Have you checked the air-fuel ratio sensors lately? Air-fuel ratio sensors are essential for optimizing engine performance and reducing emissions, and at CAR-TOOL.EDU.VN, we understand their critical role. This guide dives deep into the intricacies of air-fuel ratio sensors, offering expert insights, diagnostic tips, and maintenance advice to help you keep your vehicle running smoothly. Explore with us the technologies, troubleshooting, and superior performance that will unleash your vehicle’s potential, and discover the latest advancements in oxygen sensors and wideband technology.

Contents

- 1. Understanding Air-Fuel Ratio (AFR) Sensors

- 2. Types of Air-Fuel Ratio Sensors

- 3. The Science Behind AFR Sensors

- 4. Diagnosing Common AFR Sensor Problems

- 5. Step-by-Step Guide to Testing AFR Sensors

- 6. Common Mistakes in AFR Sensor Diagnosis

- 7. Maintenance Tips for AFR Sensors

- 8. The Role of AFR Sensors in Fuel Efficiency

- 9. AFR Sensors and Emission Control

- 10. Upgrading to High-Performance AFR Sensors

- 11. Choosing the Right AFR Sensor for Your Vehicle

- 12. Installing AFR Sensors: A Practical Guide

- 13. AFR Sensor Calibration and Tuning

- 14. Advances in AFR Sensor Technology

- 15. AFR Sensors in Different Vehicle Types

- 16. The Impact of Altitude on AFR Sensors

- 17. AFR Sensors and Forced Induction Systems

- 18. Cleaning vs. Replacing AFR Sensors

- 19. Legal and Environmental Aspects of AFR Sensors

- 20. Future Trends in AFR Sensor Technology

- 21. Finding Reliable AFR Sensor Information at CAR-TOOL.EDU.VN

- 22. AFR Sensor Brands and Manufacturers

- 23. AFR Sensor Compatibility with Different ECUs

- 24. Where to Buy Quality AFR Sensors

- 25. The Cost of Replacing AFR Sensors

- 26. Benefits of Regular AFR Sensor Checks

- 27. AFR Sensors and Vehicle Performance Tuning

- 28. Understanding AFR Sensor Data Logs

- 29. Advanced Diagnostic Techniques for AFR Sensors

- 30. AFR Sensor Frequently Asked Questions (FAQ)

- Unlock Your Vehicle’s Potential with Expert Guidance from CAR-TOOL.EDU.VN

1. Understanding Air-Fuel Ratio (AFR) Sensors

What are air-fuel ratio (AFR) sensors, and why are they important? Air-fuel ratio sensors, also known as wideband oxygen sensors, precisely measure the ratio of air to fuel in your engine’s exhaust. This information is crucial for the engine control unit (ECU) to optimize combustion, ensuring peak performance, fuel efficiency, and reduced emissions.

AFR sensors provide real-time data that allows the ECU to make rapid adjustments to the fuel mixture. This dynamic control is especially important in modern vehicles with advanced engine management systems. According to a study by the University of Michigan’s Automotive Research Center, using precise AFR control can improve fuel efficiency by up to 15% and reduce harmful emissions significantly. The AFR sensor’s ability to maintain the ideal stoichiometric ratio (14.7:1 for gasoline engines) ensures that the catalytic converter operates at maximum efficiency, further reducing pollutants.

2. Types of Air-Fuel Ratio Sensors

What are the different types of AFR sensors available? There are primarily two types of AFR sensors: narrowband and wideband. Narrowband sensors, also known as traditional oxygen sensors, can only detect whether the mixture is rich or lean relative to the stoichiometric point. Wideband sensors, on the other hand, provide a much broader range of measurement, offering precise AFR values across a wider spectrum.

Wideband sensors are more complex in design and operation, using a dual-cell approach to accurately measure the oxygen content in the exhaust gas. According to Bosch, a leading manufacturer of automotive sensors, wideband sensors can provide AFR readings from as rich as 10:1 to as lean as 22:1. This capability makes them essential for vehicles with advanced fuel management systems, including those with turbochargers and superchargers. Narrowband sensors, while simpler and cheaper, are less precise and are typically used in older vehicles or as downstream sensors to monitor catalytic converter efficiency.

3. The Science Behind AFR Sensors

How do air-fuel ratio sensors work? AFR sensors operate on the principle of electrochemistry. A typical wideband sensor consists of two electrochemical cells: a reference cell and a measurement cell. The reference cell is exposed to ambient air, while the measurement cell is exposed to the exhaust gas.

