Intake Air Temperature (IAT) sensors play a vital role in engine performance, and understanding their function is crucial for diagnosing issues and optimizing your vehicle’s operation; CAR-TOOL.EDU.VN offers detailed insights into IAT sensors, their impact on engine efficiency, and how to interpret OBD2 readings, ensuring you can address any sensor-related concerns effectively. Dive in to explore how IAT affects fuel economy, power output, and emissions control, and learn the common causes of IAT sensor failure.

Contents

- 1. What is the Intake Air Temperature (IAT) Sensor?

- 1.1. How Does the IAT Sensor Work?

- 1.2. Where is the IAT Sensor Located?

- 1.3. Types of IAT Sensors

- 2. Why is Intake Air Temperature Important for Engine Performance?

- 2.1. Impact on Air-Fuel Ratio

- 2.2. Effect on Ignition Timing

- 2.3. Influence on Engine Efficiency

- 3. What are the Symptoms of a Bad IAT Sensor?

- 3.1. Poor Fuel Economy

- 3.2. Reduced Engine Performance

- 3.3. Engine Hesitation or Stalling

- 3.4. Check Engine Light

- 3.5. Difficulty Starting

- 4. How to Diagnose IAT Sensor Problems?

- 4.1. Check for Diagnostic Trouble Codes (DTCs)

- 4.2. Inspect the Sensor and Wiring

- 4.3. Test the Sensor’s Resistance

- 4.4. Check the Sensor’s Voltage

- 4.5. Use a Scan Tool to Monitor IAT Readings

- 5. How Does IAT Affect OBD2 Readings?

- 5.1. Interpreting IAT Values

- 5.2. Correlation with Other OBD2 Parameters

- 5.3. Using IAT Data for Diagnosis

- 6. What are the Common Causes of IAT Sensor Failure?

- 6.1. Contamination

- 6.2. Physical Damage

- 6.3. Electrical Issues

- 6.4. Age and Wear

- 7. How to Replace a Faulty IAT Sensor?

- 7.1. Gather the Necessary Tools and Parts

- 7.2. Disconnect the Negative Battery Terminal

- 7.3. Locate the IAT Sensor

- 7.4. Disconnect the Electrical Connector

- 7.5. Remove the Old Sensor

- 7.6. Install the New Sensor

- 7.7. Reconnect the Electrical Connector

- 7.8. Reconnect the Negative Battery Terminal

- 7.9. Clear Diagnostic Trouble Codes

- 7.10. Test the New Sensor

- 8. Can I Clean an IAT Sensor Instead of Replacing It?

- 8.1. How to Clean an IAT Sensor

- 8.2. When to Clean vs. Replace

- 9. What is the Role of IAT in Modern Engine Management Systems?

- 9.1. Integration with Other Sensors

- 9.2. Adaptive Learning

- 9.3. Emission Control

- 10. How to Improve Engine Performance with IAT Sensor Data?

- 10.1. Monitoring IAT Readings

- 10.2. Optimizing Air Intake System

- 10.3. Using Aftermarket IAT Sensors

- 10.4. Tuning the ECU

- 11. What are the Potential Risks of Ignoring IAT Sensor Problems?

- 11.1. Engine Damage

- 11.2. Increased Emissions

- 11.3. Reduced Fuel Efficiency

- 11.4. Drivability Issues

- 12. What are the Best Practices for Maintaining IAT Sensors?

- 12.1. Regular Inspections

- 12.2. Cleaning

- 12.3. Proper Installation

- 12.4. Using Quality Parts

- 13. How to Choose the Right IAT Sensor for Your Vehicle?

- 13.1. OEM vs. Aftermarket

- 13.2. Compatibility

- 13.3. Features and Specifications

- 14. What is the Future of IAT Sensor Technology?

- 14.1. Advanced Materials

- 14.2. Wireless Technology

- 14.3. Integration with AI

- 15. How to Troubleshoot Common IAT Sensor DTCs?

