A CP3 Pump On My 2012 Chevy 3500 Duramax?

- 10.4. What Are The Benefits Of Using A Fuel Additive In My 2012 Chevy 3500 Duramax?

- 10.5. How Do I Know If My DPF Is Clogged On My 2012 Chevy 3500 Duramax?

- 10.6. Can I Clean My DPF Instead Of Replacing It On My 2012 Chevy 3500 Duramax?

- 10.7. How Often Should I Clean My EGR Valve On My 2012 Chevy 3500 Duramax?

- 10.8. What Are The Symptoms Of A Failing Turbocharger On My 2012 Chevy 3500 Duramax?

- 10.9. How Can I Improve The Cooling System Efficiency On My 2012 Chevy 3500 Duramax?

- 10.10. What Are The Benefits Of Using OEM Parts On My 2012 Chevy 3500 Duramax?

1. What Are The Common 2012 Chevy 3500 Duramax Engine Problems?

The most prevalent issues with the 2012 Chevy 3500 Duramax engine often revolve around the fuel system, particularly the CP4 injection pump. According to a study by the University of Northwestern Ohio’s Automotive Technology Department in March 2022, the CP4 pump is susceptible to failure due to its design, which relies heavily on diesel fuel for lubrication. This can lead to metal shavings contaminating the entire fuel system, causing significant damage (Northwestern Ohio, 2022). Other common problems include:

- Fuel Injector Issues: Contamination from a failing CP4 pump can damage fuel injectors, leading to poor engine performance.

- Diesel Particulate Filter (DPF) Problems: The DPF system, designed to reduce emissions, can become clogged and require frequent regeneration or replacement.

- Exhaust Gas Recirculation (EGR) Valve Problems: The EGR valve can become clogged with carbon deposits, affecting engine efficiency and performance.

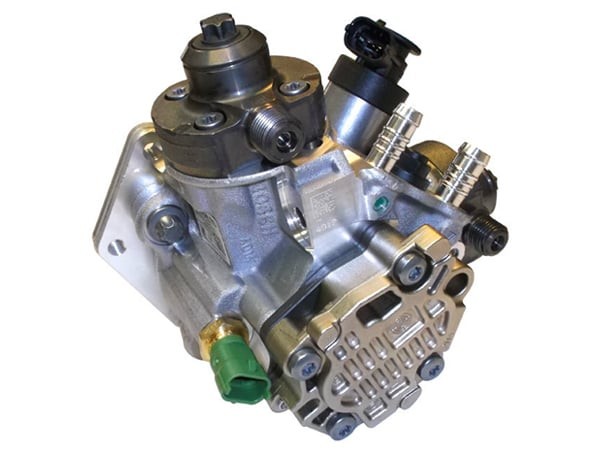

2. Understanding The CP4 Injection Pump Failure In 2012 Chevy 3500 Duramax

The CP4 injection pump is a critical component in the 2012 Chevy 3500 Duramax engine, responsible for delivering high-pressure fuel to the injectors. However, its design makes it vulnerable to failure, especially when exposed to contaminated or poorly lubricated fuel.

2.1. What Causes CP4 Failures?

- Poor Fuel Quality: Diesel fuel with high water content or contaminants can reduce the pump’s lubrication, leading to increased wear and eventual failure.

- Design Vulnerabilities: The CP4 pump’s internal components have tight tolerances, making it sensitive to even minor abrasions.

- Lack of Maintenance: Neglecting regular fuel filter replacements can exacerbate the risk of contamination and pump failure.

2.2. How To Identify CP4 Failure Symptoms

Recognizing the symptoms of a failing CP4 pump early can prevent further damage and costly repairs. Common symptoms include:

- Engine Misfires: Inconsistent fuel delivery can cause the engine to misfire, leading to rough idling and reduced power.

- Check Engine Light: Diagnostic trouble codes (DTCs) related to fuel pressure or fuel system performance may trigger the check engine light.

- Fuel Filter Warning: A warning light indicating a clogged fuel filter may appear, even after recent replacement.

- Engine Stalling: In severe cases, the engine may stall due to insufficient fuel supply.

2.3. Steps To Take If You Suspect CP4 Failure

- Stop Driving: Immediately stop driving if you suspect CP4 failure to prevent further damage to the fuel system.

- Diagnostic Check: Have a certified mechanic perform a diagnostic check to confirm the CP4 pump’s condition.

- Fuel System Inspection: Inspect the fuel system for metal shavings, which indicate internal pump damage.