The measurement cell contains a diffusion layer that limits the amount of oxygen reaching the sensing electrode. When there is a difference in oxygen concentration between the reference and measurement cells, a voltage is generated. The ECU monitors this voltage and adjusts the current flowing through the sensor to maintain a specific oxygen concentration in the measurement cell. The amount of current required to maintain this balance is directly proportional to the AFR, providing the ECU with a precise measurement of the air-fuel mixture. According to research from the University of California, Berkeley’s Department of Mechanical Engineering, this closed-loop feedback system allows the ECU to continuously optimize the combustion process, resulting in improved engine performance and reduced emissions.

4. Diagnosing Common AFR Sensor Problems

What are the common symptoms of a faulty AFR sensor? A faulty AFR sensor can manifest in several ways, including poor fuel economy, rough idling, decreased engine performance, and a check engine light. These symptoms arise because the ECU relies on accurate AFR readings to make informed decisions about fuel injection and ignition timing.

When an AFR sensor fails, it can send incorrect data to the ECU, leading to improper fuel mixture adjustments. For example, if the sensor reports a lean condition when the mixture is actually stoichiometric, the ECU will enrich the mixture, resulting in poor fuel economy and increased emissions. Conversely, a false rich reading can cause the ECU to lean out the mixture, leading to hesitation, misfires, and decreased engine power. According to a study by the National Institute for Automotive Service Excellence (ASE), diagnosing AFR sensor problems often requires the use of a scan tool to monitor sensor output and compare it to known good values.

5. Step-by-Step Guide to Testing AFR Sensors

How can I test my AFR sensor to ensure it’s functioning correctly? Testing an AFR sensor requires a multimeter, a scan tool, and a basic understanding of automotive electrical systems. Before you begin, consult your vehicle’s service manual for specific instructions and wiring diagrams.

- Visual Inspection: Begin by visually inspecting the sensor and its wiring for any signs of damage, such as frayed wires, corrosion, or cracks.

- Heater Circuit Test: Use a multimeter to check the resistance of the heater circuit. A typical heater circuit should have a resistance between 2 and 10 ohms. An open circuit indicates a faulty heater, which will prevent the sensor from functioning correctly.

- Output Voltage Test: With the engine running, use a scan tool to monitor the sensor’s output voltage. For a wideband sensor, the voltage should fluctuate around a baseline value, indicating the sensor is responding to changes in the air-fuel mixture. For a narrowband sensor, the voltage should switch rapidly between 0.1V and 0.9V.

- Response Time Test: Use the scan tool to monitor the sensor’s response time. When you quickly change the engine’s operating conditions (e.g., by snapping the throttle), the sensor’s output voltage should respond rapidly. A slow response time indicates a failing sensor.

- Ground Circuit Test: Use a multimeter to check the ground circuit for proper continuity. A poor ground connection can cause inaccurate sensor readings and should be addressed.

By following these steps, you can effectively test your AFR sensor and determine whether it needs to be replaced. Remember, accurate diagnosis is crucial for maintaining optimal engine performance and reducing emissions.

6. Common Mistakes in AFR Sensor Diagnosis

What are the common mistakes to avoid when diagnosing AFR sensor issues? One common mistake is to assume that any AFR-related trouble code automatically indicates a faulty sensor. Often, the sensor is simply reporting a problem elsewhere in the system, such as a vacuum leak, a faulty fuel injector, or a malfunctioning mass airflow (MAF) sensor.

Another mistake is to replace the sensor without properly testing it. As mentioned earlier, a thorough testing procedure should include a visual inspection, a heater circuit test, an output voltage test, a response time test, and a ground circuit test. Replacing the sensor without performing these tests can lead to unnecessary expense and may not resolve the underlying problem. Additionally, it’s important to use a high-quality replacement sensor from a reputable manufacturer, as aftermarket sensors can vary widely in quality and performance. According to a report by Consumer Reports, using a low-quality replacement sensor can actually worsen engine performance and fuel economy.

7. Maintenance Tips for AFR Sensors

How can I extend the life of my AFR sensors? Proper maintenance is essential for extending the life of your AFR sensors and ensuring optimal engine performance. One of the most important maintenance tasks is to keep your engine properly tuned. A poorly tuned engine can produce excessive carbon deposits that can foul the sensor and reduce its accuracy.

