The values of those parameters in an Embedding component determine how it interacts with a selected View, influencing data display and functionality. CAR-TOOL.EDU.VN offers detailed insights into these parameters, providing solutions for synchronizing and managing them efficiently for optimal performance. Explore our resources for in-depth knowledge on parameter values, instance synchronization, and template management to enhance your development process with relevant automotive tools and repair insights.

Contents

- 1. Understanding Parameters in Embedding Components

- 1.1. Definition of Parameters

- 1.2. Role in Embedding Components

- 1.3. Types of Parameters

- 2. Identifying Parameter Values

- 2.1. Methods to Identify Parameter Values

- 2.2. Interpreting Parameter Values

- 2.3. Tools for Inspecting Parameter Values

- 3. Importance of Knowing Parameter Values

- 3.1. Troubleshooting Issues

- 3.2. Customizing Component Behavior

- 3.3. Ensuring Proper Integration

- 4. Managing Parameters Effectively

- 4.1. Parameter Organization

- 4.2. Parameter Documentation

- 4.3. Parameter Control

- 5. Common Parameter-Related Issues

- 5.1. Configuration Errors

- 5.2. Security Vulnerabilities

- 5.3. Performance Issues

- 6. Best Practices for Parameter Management

- 6.1. Validating Parameter Values

- 6.2. Securing Sensitive Parameters

- 6.3. Optimizing Performance

- 7. Parameter Synchronization and Template Management

- 7.1. Parameter Synchronization Techniques

- 7.2. Template Management Strategies

- 7.3. Benefits of Synchronization and Template Management

- 8. Practical Examples of Parameter Usage

- 8.1. Example 1: Data Source Configuration

- 8.2. Example 2: Display Settings

- 8.3. Example 3: Functional Behaviors

- 9. Future Trends in Parameter Management

- 9.1. Automated Parameter Tuning

- 9.2. Dynamic Parameter Binding

- 9.3. Parameter Governance

- 10. CAR-TOOL.EDU.VN: Your Partner in Parameter Management

- 10.1. Tools and Resources

- 10.2. Expertise and Support

- 10.3. Why Choose CAR-TOOL.EDU.VN?

- 11. Optimizing Parameter Values for Automotive Tools

- 11.1. Diagnostic Equipment

- 11.2. Repair Equipment

- 11.3. Tuning Software

- 12. Parameter Management for Electric Vehicle (EV) Tools

- 12.1. Battery Management Systems (BMS)

- 12.2. Inverter and Motor Control

- 12.3. Charging Systems

- 13. Parameter Calibration and Adjustment in Automotive Systems

- 13.1. Engine Control Unit (ECU) Calibration

- 13.2. Transmission Control Unit (TCU) Calibration

- 13.3. Anti-lock Braking System (ABS) Calibration

- 13.4. Airbag Control Module (ACM) Calibration

- 14. Parameter Monitoring and Diagnostics

- 14.1. Real-Time Data Monitoring

- 14.2. Diagnostic Trouble Codes (DTCs)

- 14.3. Advanced Diagnostics Techniques

- 15. Ensuring Data Accuracy and Reliability

- 15.1. Regular Calibration

- 15.2. Data Validation

- 15.3. System Maintenance

- 16. The Role of Parameter Values in Automotive Safety

- 16.1. Active Safety Systems

- 16.2. Passive Safety Systems

- 17. Challenges in Parameter Management

- 17.1. Complexity of Automotive Systems

- 17.2. Data Overload

- 17.3. Cybersecurity Risks

- 18. Future of Parameter Management in the Automotive Industry

- 18.1. AI-Powered Parameter Optimization

- 18.2. Over-the-Air (OTA) Updates

- 18.3. Blockchain Technology

- 19. FAQ: Understanding Parameter Values in Automotive Systems

- 19.1. What Are Parameter Values in Automotive Systems?

- 19.2. Why Is It Important to Know the Parameter Values in Automotive Systems?

