Mode 0A (Request Permanent DTCs) refers to a specific diagnostic service within the On-Board Diagnostics (OBD-II) system that retrieves permanent diagnostic trouble codes (PDTCs). These codes are crucial for ensuring vehicles meet emissions standards and for accurate vehicle diagnostics, and CAR-TOOL.EDU.VN is committed to providing you with the latest information and tools to understand them. Mastering the interpretation of these codes enhances your diagnostic abilities and helps maintain environmental compliance.

Contents

- 1. What is Mode 0A (Request Permanent DTCs)?

- 1.1 The Significance of Permanent Diagnostic Trouble Codes (PDTCs)

- 1.2 OBD-II Modes Explained

- 1.3 Evolution and Implementation of PDTCs

- 1.4 The Role of NVRAM in Storing PDTCs

- 1.4.1 Why NVRAM?

- 1.5 Regulations and Standards

- 2. What are the Key Differences Between DTCs, Pending DTCs, and PDTCs?

- 3. How to Read and Interpret Mode 0A Data

- 3.1 Using a Scan Tool to Access Mode 0A

- 3.2 Understanding DTC Formats and Definitions

- 3.3 Common PDTCs and Their Meanings

- 3.4 Resources for Looking Up DTC Definitions

- 4. How To Clear Mode 0A (Request Permanent DTCs)?

- 4.1 Conditions Required for PDTCs to Clear

- 4.2 Understanding Drive Cycles and Monitor Tests

- 4.2.1 What is a Drive Cycle?

- 4.2.2 What are Monitor Tests?

- 4.3 Special Cases and Manufacturer-Specific Procedures

- 4.3.1 Misfire and Fuel System PDTCs

- 4.3.2 Chrysler’s Similar Conditions Windows (SCW)

- 4.3.3 California Air Resources Board (CARB) Drive Cycle

- 4.4 Troubleshooting Steps If PDTCs Won’t Clear

- 5. What is the Impact of Mode 0A on Smog Inspections?

- 5.1 How PDTCs Affect Smog Check Results

- 5.2 Warm-Up Cycles and Miles Driven

- 5.3 Exemptions and Special Cases

- 5.4 Preparing a Vehicle for Smog Inspection

- 5.5 Resources for Smog Inspectors

- 6. What are the Benefits of Understanding Mode 0A for Technicians?

- 6.1 Enhanced Diagnostic Accuracy

- 6.2 Improved Repair Effectiveness

- 6.3 Compliance with Environmental Regulations

- 6.4 Professional Credibility and Customer Satisfaction

- 6.5 Utilizing CAR-TOOL.EDU.VN for Continued Learning

- 7. What Tools are Needed to Diagnose Mode 0A (Request Permanent DTCs)?

- 7.1 Essential Scan Tools

- 7.2 Multimeters and Electrical Testers

- 7.3 Diagnostic Software and Databases

- 7.4 Smoke Machines

- 7.5 Compression Testers

- 7.6 Fuel Pressure Testers

- 7.7 Access to CAR-TOOL.EDU.VN Resources

- 8. Common Mistakes to Avoid When Diagnosing Mode 0A

- 8.1 Ignoring PDTCs

- 8.2 Clearing Codes Without Repairing the Underlying Issue

- 8.3 Not Following Proper Diagnostic Procedures

- 8.4 Overlooking Basic Maintenance Items

- 8.5 Not Verifying the Repair

- 8.6 Not Understanding Drive Cycles and Monitor Tests

- 8.7 Relying Solely on the DTC Definition

- 8.8 Not Checking for Technical Service Bulletins (TSBs)

- 8.9 Not Staying Updated on the Latest Technologies

- 8.10 CAR-TOOL.EDU.VN: Your Partner in Avoiding Diagnostic Mistakes

- 9. What are the Future Trends in Mode 0A and OBD-II Diagnostics?

- 9.1 Enhanced Data Logging and Analytics

- 9.2 Integration with Cloud-Based Services

- 9.3 Artificial Intelligence (AI) and Machine Learning (ML)

- 9.4 Enhanced Cybersecurity Measures

- 9.5 Standardization and Interoperability

1. What is Mode 0A (Request Permanent DTCs)?

Mode 0A, or Request Permanent DTCs, is an On-Board Diagnostics II (OBD-II) service that retrieves diagnostic trouble codes (DTCs) that have been stored in the vehicle’s computer memory as “permanent.” Unlike regular DTCs, PDTCs cannot be cleared by simply using a scan tool or disconnecting the battery. They remain in the vehicle’s system until the underlying issue has been resolved and the vehicle has passed a certain number of drive cycles without the fault reoccurring. This ensures that vehicles genuinely meet emissions standards before a cleared code allows them to pass inspection.

1.1 The Significance of Permanent Diagnostic Trouble Codes (PDTCs)

Permanent Diagnostic Trouble Codes (PDTCs) are a vital part of the OBD-II system, introduced to prevent individuals from clearing DTCs just before an emissions test to pass inspection temporarily.