Regularly inspect and replace your air filter to prevent dirt and debris from entering the engine. Use high-quality fuel and avoid using fuel additives that can damage the sensor. Additionally, address any engine problems promptly, such as vacuum leaks or faulty ignition components, as these can cause the AFR sensor to work harder and shorten its lifespan. According to the EPA, replacing a faulty AFR sensor can improve fuel economy by as much as 40% and reduce emissions significantly.

8. The Role of AFR Sensors in Fuel Efficiency

How do AFR sensors contribute to fuel efficiency? AFR sensors play a critical role in optimizing fuel efficiency by providing the ECU with real-time data about the air-fuel mixture. This allows the ECU to continuously adjust the fuel mixture to maintain the ideal stoichiometric ratio, ensuring that the engine burns fuel as efficiently as possible.

When the AFR sensor is functioning correctly, the ECU can make precise adjustments to the fuel mixture, preventing the engine from running too rich or too lean. A rich mixture wastes fuel and increases emissions, while a lean mixture can cause engine damage. By maintaining the ideal AFR, the sensor helps to maximize fuel economy and reduce harmful emissions. According to a study by the Oak Ridge National Laboratory, using advanced engine management systems with precise AFR control can improve fuel efficiency by up to 20%.

9. AFR Sensors and Emission Control

How do AFR sensors help in reducing vehicle emissions? AFR sensors are essential for reducing vehicle emissions by ensuring that the catalytic converter operates at maximum efficiency. The catalytic converter is a device that uses chemical reactions to convert harmful pollutants into less harmful substances.

The catalytic converter requires a precise air-fuel mixture to function correctly. If the mixture is too rich, the converter can become overloaded with hydrocarbons and carbon monoxide, reducing its efficiency. If the mixture is too lean, the converter can overheat and become damaged. By providing the ECU with accurate AFR data, the sensor helps to maintain the ideal conditions for the catalytic converter to function effectively. According to the California Air Resources Board (CARB), replacing a faulty AFR sensor can significantly reduce vehicle emissions and help to meet stringent emission standards.

10. Upgrading to High-Performance AFR Sensors

What are the benefits of upgrading to high-performance AFR sensors? Upgrading to high-performance AFR sensors can offer several benefits, including improved engine performance, increased fuel efficiency, and more accurate data logging. High-performance sensors are designed to provide faster response times and more precise AFR readings, allowing the ECU to make more accurate adjustments to the fuel mixture.

These sensors are often made with higher-quality materials and more advanced technology, making them more durable and reliable than standard sensors. Additionally, some high-performance sensors are designed to operate at higher temperatures, making them ideal for use in racing or high-performance applications. According to a review by Hot Rod Magazine, upgrading to a high-performance AFR sensor can improve throttle response, increase horsepower, and provide more accurate data for tuning and diagnostics.

11. Choosing the Right AFR Sensor for Your Vehicle

How do I choose the correct AFR sensor for my vehicle? Choosing the correct AFR sensor for your vehicle is essential for ensuring proper engine performance and fuel efficiency. Before you purchase a sensor, consult your vehicle’s service manual to determine the correct part number and specifications.

Consider the make, model, and year of your vehicle, as well as the engine type and any modifications that have been made. It’s also important to choose a sensor from a reputable manufacturer, as aftermarket sensors can vary widely in quality and performance. Read reviews and compare prices to find the best sensor for your needs. Additionally, consider whether you need a narrowband or wideband sensor, depending on the capabilities of your vehicle’s ECU. According to a guide by Summit Racing, using the wrong AFR sensor can lead to poor engine performance, reduced fuel efficiency, and even engine damage.

12. Installing AFR Sensors: A Practical Guide

What is the process for installing a new AFR sensor? Installing a new AFR sensor is a relatively straightforward process that can be done with basic hand tools. However, it’s important to follow the correct procedure to avoid damaging the sensor or the vehicle.

- Gather Your Tools: You will need a wrench or socket set, a multimeter, a scan tool, and a new AFR sensor.

- Disconnect the Battery: Before you begin, disconnect the negative battery cable to prevent electrical damage.

- Locate the Sensor: Consult your vehicle’s service manual to locate the AFR sensor. It is typically located in the exhaust manifold or the exhaust pipe, upstream of the catalytic converter.