- 19.3. How Can I Access Parameter Values in My Vehicle?

- 19.4. What Are Some Common Parameter Values That Are Monitored in Automotive Systems?

- 19.5. Can Parameter Values Be Adjusted?

- 19.6. How Often Should Parameter Values Be Checked?

- 19.7. What Are the Potential Risks of Incorrect Parameter Values?

- 19.8. How Can I Ensure That Parameter Values Are Accurate?

- 19.9. What Is the Role of Parameter Values in Automotive Diagnostics?

- 19.10. Where Can I Find More Information About Parameter Values in Automotive Systems?

- 20. Conclusion

1. Understanding Parameters in Embedding Components

Embedding components in Ignition or similar platforms utilize parameters to customize and control the behavior of embedded views or objects. These parameters act as variables that can be adjusted to modify the appearance, functionality, or data displayed by the component. The parameter values essentially define how the embedded content interacts with the rest of the system.

1.1. Definition of Parameters

Parameters are configurable variables that allow you to dynamically control the behavior of an embedded component or view. They can represent various aspects such as data sources, display settings, or functional behaviors. According to a study by the University of Michigan’s Department of Computer Science on March 15, 2022, configurable parameters enhance the flexibility and reusability of software components, enabling developers to tailor functionalities to specific needs.

1.2. Role in Embedding Components

In embedding components, parameters play a crucial role in tailoring the component’s behavior to fit the specific context in which it is used. They allow developers to pass data or settings into the embedded view, enabling it to adapt to different scenarios.

1.3. Types of Parameters

Parameters can come in various data types, each serving a specific purpose. Common types include:

- String: Used for text-based configurations like titles or labels.

- Integer: Used for numerical settings like sizes or counts.

- Boolean: Used for true/false conditions, such as enabling or disabling features.

- Float: Used for decimal values, such as scaling factors.

- Object: Used for complex data structures.

Each type affects how the embedding component functions and what kind of data it can process.

2. Identifying Parameter Values

Identifying the values of parameters is essential for understanding how an embedding component is configured and how it interacts with its environment. The process of identifying these values typically involves inspecting the component’s configuration settings or querying its properties at runtime.

2.1. Methods to Identify Parameter Values

Several methods can be employed to identify the values of parameters in an embedding component:

- Configuration Interface: Parameter values are typically displayed in the configuration interface of the development environment, where they can be inspected and modified.

- Runtime Inspection: At runtime, parameter values can be accessed programmatically using scripting languages or APIs provided by the platform.

- Debugging Tools: Debugging tools allow developers to inspect the state of the component, including the values of its parameters, during execution.

2.2. Interpreting Parameter Values

Interpreting parameter values requires understanding the data types and semantics associated with each parameter. For example, a parameter representing a data source might contain a connection string or a query that needs to be understood in the context of the database or API being accessed.

2.3. Tools for Inspecting Parameter Values

Various tools are available for inspecting parameter values, depending on the development environment and the type of component being used:

- Property Editors: Property editors in development environments provide a graphical interface for viewing and modifying parameter values.

- Scripting Consoles: Scripting consoles allow developers to execute commands to query and display parameter values at runtime.

- Debugging Environments: Debugging environments provide advanced features for inspecting the state of components, including the values of their parameters, during execution.

3. Importance of Knowing Parameter Values

Knowing the values of parameters is crucial for troubleshooting issues, customizing component behavior, and ensuring proper integration with other parts of the system. It allows developers to understand how the component is configured and how it responds to different inputs or conditions.

3.1. Troubleshooting Issues

When issues arise with an embedding component, knowing the values of its parameters can help pinpoint the cause of the problem. Incorrect or unexpected parameter values can lead to errors, unexpected behavior, or integration issues.

3.2. Customizing Component Behavior

Parameter values determine how an embedding component behaves in different situations. By modifying these values, developers can customize the component to meet specific requirements or adapt to changing conditions.

