A Free Car Diagnostic Flow Chart is a crucial resource for technicians and car enthusiasts alike, offering a systematic approach to identifying automotive problems. At CAR-TOOL.EDU.VN, we understand the importance of accurate diagnostics and provide the necessary tools and information to streamline the process, ensuring efficient troubleshooting and repair. Explore our resources for automotive diagnostic processes, troubleshooting guides, and repair solutions.

Contents

- 1. What Is A Car Diagnostic Flow Chart And Why Do I Need One?

- 1.1 What Key Elements Should A Car Diagnostic Flow Chart Include?

- 2. Where Can I Find A Free Car Diagnostic Flow Chart?

- 2.1 How Can CAR-TOOL.EDU.VN Help Me Find The Right Diagnostic Flow Chart?

- 3. What Are The Benefits Of Using A Free Car Diagnostic Flow Chart?

- 3.1 How Can A Diagnostic Flow Chart Help Me Save Time And Money?

- 4. What Are The Common Types Of Car Diagnostic Flow Charts?

- 4.1 Can You Provide Examples Of Specific Diagnostic Flow Charts?

- 5. What Tools Do I Need To Use A Car Diagnostic Flow Chart Effectively?

- 5.1 What Diagnostic Tools Does CAR-TOOL.EDU.VN Recommend?

- 6. How Do I Interpret The Results Of A Car Diagnostic Flow Chart?

- 6.1 What Do I Do If The Flow Chart Doesn’t Lead To A Solution?

- 7. How Can I Maintain My Car To Prevent Diagnostic Issues?

- 7.1 What Are The Key Preventive Maintenance Tasks?

- 8. Where Can I Get Professional Diagnostic Assistance If I Can’t Figure It Out Myself?

- 8.1 How Do I Choose The Right Automotive Technician?

- 9. What Are Some Advanced Diagnostic Techniques Beyond Flow Charts?

- 9.1 How Does Oscilloscope Testing Work?

- 10. How Is Technology Changing Car Diagnostics?

- 10.1 What Future Trends Can We Expect In Automotive Diagnostics?

- FAQ: Free Car Diagnostic Flow Chart

- What Is The Purpose Of A Car Diagnostic Flow Chart?

- Where Can I Find Free Car Diagnostic Flow Charts?

- What Are The Key Elements Of A Car Diagnostic Flow Chart?

- What Tools Do I Need To Use A Car Diagnostic Flow Chart Effectively?

- How Do I Interpret The Results Of A Car Diagnostic Flow Chart?

1. What Is A Car Diagnostic Flow Chart And Why Do I Need One?

A car diagnostic flow chart is a visual representation of a step-by-step process used to identify the root cause of a problem in a vehicle. This structured approach helps technicians systematically eliminate potential issues, leading to an accurate diagnosis and effective repair, saving time and reducing the risk of unnecessary part replacements.

- Structured Troubleshooting: A diagnostic flow chart offers a clear, methodical approach to identifying car problems, guiding technicians through a series of tests and checks to pinpoint the exact issue.

- Efficiency: By following a structured chart, technicians can avoid random guesswork and focus on targeted diagnostics, saving valuable time and resources. According to a study by the National Institute for Automotive Service Excellence (ASE), using diagnostic flow charts can reduce diagnostic time by up to 40%.

- Accuracy: Flow charts minimize the chances of misdiagnosis by ensuring all potential causes are systematically evaluated, leading to more accurate and reliable repairs.

- Cost Savings: Accurate diagnostics prevent the unnecessary replacement of parts, saving both the technician and the vehicle owner money.

- Skill Enhancement: For less experienced technicians, diagnostic flow charts serve as a learning tool, helping them understand the intricacies of automotive systems and improve their diagnostic skills.

- Standardization: Flow charts promote a standardized approach to diagnostics, ensuring that all technicians follow the same procedures, leading to consistent and reliable results.

- Improved Communication: Diagnostic flow charts can be used to explain complex issues to customers in a clear and understandable manner, improving trust and satisfaction.

- Complex System Navigation: Modern vehicles are equipped with complex electronic systems, and diagnostic flow charts provide a roadmap for navigating these systems effectively.

1.1 What Key Elements Should A Car Diagnostic Flow Chart Include?

A comprehensive car diagnostic flow chart should include several key elements to ensure accurate and efficient troubleshooting. These elements provide a structured approach to diagnosing automotive problems, guiding technicians through a systematic process of elimination.

| Element | Description |

|---|---|

| Symptom Verification | A clear description of the problem the vehicle is experiencing. This helps to ensure that the diagnostic process is focused on the correct issue. |

| Initial Inspection | A thorough visual inspection of the vehicle, including checking for any obvious signs of damage, loose connections, or leaks. |

| Diagnostic Trouble Codes | Information about any Diagnostic Trouble Codes (DTCs) that have been triggered. These codes provide valuable clues about the nature and location of the problem. |

| Step-by-Step Instructions | A series of sequential steps that the technician should follow to diagnose the problem. Each step should be clearly defined and easy to understand. |

| Decision Points | Points in the flow chart where the technician must make a decision based on the results of a test or inspection. These decision points guide the technician to the next appropriate step in the diagnostic process. |

| Testing Procedures | Detailed instructions on how to perform specific tests, such as using a multimeter to check voltage or resistance. These procedures should include information on the tools and equipment needed, as well as any safety precautions that should be taken. |

| Expected Values | The expected values for each test, which the technician can use to determine whether the component or circuit is functioning properly. |

| Possible Causes | A list of potential causes for the problem, based on the results of the tests and inspections. This helps the technician to narrow down the possible solutions. |

| Corrective Actions | The recommended actions to take to fix the problem, such as replacing a faulty component or repairing a damaged wire. |

| Verification | A final step to verify that the problem has been resolved and that the vehicle is functioning properly. This may involve repeating the initial symptom verification or performing additional tests to confirm the repair. |

| Diagrams/Illustrations | Visual aids such as wiring diagrams, component locations, and testing setups. |

| Notes/Cautions | Any specific notes or cautions related to particular steps or components. |