- Enforcing Real Repairs: PDTCs ensure that the vehicle genuinely meets emissions standards by requiring the underlying issue to be fully resolved and confirmed over multiple driving cycles.

- Reducing Emissions Cheating: By preventing temporary code clearing, PDTCs minimize the chances of vehicles with unresolved emissions issues passing inspections.

- Improving Air Quality: By ensuring vehicles comply with emissions standards, PDTCs play a crucial role in reducing air pollution and improving overall air quality.

- Compliance with Regulations: PDTCs help ensure compliance with environmental regulations set by agencies like the Environmental Protection Agency (EPA) and the California Air Resources Board (CARB).

1.2 OBD-II Modes Explained

To fully understand Mode 0A, it’s helpful to have context on other OBD-II modes. Here’s a simplified explanation:

- Mode $01: Show Current Data: Displays real-time data such as engine speed, coolant temperature, and oxygen sensor readings.

- Mode $02: Show Freeze Frame Data: Shows data recorded at the moment a DTC was set, providing a snapshot of the conditions when the fault occurred.

- Mode $03: Show Stored Diagnostic Trouble Codes: Displays DTCs that are currently stored in the vehicle’s computer.

- Mode $04: Clear/Reset Emission-Related Diagnostic Information: Clears stored DTCs and resets emission-related diagnostic information. This mode cannot clear PDTCs.

- Mode $06: Test Results for Continuously and Non-Continuously Monitored Systems: Shows the results of on-board diagnostic tests for various systems.

- Mode $07: Show Pending Diagnostic Trouble Codes: Displays DTCs that have been detected during the current or last driving cycle but have not yet been confirmed as permanent.

- Mode $09: Request Vehicle Information: Retrieves vehicle identification number (VIN), calibration identification, and calibration verification number.

- Mode $0A: Request Permanent Diagnostic Trouble Codes: Retrieves DTCs that are stored as permanent and cannot be cleared until the issue is resolved.

1.3 Evolution and Implementation of PDTCs

PDTCs were introduced in 2010 as part of a three-year phase-in, becoming mandatory for all vehicles by the 2012 model year. This implementation ensured that all vehicles had the capability to store and manage these codes, enhancing the reliability of emissions testing.

According to research from the California Air Resources Board (CARB), the introduction of PDTCs has significantly reduced the incidence of vehicles with emission problems passing smog checks due to temporary code clearing. This change has made the testing process more accurate and effective.

1.4 The Role of NVRAM in Storing PDTCs

PDTCs are stored in non-volatile RAM (NVRAM) within the vehicle’s Engine Control Module (ECM). NVRAM retains data even when the vehicle’s power is turned off, ensuring that PDTCs are not lost due to battery disconnection or other power interruptions.

1.4.1 Why NVRAM?

- Data Retention: NVRAM’s ability to retain data without power ensures that PDTCs remain stored until the underlying issue is resolved.

- Tamper Resistance: NVRAM helps prevent unauthorized clearing of PDTCs, maintaining the integrity of the diagnostic information.

- Reliability: NVRAM provides a reliable storage solution, ensuring that PDTCs are accurately stored and retrieved when needed.

1.5 Regulations and Standards

The implementation and management of PDTCs are governed by various regulations and standards set by environmental agencies such as the EPA and CARB. These standards ensure that PDTCs are consistently implemented across different vehicle manufacturers and models, promoting uniformity in emissions testing.

- EPA Standards: The EPA sets federal standards for emissions testing and diagnostic systems, including the requirements for PDTCs.

- CARB Regulations: CARB has specific regulations for emissions testing in California, which include detailed requirements for PDTCs and their role in smog checks.

2. What are the Key Differences Between DTCs, Pending DTCs, and PDTCs?

Understanding the differences between DTCs, Pending DTCs, and PDTCs is crucial for effective vehicle diagnostics and repair. Each type of code provides different information about the status of the vehicle’s systems and the severity of any detected issues.

| Feature | DTC (Diagnostic Trouble Code) | Pending DTC (Diagnostic Trouble Code) | PDTC (Permanent Diagnostic Trouble Code) |

|---|---|---|---|

| Status | Confirmed fault | Potential fault | Confirmed and unresolved fault |

| Trigger | Fault detected over multiple drive cycles | Fault detected during current or last drive cycle | Confirmed DTC that triggers MIL |

| Memory | Stored in volatile memory | Stored in volatile memory | Stored in non-volatile memory (NVRAM) |

| Clearing | Can be cleared with a scan tool or battery disconnect | May clear if fault does not reoccur | Cannot be cleared with a scan tool or battery disconnect |

| Purpose | Indicates a current or past problem | Indicates a potential problem that needs further investigation | Ensures that a vehicle meets emissions standards before a cleared code allows it to pass inspection |

| Impact on Inspection | May cause a vehicle to fail inspection | May not cause immediate failure but indicates a potential issue that needs to be addressed | Will cause a vehicle to fail inspection if warm-up cycles are ≤ 15 or distance traveled since the code was set is less than 200 miles. |

| Action Required | Diagnose and repair the issue | Investigate the potential issue and monitor for reoccurrence | Diagnose and repair the issue, then confirm resolution over multiple drive cycles before the PDTC is automatically cleared by the vehicle’s ECM |

3. How to Read and Interpret Mode 0A Data

Reading and interpreting Mode 0A data involves using a scan tool to retrieve the PDTCs stored in the vehicle’s ECM. Understanding how to access this data and what the codes mean is essential for accurate diagnostics and repair.