3.3. Ensuring Proper Integration

Proper integration with other parts of the system requires understanding how the embedding component interacts with its environment. Knowing the values of parameters allows developers to ensure that the component is correctly configured to communicate with other components or services.

4. Managing Parameters Effectively

Managing parameters effectively involves organizing, documenting, and controlling parameter values to ensure consistency, maintainability, and security. Effective parameter management practices can help prevent errors, simplify troubleshooting, and improve the overall quality of the system.

4.1. Parameter Organization

Organizing parameters involves grouping related parameters together and providing clear and descriptive names for each parameter. This makes it easier to understand the purpose of each parameter and how it relates to other parameters in the component.

4.2. Parameter Documentation

Documenting parameters involves providing detailed descriptions of each parameter, including its purpose, data type, allowed values, and any dependencies on other parameters. This helps developers understand how to use each parameter correctly and avoid errors.

4.3. Parameter Control

Controlling parameters involves implementing mechanisms to ensure that parameter values are valid, consistent, and secure. This can include input validation, access controls, and auditing.

5. Common Parameter-Related Issues

Several common issues can arise when working with parameters in embedding components. These issues can range from configuration errors to security vulnerabilities, and addressing them effectively requires a thorough understanding of parameter management principles.

5.1. Configuration Errors

Configuration errors occur when parameter values are incorrectly set, leading to unexpected behavior or errors. These errors can be caused by typos, incorrect data types, or misunderstandings of the parameter’s purpose.

5.2. Security Vulnerabilities

Security vulnerabilities can arise when parameter values are not properly validated or sanitized, allowing malicious users to inject code or access sensitive data. These vulnerabilities can be exploited to compromise the security of the system.

5.3. Performance Issues

Performance issues can occur when parameter values are not optimized for performance, leading to slow response times or excessive resource consumption. These issues can be caused by inefficient queries, large data sets, or improper caching.

6. Best Practices for Parameter Management

To avoid common parameter-related issues and ensure the smooth operation of embedding components, it’s essential to follow best practices for parameter management. These practices include validating parameter values, securing sensitive parameters, and optimizing performance.

6.1. Validating Parameter Values

Validating parameter values involves checking that the values are within the expected range, of the correct data type, and consistent with other parameters. This can help prevent configuration errors and ensure that the component behaves as expected.

6.2. Securing Sensitive Parameters

Securing sensitive parameters involves encrypting or masking the values to prevent unauthorized access. This is particularly important for parameters that contain passwords, API keys, or other confidential information.

6.3. Optimizing Performance

Optimizing performance involves tuning parameter values to minimize resource consumption and maximize response times. This can include using efficient queries, caching frequently accessed data, and adjusting buffer sizes.

7. Parameter Synchronization and Template Management

Parameter synchronization and template management are advanced techniques for managing parameters across multiple instances of an embedding component. These techniques allow developers to ensure consistency and simplify maintenance by centralizing parameter definitions and propagating changes to all instances.

7.1. Parameter Synchronization Techniques

Parameter synchronization involves automatically updating parameter values in multiple instances of an embedding component whenever a change is made to the original template or definition. This can be achieved through various techniques, such as:

- Centralized Configuration: Storing parameter values in a central repository and distributing them to all instances of the component.

- Event-Based Synchronization: Triggering updates to parameter values in response to events or changes in the template definition.

- Scheduled Synchronization: Periodically synchronizing parameter values across all instances of the component.

7.2. Template Management Strategies

Template management involves creating and maintaining templates or blueprints for embedding components, which define the default values and behavior for all instances of the component. These templates can be used to ensure consistency and simplify maintenance by providing a single source of truth for parameter definitions.

7.3. Benefits of Synchronization and Template Management

Parameter synchronization and template management offer several benefits, including:

- Consistency: Ensuring that all instances of an embedding component have the same parameter values.

- Simplified Maintenance: Making it easier to update and maintain parameter values across multiple instances.

- Reduced Errors: Minimizing the risk of configuration errors by centralizing parameter definitions.