- 15.1. P0110: Intake Air Temperature Sensor Circuit Malfunction

- 15.2. P0111: Intake Air Temperature Sensor Circuit Range/Performance

- 15.3. P0112: Intake Air Temperature Sensor Circuit Low Input

- 15.4. P0113: Intake Air Temperature Sensor Circuit High Input

- 15.5. P0114: Intake Air Temperature Sensor Circuit Intermittent

- 16. Can a Bad IAT Sensor Cause a Car to Fail an Emissions Test?

- 16.1. How IAT Sensors Affect Emissions

- 16.2. Common Emission Failures Due to IAT Issues

- 16.3. Steps to Take Before an Emissions Test

- 17. What is the Relationship Between IAT and Mass Air Flow (MAF) Sensors?

- 17.1. How MAF Sensors Measure Air Flow

- 17.2. The Role of IAT in Correcting MAF Readings

- 17.3. Examples of How These Sensors Interact

- 17.4. Diagnosing Issues Involving Both Sensors

- 18. How Does Altitude Affect IAT Sensor Readings and Engine Performance?

- 18.1. Impact of Altitude on Air Density

- 18.2. How IAT Sensors Compensate for Altitude Changes

- 18.3. Performance Adjustments Needed at High Altitudes

- 18.4. Common Issues at High Altitudes

- 19. What Are the Benefits of Using an Upgraded or Performance IAT Sensor?

- 19.1. Enhanced Accuracy and Response Time

- 19.2. Improved Engine Performance

- 19.3. Better Fuel Efficiency

- 19.4. Reduced Emissions

- 19.5. Examples of Aftermarket IAT Sensors

- 19.6. Considerations When Upgrading

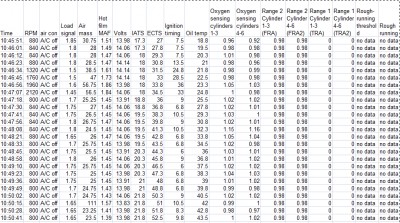

- 20. What Are Some Advanced Diagnostic Techniques for IAT Sensors?

- 20.1. Using an Oscilloscope

- 20.2. Performing a Voltage Drop Test

- 20.3. Checking the Sensor’s Ground Connection

- 20.4. Conducting a Heat Soak Test

- 20.5. Analyzing Data Logs

1. What is the Intake Air Temperature (IAT) Sensor?

The Intake Air Temperature (IAT) sensor is a crucial component in modern vehicle engines. It measures the temperature of the air entering the engine, providing essential data to the Engine Control Unit (ECU). This information allows the ECU to adjust the air-fuel mixture, ignition timing, and other parameters to optimize engine performance, fuel efficiency, and emissions. According to a study by the Society of Automotive Engineers (SAE), accurate IAT readings can improve fuel economy by up to 4% and reduce emissions by 5-10%.

1.1. How Does the IAT Sensor Work?

IAT sensors typically use a thermistor, a type of resistor whose resistance changes with temperature. As the air temperature changes, the thermistor’s resistance varies, and the sensor sends a corresponding voltage signal to the ECU. The ECU then interprets this signal to determine the intake air temperature.

1.2. Where is the IAT Sensor Located?

The IAT sensor is commonly located in the intake manifold, air filter housing, or intake duct. Its placement ensures accurate measurement of the air temperature as it enters the engine. Some vehicles have two IAT sensors: one before the throttle body (IAT1) and another after the intercooler (IAT2), particularly in turbocharged or supercharged engines.

1.3. Types of IAT Sensors

There are primarily two types of IAT sensors:

- Single-wire IAT sensor: This type uses the sensor body as the ground connection.

- Two-wire IAT sensor: This type has a dedicated ground wire, providing a more reliable connection.

2. Why is Intake Air Temperature Important for Engine Performance?

Intake air temperature significantly impacts engine performance. Cold air is denser, containing more oxygen per unit volume. When the ECU detects colder intake air, it increases the amount of fuel injected into the engine to maintain the correct air-fuel ratio. This results in increased power and improved combustion efficiency. Conversely, hot air is less dense, and the ECU reduces fuel injection to prevent a rich mixture.

