Mode 03 in OBD2, or On-Board Diagnostics II, provides access to emissions-related Diagnostic Trouble Codes (DTCs) stored in the vehicle’s computer. CAR-TOOL.EDU.VN offers resources to understand and resolve these codes, leading to efficient auto repairs. By understanding DTCs, you ensure accurate diagnostics and repairs, contributing to vehicle longevity and performance, while staying compliant with environmental regulations.

Contents

- 1. Understanding OBD2 and Its Significance

- 2. What is Mode 03 in OBD2?

- 3. The Importance of DTCs in Automotive Diagnostics

- 4. How to Access Mode 03 Data

- 5. Interpreting Diagnostic Trouble Codes (DTCs)

- 6. Common Emission-Related DTCs

- 7. Tools and Equipment for Reading DTCs

- 8. Step-by-Step Guide to Diagnosing Issues Using Mode 03

- 9. Advanced Diagnostic Techniques with Mode 03

- 10. Limitations and Challenges of Using Mode 03

- 11. Best Practices for Using Mode 03 in Automotive Repair

- 12. The Future of OBD2 and Diagnostic Technologies

- 13. Mode 03 and Vehicle Inspection Programs

- 14. Case Studies: Real-World Applications of Mode 03

- 15. FAQ: Frequently Asked Questions About Mode 03

- 16. CAR-TOOL.EDU.VN: Your Partner in Automotive Diagnostics

Table of Contents

- Understanding OBD2 and Its Significance

- What Is Mode 03 In OBD2?

- The Importance of DTCs in Automotive Diagnostics

- How to Access Mode 03 Data

- Interpreting Diagnostic Trouble Codes (DTCs)

- Common Emission-Related DTCs

- Tools and Equipment for Reading DTCs

- Step-by-Step Guide to Diagnosing Issues Using Mode 03

- Advanced Diagnostic Techniques with Mode 03

- Limitations and Challenges of Using Mode 03

- Best Practices for Using Mode 03 in Automotive Repair

- The Future of OBD2 and Diagnostic Technologies

- Mode 03 and Vehicle Inspection Programs

- Case Studies: Real-World Applications of Mode 03

- FAQ: Frequently Asked Questions About Mode 03

- CAR-TOOL.EDU.VN: Your Partner in Automotive Diagnostics

1. Understanding OBD2 and Its Significance

What is the OBD2 system and why is it important for modern vehicles? The On-Board Diagnostics II (OBD2) system is a standardized system implemented in vehicles since 1996 to monitor and control emissions-related components and systems. According to the Environmental Protection Agency (EPA), OBD2 was mandated to ensure vehicles meet stringent emission standards, contributing to cleaner air and improved environmental quality. The OBD2 system monitors components such as the engine, transmission, and exhaust system, providing valuable data for diagnosing and addressing potential issues.

OBD2’s significance lies in its ability to provide real-time data and diagnostic information, allowing technicians and vehicle owners to identify problems quickly and accurately. This system stores Diagnostic Trouble Codes (DTCs) when it detects a malfunction, which can be accessed using a scan tool. The standardization of OBD2 means that any compliant scan tool can communicate with any OBD2-equipped vehicle, simplifying the diagnostic process across different makes and models. This standardization not only makes vehicle maintenance more efficient but also aids in regulatory compliance and emissions testing. Understanding OBD2 is fundamental for anyone involved in automotive repair, as it provides a critical link between the vehicle’s performance and diagnostic insights.

2. What is Mode 03 in OBD2?

What exactly does Mode 03 entail within the OBD2 framework and how does it function? Mode 03 in OBD2 is the function that allows a scan tool to request and retrieve emissions-related Diagnostic Trouble Codes (DTCs) from the vehicle’s computer system. These DTCs are codes stored in the vehicle’s computer when a problem is detected in an emissions-related system or component. Mode 03 provides a standardized way for technicians to access these codes, enabling them to diagnose and repair issues that could affect vehicle emissions and performance.