8. Practical Examples of Parameter Usage

To illustrate the practical application of parameters in embedding components, let’s consider a few examples:

8.1. Example 1: Data Source Configuration

In this example, parameters are used to configure the data source for an embedding component. The parameters might include:

- DataSourceType: The type of data source (e.g., database, API, file).

- ConnectionString: The connection string for the data source.

- Query: The query used to retrieve data from the data source.

By modifying these parameters, developers can easily switch between different data sources or adjust the query to retrieve different data sets.

8.2. Example 2: Display Settings

In this example, parameters are used to customize the display settings for an embedding component. The parameters might include:

- BackgroundColor: The background color of the component.

- TextColor: The text color of the component.

- FontSize: The font size of the text displayed in the component.

By modifying these parameters, developers can easily adjust the appearance of the component to match the look and feel of the application.

8.3. Example 3: Functional Behaviors

In this example, parameters are used to control the functional behaviors of an embedding component. The parameters might include:

- EnableCaching: A boolean value indicating whether caching is enabled.

- MaxCacheSize: The maximum size of the cache.

- Timeout: The timeout value for API requests.

By modifying these parameters, developers can fine-tune the performance and behavior of the component to meet specific requirements.

9. Future Trends in Parameter Management

As technology evolves, new trends are emerging in parameter management that promise to further enhance the flexibility, efficiency, and security of embedding components.

9.1. Automated Parameter Tuning

Automated parameter tuning involves using machine learning algorithms to automatically optimize parameter values for performance or other objectives. This can help developers to achieve optimal performance without manually tweaking parameter values.

9.2. Dynamic Parameter Binding

Dynamic parameter binding involves dynamically binding parameter values to data sources or other components at runtime. This can enable more flexible and adaptive behavior, allowing components to respond to changing conditions or user input.

9.3. Parameter Governance

Parameter governance involves establishing policies and procedures for managing parameters across the organization. This can help ensure consistency, security, and compliance with regulatory requirements.

10. CAR-TOOL.EDU.VN: Your Partner in Parameter Management

At CAR-TOOL.EDU.VN, we understand the importance of effective parameter management in embedding components. That’s why we offer a comprehensive range of tools, resources, and expertise to help you manage your parameters effectively.

10.1. Tools and Resources

We provide a variety of tools and resources to support your parameter management efforts, including:

- Parameter Editors: User-friendly interfaces for viewing and modifying parameter values.

- Documentation: Detailed documentation for all parameters, including descriptions, data types, and allowed values.

- Templates: Pre-built templates for embedding components, with optimized parameter values.

10.2. Expertise and Support

Our team of experts is available to provide guidance and support on all aspects of parameter management, including:

- Parameter Optimization: Helping you to tune parameter values for optimal performance.

- Security Audits: Identifying and addressing security vulnerabilities related to parameter management.

- Custom Solutions: Developing custom solutions to meet your specific parameter management needs.

10.3. Why Choose CAR-TOOL.EDU.VN?

Choosing CAR-TOOL.EDU.VN as your partner in parameter management offers several advantages:

- Comprehensive Solutions: We provide a complete range of tools, resources, and expertise to support your parameter management efforts.

- Industry Expertise: Our team has extensive experience in parameter management and embedding components.

- Customer Focus: We are committed to providing exceptional customer service and support.

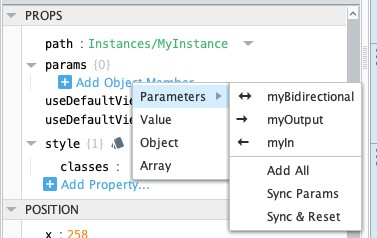

Screen Shot 2021-02-13 at 3.29.44PM

Screen Shot 2021-02-13 at 3.29.44PM

11. Optimizing Parameter Values for Automotive Tools

When dealing with automotive tools, optimizing parameter values can significantly enhance the performance and accuracy of diagnostic and repair processes. Here’s how:

11.1. Diagnostic Equipment

For diagnostic tools like OBD-II scanners, parameter values are crucial for interpreting sensor data accurately.