By including these key elements, a car diagnostic flow chart can provide a comprehensive and effective guide for diagnosing and repairing automotive problems. For more detailed information and resources, visit CAR-TOOL.EDU.VN, where you can find expert advice and quality tools to assist in your diagnostic endeavors.

2. Where Can I Find A Free Car Diagnostic Flow Chart?

Finding a free car diagnostic flow chart can be easier than you think. Several resources offer these charts to assist with automotive troubleshooting. Here are some reliable places to look:

- Online Forums: Automotive forums often have threads dedicated to diagnostics, where experienced members share flow charts and troubleshooting tips.

- Manufacturer Websites: Some manufacturers provide diagnostic flow charts as part of their service information. Check the official websites of car brands for technical documents.

- Automotive Repair Websites: Websites like CAR-TOOL.EDU.VN offer a variety of diagnostic resources, including flow charts, guides, and tool recommendations.

- Public Libraries: Libraries may have automotive repair manuals that include diagnostic flow charts.

- Educational Institutions: Automotive schools and colleges sometimes provide free resources on their websites.

2.1 How Can CAR-TOOL.EDU.VN Help Me Find The Right Diagnostic Flow Chart?

CAR-TOOL.EDU.VN is dedicated to providing comprehensive resources for automotive diagnostics. Here’s how we can assist you in finding the right diagnostic flow chart:

- Extensive Database: We maintain an extensive database of diagnostic flow charts covering various makes, models, and systems.

- Expert Advice: Our team of experienced technicians provides expert advice on selecting and using diagnostic flow charts effectively.

- Tool Recommendations: We recommend the best diagnostic tools and equipment to complement the flow charts, ensuring accurate and efficient troubleshooting.

- Step-by-Step Guides: We offer step-by-step guides on how to use diagnostic flow charts to diagnose and repair common automotive problems.

- Community Support: Our online community provides a platform for technicians to share their experiences and insights, helping you find the best solutions for your specific needs.

By leveraging the resources available at CAR-TOOL.EDU.VN, you can quickly find the right diagnostic flow chart and gain the knowledge and tools necessary to tackle any automotive diagnostic challenge.