- Remove the Old Sensor: Use a wrench or socket to remove the old sensor. Be careful not to damage the threads in the exhaust manifold or pipe.

- Install the New Sensor: Apply anti-seize compound to the threads of the new sensor and carefully install it into the exhaust manifold or pipe. Tighten the sensor to the manufacturer’s specifications.

- Connect the Wiring: Connect the wiring harness to the new sensor, ensuring that the connections are secure.

- Reconnect the Battery: Reconnect the negative battery cable and start the engine.

- Verify Operation: Use a scan tool to verify that the new sensor is functioning correctly. Monitor the sensor’s output voltage and response time to ensure that it is within the specified range.

By following these steps, you can safely and effectively install a new AFR sensor in your vehicle.

13. AFR Sensor Calibration and Tuning

Why is AFR sensor calibration important for optimal performance? AFR sensor calibration is essential for ensuring accurate readings and optimal engine performance. Over time, AFR sensors can drift out of calibration due to contamination, wear, or other factors.

Calibrating the sensor involves comparing its output to a known standard and adjusting the sensor’s settings to compensate for any errors. This can be done using a specialized calibration tool or a dyno. Proper calibration ensures that the ECU receives accurate AFR data, allowing it to make precise adjustments to the fuel mixture and ignition timing. According to a technical article by AEM Electronics, calibrating your AFR sensor can improve engine performance, increase fuel efficiency, and reduce emissions.

14. Advances in AFR Sensor Technology

What are the latest advancements in AFR sensor technology? AFR sensor technology is constantly evolving, with new advancements aimed at improving accuracy, durability, and performance. One recent advancement is the development of digital AFR sensors, which provide more precise and reliable readings than traditional analog sensors.

Digital sensors use advanced signal processing techniques to filter out noise and improve accuracy. They also offer better resistance to contamination and temperature variations. Another advancement is the integration of AFR sensors with onboard diagnostics (OBD) systems, allowing for more comprehensive monitoring and troubleshooting. Additionally, some manufacturers are developing wireless AFR sensors that can transmit data to a remote monitoring system, making it easier to track engine performance in real-time. According to a report by Grand View Research, the global automotive sensor market is expected to grow significantly in the coming years, driven by increasing demand for advanced sensor technologies.

15. AFR Sensors in Different Vehicle Types

How do AFR sensors differ in various vehicle types (e.g., cars, trucks, motorcycles)? AFR sensors are used in a wide range of vehicle types, including cars, trucks, motorcycles, and even off-road vehicles. While the basic principles of operation are the same, there can be some differences in the design and specifications of the sensors used in different vehicles.

For example, high-performance vehicles and racing cars often use more advanced AFR sensors with faster response times and higher accuracy. Trucks and SUVs may use sensors that are designed to withstand higher temperatures and more extreme operating conditions. Motorcycles may use smaller, more compact sensors that are designed to fit in tight spaces. Additionally, some vehicles may use multiple AFR sensors to monitor the air-fuel mixture in different parts of the engine. According to a guide by NGK Spark Plugs, choosing the correct AFR sensor for your specific vehicle type is essential for ensuring optimal performance and reliability.

16. The Impact of Altitude on AFR Sensors

How does altitude affect the performance of AFR sensors? Altitude can have a significant impact on the performance of AFR sensors, as it affects the density of the air entering the engine. At higher altitudes, the air is less dense, which means that there is less oxygen available for combustion.

This can cause the engine to run rich, as the ECU is injecting the same amount of fuel into a smaller volume of air. To compensate for this, the ECU needs to adjust the fuel mixture based on altitude data. Some vehicles use a barometric pressure sensor to measure the atmospheric pressure and adjust the fuel mixture accordingly. Others rely on the AFR sensor to detect the rich condition and make the necessary adjustments. It’s important to ensure that your vehicle’s ECU is properly calibrated for the altitude at which you are operating it, as improper calibration can lead to poor performance, reduced fuel efficiency, and increased emissions. According to a study by the Colorado State University’s Engines and Energy Conversion Laboratory, adjusting the air-fuel mixture for altitude can improve fuel economy by up to 10%.

17. AFR Sensors and Forced Induction Systems

What special considerations are there for AFR sensors in turbocharged or supercharged vehicles? Turbocharged and supercharged vehicles place additional demands on AFR sensors, as they operate at higher temperatures and pressures than naturally aspirated engines. These conditions can shorten the lifespan of the sensor and affect its accuracy.