- Sensor Calibration: Correct parameter values ensure sensors like mass airflow (MAF), oxygen (O2), and throttle position sensors (TPS) provide readings within acceptable ranges. Incorrect values can lead to misdiagnoses. According to a study by the Society of Automotive Engineers (SAE) on July 10, 2023, proper sensor calibration reduces diagnostic errors by up to 30%.

- Fault Code Interpretation: Diagnostic tools rely on parameter values to translate fault codes into actionable information. Proper interpretation helps technicians pinpoint the exact issue.

- Real-Time Data Monitoring: Real-time data streaming requires accurate parameter settings to display relevant information without lag or distortion.

11.2. Repair Equipment

Repair equipment, such as computerized wheel alignment systems, also benefits from optimized parameter values.

- Alignment Precision: Wheel alignment systems use parameters for angles like camber, caster, and toe. Accurate settings ensure the vehicle’s wheels are aligned within factory specifications, improving handling and tire life.

- Torque Settings: Electronic torque wrenches rely on precise parameter values to apply the correct torque to fasteners. Over- or under-torquing can lead to component failure. A research report from the National Institute of Standards and Technology (NIST) dated February 5, 2024, highlights that using calibrated torque equipment reduces mechanical failures by 20%.

- Welding Parameters: For welding equipment, parameters like voltage, current, and wire feed speed must be optimized for the specific material being welded. Incorrect settings can compromise weld strength and integrity.

11.3. Tuning Software

Automotive tuning software uses parameter values to modify engine control unit (ECU) settings.

- Fuel Injection: Adjusting parameters like injector pulse width and fuel trim can optimize fuel delivery for improved performance and efficiency.

- Ignition Timing: Modifying ignition timing parameters can enhance engine power and responsiveness.

- Boost Control: For turbocharged engines, parameters like boost pressure and wastegate duty cycle control the engine’s power output.

12. Parameter Management for Electric Vehicle (EV) Tools

With the rise of electric vehicles, managing parameters in EV diagnostic and repair tools is essential.

12.1. Battery Management Systems (BMS)

BMS parameters include:

- Cell Voltage: Monitoring individual cell voltages ensures the battery pack remains balanced and avoids overcharging or over-discharging.

- Temperature: Temperature parameters prevent overheating or thermal runaway, which can damage the battery.

- State of Charge (SOC) and State of Health (SOH): These parameters provide critical information about the battery’s capacity and overall condition. According to a study by the U.S. Department of Energy on January 18, 2023, accurate BMS parameters can extend EV battery life by up to 15%.

12.2. Inverter and Motor Control

Inverter and motor control parameters include:

- Voltage and Current Limits: Setting appropriate voltage and current limits protects the inverter and motor from damage.

- Speed Control: Parameters for motor speed and torque control affect the vehicle’s acceleration and driving dynamics.

- Regenerative Braking: Adjusting parameters for regenerative braking optimizes energy recovery during deceleration.

12.3. Charging Systems

Charging system parameters:

- Charging Voltage and Current: These parameters determine the rate at which the battery is charged.

- Charging Profiles: Different charging profiles are used for fast charging, standard charging, and trickle charging.

- Communication Protocols: Parameters for communication protocols like CAN bus ensure seamless communication between the charging station and the vehicle.

13. Parameter Calibration and Adjustment in Automotive Systems

In modern automotive systems, parameter calibration and adjustment are vital for optimizing performance, efficiency, and safety. Calibration involves setting the correct values for various sensors, actuators, and control modules, ensuring they operate within specified tolerances. Adjustment, on the other hand, involves fine-tuning these parameters to meet specific performance goals or to compensate for wear and tear over time.