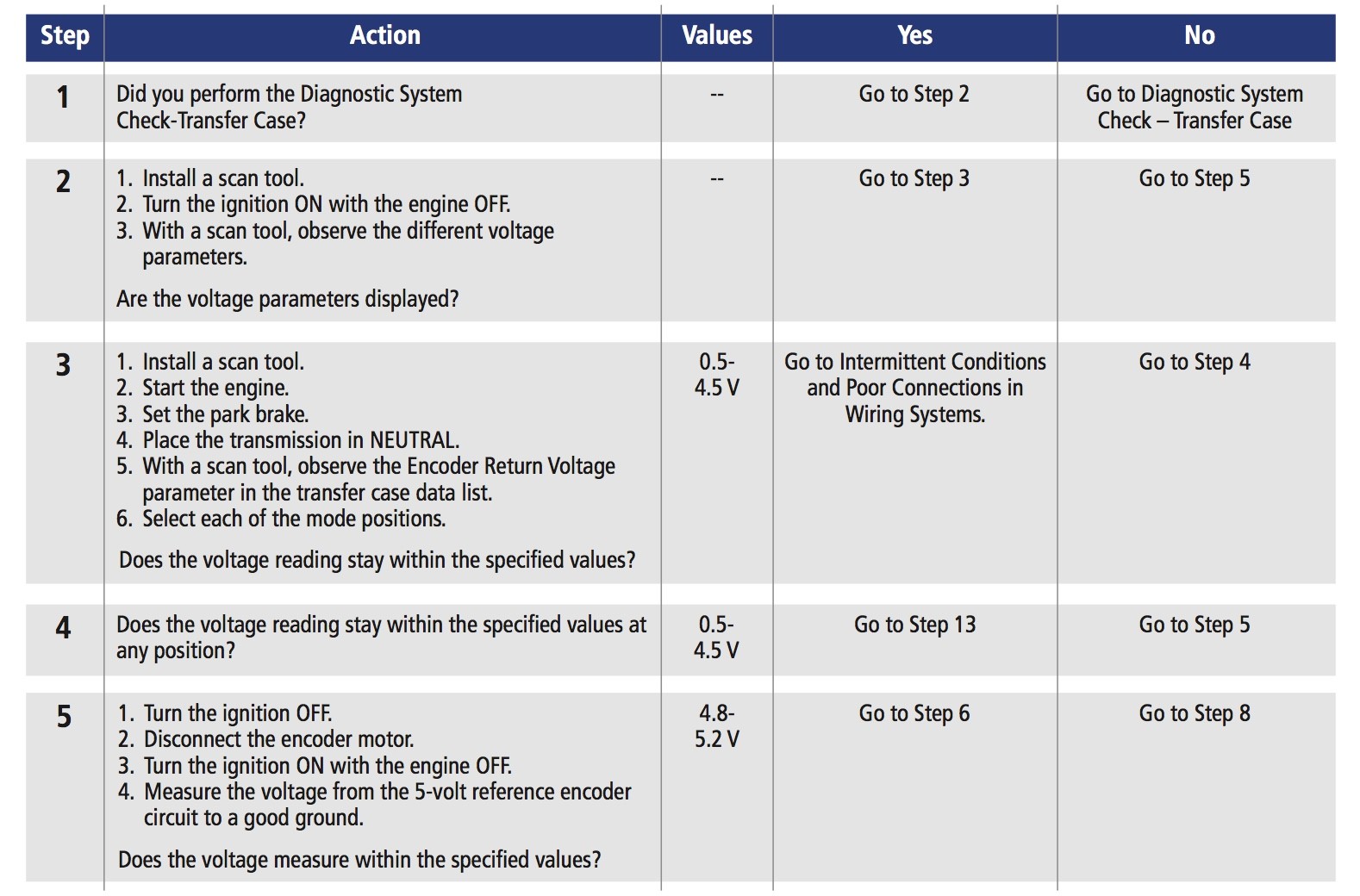

Automotive Diagnostic Flow Chart

Automotive Diagnostic Flow Chart

3. What Are The Benefits Of Using A Free Car Diagnostic Flow Chart?

Using a free car diagnostic flow chart provides numerous benefits for both professional technicians and DIY enthusiasts. These charts offer a structured approach to troubleshooting, ensuring accuracy, efficiency, and cost savings.

- Systematic Troubleshooting: Diagnostic flow charts guide users through a step-by-step process, ensuring no potential issue is overlooked.

- Time Savings: By following a structured chart, technicians can quickly identify the root cause of a problem, reducing diagnostic time.

- Accuracy: Flow charts minimize the risk of misdiagnosis by ensuring all potential causes are systematically evaluated.

- Cost Savings: Accurate diagnostics prevent the unnecessary replacement of parts, saving both the technician and the vehicle owner money.

- Improved Understanding: Using flow charts helps technicians better understand the intricacies of automotive systems, enhancing their diagnostic skills.

- Standardization: Flow charts promote a standardized approach to diagnostics, ensuring consistent and reliable results.

- Enhanced Communication: Diagnostic flow charts can be used to explain complex issues to customers in a clear and understandable manner, improving trust and satisfaction.

- Complex System Navigation: Modern vehicles are equipped with complex electronic systems, and diagnostic flow charts provide a roadmap for navigating these systems effectively.

3.1 How Can A Diagnostic Flow Chart Help Me Save Time And Money?

A diagnostic flow chart can significantly reduce both the time and money spent on automotive repairs. Here’s how:

- Targeted Diagnostics: Flow charts guide technicians directly to the source of the problem, avoiding unnecessary inspections and tests.

- Reduced Part Replacements: Accurate diagnostics prevent the replacement of functional parts, saving money on unnecessary components.

- Efficient Troubleshooting: By following a structured chart, technicians can quickly identify the root cause of a problem, reducing diagnostic time.

- Preventing Further Damage: Identifying and addressing issues early can prevent further damage to the vehicle, saving on costly repairs down the line.

- DIY Repairs: For DIY enthusiasts, flow charts provide a clear guide for performing repairs at home, saving on labor costs.

- Informed Decisions: Flow charts provide technicians with the information needed to make informed decisions about repairs, ensuring the most effective and cost-efficient solutions.

By leveraging diagnostic flow charts, technicians and DIY enthusiasts can save time, reduce costs, and ensure accurate and effective automotive repairs. For more detailed information and resources, visit CAR-TOOL.EDU.VN, where you can find expert advice and quality tools to assist in your diagnostic endeavors.