3.1 Using a Scan Tool to Access Mode 0A

To access Mode 0A data, you need an OBD-II scan tool that supports this diagnostic service. Most modern scan tools have this capability, but it’s always a good idea to check the tool’s specifications to ensure compatibility.

- Connect the Scan Tool: Plug the scan tool into the OBD-II port, typically located under the dashboard on the driver’s side.

- Power On: Turn the vehicle’s ignition to the “on” position without starting the engine.

- Navigate to Mode 0A: Use the scan tool’s menu to navigate to the OBD-II diagnostics section and select Mode 0A (Request Permanent DTCs).

- Read the Codes: The scan tool will display any PDTCs stored in the vehicle’s ECM. Record these codes for further analysis.

3.2 Understanding DTC Formats and Definitions

DTCs are typically five-character codes that follow a standard format. Understanding this format can help you quickly identify the system and component affected by the fault.

-

First Character: Indicates the system affected:

- P: Powertrain (engine, transmission)

- B: Body (e.g., airbags, power windows)

- C: Chassis (e.g., ABS, suspension)

- U: Network (communication systems)

-

Second Character: Indicates whether the code is generic or manufacturer-specific:

- 0: Generic (SAE-defined)

- 1: Manufacturer-specific

-

Third Character: Indicates the specific subsystem affected:

- 1: Fuel and air metering

- 2: Fuel and air metering (injector circuit)

- 3: Ignition system or misfire

- 4: Auxiliary emission controls

- 5: Vehicle speed control and idle control system

- 6: Computer output circuit

- 7: Transmission

- 8: Transmission

-

Fourth and Fifth Characters: Indicate the specific fault within the subsystem.

For example, a code like P0301 indicates:

- P: Powertrain

- 0: Generic

- 3: Ignition system or misfire

- 01: Cylinder 1 misfire

3.3 Common PDTCs and Their Meanings

Here are some common PDTCs you might encounter:

- P0300: Random/Multiple Cylinder Misfire Detected

- P0301-P0312: Cylinder-Specific Misfire Detected (Cylinders 1-12)

- P0171: System Too Lean (Bank 1)

- P0174: System Too Lean (Bank 2)

- P0420: Catalyst System Efficiency Below Threshold (Bank 1)

- P0440: Evaporative Emission Control System Malfunction

3.4 Resources for Looking Up DTC Definitions

To accurately diagnose and repair issues related to PDTCs, it’s essential to have access to reliable resources for looking up DTC definitions. Here are some recommended resources:

- CAR-TOOL.EDU.VN: Our website provides a comprehensive database of DTC definitions, along with detailed information on potential causes and solutions.

- Factory Service Manuals: These manuals, specific to each vehicle make and model, provide detailed diagnostic procedures and DTC definitions.

- Online Databases: Websites like OBD-Codes.com and similar sites offer extensive DTC information and troubleshooting tips.

4. How To Clear Mode 0A (Request Permanent DTCs)?

Clearing a Permanent Diagnostic Trouble Code (PDTC) requires more than just using a scan tool. Because these codes are designed to ensure that the underlying issue is fully resolved, they can only be cleared automatically by the vehicle’s Engine Control Module (ECM) after certain conditions are met.

4.1 Conditions Required for PDTCs to Clear

PDTCs cannot be cleared manually with a scan tool or by disconnecting the battery. Instead, the vehicle’s ECM will automatically clear the PDTC after the following conditions have been met:

- Repair the Underlying Issue: The first and most critical step is to diagnose and repair the underlying issue that caused the DTC to be set.

- Complete Drive Cycles: The vehicle must complete a certain number of drive cycles without the fault reoccurring. A drive cycle typically involves starting the engine, driving under various conditions (e.g., highway, city), and then turning off the engine. The exact number of drive cycles required can vary by vehicle make and model.

- Monitor Tests: The ECM must see the related monitor test complete and pass on three consecutive trips. This confirms that the system is functioning correctly under different operating conditions.

- Key-On Cycles: The PDTC will not be removed from memory until the fourth key-on cycle.

4.2 Understanding Drive Cycles and Monitor Tests

To successfully clear a PDTC, it’s essential to understand what constitutes a drive cycle and how monitor tests are performed.

4.2.1 What is a Drive Cycle?

A drive cycle is a specific sequence of driving conditions that allows the vehicle’s ECM to perform diagnostic tests on various systems. A typical drive cycle includes:

- Cold Start: Start the engine after it has cooled down completely (typically overnight).