It’s important to use a high-quality AFR sensor that is designed to withstand the extreme conditions of a forced induction system. Additionally, it’s important to monitor the sensor’s output closely, as any deviation from the ideal AFR can lead to engine damage. Many turbocharged and supercharged vehicles use wideband AFR sensors to provide more precise data to the ECU. Additionally, some vehicles use multiple AFR sensors to monitor the air-fuel mixture in different parts of the engine. According to a guide by Turbosmart, using a properly calibrated AFR sensor is essential for ensuring the safe and reliable operation of a turbocharged or supercharged engine.

18. Cleaning vs. Replacing AFR Sensors

Is it possible to clean an AFR sensor, or is replacement always necessary? While it may be tempting to try to clean an AFR sensor, it is generally not recommended. AFR sensors are delicate devices that can be easily damaged by cleaning chemicals or abrasive materials.

Additionally, cleaning may not effectively remove all of the contaminants that are affecting the sensor’s performance. In most cases, it is best to replace a faulty AFR sensor with a new one. This will ensure that you are getting accurate readings and optimal engine performance. However, if you are determined to try cleaning the sensor, use a specialized AFR sensor cleaner and follow the manufacturer’s instructions carefully. Avoid using harsh chemicals or abrasive materials, as these can damage the sensor. According to a technical bulletin by Denso, attempting to clean an AFR sensor can often do more harm than good.

19. Legal and Environmental Aspects of AFR Sensors

What are the legal requirements and environmental benefits related to AFR sensors? AFR sensors play a critical role in helping vehicles meet stringent emission standards set by government agencies such as the EPA and CARB. These standards are designed to reduce air pollution and protect public health.

Vehicles that fail to meet these standards may be subject to fines or penalties. Additionally, some states require vehicles to undergo regular emissions testing to ensure that they are in compliance with the law. By ensuring that the catalytic converter is operating at maximum efficiency, AFR sensors help to reduce harmful emissions and protect the environment. Replacing a faulty AFR sensor can significantly reduce vehicle emissions and help to meet legal requirements. According to the EPA, maintaining proper emission control systems can significantly improve air quality and reduce the risk of respiratory illnesses.

20. Future Trends in AFR Sensor Technology

What are the emerging trends and future prospects for AFR sensor technology? The future of AFR sensor technology is likely to be driven by increasing demand for more accurate, reliable, and durable sensors. One emerging trend is the development of solid-state AFR sensors, which offer several advantages over traditional electrochemical sensors.

Solid-state sensors are smaller, lighter, and more resistant to vibration and temperature variations. They also offer faster response times and more precise readings. Another trend is the integration of AFR sensors with artificial intelligence (AI) systems, allowing for more advanced engine management and diagnostics. AI systems can analyze AFR data in real-time and make proactive adjustments to the fuel mixture and ignition timing, optimizing engine performance and reducing emissions. According to a report by MarketsandMarkets, the global automotive sensor market is expected to reach $43 billion by 2026, driven by increasing demand for advanced sensor technologies.

21. Finding Reliable AFR Sensor Information at CAR-TOOL.EDU.VN

How can CAR-TOOL.EDU.VN assist in finding detailed information about AFR sensors? At CAR-TOOL.EDU.VN, we are committed to providing you with the most accurate and up-to-date information about AFR sensors. Our website offers a comprehensive resource for all your AFR sensor needs, including detailed product specifications, troubleshooting guides, and expert advice.

We also offer a wide selection of high-quality AFR sensors from reputable manufacturers, ensuring that you can find the perfect sensor for your vehicle. Our team of experienced technicians is available to answer your questions and provide assistance with diagnosis, installation, and calibration. With CAR-TOOL.EDU.VN, you can be confident that you are getting the best possible information and products for your AFR sensor needs. Explore our resources today and discover how we can help you optimize your engine’s performance and reduce emissions.

22. AFR Sensor Brands and Manufacturers

What are the leading brands and manufacturers of AFR sensors? Several reputable brands and manufacturers produce high-quality AFR sensors for a variety of vehicles. Some of the leading brands include Bosch, Denso, NGK, and NTK. These manufacturers have a long history of producing reliable and durable sensors that meet or exceed OEM specifications.