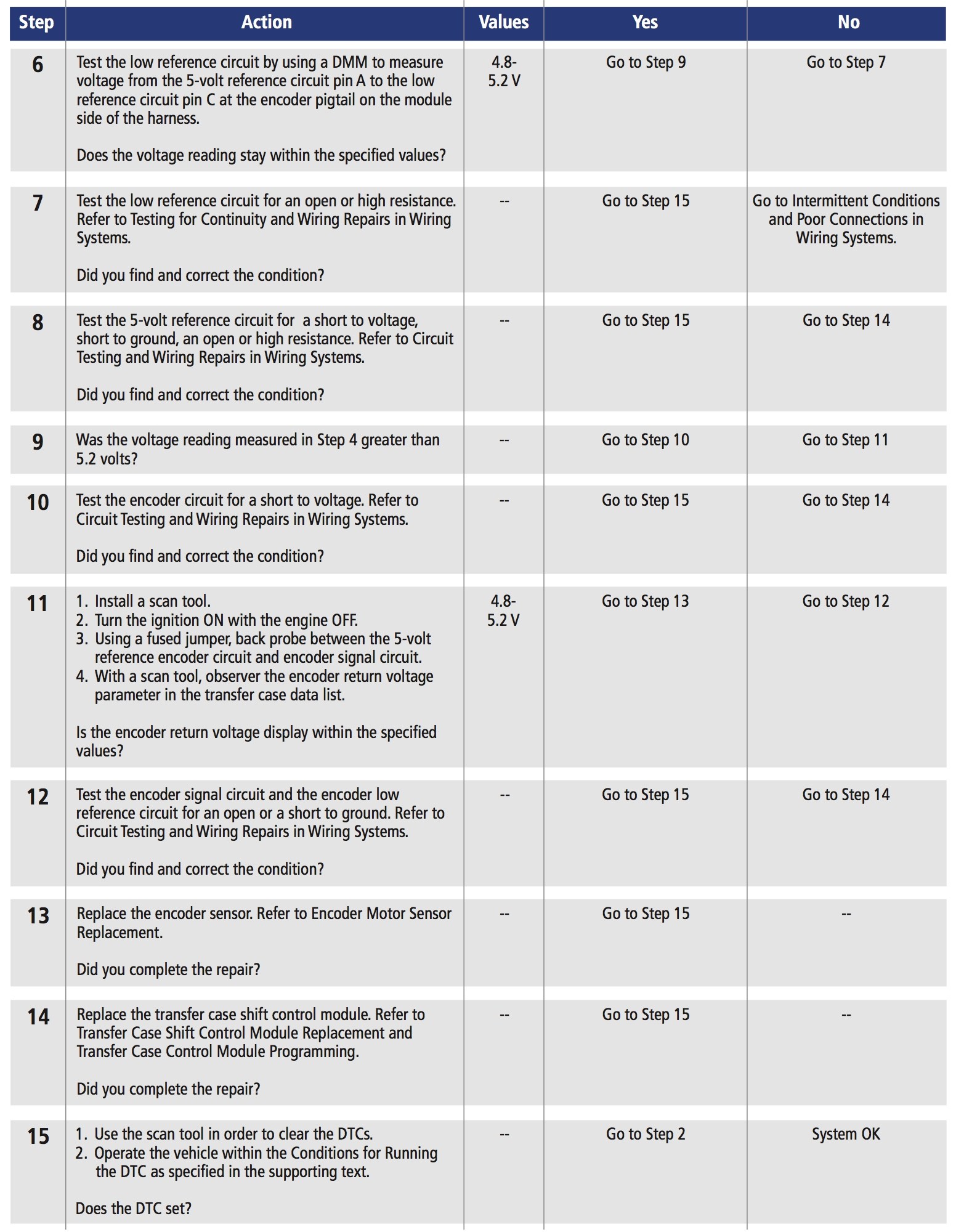

Automotive Service Chart

Automotive Service Chart

4. What Are The Common Types Of Car Diagnostic Flow Charts?

Car diagnostic flow charts come in various types, each tailored to specific automotive systems and problems. Understanding these different types can help technicians choose the most appropriate chart for a given situation.

- Engine Diagnostic Flow Charts: Used to diagnose problems related to the engine, such as misfires, poor performance, or unusual noises.

- Transmission Diagnostic Flow Charts: Used to diagnose issues with the transmission, such as slipping gears, rough shifting, or failure to engage.

- Brake System Diagnostic Flow Charts: Used to diagnose problems with the braking system, such as ABS failures, brake noise, or reduced stopping power.

- Electrical System Diagnostic Flow Charts: Used to diagnose electrical issues, such as battery drain, faulty wiring, or malfunctioning sensors.

- HVAC System Diagnostic Flow Charts: Used to diagnose problems with the heating, ventilation, and air conditioning systems, such as poor cooling, heating, or airflow.

- Body and Chassis Diagnostic Flow Charts: Used to diagnose issues related to the body and chassis of the vehicle, such as suspension problems, steering issues, or body damage.

- Network and Communication Diagnostic Flow Charts: Used to diagnose issues with the vehicle’s communication networks, such as CAN bus problems or module failures.

4.1 Can You Provide Examples Of Specific Diagnostic Flow Charts?

Here are some examples of specific diagnostic flow charts and their applications:

| Flow Chart Type | Description | Common Issues Addressed |

|---|---|---|

| Engine Misfire Diagnostic Flow Chart | Guides technicians through a series of tests to identify the cause of engine misfires, such as faulty spark plugs, ignition coils, or fuel injectors. | Engine misfires, rough idling, poor acceleration. |

| ABS Failure Diagnostic Flow Chart | Helps diagnose problems with the Anti-lock Braking System (ABS), such as faulty sensors, hydraulic units, or electronic control units. | ABS light illumination, reduced braking performance, wheel lockup. |

| HVAC Cooling Diagnostic Flow Chart | Assists in diagnosing issues with the air conditioning system, such as refrigerant leaks, compressor failures, or blower motor problems. | Poor cooling, warm air from vents, unusual noises. |

| Battery Drain Diagnostic Flow Chart | Used to identify the cause of excessive battery drain, such as parasitic draws, faulty alternators, or aging batteries. | Dead battery, difficulty starting the vehicle. |

| CAN Bus Diagnostic Flow Chart | Guides technicians through a series of tests to diagnose problems with the Controller Area Network (CAN) bus, such as communication errors or module failures. | Communication errors, multiple system failures, Diagnostic Trouble Codes (DTCs). |