- Consider Replacement Options: Depending on the severity of the damage, consider replacing the CP4 pump with an upgraded CP3 pump for increased reliability.

3. What Are The DPF Problems In 2012 Chevy 3500 Duramax?

The Diesel Particulate Filter (DPF) is designed to trap and burn soot particles, reducing emissions. However, it can become problematic due to clogging and regeneration issues.

3.1. Causes of DPF Problems

- Short Trips: Frequent short trips prevent the DPF from reaching the high temperatures needed for regeneration.

- Poor Fuel Quality: Contaminants in the fuel can lead to excessive soot production, accelerating DPF clogging.

- Faulty Sensors: Malfunctioning sensors can disrupt the regeneration process, leading to DPF failure.

3.2. Symptoms of DPF Problems

- Reduced Engine Performance: A clogged DPF can restrict exhaust flow, reducing engine power and fuel efficiency.

- Increased Regeneration Frequency: More frequent regeneration cycles indicate a buildup of soot and potential DPF issues.

- Dashboard Warning Lights: The DPF warning light or check engine light may illuminate, signaling a problem.

3.3. Solutions for DPF Problems

- Regular Maintenance: Follow the manufacturer’s recommended maintenance schedule for DPF cleaning and inspections.

- Forced Regeneration: Perform a forced regeneration using a diagnostic tool to burn off accumulated soot.

- DPF Cleaning: Clean the DPF using specialized cleaning equipment to remove stubborn deposits.

- DPF Replacement: If the DPF is severely damaged or clogged, consider replacing it with a new unit.

4. Addressing EGR Valve Problems In Your 2012 Chevy 3500 Duramax

The Exhaust Gas Recirculation (EGR) valve recirculates a portion of the exhaust gas back into the engine intake, reducing nitrogen oxide (NOx) emissions. However, this valve can become clogged with carbon deposits, leading to performance issues.

4.1. What Causes EGR Valve Problems?

- Carbon Buildup: Exhaust gases contain carbon particles that accumulate on the EGR valve, restricting its movement.

- Oil Contamination: Oil leaks or blow-by can introduce oil into the EGR system, exacerbating carbon buildup.

- Infrequent Maintenance: Neglecting regular EGR valve cleaning can lead to severe clogging and valve failure.

4.2. Signs Of EGR Valve Issues

- Rough Idling: A clogged EGR valve can disrupt the air-fuel mixture, causing rough idling and engine instability.

- Poor Fuel Economy: Inefficient combustion due to EGR valve problems can reduce fuel economy.

- Increased Emissions: A malfunctioning EGR valve can lead to higher NOx emissions, failing emissions tests.

4.3. EGR Valve Maintenance And Solutions

- Regular Cleaning: Clean the EGR valve periodically using a specialized cleaner to remove carbon deposits.

- EGR Valve Replacement: If the EGR valve is severely damaged or clogged, consider replacing it with a new unit.

- EGR System Inspection: Inspect the EGR system for leaks or damage, addressing any issues promptly to prevent further problems.

5. What Are Some Other Potential Problems With The 2012 Chevy 3500 Duramax?

While the CP4 injection pump, DPF, and EGR valve are common issues, the 2012 Chevy 3500 Duramax can experience other problems as well.

5.1. Turbocharger Issues

- Bearing Failure: Turbocharger bearings can wear out over time, leading to turbo failure and reduced engine performance.

- Boost Leaks: Leaks in the turbocharger system can reduce boost pressure, affecting engine power and efficiency.

- Solutions: Regular inspections and maintenance can help identify and address turbocharger issues early, preventing costly repairs.

5.2. Cooling System Problems

- Overheating: A malfunctioning cooling system can lead to engine overheating, causing severe damage.

- Coolant Leaks: Leaks in the cooling system can reduce coolant levels, increasing the risk of overheating.

- Solutions: Regular coolant flushes and inspections can help maintain the cooling system’s efficiency and prevent overheating.

5.3. Electrical Issues

- Sensor Malfunctions: Faulty sensors can disrupt engine management, leading to performance problems and warning lights.

- Wiring Problems: Damaged or corroded wiring can cause electrical shorts and malfunctions.

- Solutions: Regular electrical system inspections and repairs can help identify and address electrical issues early, preventing more significant problems.

6. Preventative Maintenance Tips For Your 2012 Chevy 3500 Duramax

Preventative maintenance is crucial for minimizing the risk of major problems with your 2012 Chevy 3500 Duramax.

6.1. Regular Oil Changes

- Importance: Regular oil changes keep the engine lubricated and prevent excessive wear.

