Diagnostic Test For Car Electrical Issues are crucial for maintaining your vehicle’s health and performance. CAR-TOOL.EDU.VN offers the insights and resources you need to accurately diagnose and resolve these issues, ensuring your car runs smoothly. From identifying faulty wiring to pinpointing sensor malfunctions, we provide solutions that empower you to take control of your car’s electrical system and prevent costly repairs. Explore our guides on automotive electrical troubleshooting, circuit testing, and component diagnostics to enhance your understanding.

Contents

- 1. Understanding the Importance of Diagnostic Tests for Car Electrical Issues

- 1.1. Why Electrical Diagnostics Matter

- 1.2. Common Electrical Problems in Cars

- 2. Essential Tools for Electrical Diagnostic Tests

- 2.1. Multimeter

- 2.2. Test Light

- 2.3. Diagnostic Scanner (OBD-II Scanner)

- 2.4. Circuit Tester

- 2.5. Wire Strippers and Crimpers

- 3. Step-by-Step Guide to Performing a Diagnostic Test for Car Electrical Issues

- 3.1. Gather Information

- 3.2. Visual Inspection

- 3.3. Battery Test

- 3.4. Fuse Check

- 3.5. Circuit Testing

- 3.6. Sensor Testing

- 3.7. Component Testing

- 3.8. Diagnostic Trouble Code (DTC) Analysis

- 3.9. Repair and Retest

- 3.10. Final Verification

- 4. Advanced Diagnostic Techniques for Complex Electrical Issues

- 4.1. Oscilloscope Diagnostics

- 4.2. Power Probe Diagnostics

- 4.3. CAN Bus Diagnostics

- 4.4. Thermal Imaging

- 5. Common Electrical Problems and Their Diagnostic Tests

- 5.1. Starting Problems

- 5.2. Charging System Issues

- 5.3. Lighting Problems

- 5.4. Sensor Malfunctions

- 5.5. Wiring Issues

- 6. Maintaining Your Car’s Electrical System to Prevent Issues

- 6.1. Regular Battery Maintenance

- 6.2. Inspecting and Cleaning Connections

- 6.3. Checking and Replacing Fuses

- 6.4. Monitoring Wiring and Harnesses

- 6.5. Professional Electrical System Checkups

- 7. Choosing the Right Diagnostic Service for Your Car

- 7.1. Evaluating Expertise and Experience

- 7.2. Assessing Equipment and Technology

- 7.3. Reading Customer Reviews and Testimonials

- 7.4. Comparing Pricing and Services

- 7.5. Considering Location and Convenience

- 8. CAR-TOOL.EDU.VN: Your Partner in Automotive Electrical Solutions

- 8.1. Comprehensive Resources for Electrical Diagnostics

- 8.2. Expert Recommendations for Tools and Equipment

- 8.3. Community Support and Expert Advice

- 9. FAQ: Addressing Common Questions About Diagnostic Tests for Car Electrical Issues

- 10. Get Expert Assistance with Your Car’s Electrical Issues Today

1. Understanding the Importance of Diagnostic Tests for Car Electrical Issues

Diagnostic tests for car electrical issues are vital for identifying and resolving problems within your vehicle’s electrical system. Early detection and accurate diagnosis can prevent minor issues from escalating into major, costly repairs, ensuring your car’s reliability and safety.

1.1. Why Electrical Diagnostics Matter

According to a study by the National Institute for Automotive Service Excellence (ASE), electrical issues are among the most common reasons for vehicle breakdowns, accounting for nearly 30% of all car repairs. Regular diagnostic tests can help identify these issues early, preventing unexpected breakdowns and ensuring optimal performance.

- Preventative Maintenance: Regular checks can identify potential problems before they cause breakdowns.

- Cost Savings: Early detection of electrical issues can prevent costly repairs down the line.

- Safety: Ensuring all electrical components are functioning correctly is crucial for safe driving.