| Transmission Slipping Flow Chart | Helps diagnose issues related to transmission slippage, such as worn clutch plates, low fluid levels, or faulty solenoids. | Slipping gears, delayed engagement, rough shifting. |

| Steering Noise Diagnostic Flow Chart | Used to diagnose noises in the steering system, such as power steering pump issues, worn ball joints, or damaged tie rod ends. | Steering noises, vibrations, loose steering. |

| Suspension Clunk Diagnostic Flow Chart | Assists in diagnosing clunking or rattling noises in the suspension system, such as worn bushings, damaged struts, or loose components. | Suspension noises, rough ride, poor handling. |

| Check Engine Light Flow Chart | Guides technicians in addressing various causes for the check engine light being on, including issues with the oxygen sensor, catalytic converter, or fuel cap problems. | Check engine light illuminated, reduced fuel efficiency, emissions problems. |

| Airbag System Diagnostic Flow Chart | Helps diagnose problems with the airbag system, such as faulty sensors, inflators, or control modules. | Airbag warning light illuminated, deployment failures. |

By understanding the different types of car diagnostic flow charts and their applications, technicians can effectively troubleshoot a wide range of automotive problems. For more detailed information and resources, visit CAR-TOOL.EDU.VN, where you can find expert advice and quality tools to assist in your diagnostic endeavors.

5. What Tools Do I Need To Use A Car Diagnostic Flow Chart Effectively?

To effectively use a car diagnostic flow chart, you’ll need a variety of tools that enable you to perform the necessary tests and inspections. These tools range from basic hand tools to advanced diagnostic equipment.

- Multimeter: Essential for measuring voltage, current, and resistance in electrical circuits.

- Scan Tool: Used to read Diagnostic Trouble Codes (DTCs) and monitor live data from vehicle sensors.

- Test Leads: Provide reliable connections for testing circuits and components.

- Back Probes: Allow you to test circuits without damaging wiring.

- Fused Jumper Wires: Used to bypass circuits for testing purposes, protecting against shorts.

- Pressure Tester: Used to measure pressure in fuel, oil, and cooling systems.

- Vacuum Gauge: Used to measure vacuum in the intake manifold and other vacuum-operated systems.

- Compression Tester: Used to measure cylinder compression, identifying engine problems.

- OBD-II Connector: For connecting scan tools to the vehicle’s diagnostic port.

- Wiring Diagrams: Essential for understanding the vehicle’s electrical system.

- Hand Tools: Basic tools like wrenches, sockets, screwdrivers, and pliers are needed for disassembly and component access.

5.1 What Diagnostic Tools Does CAR-TOOL.EDU.VN Recommend?

CAR-TOOL.EDU.VN recommends the following diagnostic tools to ensure accurate and efficient troubleshooting:

| Tool | Description | Benefits |

|---|---|---|

| Autel MaxiSys MS906BT | Advanced diagnostic scan tool with comprehensive coverage for a wide range of vehicles. | Extensive diagnostic capabilities, wireless connectivity, user-friendly interface. |

| Fluke 87V Multimeter | High-quality multimeter for accurate electrical measurements. | Precise measurements, rugged design, reliable performance. |

| OTC 5613 Compression Tester | Accurate and durable compression tester for diagnosing engine problems. | Easy to use, provides accurate readings, durable construction. |

| Innova 3160g Scan Tool | Affordable scan tool for reading and clearing DTCs, monitoring live data. | User-friendly interface, provides valuable diagnostic information, cost-effective. |

| Power Probe III | Circuit tester and power supply for diagnosing electrical problems. | Versatile tool for circuit testing, provides power and ground, easy to use. |

| Mityvac MV8500 Vacuum Pump | Handheld vacuum pump for testing vacuum-operated systems. | Easy to use, provides accurate vacuum readings, portable design. |

| BlueDriver Bluetooth Scan Tool | Wireless scan tool that connects to smartphones via Bluetooth for comprehensive diagnostics. | Wireless connectivity, user-friendly app, provides detailed diagnostic reports. |

| LAUNCH X431 V+ | Professional-grade scan tool with advanced diagnostic capabilities, including coding and programming. | Extensive diagnostic capabilities, coding and programming functions, comprehensive vehicle coverage. |

| Actron CP9600 Scan Tool | Enhanced scan tool for reading and clearing DTCs, displaying live data, and performing system tests. | User-friendly interface, provides valuable diagnostic information, supports multiple languages. |

| Autool BT360 Battery Tester | Battery tester for assessing the health and performance of vehicle batteries. | Accurate battery testing, provides detailed diagnostic reports, easy to use. |

By using these recommended diagnostic tools, technicians can effectively troubleshoot a wide range of automotive problems and ensure accurate and efficient repairs. For more detailed information and resources, visit CAR-TOOL.EDU.VN, where you can find expert advice and quality tools to assist in your diagnostic endeavors.

6. How Do I Interpret The Results Of A Car Diagnostic Flow Chart?

Interpreting the results of a car diagnostic flow chart involves understanding the data obtained from tests and inspections, and using that information to make informed decisions about the next steps in the diagnostic process.

- Understanding Test Results: Each step in the flow chart will require a specific test, such as measuring voltage, resistance, or pressure. Understand what the expected values are and compare them to the actual results.