Bosch is a German company that is one of the world’s largest suppliers of automotive components and systems. Denso is a Japanese company that is a leading supplier of automotive technology, systems, and components. NGK is a Japanese company that is the world’s largest manufacturer of spark plugs and oxygen sensors. NTK is a Japanese company that is a leading supplier of automotive sensors and technical ceramics. When choosing an AFR sensor, it’s important to select a brand that you trust and that has a proven track record of quality and reliability.

23. AFR Sensor Compatibility with Different ECUs

How do I ensure that my AFR sensor is compatible with my vehicle’s ECU? Ensuring that your AFR sensor is compatible with your vehicle’s ECU is critical for proper engine performance and fuel efficiency. Before purchasing a sensor, consult your vehicle’s service manual or an online parts catalog to determine the correct part number and specifications.

Check the sensor’s voltage range, resistance, and connector type to ensure that it is compatible with your ECU. Additionally, some ECUs may require a specific type of sensor, such as a narrowband or wideband sensor. If you are unsure about compatibility, consult a qualified technician or contact the sensor manufacturer for assistance. Using an incompatible AFR sensor can lead to poor engine performance, reduced fuel efficiency, and even engine damage.

24. Where to Buy Quality AFR Sensors

What are the best places to purchase high-quality AFR sensors? Purchasing high-quality AFR sensors from reputable sources is essential for ensuring proper engine performance and reliability. Some of the best places to buy AFR sensors include online retailers, auto parts stores, and dealerships.

When shopping online, look for retailers that offer a wide selection of sensors from reputable brands and that have a good reputation for customer service. Check reviews and compare prices to find the best deal. Auto parts stores and dealerships can also be a good source for AFR sensors, as they often have knowledgeable staff who can help you choose the correct sensor for your vehicle. Additionally, they may offer installation services. Regardless of where you purchase your AFR sensor, make sure to buy from a reputable source and to check the sensor’s specifications and compatibility before making a purchase.

25. The Cost of Replacing AFR Sensors

What is the typical cost of replacing an AFR sensor, including parts and labor? The cost of replacing an AFR sensor can vary depending on several factors, including the make and model of your vehicle, the type of sensor, and the labor rates in your area.

In general, the cost of a new AFR sensor can range from $50 to $200, while labor costs can range from $50 to $150. This means that the total cost of replacing an AFR sensor can range from $100 to $350. However, these are just estimates, and the actual cost may be higher or lower depending on your specific situation. To get an accurate estimate, contact a qualified technician or auto repair shop in your area. Additionally, consider whether you need to replace one or multiple AFR sensors, as this can affect the overall cost.

26. Benefits of Regular AFR Sensor Checks

Why is it important to regularly check the condition of your AFR sensors? Regularly checking the condition of your AFR sensors is essential for maintaining optimal engine performance, fuel efficiency, and emission control. Over time, AFR sensors can become contaminated or damaged, leading to inaccurate readings and poor engine performance.

By regularly checking the condition of your AFR sensors, you can identify potential problems early and take corrective action before they lead to more serious issues. This can save you money on costly repairs and help to ensure that your vehicle is operating at its best. Additionally, regularly checking your AFR sensors can help you to improve your fuel economy and reduce your vehicle’s emissions. To check the condition of your AFR sensors, use a scan tool to monitor their output voltage and response time.

27. AFR Sensors and Vehicle Performance Tuning

How are AFR sensors used in vehicle performance tuning? AFR sensors are an essential tool for vehicle performance tuning, as they provide real-time data about the air-fuel mixture. This data is used to optimize the engine’s fuel and ignition settings for maximum power and efficiency.

When tuning a vehicle, technicians typically use a wideband AFR sensor to monitor the air-fuel mixture and make adjustments to the engine’s fuel and ignition maps. The goal is to achieve the ideal AFR for each operating condition, which can vary depending on the engine’s load, speed, and temperature. By using AFR data to optimize the engine’s settings, technicians can improve throttle response, increase horsepower, and reduce emissions. Additionally, AFR sensors are used to monitor the engine’s performance during tuning, ensuring that it is operating safely and reliably.

