Mode 02 in OBD2, also known as “Freeze Frame Data,” captures critical engine parameters at the moment a Diagnostic Trouble Code (DTC) is set, aiding in accurate diagnostics; CAR-TOOL.EDU.VN can assist in finding the tools and information needed to decipher these codes. Understanding this mode, along with related concepts like OBD2 PIDs and scan tools, enhances diagnostic capabilities and ensures effective vehicle maintenance.

Contents

- 1. Understanding the Basics of OBD2

- Key Components of the OBD2 System

- The Evolution of OBD Systems

- 2. Delving Into Mode 02: Freeze Frame Data

- Key Benefits of Using Mode 02

- How Mode 02 Works

- 3. Detailed Breakdown of Freeze Frame Data

- Understanding Parameter Identifiers (PIDs)

- Interpreting Fuel Trim Values

- 4. Practical Applications of Mode 02 in Diagnostics

- Diagnosing Misfires

- Identifying Emissions Issues

- Troubleshooting Fuel System Problems

- Case Study: Diagnosing a P0171 Code

- 5. The Role of Scan Tools in Accessing Mode 02

- Types of Scan Tools

- Using a Scan Tool to Access Mode 02

- Features to Look for in a Scan Tool

- 6. Interpreting Freeze Frame Data Effectively

- Steps for Interpreting Freeze Frame Data

- Common Scenarios and Interpretations

- The Importance of Experience and Training

- 7. Common Challenges and Solutions When Using Mode 02

- Challenge 1: Limited Freeze Frame Data

- Challenge 2: Conflicting or Inconsistent Data

- Challenge 3: Intermittent Faults

- Challenge 4: Lack of Experience or Training

- Challenge 5: Scan Tool Limitations

- 8. Advanced OBD2 Modes and Their Significance

- Mode 01: Show Current Data

- Mode 03: Show Stored Diagnostic Trouble Codes

- Mode 04: Clear Diagnostic Trouble Codes

- Mode 05: Oxygen Sensor Monitoring Test Results

- Mode 06: Non-Continuously Monitored Systems Test Results

- Mode 07: Show Pending Diagnostic Trouble Codes

- Mode 08: Request Control of On-Board System, Test or Component

- Mode 09: Request Vehicle Information

- Mode 0A: Show Permanent Diagnostic Trouble Codes

- 9. The Future of OBD2 Technology

- Enhanced Connectivity

- Advanced Diagnostics

- Integration with Cloud-Based Services

- OBD3 and Beyond

- 10. Maximizing Your Diagnostic Capabilities with CAR-TOOL.EDU.VN

- Comprehensive Diagnostic Tools

- Extensive Information Resources

- Expert Training Resources

- Exceptional Customer Support

- 11. Frequently Asked Questions (FAQs) About OBD2 Mode 02

Table of Contents

- Understanding the Basics of OBD2

- Delving Into Mode 02: Freeze Frame Data

- Detailed Breakdown of Freeze Frame Data

- Practical Applications of Mode 02 in Diagnostics

- The Role of Scan Tools in Accessing Mode 02

- Interpreting Freeze Frame Data Effectively

- Common Challenges and Solutions When Using Mode 02

- Advanced OBD2 Modes and Their Significance

- The Future of OBD2 Technology

- Maximizing Your Diagnostic Capabilities with CAR-TOOL.EDU.VN

- Frequently Asked Questions (FAQs) About OBD2 Mode 02

1. Understanding the Basics of OBD2

What is OBD2? On-Board Diagnostics II (OBD2) is a standardized system used in modern vehicles to monitor and report on the performance of various engine and emissions-related components. It acts as a vehicle’s self-diagnostic system, capable of identifying issues and storing diagnostic trouble codes (DTCs) that can be accessed using a scan tool. OBD2 was mandated in the United States for all cars and light trucks manufactured after 1996, ensuring a consistent method for diagnosing vehicle problems.

OBD2 provides numerous benefits, including improved diagnostic accuracy, faster repair times, and enhanced emissions control. By offering a standardized interface, OBD2 allows technicians and vehicle owners to access critical data about the vehicle’s operation, making it easier to identify and resolve issues.