- Following Decision Points: Flow charts have decision points based on test results. If the result is within the expected range, you move to the next step. If not, you follow the path indicated for the abnormal result.

- Analyzing Diagnostic Trouble Codes (DTCs): DTCs provide valuable clues about the nature and location of the problem. Use a scan tool to read the DTCs and research their meaning.

- Consulting Wiring Diagrams: Wiring diagrams help you understand the electrical circuits and identify potential faults.

- Using Diagnostic Aids: Refer to diagnostic aids provided by the manufacturer or other reliable sources for additional information and troubleshooting tips.

- Systematic Approach: Follow the flow chart systematically, completing each step and recording your results.

- Verifying Repairs: After making a repair, verify that the problem has been resolved by repeating the initial symptom verification or performing additional tests.

6.1 What Do I Do If The Flow Chart Doesn’t Lead To A Solution?

If a car diagnostic flow chart doesn’t lead to a solution, consider the following steps:

| Step | Description |

|---|---|

| Review the Basics | Double-check that you have accurately verified the symptom and performed the initial inspection. |

| Check Wiring and Connections | Carefully inspect wiring and connections for any signs of damage, corrosion, or looseness. |

| Revisit DTCs | Re-read the Diagnostic Trouble Codes (DTCs) and research their meaning. There may be additional codes that were not initially present. |

| Consult Additional Resources | Refer to additional diagnostic resources, such as service manuals, technical bulletins, or online forums. |

| Seek Expert Advice | Consult with experienced technicians or a diagnostic specialist for assistance. |

| Perform Advanced Testing | Consider performing advanced tests, such as oscilloscope testing or component testing, to further diagnose the problem. |

| Check for Intermittent Issues | Be aware that some problems are intermittent and may not be present during testing. Look for factors that trigger the issue. |

| Verify Tool Functionality | Ensure that your diagnostic tools are functioning correctly and providing accurate readings. |

| Document and Analyze Data | Thoroughly document all test results and data collected during the diagnostic process. Analyze the data to identify any patterns or anomalies. |

By following these steps, you can overcome challenges and effectively diagnose even the most complex automotive problems. For more detailed information and resources, visit CAR-TOOL.EDU.VN, where you can find expert advice and quality tools to assist in your diagnostic endeavors.

7. How Can I Maintain My Car To Prevent Diagnostic Issues?

Maintaining your car regularly can significantly reduce the likelihood of diagnostic issues. Preventive maintenance helps keep your vehicle in optimal condition, preventing problems before they occur.

- Regular Oil Changes: Changing your oil regularly keeps the engine lubricated and prevents wear and tear.

- Check Fluid Levels: Regularly check and top off all fluid levels, including coolant, brake fluid, power steering fluid, and transmission fluid.

- Inspect Brakes: Inspect your brakes regularly for wear and tear, and replace them as needed.

- Check Tire Pressure: Maintain proper tire pressure to ensure even wear and optimal fuel efficiency.

- Replace Air Filters: Replace your air filters regularly to ensure proper airflow to the engine.

- Inspect Belts and Hoses: Inspect belts and hoses for cracks or wear, and replace them as needed.

- Tune-Ups: Schedule regular tune-ups to keep your engine running smoothly.

- Battery Maintenance: Keep your battery terminals clean and check the battery’s charge level.

- Address Issues Promptly: Address any issues as soon as they arise to prevent them from escalating into more significant problems.

7.1 What Are The Key Preventive Maintenance Tasks?

Here are the key preventive maintenance tasks that can help prevent diagnostic issues:

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Oil Change | Every 3,000-5,000 miles or as recommended by the manufacturer. | Keeps the engine lubricated, reduces wear and tear, and extends engine life. |

| Fluid Level Check | Monthly | Ensures proper fluid levels for optimal performance of various systems, such as cooling, braking, and power steering. |

| Brake Inspection | Every 6 months or 6,000 miles | Identifies worn brake pads, rotors, or other brake components, preventing brake failure and ensuring safe stopping. |

| Tire Pressure Check | Monthly | Ensures proper tire inflation for optimal handling, fuel efficiency, and tire wear. |

| Air Filter Replacement | Every 12,000-15,000 miles or as recommended by the manufacturer. | Ensures proper airflow to the engine, improving performance and fuel efficiency. |

| Belt and Hose Inspection | Annually | Identifies worn or cracked belts and hoses, preventing engine overheating and other system failures. |

| Tune-Up | As recommended by the manufacturer (typically every 30,000-60,000 miles). | Ensures optimal engine performance, fuel efficiency, and emissions control. |

| Battery Maintenance | Monthly | Keeps battery terminals clean and checks battery health, preventing starting problems and extending battery life. |

| Spark Plug Replacement | As recommended by the manufacturer (typically every 30,000-100,000 miles depending on the type of plug). | Maintains proper ignition, ensuring optimal engine performance and fuel efficiency. |

| Wheel Alignment | Every 12,000 miles or as needed (if experiencing uneven tire wear or handling issues). | Ensures proper tire alignment for optimal handling, tire wear, and fuel efficiency. |

By performing these key preventive maintenance tasks, you can significantly reduce the likelihood of diagnostic issues and keep your car running smoothly. For more detailed information and resources, visit CAR-TOOL.EDU.VN, where you can find expert advice and quality tools to assist in your diagnostic endeavors.