- Performance: Addressing electrical issues can improve overall vehicle performance and fuel efficiency.

1.2. Common Electrical Problems in Cars

Understanding the common electrical problems can help you recognize when a diagnostic test is needed. These issues often manifest as starting problems, lighting malfunctions, or sensor errors.

- Dead Battery: Often caused by leaving lights on, a faulty alternator, or a parasitic drain.

- Faulty Alternator: Leads to insufficient battery charging and can cause the car to stall.

- Starter Problems: Difficulty starting the car, often due to a failing starter motor or solenoid.

- Wiring Issues: Corroded, damaged, or loose wiring can cause a variety of electrical problems.

- Sensor Malfunctions: Faulty sensors can lead to incorrect readings and poor engine performance.

- Blown Fuses: Indicate an overload or short circuit in the electrical system.

- Lighting Problems: Headlights, taillights, or interior lights not working properly.

2. Essential Tools for Electrical Diagnostic Tests

Having the right tools is essential for performing effective diagnostic tests for car electrical issues. These tools range from basic testers to advanced diagnostic scanners, each serving a specific purpose in identifying electrical faults.

2.1. Multimeter

A multimeter is an indispensable tool for any automotive technician. It measures voltage, current, and resistance, allowing you to test circuits, check for shorts, and verify component functionality.

Key Features of a Multimeter:

- Voltage Measurement: Measures the electrical potential difference in volts.

- Current Measurement: Measures the flow of electrical charge in amperes.

- Resistance Measurement: Measures the opposition to the flow of current in ohms.

- Continuity Testing: Checks if a circuit is complete and unbroken.

How to Use a Multimeter:

- Safety First: Always wear safety glasses and gloves when working with electrical systems.

- Set the Multimeter: Select the appropriate setting (voltage, current, or resistance) based on what you need to measure.

- Connect the Leads: Connect the black lead to the ground (negative) and the red lead to the test point (positive).

- Read the Measurement: Observe the reading on the multimeter’s display.

2.2. Test Light

A test light is a simple but effective tool for quickly checking if a circuit is live. It illuminates when current is present, indicating whether a circuit is receiving power.

Advantages of Using a Test Light:

- Simple and Quick: Easy to use for basic circuit testing.

- Affordable: Test lights are inexpensive compared to other diagnostic tools.

- Visual Indication: Provides a clear visual indication of current flow.

How to Use a Test Light:

- Connect the Clip: Attach the alligator clip to a known good ground.

- Probe the Circuit: Touch the probe to the circuit you want to test.

- Check for Illumination: If the light illuminates, the circuit is receiving power.

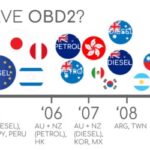

2.3. Diagnostic Scanner (OBD-II Scanner)

A diagnostic scanner, also known as an OBD-II scanner, is a sophisticated tool that reads diagnostic trouble codes (DTCs) from the vehicle’s computer. These codes can pinpoint specific electrical issues, making diagnosis more efficient.

Benefits of Using an OBD-II Scanner:

- Accurate Diagnosis: Reads specific DTCs to identify the source of the problem.

- Real-Time Data: Provides live data from various sensors and systems.

- Code Clearing: Allows you to clear DTCs after resolving the issue.

- Comprehensive Testing: Supports a wide range of diagnostic tests, including sensor checks and system monitoring.

How to Use an OBD-II Scanner:

- Connect the Scanner: Plug the scanner into the OBD-II port, typically located under the dashboard.

- Turn on the Ignition: Turn the ignition to the “on” position without starting the engine.

- Read the Codes: Follow the scanner’s prompts to read the stored DTCs.

- Interpret the Codes: Consult a repair manual or online database to understand the meaning of each code.

- Clear the Codes (Optional): After addressing the issue, you can clear the codes using the scanner.

2.4. Circuit Tester

A circuit tester is designed to verify the presence of voltage in a circuit without needing to cut or pierce the wire. This tool is particularly useful for checking fuses, switches, and relays.