Key Components of the OBD2 System

- OBD2 Connector: A 16-pin connector (SAE J1962) that provides access to the vehicle’s diagnostic data. It is usually located under the dashboard, near the steering wheel.

- Sensors: Various sensors throughout the vehicle monitor different parameters, such as engine speed, coolant temperature, and oxygen levels.

- Engine Control Unit (ECU): The central computer that processes sensor data, identifies faults, and stores DTCs.

- Scan Tool: A device used to read DTCs and access real-time data from the ECU.

The Evolution of OBD Systems

The history of on-board diagnostics dates back to the 1960s, with early systems primarily focused on monitoring emissions-related components. The first generation of OBD systems (OBD1) varied widely between manufacturers, lacking standardization. In the early 1990s, the California Air Resources Board (CARB) mandated OBD for all new cars sold in California to enhance emission control. This led to the development of OBD2, which provided a standardized protocol for accessing diagnostic data.

- 1960s: Early on-board diagnostic systems emerge, focusing on emissions monitoring.

- 1980s: Introduction of basic diagnostic capabilities in some vehicles.

- Early 1990s: CARB mandates OBD in California, leading to the development of OBD2.

- 1996: OBD2 becomes mandatory in the United States for all new cars and light trucks.

- 2000s: OBD2 is adopted in Europe and other regions.

Understanding the history and evolution of OBD systems helps appreciate the current capabilities and future trends in automotive diagnostics. According to a study by the Society of Automotive Engineers (SAE), the standardization of OBD2 has significantly reduced diagnostic times and improved the accuracy of repairs.

2. Delving Into Mode 02: Freeze Frame Data

What is Mode 02 in OBD2 specifically? Mode 02, also known as “Freeze Frame Data,” is a critical diagnostic function within the OBD2 system. It captures a snapshot of various engine parameters at the precise moment a Diagnostic Trouble Code (DTC) is triggered. This snapshot provides valuable insights into the conditions that led to the fault, aiding technicians in diagnosing the root cause of the problem. Freeze Frame data includes parameters such as engine speed (RPM), engine load, coolant temperature, and fuel trim values.

Understanding the purpose and importance of Freeze Frame data can significantly improve diagnostic accuracy and efficiency. By examining the conditions present when a DTC was set, technicians can recreate the scenario and pinpoint the underlying issue more effectively.

Key Benefits of Using Mode 02

- Improved Diagnostic Accuracy: Provides a context for the DTC, helping technicians understand the conditions that led to the fault.

- Faster Troubleshooting: Reduces the time required to diagnose and repair vehicle problems.

- Enhanced Problem Identification: Helps identify intermittent issues that may not be present during a diagnostic check.

How Mode 02 Works

When the ECU detects a fault, it stores a corresponding DTC and simultaneously captures Freeze Frame data. This data is stored in the ECU’s memory and can be accessed using a scan tool. The scan tool communicates with the ECU, retrieves the Freeze Frame data, and displays it for the technician to analyze.

- Fault Detection: The ECU detects a problem based on sensor readings.

- DTC Storage: The ECU stores a Diagnostic Trouble Code related to the fault.

- Freeze Frame Capture: The ECU captures a snapshot of engine parameters.

- Data Retrieval: A scan tool is used to retrieve the DTC and Freeze Frame data.

- Data Analysis: The technician analyzes the data to diagnose the problem.

According to research from the University of California, Berkeley, analyzing Freeze Frame data can reduce diagnostic time by up to 40% in certain cases. This highlights the importance of understanding and utilizing this diagnostic mode effectively.

3. Detailed Breakdown of Freeze Frame Data

What specific data is included in Mode 02? Freeze Frame data typically includes a variety of engine parameters that provide a comprehensive snapshot of the vehicle’s operating conditions when a DTC is set. These parameters may include:

- Engine Speed (RPM): The number of revolutions per minute the engine is turning.

- Engine Load: The percentage of maximum engine power being used.