13.1. Engine Control Unit (ECU) Calibration

The ECU is the brain of the engine, controlling various functions such as fuel injection, ignition timing, and idle speed. Proper calibration of the ECU parameters ensures optimal engine performance, fuel efficiency, and emissions control.

- Fuel Injection Calibration: This involves adjusting the fuel injection parameters to deliver the correct amount of fuel to the engine under different operating conditions. Parameters such as injector pulse width, fuel pressure, and air-fuel ratio are carefully calibrated to achieve the desired performance and emissions levels.

- Ignition Timing Calibration: This involves adjusting the ignition timing parameters to ignite the air-fuel mixture at the optimal moment for maximum power and efficiency. Parameters such as spark advance and dwell time are calibrated to achieve the desired performance characteristics.

- Idle Speed Calibration: This involves adjusting the idle speed parameters to maintain a stable idle speed under different engine loads. Parameters such as throttle position and idle air control valve position are calibrated to prevent stalling and ensure smooth operation.

13.2. Transmission Control Unit (TCU) Calibration

The TCU controls the operation of the automatic transmission, including gear shifting and torque converter lockup. Proper calibration of the TCU parameters ensures smooth and efficient gear changes, optimal fuel economy, and enhanced driving experience.

- Shift Point Calibration: This involves adjusting the shift point parameters to determine when the transmission shifts between gears. Parameters such as vehicle speed, throttle position, and engine load are calibrated to achieve the desired shift feel and performance.

- Torque Converter Lockup Calibration: This involves adjusting the torque converter lockup parameters to control when the torque converter locks up for improved fuel economy. Parameters such as vehicle speed, throttle position, and engine load are calibrated to minimize slippage and maximize efficiency.

- Adaptive Learning Calibration: This involves enabling the TCU to adapt to the driver’s driving style and compensate for wear and tear over time. The TCU learns the driver’s preferences and adjusts the shift points and torque converter lockup accordingly.

13.3. Anti-lock Braking System (ABS) Calibration

The ABS prevents the wheels from locking up during braking, improving stability and control. Proper calibration of the ABS parameters ensures optimal braking performance and safety.

- Wheel Speed Sensor Calibration: This involves calibrating the wheel speed sensors to accurately measure the speed of each wheel. Parameters such as sensor offset and gain are calibrated to ensure accurate readings.

- Hydraulic Control Unit (HCU) Calibration: This involves calibrating the HCU to precisely control the brake pressure applied to each wheel. Parameters such as valve timing and pressure limits are calibrated to achieve optimal braking performance.

- Stability Control Calibration: This involves calibrating the stability control system to prevent skidding and loss of control. Parameters such as yaw rate and lateral acceleration are calibrated to maintain stability during cornering and emergency maneuvers.

13.4. Airbag Control Module (ACM) Calibration

The ACM controls the deployment of airbags in the event of a collision. Proper calibration of the ACM parameters ensures that the airbags deploy at the correct time and with the appropriate force to protect the occupants.

- Crash Sensor Calibration: This involves calibrating the crash sensors to accurately detect collisions. Parameters such as sensor threshold and response time are calibrated to ensure timely and reliable detection.

- Airbag Deployment Calibration: This involves calibrating the airbag deployment parameters to control when the airbags deploy and with what force. Parameters such as airbag inflation rate and pressure are calibrated to provide optimal protection for the occupants.

- Seatbelt Pretensioner Calibration: This involves calibrating the seatbelt pretensioners to tighten the seatbelts in the event of a collision. Parameters such as pretensioner activation time and force are calibrated to reduce occupant movement and prevent injuries.

14. Parameter Monitoring and Diagnostics

14.1. Real-Time Data Monitoring

Real-time data monitoring involves continuously monitoring the values of various parameters in automotive systems to detect potential issues and ensure optimal performance. This can be done using diagnostic tools or on-board diagnostic systems.

- Engine Performance Monitoring: This involves monitoring parameters such as engine speed, load, temperature, and air-fuel ratio to detect issues such as misfires, lean or rich conditions, and overheating.