Features of a Circuit Tester:

- Non-Invasive Testing: Checks circuits without damaging wires.

- Quick Verification: Quickly confirms the presence of voltage in a circuit.

- Safe to Use: Minimizes the risk of electrical shock.

How to Use a Circuit Tester:

- Ground the Tester: Connect the tester’s ground clip to a known good ground.

- Position the Probe: Place the probe near the wire or component you want to test.

- Check for Indication: The tester will light up or beep if voltage is present.

2.5. Wire Strippers and Crimpers

Wire strippers and crimpers are essential for repairing and modifying electrical wiring. These tools allow you to safely remove insulation from wires and create secure connections.

Importance of Quality Wire Strippers and Crimpers:

- Safe Wire Handling: Ensures clean and safe removal of wire insulation.

- Secure Connections: Creates reliable and durable electrical connections.

- Prevents Damage: Minimizes the risk of damaging wires during stripping and crimping.

How to Use Wire Strippers and Crimpers:

- Select the Correct Gauge: Choose the appropriate wire gauge setting on the stripper.

- Strip the Insulation: Place the wire in the stripper and remove the insulation.

- Attach the Connector: Place the connector on the wire and use the crimper to secure it.

3. Step-by-Step Guide to Performing a Diagnostic Test for Car Electrical Issues

Performing a diagnostic test for car electrical issues involves a systematic approach to identify and resolve the problem. Follow these steps to ensure accurate and effective diagnostics.

3.1. Gather Information

Before starting any diagnostic test, gather as much information as possible about the electrical issue. This includes understanding the symptoms, the conditions under which the problem occurs, and any recent repairs or modifications.

Key Questions to Ask:

- What are the specific symptoms (e.g., lights not working, engine not starting)?

- When did the problem start?

- Under what conditions does the problem occur (e.g., when it’s cold, when the engine is hot)?

- Have there been any recent repairs or modifications to the electrical system?

3.2. Visual Inspection

Begin with a thorough visual inspection of the electrical system. Look for obvious signs of damage, such as frayed wires, corroded connectors, and blown fuses.

Checklist for Visual Inspection:

- Battery Terminals: Check for corrosion and loose connections.

- Fuses: Inspect all fuses for signs of burning or breakage.

- Wiring Harnesses: Look for damaged, frayed, or exposed wires.

- Connectors: Check for corrosion, loose connections, and broken clips.

- Ground Connections: Ensure all ground connections are clean and secure.

3.3. Battery Test

The battery is the heart of the car’s electrical system. Use a multimeter to check the battery voltage and perform a load test to ensure it can hold a charge under load.

How to Test the Battery:

- Voltage Test: With the engine off, the battery voltage should be around 12.6 volts.

- Load Test: Use a load tester to simulate the load of starting the engine. The voltage should not drop below 9.6 volts during the test.

3.4. Fuse Check

Check all fuses related to the affected circuit. Use a test light or multimeter to verify that each fuse is intact and receiving power.

How to Check Fuses:

- Visual Inspection: Look for signs of burning or breakage.

- Continuity Test: Use a multimeter to check for continuity across the fuse.

- Voltage Test: Use a test light or multimeter to verify that the fuse is receiving power.

3.5. Circuit Testing

Use a multimeter or test light to trace the affected circuit. Check for voltage drops, shorts to ground, and open circuits.

Steps for Circuit Testing:

- Identify the Circuit: Consult a wiring diagram to identify the circuit you need to test.

- Check for Voltage: Use a test light or multimeter to verify that voltage is present at various points in the circuit.

- Check for Continuity: Use a multimeter to check for continuity between different points in the circuit.

- Check for Shorts to Ground: Use a multimeter to check for shorts to ground by measuring the resistance between the circuit and ground.