- Idle: Allow the engine to idle for a specified period (e.g., 2-3 minutes).

- Acceleration: Accelerate to a moderate speed (e.g., 45-55 mph) and maintain that speed for a specified distance (e.g., 5-10 miles).

- Deceleration: Decelerate gradually without using the brakes, allowing the vehicle to coast down to a lower speed.

- Highway Driving: Drive at highway speeds (e.g., 55-65 mph) for a specified distance (e.g., 10-15 miles).

- City Driving: Drive in stop-and-go traffic conditions for a specified period (e.g., 5-10 minutes).

- Stop and Idle: Come to a complete stop and allow the engine to idle for a specified period (e.g., 2-3 minutes).

- Turn Off Engine: Turn off the engine and allow the vehicle to sit for a specified period (e.g., 5-10 minutes).

4.2.2 What are Monitor Tests?

Monitor tests are diagnostic routines performed by the vehicle’s ECM to check the functionality of various systems, such as the oxygen sensors, catalytic converter, and evaporative emissions system. These tests run automatically during normal driving conditions and provide feedback to the ECM about the system’s performance.

- Continuous Monitors: These monitors run continuously during normal driving conditions, checking systems like misfire detection, fuel trim, and comprehensive component monitoring.

- Non-Continuous Monitors: These monitors run only under specific conditions, such as a certain engine temperature or vehicle speed. Examples include the oxygen sensor heater monitor, evaporative system monitor, and catalyst monitor.

4.3 Special Cases and Manufacturer-Specific Procedures

While the general process for clearing PDTCs is the same across most vehicles, there may be some special cases or manufacturer-specific procedures that need to be followed.

4.3.1 Misfire and Fuel System PDTCs

For Misfire and Fuel System PDTCs, the ECM must support storing up to four similar conditions window (SCW) in NVRAM to allow proper clearing from memory. An SCW includes engine speed, engine load, and warmup condition. The ECM monitors these conditions to determine if the misfire or fuel system problem has been resolved.

4.3.2 Chrysler’s Similar Conditions Windows (SCW)

Chrysler is the only manufacturer that provides information about SCWs through its factory scan tool. This information can be helpful in diagnosing and resolving misfire and fuel system issues.

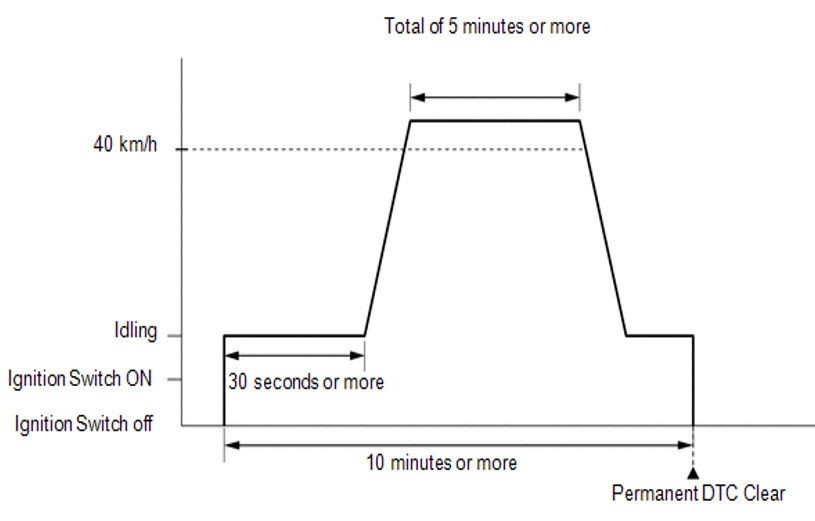

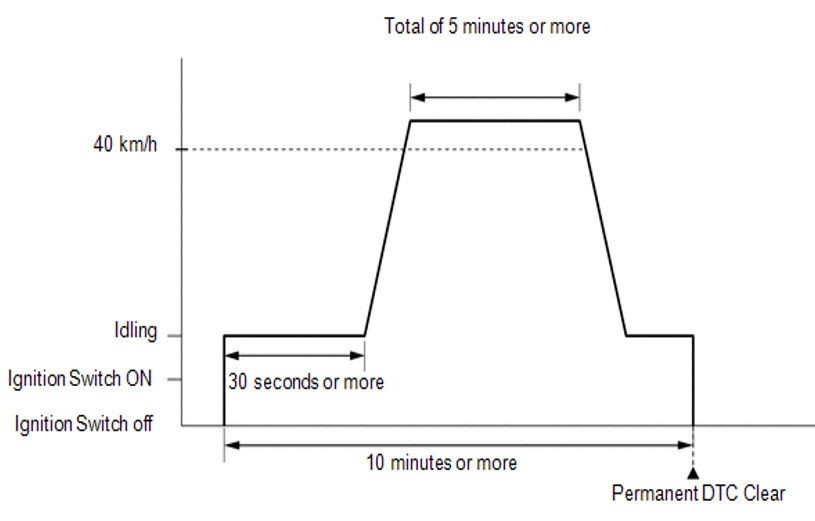

4.3.3 California Air Resources Board (CARB) Drive Cycle

CARB has created a universal drive cycle pattern for clearing misfire and fuel systems DTCs. This drive cycle includes specific requirements for cumulative time since engine start, vehicle operation above a certain speed, and continuous vehicle operation at idle.