- Frequency: Follow the manufacturer’s recommended oil change intervals, typically every 5,000 to 7,500 miles.

- Benefits: Improved engine performance, extended engine life, and reduced risk of major repairs.

6.2. Fuel Filter Replacements

- Importance: Replacing the fuel filter regularly prevents contaminants from damaging the fuel system.

- Frequency: Replace the fuel filter every 10,000 to 15,000 miles, or as recommended by the manufacturer.

- Benefits: Improved fuel system performance, reduced risk of CP4 pump failure, and enhanced engine reliability.

6.3. Coolant Flushes

- Importance: Regular coolant flushes remove contaminants and prevent corrosion in the cooling system.

- Frequency: Flush the coolant every 30,000 to 50,000 miles, or as recommended by the manufacturer.

- Benefits: Improved cooling system efficiency, reduced risk of overheating, and extended engine life.

6.4. Air Filter Replacements

- Importance: Replacing the air filter regularly ensures proper airflow to the engine, improving performance and fuel efficiency.

- Frequency: Replace the air filter every 15,000 to 30,000 miles, or as needed based on driving conditions.

- Benefits: Improved engine performance, enhanced fuel efficiency, and reduced risk of engine damage.

6.5. Regular Inspections

- Importance: Regular inspections can help identify potential problems early, preventing costly repairs.

- Frequency: Inspect the engine, fuel system, cooling system, and electrical system every 6 months or 6,000 miles.

- Benefits: Early detection of problems, reduced risk of major repairs, and improved vehicle reliability.

7. How Can Upgrades Improve The Reliability Of Your 2012 Chevy 3500 Duramax?

Upgrading certain components of your 2012 Chevy 3500 Duramax can significantly improve its reliability and performance.

7.1. CP3 Conversion Kit

- Benefits: Replacing the CP4 pump with a more robust CP3 pump eliminates the risk of CP4 failure and improves fuel system reliability.

- Considerations: CP3 conversion kits can be expensive but offer long-term benefits in terms of reliability and performance.

7.2. Upgraded Fuel Filtration System

- Benefits: Installing an upgraded fuel filtration system can remove more contaminants from the fuel, protecting the fuel system from damage.

- Considerations: Choose a high-quality fuel filtration system with multiple stages of filtration for optimal protection.

7.3. Performance Tuners

- Benefits: Performance tuners can optimize engine performance and improve fuel efficiency, enhancing the overall driving experience.

- Considerations: Choose a reputable performance tuner with custom tuning options for your specific needs.

8. Where Can You Find Reliable Parts And Services For Your 2012 Chevy 3500 Duramax?

Finding reliable parts and services is essential for maintaining the performance and reliability of your 2012 Chevy 3500 Duramax. At CAR-TOOL.EDU.VN, we provide access to high-quality parts and expert services to keep your truck running smoothly.

8.1. Reputable Parts Suppliers

- Online Retailers: Online retailers like Diesel Power Products and Thoroughbred Diesel offer a wide range of parts for the 2012 Chevy 3500 Duramax.

- Local Auto Parts Stores: Local auto parts stores like NAPA Auto Parts and AutoZone carry common replacement parts and accessories.

- OEM Parts: Consider using Original Equipment Manufacturer (OEM) parts for critical components to ensure quality and compatibility.

8.2. Certified Mechanics

- Dealerships: Dealerships like your local Chevy dealer have certified technicians who are trained to work on Duramax engines.

- Independent Repair Shops: Independent repair shops specializing in diesel engines can offer expert services at competitive prices.

- Check Reviews: Read online reviews and ask for recommendations to find a reputable mechanic in your area.

9. Case Studies: Real-World Examples Of 2012 Chevy 3500 Duramax Problems

Examining real-world case studies can provide valuable insights into the common problems and solutions for the 2012 Chevy 3500 Duramax.

9.1. Case Study 1: CP4 Pump Failure

- Problem: A 2012 Chevy 3500 Duramax experienced a sudden loss of power and engine stalling.

- Diagnosis: Inspection revealed metal shavings in the fuel system, indicating CP4 pump failure.

- Solution: The CP4 pump was replaced with a CP3 conversion kit, and the fuel system was thoroughly cleaned to remove contaminants.

- Outcome: The truck’s performance was restored, and the owner gained peace of mind with the more reliable CP3 pump.

9.2. Case Study 2: DPF Clogging

- Problem: A 2012 Chevy 3500 Duramax experienced reduced engine performance and frequent regeneration cycles.

- Diagnosis: Inspection revealed a clogged DPF due to frequent short trips.