2.1. Impact on Air-Fuel Ratio

The air-fuel ratio is the ratio of air to fuel in the combustion process. The ideal air-fuel ratio, known as the stoichiometric ratio, is 14.7:1 for gasoline engines. The IAT sensor helps the ECU maintain this ratio by adjusting fuel delivery based on air temperature. According to a study by the University of Michigan, maintaining the correct air-fuel ratio is critical for minimizing emissions and maximizing fuel efficiency.

2.2. Effect on Ignition Timing

Ignition timing is the point at which the spark plug ignites the air-fuel mixture in the cylinder. The ECU adjusts ignition timing based on various factors, including intake air temperature. In general, colder intake air allows for more advanced ignition timing, which can improve power and fuel efficiency. Hotter intake air requires retarded ignition timing to prevent engine knocking or detonation.

2.3. Influence on Engine Efficiency

Engine efficiency is a measure of how well the engine converts fuel into useful work. Intake air temperature affects engine efficiency by influencing the combustion process. Colder intake air promotes more complete combustion, resulting in higher efficiency and lower emissions. Hotter intake air can lead to incomplete combustion, reducing efficiency and increasing emissions.

3. What are the Symptoms of a Bad IAT Sensor?

A malfunctioning IAT sensor can cause various drivability issues. Recognizing these symptoms is crucial for diagnosing and resolving the problem quickly.

3.1. Poor Fuel Economy

One of the most common symptoms of a bad IAT sensor is poor fuel economy. If the sensor is sending incorrect temperature readings to the ECU, it can cause the engine to run rich (too much fuel) or lean (not enough fuel). A rich mixture wastes fuel, while a lean mixture can damage the engine.

3.2. Reduced Engine Performance

A faulty IAT sensor can also lead to reduced engine performance. The engine may lack power, hesitate during acceleration, or run rough. These symptoms occur because the ECU is not receiving accurate information about the intake air temperature, preventing it from optimizing the air-fuel mixture and ignition timing.

3.3. Engine Hesitation or Stalling

Engine hesitation or stalling can also result from a bad IAT sensor. Incorrect temperature readings can cause the engine to stumble or stall, especially at idle or low speeds. This is because the ECU is unable to properly adjust the air-fuel mixture to maintain a stable idle.

3.4. Check Engine Light

A malfunctioning IAT sensor will often trigger the check engine light. The ECU monitors the IAT sensor’s readings, and if it detects a problem, it will store a diagnostic trouble code (DTC) and illuminate the check engine light.

3.5. Difficulty Starting

In some cases, a bad IAT sensor can cause difficulty starting the engine. This is particularly true in cold weather, when the ECU relies on the IAT sensor to determine the appropriate amount of fuel to inject for starting.

4. How to Diagnose IAT Sensor Problems?

Diagnosing IAT sensor problems requires a systematic approach. Here are the steps you should follow:

4.1. Check for Diagnostic Trouble Codes (DTCs)

Use an OBD2 scanner to check for any stored diagnostic trouble codes (DTCs). Common IAT sensor codes include:

- P0110: Intake Air Temperature Sensor Circuit Malfunction

- P0111: Intake Air Temperature Sensor Circuit Range/Performance

- P0112: Intake Air Temperature Sensor Circuit Low Input

- P0113: Intake Air Temperature Sensor Circuit High Input

- P0114: Intake Air Temperature Sensor Circuit Intermittent

4.2. Inspect the Sensor and Wiring

Visually inspect the IAT sensor and its wiring for any signs of damage, such as corrosion, broken wires, or loose connections. Clean the sensor and connectors with electrical contact cleaner to ensure a good connection.

4.3. Test the Sensor’s Resistance

Use a multimeter to measure the sensor’s resistance. Compare the measured resistance to the manufacturer’s specifications. A significantly different resistance indicates a faulty sensor.