4.4 Troubleshooting Steps If PDTCs Won’t Clear

If you’ve repaired the underlying issue and completed multiple drive cycles, but the PDTCs still won’t clear, here are some troubleshooting steps to consider:

- Verify the Repair: Double-check that the underlying issue has been completely resolved. Use a scan tool to monitor the relevant sensor readings and system parameters to ensure they are within the specified range.

- Check for Other DTCs: Make sure there are no other DTCs present, as these can prevent the PDTC from clearing. Address any other DTCs before attempting to clear the PDTC.

- Follow Manufacturer-Specific Procedures: Consult the vehicle’s service manual for any manufacturer-specific procedures or requirements for clearing PDTCs.

- Perform a Forced Monitor Test: Some scan tools have the ability to perform a forced monitor test, which can help speed up the clearing process.

- Consider an ECM Reprogramming: In some cases, an ECM reprogramming may be necessary to resolve issues that prevent PDTCs from clearing.

5. What is the Impact of Mode 0A on Smog Inspections?

Mode 0A and Permanent Diagnostic Trouble Codes (PDTCs) have a significant impact on smog inspections, particularly in states like California, which have strict emissions standards. PDTCs ensure that vehicles genuinely meet emissions requirements before they can pass inspection, preventing temporary code clearing and promoting real repairs.

5.1 How PDTCs Affect Smog Check Results

PDTCs are used by smog check programs to determine whether a vehicle is eligible to pass inspection. If a vehicle has PDTCs stored in its ECM, it may fail the smog check, even if the Malfunction Indicator Lamp (MIL) is not illuminated.

- California’s Smog Check Program: California is the only state that uses PDTCs to fail a vehicle. According to the California Bureau of Automotive Repair, a vehicle will fail the smog check if it has PDTCs stored in its ECM and the warm-up cycles since cleared are 14 or less, or the distance traveled since cleared is less than 200 miles.

- Pass/Fail Criteria: If the warm-up cycle counter is ≥ 15 and the distance traveled is ≥ 200 miles, the smog check system will ignore the PDTC and pass the inspection portion.

5.2 Warm-Up Cycles and Miles Driven

Warm-up cycles and miles driven are key parameters used by smog check systems to evaluate PDTCs. These parameters help determine whether the vehicle has been driven enough to confirm that the underlying issue has been resolved.

- Warm-Up Cycle: A warm-up cycle is defined as a driving cycle that includes a cold start, engine warm-up, and a period of normal driving. The number of warm-up cycles since the last code clearing is tracked by the ECM.

- Miles Driven: The distance traveled since the last code clearing is also tracked by the ECM. This parameter helps ensure that the vehicle has been driven enough to perform all necessary monitor tests and confirm that the underlying issue has been resolved.

5.3 Exemptions and Special Cases

While PDTCs generally lead to a failed smog check, there are some exemptions and special cases to be aware of.

- Exemptions: Certain vehicles may be exempt from PDTC-related smog check failures. These exemptions may vary by state and local regulations.

- Special Cases: In some cases, a vehicle may be allowed to pass a smog check with PDTCs if the underlying issue has been repaired and the vehicle has completed the required number of warm-up cycles and miles driven.

For more detailed information on exemptions and special cases, you can refer to the On-Board Diagnostic Test Reference – Bureau of Automotive Repair.

5.4 Preparing a Vehicle for Smog Inspection

To ensure that a vehicle passes smog inspection, it’s essential to take the following steps:

- Check for DTCs: Use a scan tool to check for any DTCs, including PDTCs.

- Repair Any Issues: Diagnose and repair any issues that are causing DTCs to be set.

- Clear DTCs: Clear any DTCs that have been resolved. Note that PDTCs cannot be cleared manually and will only be cleared automatically by the ECM after certain conditions have been met.

- Complete Drive Cycles: Complete the required number of drive cycles to allow the ECM to perform all necessary monitor tests and confirm that the underlying issue has been resolved.

- Monitor Warm-Up Cycles and Miles Driven: Keep track of the number of warm-up cycles and miles driven since the last code clearing. Ensure that the vehicle meets the minimum requirements for these parameters before taking it in for smog inspection.

5.5 Resources for Smog Inspectors

For smog inspectors in California, it’s crucial to pay attention to Warmup cycles and Miles Driven. PID $30 (Warm-up Cycles Since Cleared) and PID $31 (Distance Traveled Since Cleared) are used by the OIS to Pass or Fail a vehicle with a PDTC(s). If the Warm-Up Cycles are 14 or less or the Distance Traveled is less than 200 miles, the OIS will fail the vehicle. If the Warm-Up Cycle counter is => 15 and the Distance Traveled is => 200 miles, the OIS will ignore the PDTC and pass this inspection portion.