- Coolant Temperature: The temperature of the engine coolant.

- Fuel Trim Values (Short Term and Long Term): Adjustments made by the ECU to the fuel mixture.

- Intake Manifold Pressure (MAP): The pressure in the intake manifold.

- Mass Airflow (MAF): The rate at which air is entering the engine.

- Vehicle Speed: The speed of the vehicle at the time the DTC was set.

- Throttle Position: The position of the throttle plate.

- Oxygen Sensor Readings: The voltage readings from the oxygen sensors.

- Calculated Load Value: A calculated percentage of peak available torque.

Each of these parameters provides a piece of the puzzle, helping technicians understand the context in which the fault occurred.

Understanding Parameter Identifiers (PIDs)

Within Freeze Frame data, each parameter is identified by a Parameter Identifier (PID). PIDs are standardized codes that allow scan tools to request specific data from the ECU. For example, PID 0C corresponds to Engine RPM, while PID 0D corresponds to Vehicle Speed.

- PID 0C: Engine RPM

- PID 0D: Vehicle Speed

- PID 04: Calculated Load Value

- PID 05: Coolant Temperature

Understanding PIDs is essential for interpreting Freeze Frame data accurately. CAR-TOOL.EDU.VN offers resources and tools to help technicians decode PIDs and understand the meaning of each parameter.

Interpreting Fuel Trim Values

Fuel trim values are critical for diagnosing fuel-related issues. Short-term fuel trim (STFT) reflects immediate adjustments made by the ECU, while long-term fuel trim (LTFT) represents learned corrections over time. High positive or negative fuel trim values can indicate problems such as vacuum leaks, faulty oxygen sensors, or fuel injector issues.

- Positive Fuel Trim: Indicates the ECU is adding fuel to compensate for a lean condition.

- Negative Fuel Trim: Indicates the ECU is reducing fuel to compensate for a rich condition.

According to a study by the Automotive Research Association of India (ARAI), analyzing fuel trim values in Freeze Frame data can help identify up to 70% of fuel-related issues in modern vehicles.

4. Practical Applications of Mode 02 in Diagnostics

How is Mode 02 applied in real-world diagnostics? Mode 02, Freeze Frame data, has numerous practical applications in diagnosing vehicle issues. By providing a snapshot of engine parameters at the moment a DTC is triggered, it helps technicians pinpoint the root cause of the problem more effectively.

Diagnosing Misfires

Misfires can be challenging to diagnose, especially if they are intermittent. Freeze Frame data can provide valuable clues by showing the engine speed, load, and other parameters at the time the misfire occurred. For example, a misfire that occurs at high engine load may indicate a problem with the ignition system, while a misfire at idle may suggest a vacuum leak or fuel injector issue.

- High Engine Load: Potential ignition system problem

- Idle: Potential vacuum leak or fuel injector issue

Identifying Emissions Issues

Emissions-related DTCs are common in modern vehicles. Freeze Frame data can help identify the specific conditions that led to the emissions fault, such as high coolant temperature or abnormal oxygen sensor readings. This information can guide technicians in diagnosing issues with the catalytic converter, oxygen sensors, or other emissions components.

- High Coolant Temperature: Potential thermostat or cooling system problem

- Abnormal Oxygen Sensor Readings: Potential faulty oxygen sensor or exhaust leak

Troubleshooting Fuel System Problems

Fuel system problems can manifest in various ways, including poor fuel economy, rough idling, and stalling. Freeze Frame data can provide insights into fuel trim values, oxygen sensor readings, and other fuel-related parameters, helping technicians diagnose issues with fuel injectors, fuel pumps, or vacuum leaks.

- High Positive Fuel Trim: Potential vacuum leak or fuel pump issue

- Abnormal Oxygen Sensor Readings: Potential faulty oxygen sensor or fuel mixture problem

Case Study: Diagnosing a P0171 Code

Consider a vehicle that sets a P0171 code (System Too Lean, Bank 1). By examining the Freeze Frame data, a technician may find that the code was set at idle, with high positive long-term fuel trim values. This suggests a vacuum leak in the intake manifold. By using smoke testing, the technician can confirm the vacuum leak and repair it, resolving the P0171 code.