3.6. Sensor Testing

If the problem involves a sensor, use a diagnostic scanner to read the sensor’s output and compare it to the expected values. You can also use a multimeter to check the sensor’s voltage and resistance.

How to Test Sensors:

- Read Sensor Output: Use a diagnostic scanner to read the sensor’s output and compare it to the expected values.

- Check Voltage and Resistance: Use a multimeter to check the sensor’s voltage and resistance.

- Consult Repair Manual: Refer to the repair manual for specific testing procedures and values for each sensor.

3.7. Component Testing

Test individual components, such as relays, switches, and motors, to ensure they are functioning correctly. Use a multimeter to check their voltage, resistance, and continuity.

Testing Common Components:

- Relays: Check for continuity between the coil terminals and the switch terminals.

- Switches: Check for continuity in the open and closed positions.

- Motors: Check for voltage and current draw.

3.8. Diagnostic Trouble Code (DTC) Analysis

Use a diagnostic scanner to read and interpret any diagnostic trouble codes (DTCs) stored in the vehicle’s computer. These codes can provide valuable clues about the nature and location of the electrical issue.

Steps for DTC Analysis:

- Read the Codes: Use a diagnostic scanner to read the stored DTCs.

- Interpret the Codes: Consult a repair manual or online database to understand the meaning of each code.

- Research the Causes: Research the possible causes of each code.

- Verify the Problem: Perform additional tests to verify the problem indicated by the code.

3.9. Repair and Retest

After identifying the problem, perform the necessary repairs, such as replacing damaged wires, cleaning corroded connections, or replacing faulty components. After completing the repairs, retest the system to ensure the problem has been resolved.

Best Practices for Repairing Electrical Issues:

- Use Quality Parts: Use high-quality replacement parts to ensure reliability.

- Follow Proper Procedures: Follow proper repair procedures to avoid causing additional damage.

- Secure Connections: Ensure all connections are clean and secure.

- Protect Wires: Protect wires from abrasion and heat.

3.10. Final Verification

After completing the repairs and retesting the system, perform a final verification to ensure that the problem has been completely resolved and that all related systems are functioning correctly.

Checklist for Final Verification:

- Retest the System: Retest the system to ensure the problem has been resolved.

- Check Related Systems: Check related systems to ensure they are functioning correctly.

- Clear DTCs: Clear any remaining DTCs from the vehicle’s computer.

- Road Test: Perform a road test to verify that the problem has been completely resolved.

4. Advanced Diagnostic Techniques for Complex Electrical Issues

For complex electrical issues, advanced diagnostic techniques may be required to pinpoint the problem. These techniques often involve the use of specialized equipment and a deeper understanding of automotive electrical systems.

4.1. Oscilloscope Diagnostics

An oscilloscope is a powerful tool for analyzing electrical signals. It displays voltage over time, allowing you to visualize waveforms and identify anomalies that may not be apparent with a multimeter.

Benefits of Using an Oscilloscope:

- Visual Signal Analysis: Provides a visual representation of electrical signals.

- Identification of Anomalies: Detects signal anomalies that may not be apparent with a multimeter.

- Precise Measurements: Allows for precise measurements of voltage, frequency, and pulse width.

How to Use an Oscilloscope:

- Connect the Probes: Connect the oscilloscope probes to the circuit you want to test.

- Set the Timebase and Voltage Scale: Adjust the timebase and voltage scale to display the signal clearly.

- Analyze the Waveform: Analyze the waveform for anomalies, such as excessive noise, distorted signals, or missing pulses.

4.2. Power Probe Diagnostics

A power probe is a versatile tool that combines the functions of a multimeter, test light, and circuit tester. It can supply power or ground to a circuit, allowing you to test components and diagnose wiring issues.

Advantages of Using a Power Probe:

- Versatile Functionality: Combines the functions of multiple diagnostic tools.

- Power Supply Capability: Can supply power or ground to a circuit.

- Circuit Testing: Tests circuits for voltage, continuity, and shorts.