8. Where Can I Get Professional Diagnostic Assistance If I Can’t Figure It Out Myself?

If you’re unable to diagnose a car problem using a diagnostic flow chart, seeking professional assistance is the next logical step. Professional technicians have the expertise, experience, and advanced tools to accurately diagnose and repair complex automotive issues.

- Local Repair Shops: Start by researching local repair shops in your area. Look for shops with ASE-certified technicians and positive customer reviews.

- Dealerships: Dealerships specialize in specific car brands and have technicians trained to work on those vehicles.

- Specialty Shops: Some shops specialize in specific types of repairs, such as electrical work, transmission repairs, or brake services.

- Mobile Mechanics: Mobile mechanics offer convenient on-site diagnostic and repair services.

- Online Technician Services: Some online platforms connect you with experienced technicians who can provide remote diagnostic assistance.

8.1 How Do I Choose The Right Automotive Technician?

Choosing the right automotive technician is crucial for ensuring accurate diagnostics and quality repairs. Here are some factors to consider:

| Factor | Description |

|---|---|

| ASE Certification | Look for technicians who are certified by the National Institute for Automotive Service Excellence (ASE). This certification demonstrates competence and expertise. |

| Experience | Consider the technician’s experience, particularly with your car’s make and model. |

| Reputation | Check online reviews and ask for recommendations from friends and family. |

| Diagnostic Tools | Ensure the shop has modern diagnostic tools and equipment. |

| Communication Skills | Choose a technician who communicates clearly and explains the problem and repair process in a way you understand. |

| Warranty | Ask about the shop’s warranty policy on parts and labor. |

| Shop Cleanliness | A clean and organized shop is often an indicator of professionalism and attention to detail. |

| Estimates | Get a written estimate before authorizing any repairs. |

| Customer Service | Consider the overall customer service experience, including the shop’s responsiveness and willingness to answer questions. |

| Specialization | If your car has a specific issue (e.g., electrical problems), consider a shop that specializes in that area. |

By carefully considering these factors, you can choose the right automotive technician to accurately diagnose and repair your car. For more detailed information and resources, visit CAR-TOOL.EDU.VN, where you can find expert advice and quality tools to assist in your diagnostic endeavors.

9. What Are Some Advanced Diagnostic Techniques Beyond Flow Charts?

While diagnostic flow charts are a valuable tool, advanced diagnostic techniques can be necessary for complex or intermittent issues. These techniques often require specialized tools and expertise.

- Oscilloscope Testing: Using an oscilloscope to analyze electrical signals and identify anomalies.

- Component Testing: Testing individual components to determine if they are functioning correctly.

- Fuel System Testing: Measuring fuel pressure, injector pulse width, and fuel trim to diagnose fuel-related problems.

- Compression Testing: Measuring cylinder compression to identify engine problems.

- Leak-Down Testing: Measuring the rate of cylinder leakage to identify valve or ring problems.

- Smoke Testing: Using smoke to identify leaks in the intake or exhaust system.

- Thermal Imaging: Using a thermal camera to identify overheating components or leaks.

- CAN Bus Diagnostics: Analyzing Controller Area Network (CAN) bus data to identify communication problems.

- Module Programming: Reprogramming or updating vehicle modules to address software issues.

9.1 How Does Oscilloscope Testing Work?

Oscilloscope testing is an advanced diagnostic technique that allows technicians to visualize electrical signals over time. This can help identify problems that are not apparent with other diagnostic methods.

| Aspect | Description |

|---|---|

| Function | Oscilloscopes display electrical signals as waveforms, showing voltage and current changes over time. |

| Applications | Used to diagnose issues with sensors, actuators, ignition systems, and other electrical components. |

| Components | An oscilloscope consists of a display screen, probes, and various controls for adjusting the display. |

| Measurement | Technicians connect the oscilloscope probes to the circuit being tested and observe the waveform on the screen. |

| Waveform Analysis | By analyzing the shape, amplitude, and frequency of the waveform, technicians can identify abnormalities that indicate a problem. |

| Common Issues Detected | Oscilloscope testing can detect issues such as signal dropouts, noise, and incorrect timing. |

| Advantages | Provides a detailed view of electrical signals, allowing for precise diagnosis of complex electrical problems. |

| Skill Required | Requires specialized training and expertise to interpret waveforms accurately. |

| Example Use Case | Diagnosing a faulty crankshaft position sensor by analyzing the waveform of the signal. |

| Tool Recommendations | High-quality oscilloscopes from brands like Fluke, PicoScope, and Snap-on are recommended. |

By using oscilloscope testing, technicians can effectively diagnose complex electrical problems and ensure accurate repairs. For more detailed information and resources, visit CAR-TOOL.EDU.VN, where you can find expert advice and quality tools to assist in your diagnostic endeavors.

10. How Is Technology Changing Car Diagnostics?

Technology is rapidly changing car diagnostics, with new tools and techniques emerging regularly. These advancements are making diagnostics more accurate, efficient, and accessible.

- Advanced Scan Tools: Modern scan tools offer comprehensive diagnostic capabilities, including reading and clearing DTCs, monitoring live data, and performing system tests.

- Wireless Diagnostics: Wireless diagnostic tools allow technicians to diagnose problems remotely, increasing efficiency and convenience.