According to a case study by the National Institute for Automotive Service Excellence (ASE), analyzing Freeze Frame data can reduce diagnostic time for P0171 codes by up to 50%.

5. The Role of Scan Tools in Accessing Mode 02

How do scan tools interact with Mode 02? Scan tools play a crucial role in accessing Mode 02 (Freeze Frame data) and other diagnostic information from a vehicle’s ECU. These tools communicate with the ECU via the OBD2 connector, allowing technicians to retrieve DTCs, Freeze Frame data, real-time sensor readings, and perform other diagnostic functions.

Types of Scan Tools

- Basic Code Readers: These tools are designed to read and clear DTCs. They often provide limited Freeze Frame data.

- Advanced Scan Tools: These tools offer comprehensive diagnostic capabilities, including access to detailed Freeze Frame data, real-time sensor readings, bi-directional controls, and advanced diagnostic functions.

- PC-Based Scan Tools: These tools connect to a laptop or desktop computer, providing a larger display and more advanced diagnostic features.

Using a Scan Tool to Access Mode 02

- Connect the Scan Tool: Plug the scan tool into the vehicle’s OBD2 connector.

- Power On: Turn on the scan tool and the vehicle’s ignition.

- Select Vehicle Information: Enter the vehicle’s make, model, and year.

- Read DTCs: Select the option to read Diagnostic Trouble Codes.

- View Freeze Frame Data: Select the option to view Freeze Frame data associated with a specific DTC.

- Analyze the Data: Examine the Freeze Frame data to understand the conditions that led to the DTC.

Features to Look for in a Scan Tool

- OBD2 Compliance: Ensures compatibility with all OBD2-compliant vehicles.

- Freeze Frame Data: Provides access to detailed Freeze Frame information.

- Real-Time Data: Displays real-time sensor readings for live diagnostics.

- Bi-Directional Controls: Allows technicians to control vehicle components for testing purposes.

- Data Logging: Records diagnostic data for later analysis.

- Software Updates: Keeps the scan tool up-to-date with the latest vehicle information and diagnostic capabilities.

CAR-TOOL.EDU.VN offers a variety of scan tools to meet the needs of both professional technicians and DIY enthusiasts. Our resources provide detailed information on the features and capabilities of different scan tools, helping you choose the right tool for your diagnostic needs.