How to Use a Power Probe:

- Connect the Power Probe: Connect the power probe to the vehicle’s battery.

- Select the Function: Choose the appropriate function (voltage, ground, or circuit testing).

- Probe the Circuit: Use the probe to test the circuit or component you want to diagnose.

4.3. CAN Bus Diagnostics

The Controller Area Network (CAN) bus is a communication network that allows various electronic control units (ECUs) in the vehicle to communicate with each other. Diagnosing CAN bus issues requires specialized tools and knowledge.

Common CAN Bus Problems:

- Communication Errors: ECUs not communicating with each other.

- Data Corruption: Corrupted data being transmitted on the CAN bus.

- Bus Overload: Excessive traffic on the CAN bus.

Tools for CAN Bus Diagnostics:

- CAN Bus Analyzer: Analyzes the data being transmitted on the CAN bus.

- Diagnostic Scanner with CAN Bus Support: Reads DTCs related to the CAN bus.

- Oscilloscope: Visualizes the CAN bus signals.

How to Diagnose CAN Bus Issues:

- Read DTCs: Use a diagnostic scanner to read DTCs related to the CAN bus.

- Analyze CAN Bus Data: Use a CAN bus analyzer to monitor the data being transmitted on the CAN bus.

- Check Wiring and Connections: Inspect the CAN bus wiring and connections for damage or corrosion.

- Isolate Faulty ECUs: Disconnect ECUs one by one to identify the faulty unit.

4.4. Thermal Imaging

Thermal imaging can be used to detect hot spots in electrical circuits, which can indicate shorts, loose connections, or overloaded components.

Benefits of Using Thermal Imaging:

- Non-Contact Measurement: Measures temperature without physical contact.

- Detection of Hot Spots: Identifies hot spots in electrical circuits.

- Efficient Diagnosis: Quickly pinpoints the location of electrical faults.

How to Use Thermal Imaging:

- Prepare the Vehicle: Turn on the electrical system and allow it to warm up.

- Scan the Circuits: Use a thermal imaging camera to scan the electrical circuits.

- Identify Hot Spots: Look for areas of elevated temperature, which may indicate a fault.

5. Common Electrical Problems and Their Diagnostic Tests

Certain electrical problems are more common than others. Understanding these common issues and their associated diagnostic tests can streamline the troubleshooting process.

5.1. Starting Problems

Starting problems can be caused by a variety of electrical issues, including a dead battery, a faulty starter motor, or a problem with the ignition system.

Diagnostic Tests for Starting Problems:

- Battery Test: Check the battery voltage and perform a load test.

- Starter Motor Test: Check the voltage and current draw of the starter motor.

- Ignition System Test: Check the spark plugs, ignition coil, and ignition module.

- Fuel System Test: Check the fuel pump, fuel filter, and fuel injectors.

5.2. Charging System Issues

Charging system issues can result in a dead battery or a battery that is not fully charged. These issues are often caused by a faulty alternator, a loose or corroded belt, or a problem with the voltage regulator.

Diagnostic Tests for Charging System Issues:

- Alternator Test: Check the alternator output voltage and current.

- Belt Inspection: Check the condition and tension of the alternator belt.

- Voltage Regulator Test: Check the voltage regulator output.

- Battery Cable Inspection: Check the battery cables for corrosion and loose connections.

5.3. Lighting Problems

Lighting problems can range from dim headlights to non-functional taillights. These issues can be caused by blown bulbs, faulty switches, or wiring problems.

Diagnostic Tests for Lighting Problems:

- Bulb Check: Check the condition of the bulbs.

- Switch Test: Check the continuity of the switches.

- Wiring Inspection: Check the wiring for damage and loose connections.

- Ground Connection Check: Check the ground connections for corrosion and loose connections.

5.4. Sensor Malfunctions

Sensor malfunctions can cause a variety of performance issues, including poor fuel economy, rough idling, and engine misfires. These issues can be diagnosed using a diagnostic scanner and a multimeter.