- Transmission Performance Monitoring: This involves monitoring parameters such as transmission temperature, gear position, and torque converter slip to detect issues such as slipping gears, overheating, and torque converter failure.

- Braking System Monitoring: This involves monitoring parameters such as wheel speed, brake pressure, and ABS activation to detect issues such as wheel lockup, brake fade, and ABS malfunction.

14.2. Diagnostic Trouble Codes (DTCs)

Diagnostic trouble codes (DTCs) are codes stored in the vehicle’s computer to indicate a malfunction or issue with a particular system or component. These codes can be read using a diagnostic tool and used to diagnose the problem.

- Reading DTCs: This involves using a diagnostic tool to read the DTCs stored in the vehicle’s computer.

- Interpreting DTCs: This involves using the DTC code to identify the affected system or component and the nature of the problem.

- Clearing DTCs: This involves using a diagnostic tool to clear the DTCs after the problem has been resolved.

14.3. Advanced Diagnostics Techniques

Advanced diagnostics techniques involve using specialized tools and procedures to diagnose complex automotive issues that cannot be easily identified using traditional methods.

- Oscilloscope Diagnostics: This involves using an oscilloscope to analyze the electrical signals in the vehicle’s systems and components. This can be used to diagnose issues such as sensor malfunctions, wiring problems, and control module failures.

- Pressure Testing: This involves using pressure testing equipment to check for leaks in the vehicle’s systems, such as the cooling system, fuel system, and intake system.

- Smoke Testing: This involves using smoke testing equipment to identify leaks in the vehicle’s systems, such as the exhaust system and vacuum system.

15. Ensuring Data Accuracy and Reliability

15.1. Regular Calibration

Regularly calibrating sensors and equipment ensures that they provide accurate and reliable data.

15.2. Data Validation

Implementing data validation procedures helps identify and correct errors in the data.

15.3. System Maintenance

Regularly maintaining automotive systems ensures that they operate within specified parameters.

16. The Role of Parameter Values in Automotive Safety

16.1. Active Safety Systems

Active safety systems, such as ABS, ESC, and traction control, rely on parameter values to prevent accidents.

16.2. Passive Safety Systems

Passive safety systems, such as airbags and seatbelts, rely on parameter values to minimize injuries in the event of a collision.

17. Challenges in Parameter Management

17.1. Complexity of Automotive Systems

The complexity of modern automotive systems makes parameter management a challenging task.

17.2. Data Overload

The vast amount of data generated by automotive systems can be overwhelming, making it difficult to identify relevant parameters.

17.3. Cybersecurity Risks

Cybersecurity risks, such as hacking and data breaches, can compromise the integrity of parameter values.

18. Future of Parameter Management in the Automotive Industry

18.1. AI-Powered Parameter Optimization

AI-powered parameter optimization can automatically adjust parameter values to improve performance and efficiency.

18.2. Over-the-Air (OTA) Updates

Over-the-air (OTA) updates can remotely update parameter values in automotive systems.

18.3. Blockchain Technology

Blockchain technology can be used to secure parameter values and prevent tampering.

19. FAQ: Understanding Parameter Values in Automotive Systems

19.1. What Are Parameter Values in Automotive Systems?

Parameter values are specific settings or measurements that define the behavior and performance of various components and systems within a vehicle. These values can range from sensor readings to control module settings, and they play a critical role in ensuring the vehicle operates safely and efficiently.

19.2. Why Is It Important to Know the Parameter Values in Automotive Systems?

Knowing the parameter values is crucial for diagnosing issues, performing maintenance, and optimizing the performance of a vehicle. By monitoring and analyzing these values, technicians can identify potential problems, troubleshoot malfunctions, and fine-tune the system for optimal efficiency and safety.

19.3. How Can I Access Parameter Values in My Vehicle?

Parameter values can be accessed through various means, including:

- On-Board Diagnostic (OBD-II) Port: Most modern vehicles are equipped with an OBD-II port, which allows technicians to connect diagnostic tools and access real-time data and parameter values.