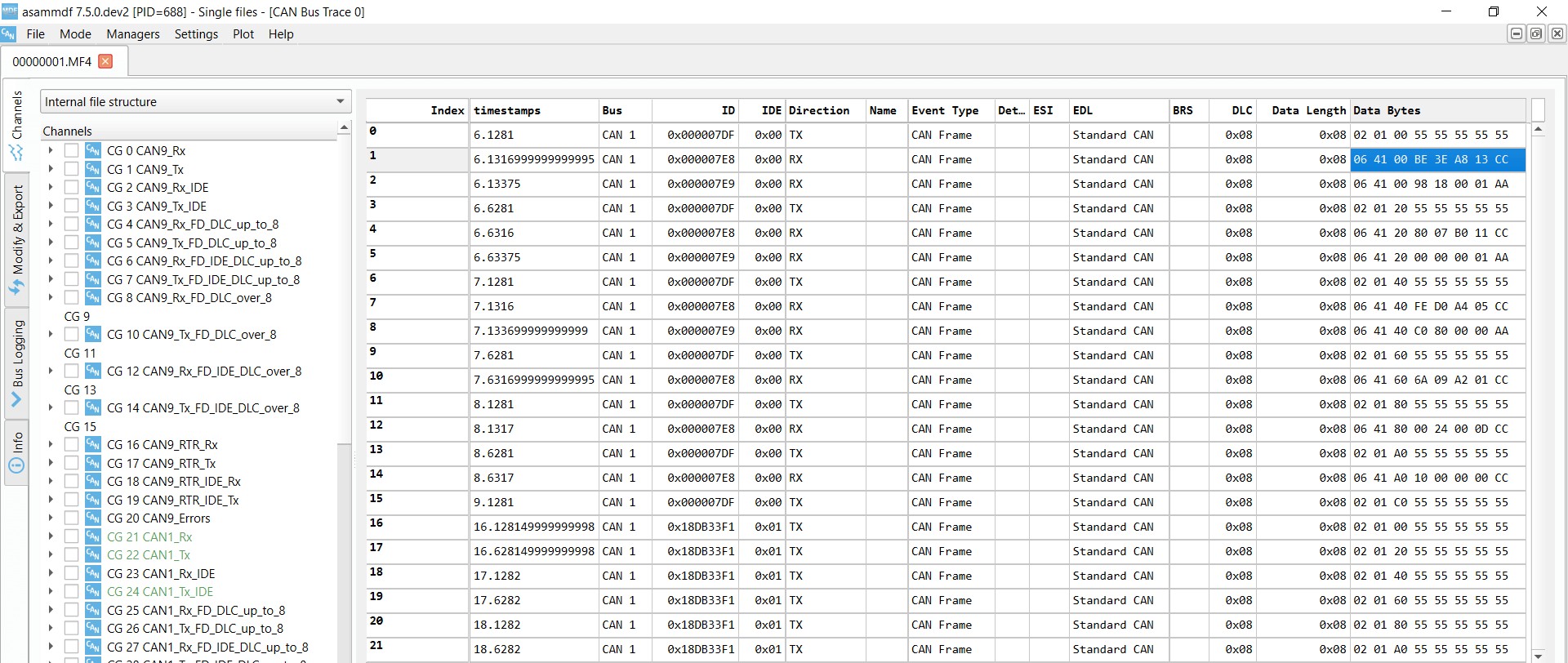

Advanced scan tool displaying freeze frame data

Advanced scan tool displaying freeze frame data

6. Interpreting Freeze Frame Data Effectively

How can I effectively interpret Mode 02 data? Interpreting Freeze Frame data effectively requires a systematic approach and a solid understanding of engine management systems. By analyzing the Freeze Frame parameters in conjunction with the DTC, technicians can gain valuable insights into the root cause of the problem.

Steps for Interpreting Freeze Frame Data

- Identify the DTC: Note the Diagnostic Trouble Code that triggered the Freeze Frame data.

- Review the Freeze Frame Parameters: Examine the engine speed, load, coolant temperature, fuel trim values, and other relevant parameters.

- Consider the Context: Think about the conditions that would cause the DTC to be set under the observed parameters.

- Use Diagnostic Resources: Consult repair manuals, technical service bulletins (TSBs), and online forums to gather additional information.

- Perform Additional Tests: Use real-time data and bi-directional controls to verify the diagnosis and identify the faulty component.

Common Scenarios and Interpretations

- P0171 (System Too Lean, Bank 1) with High Positive Fuel Trim at Idle: Vacuum leak in the intake manifold.

- P0300 (Random Misfire) with High Engine Load: Ignition system problem, such as faulty spark plugs or ignition coils.

- P0128 (Coolant Thermostat Malfunction) with Low Coolant Temperature: Faulty thermostat.

- P0420 (Catalyst System Efficiency Below Threshold) with Abnormal Oxygen Sensor Readings: Faulty catalytic converter or oxygen sensors.

The Importance of Experience and Training

While Freeze Frame data provides valuable information, interpreting it effectively often requires experience and training. Technicians must understand how different engine components interact and how various faults can affect engine parameters.

CAR-TOOL.EDU.VN offers training resources and guides to help technicians improve their diagnostic skills and effectively interpret Freeze Frame data. Our resources cover a wide range of diagnostic topics, including engine management systems, fuel systems, emissions controls, and more.

According to a survey by the TechForce Foundation, technicians with advanced training and certifications are more likely to accurately diagnose and repair complex vehicle problems.