Diagnostic Tests for Sensor Malfunctions:

- Diagnostic Scanner Test: Read the sensor output using a diagnostic scanner.

- Voltage and Resistance Test: Check the sensor voltage and resistance using a multimeter.

- Wiring Inspection: Check the wiring for damage and loose connections.

- Ground Connection Check: Check the ground connections for corrosion and loose connections.

5.5. Wiring Issues

Wiring issues can be difficult to diagnose, as they can cause a wide range of electrical problems. These issues can be caused by corrosion, damage, or loose connections.

Diagnostic Tests for Wiring Issues:

- Visual Inspection: Check the wiring for damage and corrosion.

- Continuity Test: Check the continuity of the wires using a multimeter.

- Voltage Drop Test: Measure the voltage drop across the wires to identify areas of high resistance.

- Short to Ground Test: Check for shorts to ground using a multimeter.

6. Maintaining Your Car’s Electrical System to Prevent Issues

Preventive maintenance is key to avoiding electrical problems in your car. Regular checks and proactive measures can help ensure your car’s electrical system remains in good working order.

6.1. Regular Battery Maintenance

Proper battery maintenance can extend the life of your battery and prevent starting problems.

Tips for Battery Maintenance:

- Keep Terminals Clean: Clean battery terminals regularly to prevent corrosion.

- Check Battery Voltage: Check battery voltage periodically to ensure it is within the proper range.

- Secure Battery Hold-Down: Ensure the battery is securely mounted to prevent vibration damage.

- Avoid Deep Discharges: Avoid leaving lights on or running accessories for extended periods with the engine off.

6.2. Inspecting and Cleaning Connections

Corroded and loose connections are a common cause of electrical problems. Regularly inspect and clean connections to ensure good electrical contact.

Steps for Inspecting and Cleaning Connections:

- Disconnect the Battery: Disconnect the battery before working on electrical connections.

- Inspect Connections: Look for signs of corrosion, damage, and loose connections.

- Clean Connections: Use a wire brush or sandpaper to clean corroded connections.

- Apply Dielectric Grease: Apply dielectric grease to protect connections from corrosion.

- Secure Connections: Ensure all connections are tight and secure.

6.3. Checking and Replacing Fuses

Regularly check fuses and replace any that are blown or damaged. Use the correct amperage fuse to avoid overloading the circuit.

How to Check and Replace Fuses:

- Locate the Fuse Box: Consult the owner’s manual to locate the fuse box.

- Inspect Fuses: Check fuses for signs of burning or breakage.

- Test Fuses: Use a test light or multimeter to verify that the fuse is intact.

- Replace Fuses: Replace any blown or damaged fuses with the correct amperage fuse.

6.4. Monitoring Wiring and Harnesses

Regularly inspect wiring and harnesses for damage, wear, and loose connections. Repair or replace any damaged wires to prevent electrical problems.

Tips for Monitoring Wiring and Harnesses:

- Visual Inspection: Look for signs of damage, such as frayed wires and cracked insulation.

- Secure Wiring: Ensure wiring is properly secured to prevent chafing and vibration damage.

- Protect Wiring: Protect wiring from heat and abrasion.

- Repair Damaged Wires: Repair or replace any damaged wires promptly.

6.5. Professional Electrical System Checkups

Consider having your car’s electrical system professionally checked at least once a year. A qualified technician can perform a comprehensive inspection and identify potential problems before they cause a breakdown.

Benefits of Professional Electrical System Checkups:

- Comprehensive Inspection: A qualified technician can perform a thorough inspection of the entire electrical system.

- Early Detection of Problems: Potential problems can be identified before they cause a breakdown.

- Expert Advice: A technician can provide expert advice on maintaining your car’s electrical system.

7. Choosing the Right Diagnostic Service for Your Car

Selecting the right diagnostic service for your car is crucial for accurate and effective troubleshooting. Consider factors such as the service’s expertise, equipment, and customer reviews to make an informed decision.