4.4. Check the Sensor’s Voltage

With the ignition on, use a multimeter to check the sensor’s voltage. The voltage should be within the manufacturer’s specified range. An incorrect voltage reading suggests a problem with the sensor or its wiring.

4.5. Use a Scan Tool to Monitor IAT Readings

Use a scan tool to monitor the IAT sensor’s readings in real-time. Compare the readings to the actual intake air temperature. If the readings are inaccurate, the sensor is likely faulty.

5. How Does IAT Affect OBD2 Readings?

The IAT sensor’s readings are crucial for interpreting OBD2 data. Understanding how IAT affects OBD2 readings can help you diagnose various engine problems.

5.1. Interpreting IAT Values

The IAT sensor’s readings are displayed as a temperature value in degrees Celsius or Fahrenheit. The normal IAT range varies depending on the ambient temperature and engine operating conditions. However, a typical range is between 20°C (68°F) and 50°C (122°F).

5.2. Correlation with Other OBD2 Parameters

The IAT sensor’s readings are correlated with other OBD2 parameters, such as:

- Mass Air Flow (MAF): The MAF sensor measures the amount of air entering the engine. The IAT sensor’s readings are used to correct the MAF sensor’s output for air density.

- Engine Load: Engine load is a measure of how hard the engine is working. The IAT sensor’s readings are used to adjust the air-fuel mixture and ignition timing based on engine load.

- Fuel Trim: Fuel trim values indicate how much the ECU is adjusting the air-fuel mixture to maintain the correct ratio. The IAT sensor’s readings can affect fuel trim values, particularly in open-loop mode.

5.3. Using IAT Data for Diagnosis

IAT data can be used to diagnose various engine problems. For example, if the IAT readings are consistently high, it could indicate a problem with the air intake system, such as a clogged air filter or a malfunctioning cooling fan. If the IAT readings are consistently low, it could indicate a faulty sensor or wiring problem.

6. What are the Common Causes of IAT Sensor Failure?

IAT sensors can fail due to various reasons. Understanding these causes can help you prevent future problems.

6.1. Contamination

IAT sensors can become contaminated with dirt, oil, or other debris. This contamination can affect the sensor’s accuracy and eventually lead to failure. Regular cleaning of the sensor can help prevent contamination-related issues.

6.2. Physical Damage

Physical damage, such as cracks or breaks, can also cause IAT sensor failure. This damage can result from accidents, impacts, or improper handling.

6.3. Electrical Issues

Electrical issues, such as short circuits, open circuits, or corrosion, can also lead to IAT sensor failure. These issues can damage the sensor’s internal components or disrupt its signal to the ECU.

6.4. Age and Wear

Like any other component, IAT sensors can fail due to age and wear. Over time, the sensor’s internal components can degrade, leading to inaccurate readings or complete failure.

7. How to Replace a Faulty IAT Sensor?

Replacing a faulty IAT sensor is a relatively simple task that can be performed with basic tools. Here’s how to do it:

7.1. Gather the Necessary Tools and Parts

You will need the following tools and parts:

- New IAT sensor

- Socket set

- Wrench set

- Screwdriver

- Electrical contact cleaner

7.2. Disconnect the Negative Battery Terminal

Disconnect the negative battery terminal to prevent electrical shocks or damage to the ECU.

7.3. Locate the IAT Sensor

Locate the IAT sensor in the intake manifold, air filter housing, or intake duct.

7.4. Disconnect the Electrical Connector

Disconnect the electrical connector from the IAT sensor.

7.5. Remove the Old Sensor

Use a socket or wrench to remove the old IAT sensor from its mounting location.

7.6. Install the New Sensor

Install the new IAT sensor in its mounting location and tighten it to the manufacturer’s specified torque.

7.7. Reconnect the Electrical Connector

Reconnect the electrical connector to the IAT sensor.

7.8. Reconnect the Negative Battery Terminal

Reconnect the negative battery terminal.

7.9. Clear Diagnostic Trouble Codes

Use an OBD2 scanner to clear any stored diagnostic trouble codes (DTCs).