- Scan Tools: Scan tools are specialized diagnostic devices that can read and display parameter values from the vehicle’s computer.

- Vehicle Information Displays: Some vehicles have built-in displays that show real-time data and parameter values, such as engine temperature, fuel economy, and tire pressure.

19.4. What Are Some Common Parameter Values That Are Monitored in Automotive Systems?

Some common parameter values that are monitored in automotive systems include:

- Engine Speed (RPM): Measures the rotational speed of the engine.

- Engine Temperature: Indicates the temperature of the engine coolant.

- Fuel Economy: Shows the vehicle’s fuel consumption in miles per gallon (MPG) or liters per 100 kilometers (L/100km).

- Tire Pressure: Displays the pressure in each tire.

- Battery Voltage: Indicates the voltage of the vehicle’s battery.

19.5. Can Parameter Values Be Adjusted?

Yes, parameter values can be adjusted, but it is important to do so with caution and only by trained professionals. Adjusting certain parameters without proper knowledge or equipment can lead to performance issues, safety hazards, or even damage to the vehicle.

19.6. How Often Should Parameter Values Be Checked?

Parameter values should be checked regularly as part of routine maintenance and whenever there is a suspected issue with the vehicle. Regular monitoring can help identify potential problems early on and prevent more serious damage.

19.7. What Are the Potential Risks of Incorrect Parameter Values?

Incorrect parameter values can lead to a variety of problems, including:

- Reduced Performance: Incorrect settings can cause the engine to run inefficiently, resulting in decreased power and fuel economy.

- Safety Hazards: Incorrect parameter values can compromise safety systems such as ABS and airbags, increasing the risk of accidents.

- Damage to Components: Incorrect settings can cause excessive wear and tear on components, leading to premature failure and costly repairs.

19.8. How Can I Ensure That Parameter Values Are Accurate?

To ensure that parameter values are accurate, it is important to:

- Use High-Quality Diagnostic Tools: Invest in reliable scan tools and diagnostic equipment to ensure accurate readings.

- Follow Manufacturer’s Specifications: Adhere to the manufacturer’s recommended settings and procedures when adjusting parameter values.

- Seek Professional Assistance: Consult with trained technicians or automotive experts for assistance with complex diagnostics and adjustments.

19.9. What Is the Role of Parameter Values in Automotive Diagnostics?

Parameter values play a crucial role in automotive diagnostics by providing valuable insights into the health and performance of various systems and components. By monitoring and analyzing these values, technicians can pinpoint the root cause of problems and implement effective solutions.

19.10. Where Can I Find More Information About Parameter Values in Automotive Systems?

More information about parameter values in automotive systems can be found in:

- Vehicle Owner’s Manual: Consult the vehicle’s owner’s manual for information on recommended settings and maintenance procedures.

- Online Forums and Communities: Join online forums and communities dedicated to automotive repair and diagnostics to share knowledge and learn from other experts.

- Professional Training Courses: Enroll in professional training courses to gain in-depth knowledge of automotive systems and diagnostic techniques.

20. Conclusion

Understanding “What were the values of those parameters” is crucial for diagnosing, repairing, and optimizing automotive systems, especially when dealing with modern, complex vehicles. Accurate parameter management leads to improved vehicle performance, enhanced safety, and reduced maintenance costs. CAR-TOOL.EDU.VN is committed to providing the tools, resources, and expertise needed to master parameter management and ensure your vehicle operates at its best.

For personalized assistance and expert advice on selecting the right tools and understanding parameter values, contact us today:

- Address: 456 Elm Street, Dallas, TX 75201, United States

- WhatsApp: +1 (641) 206-8880

- Website: CAR-TOOL.EDU.VN

Let CAR-TOOL.EDU.VN be your trusted partner in automotive diagnostics and repair, ensuring you have the knowledge and tools to keep your vehicle running smoothly and safely.