7.1. Evaluating Expertise and Experience

Look for a diagnostic service with experienced technicians who specialize in automotive electrical systems. Check for certifications from organizations such as ASE.

Key Considerations for Evaluating Expertise:

- Technician Certifications: Look for technicians with ASE certifications.

- Years of Experience: Consider the number of years the service has been in business.

- Specialization: Choose a service that specializes in automotive electrical systems.

7.2. Assessing Equipment and Technology

Ensure the diagnostic service has state-of-the-art equipment and technology, including diagnostic scanners, oscilloscopes, and thermal imaging cameras.

Essential Equipment for Diagnostic Services:

- Diagnostic Scanners: For reading DTCs and accessing real-time data.

- Oscilloscopes: For analyzing electrical signals.

- Thermal Imaging Cameras: For detecting hot spots in electrical circuits.

- Multimeters: For measuring voltage, current, and resistance.

7.3. Reading Customer Reviews and Testimonials

Check online reviews and testimonials to get an idea of the service’s reputation and customer satisfaction. Look for positive feedback regarding their diagnostic accuracy and quality of repairs.

Sources for Customer Reviews:

- Google Reviews: Check Google for reviews and ratings.

- Yelp: Look for reviews on Yelp.

- BBB (Better Business Bureau): Check the BBB for ratings and complaints.

7.4. Comparing Pricing and Services

Compare the pricing and services offered by different diagnostic services. Ensure that the service provides a detailed estimate before starting any work.

Key Questions to Ask About Pricing and Services:

- What is the diagnostic fee?

- Does the diagnostic fee include a written report?

- What is the hourly labor rate?

- What is the warranty on repairs?

7.5. Considering Location and Convenience

Choose a diagnostic service that is conveniently located and offers flexible appointment scheduling. Consider whether the service provides loaner cars or shuttle services.

Factors to Consider for Location and Convenience:

- Location: Choose a service that is conveniently located.

- Appointment Scheduling: Look for flexible appointment scheduling.

- Loaner Cars or Shuttle Services: Consider whether the service provides loaner cars or shuttle services.

8. CAR-TOOL.EDU.VN: Your Partner in Automotive Electrical Solutions

At CAR-TOOL.EDU.VN, we are dedicated to providing you with the information and resources you need to tackle any automotive electrical challenge. From detailed guides and tool recommendations to expert advice, we’re here to support you every step of the way.

8.1. Comprehensive Resources for Electrical Diagnostics

CAR-TOOL.EDU.VN offers a comprehensive collection of articles, tutorials, and videos covering all aspects of automotive electrical diagnostics. Whether you’re a seasoned mechanic or a DIY enthusiast, you’ll find valuable information to enhance your skills and knowledge.

Explore Our Resources:

- Diagnostic Guides: Step-by-step guides for diagnosing common electrical problems.

- Tool Reviews: Expert reviews of the latest diagnostic tools.

- Wiring Diagrams: Detailed wiring diagrams for various makes and models.

- Troubleshooting Tips: Practical tips and tricks for resolving electrical issues.

8.2. Expert Recommendations for Tools and Equipment

Choosing the right tools and equipment is essential for effective electrical diagnostics. CAR-TOOL.EDU.VN provides expert recommendations based on thorough testing and analysis.

Our Recommendations Include:

- Multimeters: Recommendations for multimeters at various price points.

- Diagnostic Scanners: Reviews of diagnostic scanners with different features and capabilities.

- Test Lights: Recommendations for reliable and affordable test lights.

- Circuit Testers: Reviews of circuit testers for quick and safe circuit verification.

8.3. Community Support and Expert Advice

Join the CAR-TOOL.EDU.VN community to connect with other automotive enthusiasts and experts. Ask questions, share your experiences, and get advice from experienced technicians.