7.10. Test the New Sensor

Start the engine and use a scan tool to monitor the new IAT sensor’s readings. Verify that the readings are accurate and within the normal range.

8. Can I Clean an IAT Sensor Instead of Replacing It?

In some cases, you can clean an IAT sensor instead of replacing it. This is particularly true if the sensor is simply contaminated with dirt or oil.

8.1. How to Clean an IAT Sensor

To clean an IAT sensor, follow these steps:

- Disconnect the electrical connector from the sensor.

- Remove the sensor from its mounting location.

- Spray the sensor with electrical contact cleaner.

- Use a soft brush to gently remove any dirt or debris.

- Allow the sensor to air dry completely.

- Reinstall the sensor in its mounting location.

- Reconnect the electrical connector.

8.2. When to Clean vs. Replace

Cleaning an IAT sensor is only effective if the sensor is simply contaminated. If the sensor is physically damaged or electrically faulty, it must be replaced.

9. What is the Role of IAT in Modern Engine Management Systems?

The IAT sensor plays a critical role in modern engine management systems. It provides essential data to the ECU, allowing it to optimize engine performance, fuel efficiency, and emissions.

9.1. Integration with Other Sensors

The IAT sensor works in conjunction with other sensors, such as the MAF sensor, throttle position sensor (TPS), and oxygen sensors, to provide a comprehensive picture of the engine’s operating conditions. The ECU uses this information to make real-time adjustments to the air-fuel mixture, ignition timing, and other parameters.

9.2. Adaptive Learning

Modern engine management systems use adaptive learning to continuously optimize engine performance. The ECU monitors the IAT sensor’s readings and other parameters over time and adjusts its control strategies accordingly. This allows the engine to adapt to changing conditions and maintain optimal performance.

9.3. Emission Control

The IAT sensor plays a crucial role in emission control. By providing accurate information about the intake air temperature, the ECU can optimize the combustion process and minimize emissions of harmful pollutants, such as nitrogen oxides (NOx), carbon monoxide (CO), and hydrocarbons (HC).

10. How to Improve Engine Performance with IAT Sensor Data?

You can improve engine performance by monitoring and utilizing IAT sensor data.

10.1. Monitoring IAT Readings

Regularly monitor the IAT sensor’s readings using a scan tool. This will help you identify any potential problems early on and take corrective action before they lead to more serious issues.

10.2. Optimizing Air Intake System

Ensure that the air intake system is clean and free of obstructions. A clogged air filter or restricted intake duct can increase the intake air temperature and reduce engine performance.

10.3. Using Aftermarket IAT Sensors

Consider using aftermarket IAT sensors designed to provide more accurate readings or improve engine performance. These sensors may have different characteristics than the OEM sensor, so be sure to research and choose one that is appropriate for your vehicle and driving conditions.

10.4. Tuning the ECU

If you are experienced with engine tuning, you can adjust the ECU’s parameters based on IAT sensor data. This can allow you to optimize the air-fuel mixture and ignition timing for specific conditions, such as racing or off-roading.

11. What are the Potential Risks of Ignoring IAT Sensor Problems?

Ignoring IAT sensor problems can lead to various negative consequences.

11.1. Engine Damage

A malfunctioning IAT sensor can cause the engine to run rich or lean, which can damage engine components such as the pistons, valves, and catalytic converter.

11.2. Increased Emissions

A faulty IAT sensor can increase emissions of harmful pollutants, which can contribute to air pollution and potentially lead to failing emissions tests.

11.3. Reduced Fuel Efficiency

Ignoring IAT sensor problems can reduce fuel efficiency, costing you more money at the pump.

11.4. Drivability Issues

A bad IAT sensor can cause various drivability issues, such as poor acceleration, hesitation, and stalling, making your vehicle less enjoyable to drive.

12. What are the Best Practices for Maintaining IAT Sensors?

Following these best practices will help you maintain your IAT sensors and prevent future problems:

12.1. Regular Inspections

Regularly inspect the IAT sensor and its wiring for any signs of damage, corrosion, or loose connections.