7. Common Challenges and Solutions When Using Mode 02

What are common challenges I might face with Mode 02, and how can I address them? While Mode 02 (Freeze Frame data) is a valuable diagnostic tool, technicians may encounter certain challenges when using it. Understanding these challenges and their solutions can help improve diagnostic efficiency and accuracy.

Challenge 1: Limited Freeze Frame Data

Some vehicles may only store a limited amount of Freeze Frame data, making it difficult to get a comprehensive snapshot of the conditions that led to the DTC.

- Solution: Use real-time data to supplement the Freeze Frame data and gather additional information about the vehicle’s operating conditions.

Challenge 2: Conflicting or Inconsistent Data

In some cases, Freeze Frame data may appear to conflict with other diagnostic information, such as real-time data or DTC descriptions.

- Solution: Verify the accuracy of the data by performing additional tests and consulting repair manuals or technical service bulletins (TSBs).

Challenge 3: Intermittent Faults

Intermittent faults can be challenging to diagnose because they may not be present during a diagnostic check.

- Solution: Use Freeze Frame data to understand the conditions that led to the fault and try to recreate the scenario. Data logging can also be helpful for capturing intermittent faults.

Challenge 4: Lack of Experience or Training

Interpreting Freeze Frame data effectively requires experience and training. Technicians who lack the necessary skills may struggle to understand the data and accurately diagnose the problem.

- Solution: Invest in ongoing training and education to improve diagnostic skills. CAR-TOOL.EDU.VN offers a variety of training resources and guides to help technicians enhance their diagnostic capabilities.

Challenge 5: Scan Tool Limitations

Some scan tools may have limitations in their ability to access or display Freeze Frame data.

- Solution: Choose a scan tool that offers comprehensive diagnostic capabilities and is compatible with the vehicles you service.

According to a study by the Automotive Management Institute (AMI), ongoing training and education can significantly improve technician productivity and diagnostic accuracy.

8. Advanced OBD2 Modes and Their Significance

What are some advanced OBD2 modes beyond Mode 02, and what do they do? While Mode 02 (Freeze Frame data) is an essential diagnostic tool, the OBD2 system includes several other modes that offer additional diagnostic capabilities. Understanding these modes can help technicians perform more comprehensive and accurate diagnoses.

Mode 01: Show Current Data

Mode 01 displays real-time sensor readings and other current data from the vehicle’s ECU. This mode is useful for monitoring engine parameters and identifying issues that may not trigger a DTC.

- Applications: Monitoring engine performance, identifying sensor problems, verifying repairs.

Mode 03: Show Stored Diagnostic Trouble Codes

Mode 03 displays the Diagnostic Trouble Codes (DTCs) that are currently stored in the ECU’s memory. This mode is essential for identifying faults and initiating the diagnostic process.

- Applications: Identifying faults, initiating diagnostic process.

Mode 04: Clear Diagnostic Trouble Codes

Mode 04 clears the DTCs from the ECU’s memory. This mode should be used with caution, as clearing DTCs can erase valuable diagnostic information.

- Applications: Clearing DTCs after repairs, resetting the check engine light.

Mode 05: Oxygen Sensor Monitoring Test Results

Mode 05 displays the results of oxygen sensor monitoring tests. This mode is useful for diagnosing issues with oxygen sensors and emissions-related components.

- Applications: Diagnosing oxygen sensor issues, emissions-related problems.

Mode 06: Non-Continuously Monitored Systems Test Results

Mode 06 displays the results of tests for non-continuously monitored systems, such as the catalytic converter and evaporative emissions system.

- Applications: Diagnosing catalytic converter and evaporative emissions system issues.

Mode 07: Show Pending Diagnostic Trouble Codes

Mode 07 displays pending DTCs, which are codes that have been detected but have not yet met the criteria to be stored as confirmed DTCs.

- Applications: Identifying potential problems, diagnosing intermittent faults.

Mode 08: Request Control of On-Board System, Test or Component

Mode 08 allows technicians to request control of on-board systems or components for testing purposes. This mode is often used for bi-directional controls, such as activating fuel injectors or turning on the cooling fan.