6. What are the Benefits of Understanding Mode 0A for Technicians?

Understanding Mode 0A and Permanent Diagnostic Trouble Codes (PDTCs) offers numerous benefits for automotive technicians. It enhances diagnostic accuracy, improves repair effectiveness, and ensures compliance with environmental regulations, leading to increased customer satisfaction and professional credibility.

6.1 Enhanced Diagnostic Accuracy

PDTCs provide technicians with critical information about the vehicle’s emissions-related issues that may not be immediately apparent. By understanding Mode 0A and how to interpret PDTCs, technicians can:

- Identify Underlying Issues: PDTCs help pinpoint the root cause of emissions problems, even if the Malfunction Indicator Lamp (MIL) is not illuminated.

- Avoid Misdiagnosis: PDTCs prevent technicians from being misled by temporary code clearings, ensuring that repairs are based on actual faults rather than cleared codes.

- Improve First-Time Fix Rate: By accurately diagnosing and repairing the underlying issues, technicians can improve their first-time fix rate, reducing the need for repeat repairs.

6.2 Improved Repair Effectiveness

Understanding Mode 0A enables technicians to perform more effective repairs that address the root cause of emissions-related issues. This leads to:

- Longer-Lasting Repairs: By fixing the underlying problem, technicians can ensure that the repair lasts longer and the vehicle continues to meet emissions standards.

- Reduced Comebacks: Effective repairs reduce the likelihood of customers returning with the same issue, improving customer satisfaction.

- Enhanced Vehicle Performance: Addressing emissions-related issues can improve overall vehicle performance, including fuel economy and drivability.

6.3 Compliance with Environmental Regulations

PDTCs are a key component of environmental regulations aimed at reducing vehicle emissions. By understanding Mode 0A and PDTCs, technicians can:

- Ensure Compliance: Technicians can ensure that their repairs comply with environmental regulations, helping vehicle owners avoid penalties and fines.

- Support Environmental Goals: By properly diagnosing and repairing emissions-related issues, technicians contribute to the overall goal of reducing air pollution and improving air quality.

- Stay Updated on Regulations: Understanding Mode 0A helps technicians stay informed about changes and updates to environmental regulations, ensuring they are always up-to-date on the latest requirements.

6.4 Professional Credibility and Customer Satisfaction

Technicians who understand Mode 0A and PDTCs are viewed as more knowledgeable and competent by their customers. This leads to:

- Increased Customer Trust: Customers are more likely to trust technicians who can accurately diagnose and repair emissions-related issues.

- Positive Word-of-Mouth: Satisfied customers are more likely to recommend the technician to others, leading to increased business.

- Enhanced Reputation: A reputation for quality and expertise can enhance a technician’s professional standing in the automotive industry.

6.5 Utilizing CAR-TOOL.EDU.VN for Continued Learning

To further enhance your understanding of Mode 0A and other automotive diagnostic techniques, CAR-TOOL.EDU.VN offers a wealth of resources, including:

- Detailed Articles: Access in-depth articles on various automotive diagnostic topics, including Mode 0A and PDTCs.

- Training Materials: Utilize our training materials to improve your diagnostic skills and stay updated on the latest technologies.

- Technical Support: Contact our technical support team for assistance with diagnostic challenges and questions.

By leveraging the resources available at CAR-TOOL.EDU.VN, technicians can continuously improve their skills and knowledge, leading to greater success in their careers.

7. What Tools are Needed to Diagnose Mode 0A (Request Permanent DTCs)?

Diagnosing issues related to Mode 0A and Permanent Diagnostic Trouble Codes (PDTCs) requires the right tools and equipment. Having the appropriate tools ensures accurate diagnostics, efficient repairs, and compliance with environmental regulations.

7.1 Essential Scan Tools

The most essential tool for diagnosing Mode 0A is an OBD-II scan tool that supports this diagnostic service. These tools allow technicians to access and interpret PDTCs stored in the vehicle’s Engine Control Module (ECM).

- Basic Scan Tools: These tools can read and clear DTCs, display freeze frame data, and provide basic diagnostic information.

- Advanced Scan Tools: These tools offer more advanced features, such as bidirectional control, live data streaming, and access to manufacturer-specific diagnostic codes and procedures.

When selecting a scan tool, consider the following features:

- Mode 0A Support: Ensure that the scan tool supports Mode 0A (Request Permanent DTCs).

- DTC Definitions: The scan tool should provide detailed DTC definitions and troubleshooting tips.

- Data Logging: Look for a scan tool with data logging capabilities, which allows you to record and analyze live data during a drive cycle.

- Software Updates: Choose a scan tool that receives regular software updates to ensure compatibility with the latest vehicle models and diagnostic protocols.