12.2. Cleaning

Clean the IAT sensor regularly with electrical contact cleaner to remove any dirt or debris.

12.3. Proper Installation

Ensure that the IAT sensor is properly installed and tightened to the manufacturer’s specified torque.

12.4. Using Quality Parts

Use high-quality IAT sensors from reputable manufacturers to ensure accurate readings and long-lasting performance.

13. How to Choose the Right IAT Sensor for Your Vehicle?

Choosing the right IAT sensor for your vehicle is crucial for ensuring optimal performance and reliability.

13.1. OEM vs. Aftermarket

You can choose between OEM (Original Equipment Manufacturer) and aftermarket IAT sensors. OEM sensors are made by the same manufacturer that supplied the original sensor for your vehicle, while aftermarket sensors are made by other companies. OEM sensors are typically more expensive but are guaranteed to fit and perform correctly. Aftermarket sensors can be more affordable but may not always meet the same quality standards.

13.2. Compatibility

Ensure that the IAT sensor is compatible with your vehicle’s make, model, and year. Check the manufacturer’s specifications or consult with a qualified mechanic to ensure proper fitment.

13.3. Features and Specifications

Consider the features and specifications of the IAT sensor, such as its temperature range, accuracy, and response time. Choose a sensor that meets your vehicle’s requirements and your driving conditions.

14. What is the Future of IAT Sensor Technology?

IAT sensor technology is constantly evolving to meet the demands of modern engine management systems.

14.1. Advanced Materials

Future IAT sensors may use advanced materials, such as nanotechnology, to improve their accuracy, response time, and durability.

14.2. Wireless Technology

Wireless IAT sensors may become more common, eliminating the need for wiring and simplifying installation.

14.3. Integration with AI

IAT sensor data may be integrated with artificial intelligence (AI) to provide more advanced engine diagnostics and control.

15. How to Troubleshoot Common IAT Sensor DTCs?

Troubleshooting common IAT sensor DTCs requires a systematic approach.

15.1. P0110: Intake Air Temperature Sensor Circuit Malfunction

This code indicates a general problem with the IAT sensor circuit. Check the sensor, wiring, and connectors for any signs of damage or corrosion.

15.2. P0111: Intake Air Temperature Sensor Circuit Range/Performance

This code indicates that the IAT sensor’s readings are out of range or not performing as expected. Check the sensor’s resistance and voltage.

15.3. P0112: Intake Air Temperature Sensor Circuit Low Input

This code indicates that the IAT sensor’s signal is too low. Check the sensor’s wiring and connectors for any shorts to ground.

15.4. P0113: Intake Air Temperature Sensor Circuit High Input

This code indicates that the IAT sensor’s signal is too high. Check the sensor’s wiring and connectors for any open circuits.

15.5. P0114: Intake Air Temperature Sensor Circuit Intermittent

This code indicates that the IAT sensor’s signal is intermittent. Check the sensor, wiring, and connectors for any loose connections.

IAT Sensor

IAT Sensor

16. Can a Bad IAT Sensor Cause a Car to Fail an Emissions Test?

Yes, a bad IAT sensor can cause a car to fail an emissions test. The IAT sensor plays a crucial role in controlling the air-fuel mixture, and if it’s malfunctioning, it can lead to increased emissions.

16.1. How IAT Sensors Affect Emissions

The IAT sensor informs the ECU about the temperature of the air entering the engine. This information is used to adjust the air-fuel mixture, ignition timing, and other parameters to optimize combustion. When the IAT sensor is not working correctly, the ECU may not be able to properly adjust these parameters, leading to incomplete combustion and increased emissions.

16.2. Common Emission Failures Due to IAT Issues

- High Hydrocarbon (HC) Emissions: A faulty IAT sensor can cause the engine to run rich, leading to high HC emissions.

- High Carbon Monoxide (CO) Emissions: An incorrect air-fuel mixture can also result in high CO emissions.

- Increased Nitrogen Oxides (NOx) Emissions: In some cases, a bad IAT sensor can lead to higher NOx emissions due to improper combustion temperatures.