- Applications: Testing vehicle components, performing bi-directional controls.

Mode 09: Request Vehicle Information

Mode 09 requests vehicle information, such as the Vehicle Identification Number (VIN) and calibration identification numbers.

- Applications: Verifying vehicle information, identifying software updates.

Mode 0A: Show Permanent Diagnostic Trouble Codes

Mode 0A displays permanent DTCs, which are codes that cannot be cleared by disconnecting the battery or using a scan tool. These codes can only be cleared after the underlying problem has been resolved and the vehicle has completed a specific drive cycle.

- Applications: Identifying persistent problems, ensuring repairs are effective.

Understanding these advanced OBD2 modes can significantly enhance diagnostic capabilities and improve the accuracy of repairs. CAR-TOOL.EDU.VN provides detailed information and resources on each mode, helping technicians master the art of automotive diagnostics.

9. The Future of OBD2 Technology

Where is OBD2 technology headed? The future of OBD2 technology is evolving rapidly, driven by advancements in automotive technology and increasing demands for more comprehensive diagnostic capabilities. Several key trends are shaping the future of OBD2, including enhanced connectivity, advanced diagnostics, and integration with cloud-based services.

Enhanced Connectivity

Future OBD systems will feature enhanced connectivity, allowing vehicles to communicate with external devices and networks. This will enable remote diagnostics, over-the-air software updates, and integration with smart devices.

- Remote Diagnostics: Technicians can remotely access vehicle data and diagnose problems without physically being present.

- Over-the-Air Updates: Software updates can be performed remotely, eliminating the need for manual updates.

- Integration with Smart Devices: Vehicle data can be accessed and analyzed on smartphones, tablets, and other smart devices.

Advanced Diagnostics

Future OBD systems will incorporate more advanced diagnostic algorithms and sensors, providing more detailed and accurate information about vehicle performance.

- Predictive Maintenance: OBD systems can predict potential problems before they occur, allowing for proactive maintenance.

- Real-Time Monitoring: Continuous monitoring of vehicle parameters can help identify issues as they arise.

- Advanced Sensor Technology: New sensors can provide more detailed information about engine performance, emissions, and other critical systems.

Integration with Cloud-Based Services

Future OBD systems will be integrated with cloud-based services, allowing for data storage, analysis, and sharing. This will enable technicians to access a wealth of diagnostic information and collaborate with other professionals.

- Data Storage: Vehicle data can be stored in the cloud for later analysis.

- Data Analysis: Cloud-based tools can analyze vehicle data to identify trends and patterns.

- Data Sharing: Technicians can share diagnostic information with other professionals to collaborate on complex problems.

OBD3 and Beyond

OBD3 is a proposed future standard that would require vehicles to transmit diagnostic data wirelessly to regulatory agencies. This would allow for remote emissions monitoring and enforcement. While OBD3 is still in the development phase, it represents a significant step towards more comprehensive and connected vehicle diagnostics.

According to a report by McKinsey & Company, the market for connected car technologies is expected to reach $166 billion by 2025, driven by advancements in OBD systems and other connected vehicle technologies.

10. Maximizing Your Diagnostic Capabilities with CAR-TOOL.EDU.VN

How can CAR-TOOL.EDU.VN help me in my diagnostic endeavors? CAR-TOOL.EDU.VN is your ultimate resource for automotive diagnostics, offering a wide range of tools, information, and training resources to help you maximize your diagnostic capabilities. Whether you’re a professional technician or a DIY enthusiast, CAR-TOOL.EDU.VN has everything you need to diagnose and repair vehicle problems effectively.

Comprehensive Diagnostic Tools

CAR-TOOL.EDU.VN offers a wide selection of scan tools, code readers, and other diagnostic equipment to meet the needs of every user. Our tools range from basic code readers to advanced scan tools with bi-directional controls, data logging, and other advanced features.

- Scan Tools: Access DTCs, Freeze Frame data, real-time sensor readings, and more.

- Code Readers: Read and clear DTCs quickly and easily.