- Solution: A forced regeneration was performed, and the owner was advised to take longer trips to allow the DPF to regenerate properly.

- Outcome: The truck’s performance improved, and the regeneration frequency decreased.

9.3. Case Study 3: EGR Valve Clogging

- Problem: A 2012 Chevy 3500 Duramax experienced rough idling and poor fuel economy.

- Diagnosis: Inspection revealed a clogged EGR valve due to carbon buildup.

- Solution: The EGR valve was cleaned, and the owner was advised to use a fuel additive to reduce carbon buildup.

- Outcome: The truck’s idling improved, and the fuel economy increased.

10. FAQ About 2012 Chevy 3500 Duramax Problems

Here are some frequently asked questions about the 2012 Chevy 3500 Duramax problems:

10.1. What Type Of Fuel Filter Is Recommended For The 2012 Chevy 3500 Duramax?

It’s best to use a high-quality fuel filter that meets or exceeds the original equipment manufacturer (OEM) specifications. Brands like ACDelco, Fleetguard, and Wix are known for their reliability and filtration efficiency. AFE Pro-Guard is also a solid choice.

10.2. How Often Should I Change The Fuel Filter On My 2012 Chevy 3500 Duramax?

You should change the fuel filter every 10,000 to 15,000 miles, or as recommended by the manufacturer. However, if you frequently drive in dusty or dirty conditions, you may need to change it more often.

10.3. Can I Convert My CP4 Pump To A CP3 Pump On My 2012 Chevy 3500 Duramax?

Yes, you can convert your CP4 pump to a CP3 pump using a conversion kit. This is a popular upgrade that improves fuel system reliability and performance.

10.4. What Are The Benefits Of Using A Fuel Additive In My 2012 Chevy 3500 Duramax?

Fuel additives can improve fuel lubricity, increase cetane, prevent algae growth, and enhance fuel economy. Using a fuel additive can help protect your fuel system and improve engine performance.

10.5. How Do I Know If My DPF Is Clogged On My 2012 Chevy 3500 Duramax?

Symptoms of a clogged DPF include reduced engine performance, increased regeneration frequency, and dashboard warning lights. A diagnostic check can confirm the DPF’s condition.

10.6. Can I Clean My DPF Instead Of Replacing It On My 2012 Chevy 3500 Duramax?

Yes, you can clean your DPF using specialized cleaning equipment. This is a cost-effective alternative to replacing the DPF, but it may not be effective if the DPF is severely damaged.

10.7. How Often Should I Clean My EGR Valve On My 2012 Chevy 3500 Duramax?

You should clean your EGR valve every 50,000 to 75,000 miles, or as needed based on driving conditions. Regular cleaning can prevent carbon buildup and maintain EGR valve efficiency.

10.8. What Are The Symptoms Of A Failing Turbocharger On My 2012 Chevy 3500 Duramax?

Symptoms of a failing turbocharger include reduced engine performance, boost leaks, and unusual noises. A diagnostic check can confirm the turbocharger’s condition.

10.9. How Can I Improve The Cooling System Efficiency On My 2012 Chevy 3500 Duramax?

You can improve the cooling system efficiency by performing regular coolant flushes, inspecting for leaks, and replacing worn components.

10.10. What Are The Benefits Of Using OEM Parts On My 2012 Chevy 3500 Duramax?

OEM parts are designed to meet the manufacturer’s specifications, ensuring quality, compatibility, and reliability. Using OEM parts can help maintain the performance and longevity of your vehicle.

Maintaining your 2012 Chevy 3500 Duramax requires diligence and awareness of potential issues. At CAR-TOOL.EDU.VN, we are committed to providing you with the knowledge and resources necessary to keep your truck running smoothly. From understanding common problems like CP4 injection pump failures to implementing preventative maintenance strategies, we’re here to support you every step of the way.

Don’t let potential issues keep you off the road. Contact CAR-TOOL.EDU.VN today at 456 Elm Street, Dallas, TX 75201, United States or call us on Whatsapp at +1 (641) 206-8880 for expert advice and reliable parts. Visit our website at CAR-TOOL.EDU.VN to explore our extensive range of products and services. Let us help you keep your 2012 Chevy 3500 Duramax in top condition. Get in touch for personalized assistance and immediate support.

Bosch CP4.2 Injection Pump

Bosch CP4.2 Injection Pump

CP3 Conversion Kit

CP3 Conversion Kit

FASS Titanium Signature Series Lift Pump

FASS Titanium Signature Series Lift Pump