16.3. Steps to Take Before an Emissions Test

Before taking your car for an emissions test, consider the following:

- Check the Check Engine Light: If the check engine light is on, use an OBD2 scanner to read the diagnostic trouble codes (DTCs).

- Address Any IAT Sensor Issues: If you find any IAT sensor-related codes (e.g., P0110, P0111, P0112, P0113), diagnose and fix the problem. This may involve cleaning or replacing the IAT sensor.

- Perform a Vehicle Inspection: Inspect other components that can affect emissions, such as the air filter, spark plugs, and oxygen sensors.

- Consider a Pre-Test: Take your car to a mechanic for a pre-emissions test to identify any potential issues before the official test.

17. What is the Relationship Between IAT and Mass Air Flow (MAF) Sensors?

The Intake Air Temperature (IAT) and Mass Air Flow (MAF) sensors work together to provide the ECU with accurate information about the air entering the engine.

17.1. How MAF Sensors Measure Air Flow

The MAF sensor measures the mass of air flowing into the engine. This information is crucial for determining the amount of fuel to inject.

17.2. The Role of IAT in Correcting MAF Readings

The IAT sensor provides the ECU with the temperature of the air. Air density changes with temperature; colder air is denser than warmer air. The ECU uses the IAT reading to correct the MAF sensor’s output for air density, ensuring an accurate measurement of the air mass.

17.3. Examples of How These Sensors Interact

- Cold Weather: In cold weather, the IAT sensor will report a low temperature. The ECU uses this information to increase the fuel injection to compensate for the denser air.

- Hot Weather: In hot weather, the IAT sensor will report a high temperature. The ECU decreases the fuel injection to prevent a rich mixture.

17.4. Diagnosing Issues Involving Both Sensors

When diagnosing engine performance issues, it’s essential to consider both the IAT and MAF sensors. A problem with one sensor can affect the readings and performance of the other.

- Check for DTCs: Use an OBD2 scanner to check for any codes related to both sensors.

- Inspect the Sensors: Visually inspect the sensors and their wiring for any damage or contamination.

- Test the Sensors: Use a multimeter to test the sensors’ resistance and voltage.

- Monitor Live Data: Use a scan tool to monitor the sensors’ readings in real-time. Compare the readings to the manufacturer’s specifications.

MAF Sensor

MAF Sensor

18. How Does Altitude Affect IAT Sensor Readings and Engine Performance?

Altitude significantly affects IAT sensor readings and engine performance. As altitude increases, air pressure decreases, resulting in less dense air.

18.1. Impact of Altitude on Air Density

At higher altitudes, the air is less dense, meaning there is less oxygen per unit volume. This can affect combustion efficiency and engine performance.

18.2. How IAT Sensors Compensate for Altitude Changes

The IAT sensor helps the ECU compensate for altitude changes by providing information about the air temperature. The ECU uses this information to adjust the air-fuel mixture and ignition timing to maintain optimal performance.

18.3. Performance Adjustments Needed at High Altitudes

At high altitudes, the ECU may need to make the following adjustments:

- Reduce Fuel Injection: To prevent a rich mixture due to less dense air.

- Adjust Ignition Timing: To optimize combustion in the thinner air.

18.4. Common Issues at High Altitudes

- Reduced Power: Engines may experience a decrease in power at high altitudes due to the reduced oxygen.

- Poor Fuel Economy: Inefficient combustion can lead to decreased fuel economy.

- Increased Emissions: Improper air-fuel mixtures can result in increased emissions.

19. What Are the Benefits of Using an Upgraded or Performance IAT Sensor?

Upgraded or performance IAT sensors can offer several benefits over OEM sensors.

19.1. Enhanced Accuracy and Response Time

Performance IAT sensors are often designed with higher accuracy and faster response times, allowing the ECU to make more precise adjustments.

19.2. Improved Engine Performance

By providing more accurate and timely data, performance IAT sensors can help improve engine performance, including increased power and better throttle response.