7.2 Multimeters and Electrical Testers

Multimeters and electrical testers are essential for diagnosing electrical issues that may be related to PDTCs. These tools allow technicians to measure voltage, current, and resistance in various circuits and components.

- Digital Multimeter (DMM): A DMM is a versatile tool that can measure voltage, current, resistance, and continuity.

- Test Lights: Test lights are simple tools that can be used to check for voltage and ground in electrical circuits.

- Oscilloscopes: Oscilloscopes provide a visual representation of electrical signals, allowing technicians to analyze complex waveforms and identify intermittent problems.

7.3 Diagnostic Software and Databases

Diagnostic software and databases provide technicians with access to valuable information, such as DTC definitions, wiring diagrams, technical service bulletins (TSBs), and diagnostic procedures.

- Factory Service Manuals: These manuals, specific to each vehicle make and model, provide detailed diagnostic procedures and DTC definitions.

- Online Databases: Websites like ALLDATA, Mitchell 1, and Identifix offer extensive diagnostic information and troubleshooting tips.

- Manufacturer-Specific Software: Some vehicle manufacturers offer their own diagnostic software, which provides access to advanced diagnostic features and programming capabilities.

7.4 Smoke Machines

Smoke machines are used to detect leaks in the vehicle’s evaporative emissions system. These leaks can cause DTCs related to the evaporative emissions system, such as P0440, P0442, and P0455.

- Evaporative Emissions System Testing: A smoke machine injects a safe, non-toxic smoke into the evaporative emissions system, allowing technicians to visually identify leaks.

7.5 Compression Testers

Compression testers are used to measure the compression in each cylinder of the engine. Low compression can cause misfires and other engine-related issues, which can trigger DTCs related to the misfire detection system.

- Cylinder Compression Measurement: A compression tester measures the pressure in each cylinder, providing valuable information about the condition of the piston rings, valves, and cylinder head.

7.6 Fuel Pressure Testers

Fuel pressure testers are used to measure the fuel pressure in the vehicle’s fuel system. Low fuel pressure can cause lean fuel conditions and other fuel-related issues, which can trigger DTCs related to the fuel system.

- Fuel System Pressure Measurement: A fuel pressure tester measures the pressure in the fuel system, providing valuable information about the condition of the fuel pump, fuel filter, and fuel pressure regulator.

7.7 Access to CAR-TOOL.EDU.VN Resources

CAR-TOOL.EDU.VN offers a variety of resources that can help technicians diagnose and repair issues related to Mode 0A and PDTCs. These resources include:

- Detailed Articles: Access in-depth articles on various automotive diagnostic topics, including Mode 0A and PDTCs.

- Training Materials: Utilize our training materials to improve your diagnostic skills and stay updated on the latest technologies.

- Technical Support: Contact our technical support team for assistance with diagnostic challenges and questions.

By having access to these tools and resources, technicians can accurately diagnose and repair issues related to Mode 0A and PDTCs, ensuring compliance with environmental regulations and improving customer satisfaction.

{width=815 height=521}8. Common Mistakes to Avoid When Diagnosing Mode 0A

Diagnosing issues related to Mode 0A and Permanent Diagnostic Trouble Codes (PDTCs) can be complex, and it’s essential to avoid common mistakes that can lead to misdiagnosis and ineffective repairs. Being aware of these pitfalls can help technicians improve their diagnostic accuracy and efficiency.

8.1 Ignoring PDTCs

One of the most common mistakes is ignoring PDTCs altogether. Technicians may focus solely on current DTCs and overlook the presence of PDTCs, which can provide valuable information about underlying issues.

- Importance of Addressing PDTCs: PDTCs indicate that an emissions-related issue has occurred and requires attention, even if the Malfunction Indicator Lamp (MIL) is not illuminated. Ignoring PDTCs can lead to repeat repairs and customer dissatisfaction.

8.2 Clearing Codes Without Repairing the Underlying Issue

Another common mistake is clearing DTCs, including PDTCs (if possible), without properly diagnosing and repairing the underlying issue. This can result in the issue recurring and the vehicle failing a smog inspection.

- PDTCs Cannot Be Cleared Manually: It’s important to remember that PDTCs cannot be cleared manually with a scan tool or by disconnecting the battery. They can only be cleared automatically by the vehicle’s ECM after certain conditions have been met.

8.3 Not Following Proper Diagnostic Procedures

Failing to follow proper diagnostic procedures can lead to misdiagnosis and ineffective repairs. It’s essential to consult the vehicle’s service manual and follow the recommended diagnostic steps for each DTC.

- Importance of Service Manuals: Service manuals provide detailed information about the vehicle’s systems and components, including DTC definitions, troubleshooting tips, and diagnostic procedures.

8.4 Overlooking Basic Maintenance Items

Sometimes, DTCs and PDTCs can be caused by simple maintenance issues, such as a dirty air filter, worn spark plugs, or a loose gas cap. Overlooking these basic maintenance items can lead to unnecessary and costly repairs.