- Cloud-Based Diagnostics: Cloud-based diagnostic platforms provide access to vast databases of diagnostic information and troubleshooting tips.

- Artificial Intelligence (AI): AI is being used to analyze diagnostic data and provide technicians with insights and recommendations.

- Telematics: Telematics systems collect data from vehicles and provide insights into their performance and maintenance needs.

- Augmented Reality (AR): AR is being used to provide technicians with visual guidance during diagnostic and repair procedures.

- Remote Diagnostics: Remote diagnostic services allow technicians to diagnose problems from a remote location, reducing the need for on-site visits.

10.1 What Future Trends Can We Expect In Automotive Diagnostics?

Several future trends are expected to shape the landscape of automotive diagnostics:

| Trend | Description |

|---|---|

| AI-Powered Diagnostics | Artificial intelligence (AI) will play an increasingly important role in analyzing diagnostic data and providing technicians with insights and recommendations. AI algorithms can identify patterns and anomalies that humans may miss, leading to more accurate diagnoses. |

| Predictive Maintenance | Predictive maintenance systems will use data from vehicles to predict when maintenance is needed, preventing breakdowns and reducing downtime. These systems can monitor vehicle performance, analyze data patterns, and alert owners or technicians to potential problems. |

| Remote Diagnostics Expansion | Remote diagnostic services will become more widespread, allowing technicians to diagnose problems from a remote location and provide guidance to on-site personnel. This can reduce the need for on-site visits and improve efficiency. |

| Enhanced Cybersecurity | With the increasing connectivity of vehicles, cybersecurity will become a critical concern. Diagnostic tools and systems will need to be secured against hacking and unauthorized access to protect vehicle data and prevent malicious attacks. |

| Integration of AR and VR | Augmented reality (AR) and virtual reality (VR) technologies will be integrated into diagnostic procedures, providing technicians with visual guidance and training. AR can overlay diagnostic information onto the real world, while VR can simulate complex repair procedures. |

| Standardization of Data | Efforts to standardize diagnostic data will improve interoperability and make it easier to share information between different systems and stakeholders. Standardized data formats can facilitate the development of new diagnostic tools and services. |

| Over-the-Air (OTA) Updates | Over-the-air (OTA) updates will become more common, allowing manufacturers to remotely update vehicle software and address issues without requiring a visit to the repair shop. This can improve vehicle performance, enhance security, and add new features. |

| Focus on Electric Vehicles (EVs) | Diagnostic tools and techniques will need to adapt to the increasing prevalence of electric vehicles (EVs). New tools and procedures will be developed to diagnose and repair EV-specific components, such as batteries, motors, and charging systems. |

| Data-Driven Decision Making | Diagnostic decisions will be increasingly driven by data, with technicians relying on data analysis and machine learning to identify the root causes of problems. This can lead to more accurate and efficient diagnoses. |

| Subscription-Based Services | Subscription-based diagnostic services will become more common, providing access to diagnostic tools, data, and support on a recurring basis. This can make advanced diagnostic capabilities more accessible to smaller repair shops and independent technicians. |

By staying abreast of these technological advancements, technicians can remain at the forefront of automotive diagnostics and provide their customers with the best possible service. For more detailed information and resources, visit CAR-TOOL.EDU.VN, where you can find expert advice and quality tools to assist in your diagnostic endeavors.

Don’t let car diagnostic challenges slow you down. At CAR-TOOL.EDU.VN, we provide the tools, resources, and expert advice you need to accurately diagnose and repair automotive problems. Whether you’re a seasoned technician or a DIY enthusiast, we have something for everyone.

Ready to take your diagnostic skills to the next level? Contact us today at 456 Elm Street, Dallas, TX 75201, United States or Whatsapp: +1 (641) 206-8880. Visit our website CAR-TOOL.EDU.VN for all your automotive diagnostic needs. Our team is standing by to answer your questions and provide personalized recommendations. Invest in the right diagnostic tools and knowledge, and experience the difference!

FAQ: Free Car Diagnostic Flow Chart

What Is The Purpose Of A Car Diagnostic Flow Chart?

A car diagnostic flow chart provides a structured, step-by-step process for identifying the root cause of a problem in a vehicle. It helps technicians systematically eliminate potential issues, leading to an accurate diagnosis and effective repair.

Where Can I Find Free Car Diagnostic Flow Charts?

You can find free car diagnostic flow charts on automotive forums, manufacturer websites, automotive repair websites like CAR-TOOL.EDU.VN, public libraries, and educational institutions.

What Are The Key Elements Of A Car Diagnostic Flow Chart?

Key elements include symptom verification, initial inspection, Diagnostic Trouble Codes (DTCs), step-by-step instructions, decision points, testing procedures, expected values, possible causes, corrective actions, and verification.

What Tools Do I Need To Use A Car Diagnostic Flow Chart Effectively?

Essential tools include a multimeter, scan tool, test leads, back probes, fused jumper wires, pressure tester, vacuum gauge, compression tester, OBD-II connector, wiring diagrams, and hand tools.

How Do I Interpret The Results Of A Car Diagnostic Flow Chart?

Interpreting results involves understanding test values, following decision points based on test results, analyzing DTCs, consulting wiring diagrams, and using diagnostic aids.