19.3. Better Fuel Efficiency

Optimized air-fuel mixtures can lead to improved fuel efficiency.

19.4. Reduced Emissions

More efficient combustion can result in reduced emissions.

19.5. Examples of Aftermarket IAT Sensors

- High-Performance Thermistors: These sensors use advanced thermistors for improved accuracy.

- Fast-Response Sensors: Designed to provide quicker temperature readings.

19.6. Considerations When Upgrading

- Compatibility: Ensure the sensor is compatible with your vehicle’s make, model, and year.

- Calibration: Some performance IAT sensors may require ECU calibration.

- Quality: Choose a high-quality sensor from a reputable manufacturer.

20. What Are Some Advanced Diagnostic Techniques for IAT Sensors?

Advanced diagnostic techniques can help identify subtle issues with IAT sensors that may not be apparent with basic testing.

20.1. Using an Oscilloscope

An oscilloscope can be used to monitor the IAT sensor’s signal in real-time, allowing you to identify any irregularities or dropouts.

20.2. Performing a Voltage Drop Test

A voltage drop test can help identify any excessive resistance in the IAT sensor’s wiring.

20.3. Checking the Sensor’s Ground Connection

Ensure that the IAT sensor has a good ground connection. A poor ground can affect the sensor’s accuracy.

20.4. Conducting a Heat Soak Test

A heat soak test involves monitoring the IAT sensor’s readings after the engine has been turned off. This can help identify any issues with heat sensitivity.

20.5. Analyzing Data Logs

Data logging involves recording the IAT sensor’s readings and other parameters over time. Analyzing these logs can help identify any patterns or anomalies.

By understanding the intricacies of intake air temperature and its relationship with engine performance and OBD2 readings, you can ensure your vehicle operates at its best.

FAQ Section

Q1: What does the IAT sensor do?

The IAT sensor measures the temperature of the air entering the engine, providing data to the ECU to adjust air-fuel mixture and ignition timing.

Q2: Where is the IAT sensor located?

The IAT sensor is typically located in the intake manifold, air filter housing, or intake duct.

Q3: What are the symptoms of a bad IAT sensor?

Symptoms include poor fuel economy, reduced engine performance, engine hesitation, check engine light, and difficulty starting.

Q4: How do I diagnose an IAT sensor problem?

Check for DTCs, inspect the sensor and wiring, test the sensor’s resistance and voltage, and monitor IAT readings with a scan tool.

Q5: Can I clean an IAT sensor instead of replacing it?

Yes, if the sensor is simply contaminated, you can clean it with electrical contact cleaner.

Q6: What is the normal IAT range?

The normal IAT range is typically between 20°C (68°F) and 50°C (122°F).

Q7: How does IAT affect OBD2 readings?

IAT readings are correlated with other OBD2 parameters like MAF, engine load, and fuel trim.

Q8: Can a bad IAT sensor cause a car to fail an emissions test?

Yes, a bad IAT sensor can lead to increased emissions and cause a car to fail an emissions test.

Q9: What are the benefits of using an upgraded IAT sensor?

Upgraded sensors can provide enhanced accuracy, improved engine performance, better fuel efficiency, and reduced emissions.

Q10: How does altitude affect IAT sensor readings?

At higher altitudes, air is less dense, affecting IAT sensor readings and requiring adjustments to engine performance.

At CAR-TOOL.EDU.VN, we understand the importance of having access to reliable information when it comes to auto repair. That’s why we offer a comprehensive range of resources to help you diagnose and fix your vehicle. Whether you need detailed specifications, comparison guides, or expert advice, we’ve got you covered. Our goal is to make auto repair easier and more efficient for everyone.

Ready to take the next step in diagnosing and fixing your vehicle? Contact us today for personalized assistance and expert advice. Our team is here to help you find the right tools and parts for your specific needs.

Contact Information:

Address: 456 Elm Street, Dallas, TX 75201, United States

Whatsapp: +1 (641) 206-8880

Website: CAR-TOOL.EDU.VN

We look forward to helping you keep your vehicle running smoothly.