Engage with Our Community:

- Forums: Participate in discussions and ask questions in our online forums.

- Expert Q&A: Get answers to your questions from our team of expert technicians.

- User Reviews: Share your experiences with diagnostic tools and services.

9. FAQ: Addressing Common Questions About Diagnostic Tests for Car Electrical Issues

9.1. What is a diagnostic test for car electrical issues?

A diagnostic test for car electrical issues is a systematic process used to identify and resolve problems within a vehicle’s electrical system. It involves using various tools and techniques to check components, circuits, and sensors to pinpoint the source of the issue.

9.2. How often should I perform a diagnostic test on my car’s electrical system?

It’s recommended to perform a diagnostic test whenever you notice any electrical issues, such as dimming lights, frequent battery drainage, or sensor malfunctions. Additionally, having a professional electrical system checkup at least once a year can help catch potential problems early.

9.3. What are the common tools needed for car electrical diagnostic tests?

The common tools needed include a multimeter, test light, diagnostic scanner (OBD-II scanner), circuit tester, wire strippers, and crimpers. Advanced diagnostic techniques may require an oscilloscope, power probe, CAN bus analyzer, and thermal imaging camera.

9.4. Can I perform diagnostic tests for car electrical issues myself, or do I need a professional?

Simple tests like checking battery voltage, fuses, and connections can be done yourself with basic tools. However, for complex issues involving sensors, wiring, or computer systems, it’s best to consult a professional with specialized equipment and knowledge.

9.5. What are the common electrical problems that require diagnostic tests?

Common electrical problems include starting problems, charging system issues, lighting problems, sensor malfunctions, and wiring issues. Each of these problems has specific diagnostic tests to identify the root cause.

9.6. How do I use a diagnostic scanner (OBD-II scanner) for electrical tests?

To use a diagnostic scanner, plug it into the OBD-II port, turn the ignition to the “on” position without starting the engine, read the stored DTCs, interpret the codes, and clear the codes after addressing the issue.

9.7. What is a diagnostic trouble code (DTC) and how is it used?

A diagnostic trouble code (DTC) is a code stored in the vehicle’s computer that indicates a specific electrical or mechanical issue. DTCs are read using a diagnostic scanner and are used to pinpoint the nature and location of the problem.

9.8. How can I maintain my car’s electrical system to prevent issues?

To maintain your car’s electrical system, perform regular battery maintenance, inspect and clean connections, check and replace fuses, monitor wiring and harnesses, and consider professional electrical system checkups.

9.9. What should I look for when choosing a diagnostic service for my car?

When choosing a diagnostic service, evaluate their expertise and experience, assess their equipment and technology, read customer reviews and testimonials, compare pricing and services, and consider their location and convenience.

9.10. How does CAR-TOOL.EDU.VN support automotive electrical solutions?

CAR-TOOL.EDU.VN provides comprehensive resources for electrical diagnostics, expert recommendations for tools and equipment, and community support with expert advice to help you tackle any automotive electrical challenge.

10. Get Expert Assistance with Your Car’s Electrical Issues Today

Are you struggling with electrical problems in your car? Don’t let these issues compromise your vehicle’s performance and safety. Contact CAR-TOOL.EDU.VN today for expert assistance and reliable solutions.

Our team of experienced technicians is ready to provide you with:

- Accurate Diagnostic Tests: Pinpointing the root cause of your car’s electrical issues.

- Comprehensive Repairs: Addressing all electrical problems with quality parts and expert workmanship.

- Preventive Maintenance: Ensuring your car’s electrical system remains in top condition.

Contact Information:

- Address: 456 Elm Street, Dallas, TX 75201, United States

- WhatsApp: +1 (641) 206-8880

- Website: CAR-TOOL.EDU.VN

Take the first step towards resolving your car’s electrical issues. Contact us today and let CAR-TOOL.EDU.VN be your trusted partner in automotive electrical solutions! Find detailed information about automotive electrical troubleshooting.