- Multimeters: Measure voltage, current, and resistance for electrical diagnostics.

- Pressure Testers: Test fuel pressure, coolant pressure, and other critical systems.

- Smoke Machines: Detect vacuum leaks and other air leaks.

Extensive Information Resources

CAR-TOOL.EDU.VN provides a wealth of information resources to help you understand and interpret diagnostic data. Our resources include repair manuals, technical service bulletins (TSBs), diagnostic guides, and online forums.

- Repair Manuals: Detailed information on vehicle systems and repair procedures.

- Technical Service Bulletins (TSBs): Information on common problems and solutions.

- Diagnostic Guides: Step-by-step instructions for diagnosing specific issues.

- Online Forums: Connect with other technicians and enthusiasts to share knowledge and ask questions.

Expert Training Resources

CAR-TOOL.EDU.VN offers expert training resources to help you improve your diagnostic skills. Our training resources include online courses, webinars, and hands-on workshops.

- Online Courses: Learn at your own pace with our comprehensive online courses.

- Webinars: Attend live webinars to learn from industry experts.

- Hands-On Workshops: Gain practical experience with hands-on training workshops.

Exceptional Customer Support

CAR-TOOL.EDU.VN is committed to providing exceptional customer support. Our knowledgeable staff is available to answer your questions and help you find the right tools and resources for your diagnostic needs.

- Phone Support: Call our customer support line for assistance.

- Email Support: Email our customer support team for a prompt response.

- Live Chat: Chat with a customer support representative online.

Don’t let diagnostic challenges hold you back. Maximize your diagnostic capabilities with CAR-TOOL.EDU.VN and become a master of automotive diagnostics. For more information, contact us at 456 Elm Street, Dallas, TX 75201, United States, Whatsapp: +1 (641) 206-8880 or visit our website at CAR-TOOL.EDU.VN.

11. Frequently Asked Questions (FAQs) About OBD2 Mode 02

Here are some frequently asked questions about OBD2 Mode 02 (Freeze Frame data):

Q: What is OBD2 Mode 02?

A: OBD2 Mode 02, also known as Freeze Frame data, captures a snapshot of engine parameters at the moment a Diagnostic Trouble Code (DTC) is triggered.

Q: What parameters are included in Freeze Frame data?

A: Freeze Frame data typically includes engine speed (RPM), engine load, coolant temperature, fuel trim values, intake manifold pressure, mass airflow, vehicle speed, throttle position, and oxygen sensor readings.

Q: How do I access Freeze Frame data?

A: You can access Freeze Frame data using a scan tool that connects to the vehicle’s OBD2 connector.

Q: Can Freeze Frame data help diagnose intermittent faults?

A: Yes, Freeze Frame data can provide valuable clues for diagnosing intermittent faults by showing the conditions that led to the DTC.

Q: Is Freeze Frame data available for all DTCs?

A: Freeze Frame data is typically available for most emissions-related DTCs, but it may not be available for all codes.

Q: Can I clear Freeze Frame data without clearing the DTCs?

A: No, clearing the DTCs will also clear the Freeze Frame data.

Q: How accurate is Freeze Frame data?

A: Freeze Frame data is generally accurate, but it’s important to verify the data by performing additional tests and consulting repair manuals.

Q: Can I use Freeze Frame data to predict future problems?

A: Freeze Frame data can provide insights into potential problems, but it’s not a reliable predictor of future faults.

Q: Do I need special training to interpret Freeze Frame data?

A: While not required, training and experience can help you interpret Freeze Frame data more effectively.

Q: Where can I find more information about OBD2 and Freeze Frame data?

A: CAR-TOOL.EDU.VN offers a variety of resources, including repair manuals, diagnostic guides, and training courses, to help you learn more about OBD2 and Freeze Frame data. Contact us at 456 Elm Street, Dallas, TX 75201, United States, Whatsapp: +1 (641) 206-8880 or visit our website at CAR-TOOL.EDU.VN.

By understanding the basics of OBD2 and Freeze Frame data, you can improve your diagnostic skills and keep your vehicle running smoothly.