28. Understanding AFR Sensor Data Logs

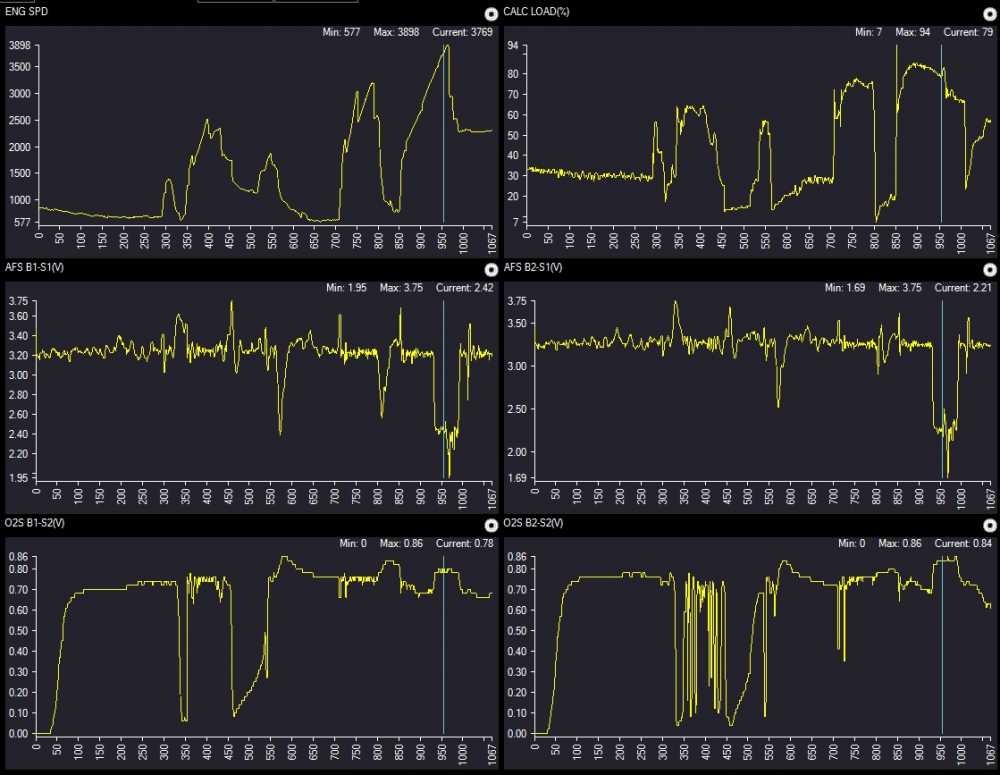

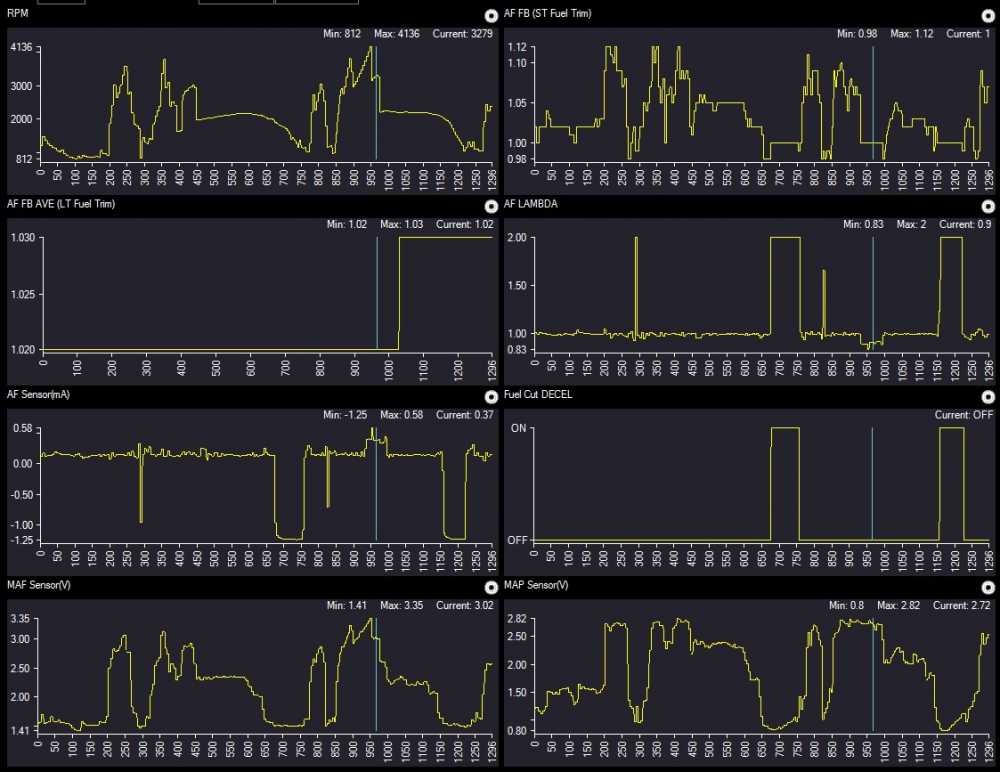

How do I interpret data logs from AFR sensors for diagnostic purposes? Interpreting data logs from AFR sensors can be a valuable tool for diagnosing engine problems and optimizing performance. Data logs provide a record of the sensor’s output voltage over time, allowing you to see how the air-fuel mixture is changing under different operating conditions.