- Checking Basic Maintenance Items First: Before performing any major diagnostic work, it’s always a good idea to check the vehicle’s basic maintenance items to rule out any simple causes of the issue.

8.5 Not Verifying the Repair

After performing a repair, it’s essential to verify that the issue has been resolved and that the vehicle is functioning properly. This can involve monitoring live data with a scan tool, performing a drive cycle, and checking for any recurring DTCs.

- Importance of Verification: Verifying the repair helps ensure that the customer is satisfied with the work and that the vehicle is meeting emissions standards.

8.6 Not Understanding Drive Cycles and Monitor Tests

Understanding drive cycles and monitor tests is crucial for clearing PDTCs and ensuring that the vehicle is ready for a smog inspection. Failing to understand these concepts can lead to frustration and delays in the repair process.

- Importance of Completing Drive Cycles: Completing the required number of drive cycles allows the vehicle’s ECM to perform all necessary monitor tests and confirm that the underlying issue has been resolved.

8.7 Relying Solely on the DTC Definition

While DTC definitions can provide valuable information about the potential cause of an issue, it’s important not to rely solely on the DTC definition. It’s essential to perform a thorough diagnostic evaluation to pinpoint the root cause of the problem.

- Importance of Thorough Diagnostics: A thorough diagnostic evaluation can help identify any underlying issues that may not be immediately apparent from the DTC definition.

8.8 Not Checking for Technical Service Bulletins (TSBs)

Technical Service Bulletins (TSBs) provide information about common issues and recommended repairs for specific vehicle makes and models. Not checking for TSBs can lead to missed opportunities to resolve the issue quickly and effectively.

- Importance of Checking TSBs: TSBs can provide valuable insights into common issues and recommended repairs, saving time and effort in the diagnostic process.

8.9 Not Staying Updated on the Latest Technologies

The automotive industry is constantly evolving, with new technologies and diagnostic procedures being introduced regularly. Not staying updated on the latest technologies can lead to outdated diagnostic techniques and ineffective repairs.

- Importance of Continued Learning: Continued learning is essential for automotive technicians to stay current with the latest technologies and diagnostic procedures.

8.10 CAR-TOOL.EDU.VN: Your Partner in Avoiding Diagnostic Mistakes

CAR-TOOL.EDU.VN is dedicated to helping automotive technicians avoid common diagnostic mistakes and improve their skills. We offer a variety of resources, including detailed articles, training materials, and technical support, to help you stay updated on the latest technologies and diagnostic procedures. Visit CAR-TOOL.EDU.VN today to learn more.

9. What are the Future Trends in Mode 0A and OBD-II Diagnostics?

The field of On-Board Diagnostics (OBD-II) is constantly evolving, and Mode 0A is no exception. Several future trends are expected to shape the landscape of OBD-II diagnostics, improving accuracy, efficiency, and compliance with environmental regulations.

9.1 Enhanced Data Logging and Analytics

Future OBD-II systems are expected to feature enhanced data logging and analytics capabilities. This will allow technicians to capture and analyze more data from the vehicle’s sensors and systems, providing a more comprehensive view of the vehicle’s performance.

- Predictive Diagnostics: Advanced data analytics can be used to identify patterns and trends that may indicate potential issues before they become major problems.

- Remote Diagnostics: Data logging and analytics can be used to remotely diagnose vehicles, allowing technicians to provide assistance and guidance from a distance.

9.2 Integration with Cloud-Based Services

Cloud-based services are expected to play a larger role in OBD-II diagnostics. This will allow technicians to access real-time data, diagnostic information, and repair procedures from anywhere with an internet connection.

- Remote Access to Data: Cloud-based services will provide technicians with remote access to vehicle data, allowing them to diagnose issues without having to physically connect to the vehicle.

- Collaboration and Knowledge Sharing: Cloud-based services will facilitate collaboration and knowledge sharing among technicians, allowing them to learn from each other’s experiences and expertise.

9.3 Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML technologies are expected to revolutionize OBD-II diagnostics. These technologies can be used to analyze vast amounts of data and identify patterns that may be difficult for humans to detect.

- Automated Diagnostics: AI and ML can be used to automate the diagnostic process, reducing the need for manual analysis and interpretation.

- Predictive Maintenance: AI and ML can be used to predict when maintenance is needed, allowing vehicle owners to proactively address potential issues before they become major problems.

9.4 Enhanced Cybersecurity Measures

As vehicles become more connected and reliant on software, cybersecurity is becoming an increasingly important concern. Future OBD-II systems will need to incorporate enhanced cybersecurity measures to protect against hacking and unauthorized access.

- Secure Communication Protocols: Secure communication protocols will be used to protect data transmitted between the vehicle and external devices.

- Intrusion Detection Systems: Intrusion detection systems will be used to monitor vehicle systems for signs of hacking and unauthorized access.

9.5 Standardization and Interoperability

Standardization and interoperability are essential for ensuring that OBD-II systems can communicate with a wide range of scan tools and diagnostic equipment