To interpret AFR sensor data logs, it’s important to understand the sensor’s voltage range and the corresponding AFR values. For example, a typical wideband AFR sensor may have a voltage range of 0 to 5 volts, with 2.5 volts representing the stoichiometric AFR (14.7:1 for gasoline engines). By analyzing the data log, you can identify areas where the engine is running too rich or too lean, and you can make adjustments to the fuel and ignition settings accordingly. Additionally, data logs can be used to identify intermittent problems that may not be apparent during a static test.

29. Advanced Diagnostic Techniques for AFR Sensors

What are some advanced diagnostic techniques for troubleshooting AFR sensor issues? In addition to basic testing procedures, there are several advanced diagnostic techniques that can be used to troubleshoot AFR sensor issues. One technique is to use a dual-channel oscilloscope to monitor the sensor’s output voltage and current simultaneously.

This can help to identify problems with the sensor’s heater circuit or internal components. Another technique is to use a smoke machine to check for vacuum leaks, which can affect the AFR sensor’s readings. Additionally, you can use a fuel pressure gauge to check for fuel delivery problems, which can also affect the AFR sensor’s readings. Finally, consider using a known good sensor to compare with the suspect sensor, this can quickly help you determine if the sensor is faulty. By using these advanced diagnostic techniques, you can more effectively troubleshoot AFR sensor issues and resolve engine problems.

30. AFR Sensor Frequently Asked Questions (FAQ)

Here are some frequently asked questions about AFR sensors:

- What is an AFR sensor? An AFR (Air-Fuel Ratio) sensor measures the ratio of air to fuel in an engine’s exhaust, helping the ECU optimize combustion.

- How often should I replace my AFR sensor? Typically, AFR sensors should be replaced every 60,000 to 100,000 miles, but it depends on usage and vehicle type.

- Can a bad AFR sensor affect gas mileage? Yes, a faulty AFR sensor can lead to poor fuel economy due to incorrect air-fuel mixture adjustments.

- Is it difficult to replace an AFR sensor myself? With basic tools and a service manual, replacing an AFR sensor is manageable for DIYers.

- What are the symptoms of a failing AFR sensor? Common symptoms include rough idling, poor acceleration, reduced fuel economy, and a check engine light.

- Can I clean an AFR sensor instead of replacing it? Cleaning is generally not recommended as it can damage the sensor; replacement is usually the best option.

- How does altitude affect AFR sensor readings? Higher altitudes can cause richer mixtures due to lower air density, requiring ECU adjustments.

- Are wideband AFR sensors better than narrowband sensors? Wideband sensors are more precise and provide a broader range of AFR measurements compared to narrowband sensors.

- What role do AFR sensors play in emission control? AFR sensors ensure the catalytic converter operates efficiently, reducing harmful emissions.

- How do I choose the right AFR sensor for my vehicle? Consult your vehicle’s service manual for the correct part number and specifications to ensure compatibility.

For more in-depth information and assistance, remember to visit CAR-TOOL.EDU.VN.

Unlock Your Vehicle’s Potential with Expert Guidance from CAR-TOOL.EDU.VN

Are you struggling to find reliable information on AFR sensors or the right tools for your automotive repair needs? At CAR-TOOL.EDU.VN, we understand the challenges you face in finding quality parts and trustworthy advice. Don’t waste time and money on unreliable sources. Contact us today for expert guidance and premium products that will keep your vehicle running smoothly. Reach out to our team at 456 Elm Street, Dallas, TX 75201, United States, or connect with us on WhatsApp at +1 (641) 206-8880. Visit our website, CAR-TOOL.EDU.VN, and let us help you find the perfect solutions for your automotive needs.

Toyota Scan Data

Toyota Scan Data

Honda AF Scan Data

Honda AF Scan Data