When a fault is detected, the vehicle’s computer stores a specific DTC that corresponds to the identified problem. According to the Society of Automotive Engineers (SAE), these codes follow a standardized format, making it easier for technicians to identify the nature and location of the issue. For instance, a P0300 code indicates a random or multiple cylinder misfire, while a P0420 code suggests a problem with the catalytic converter efficiency.

Mode 03 retrieves these DTCs, providing a starting point for diagnosing the problem. The scan tool communicates with the vehicle’s computer, requests the stored DTCs, and displays them for the technician. This information is critical for identifying the source of the issue and guiding the repair process. By accessing Mode 03, technicians can quickly determine what the vehicle’s computer has flagged as a problem, saving time and improving the accuracy of the diagnostic process. Therefore, Mode 03 is a key function within the OBD2 system for accessing and interpreting diagnostic information.

3. The Importance of DTCs in Automotive Diagnostics

Why are Diagnostic Trouble Codes (DTCs) crucial in diagnosing automotive issues and what role do they play in the repair process? DTCs are essential in automotive diagnostics because they provide a standardized way to identify and address issues affecting vehicle performance and emissions. These codes are stored by the vehicle’s computer when a sensor or system detects a problem, offering technicians a specific starting point for diagnosis. According to a study by the National Institute for Automotive Service Excellence (ASE), using DTCs can significantly reduce diagnostic time and improve the accuracy of repairs.

DTCs help technicians quickly identify the general area of a problem, such as the engine, transmission, or exhaust system. Each code corresponds to a specific fault, such as a misfire, a faulty sensor, or a malfunctioning component. By retrieving these codes using Mode 03 of the OBD2 system, technicians can focus their attention on the affected system and perform targeted tests to pinpoint the exact cause of the issue.

For instance, if a DTC indicates a problem with the oxygen sensor, the technician can then test the sensor’s functionality, check for wiring issues, or examine related components. Without DTCs, diagnosing such problems would require a much more time-consuming and less precise process of trial and error. DTCs also ensure consistency in diagnostics across different makes and models, thanks to the standardized OBD2 system. This standardization allows technicians to use the same diagnostic tools and procedures for a wide range of vehicles, improving efficiency and reducing the likelihood of misdiagnosis. Therefore, DTCs are an indispensable tool for modern automotive repair, enhancing accuracy and speed in the diagnostic process.

4. How to Access Mode 03 Data

What steps are involved in accessing Mode 03 data using a scan tool, and what should technicians be aware of during this process? Accessing Mode 03 data involves connecting a scan tool to the vehicle’s OBD2 port, typically located under the dashboard, and following the tool’s prompts to retrieve the Diagnostic Trouble Codes (DTCs). The process is relatively straightforward, but technicians should be aware of certain precautions to ensure accurate and reliable results.

First, the scan tool must be compatible with the vehicle’s OBD2 system. Most modern scan tools support all OBD2 protocols, but it’s essential to verify compatibility, especially with older or less common vehicles. Once the scan tool is connected to the OBD2 port, turn the vehicle’s ignition to the “on” position without starting the engine. This provides power to the vehicle’s computer and allows the scan tool to communicate with it.

Next, navigate the scan tool’s menu to find the “Read Codes” or “Diagnostic Codes” option, which corresponds to Mode 03. Select this option, and the scan tool will request the DTCs stored in the vehicle’s computer. The scan tool will then display the DTCs along with a brief description of each code. Technicians should record all the DTCs present, as multiple codes can provide a more complete picture of the vehicle’s issues.

According to Bosch Automotive Service Solutions, it is important to note that some scan tools may offer additional information, such as freeze frame data, which captures the conditions present when the DTC was set. This data can be invaluable for diagnosing intermittent problems. Finally, before clearing any DTCs, technicians should thoroughly investigate and repair the underlying issues. Clearing codes without addressing the root cause can lead to recurring problems and inaccurate diagnostics. Thus, accessing Mode 03 data is a critical step, but it should be performed carefully and methodically to ensure effective diagnostics.

5. Interpreting Diagnostic Trouble Codes (DTCs)

How do you interpret Diagnostic Trouble Codes (DTCs) and understand their meaning in the context of automotive diagnostics? Interpreting DTCs involves understanding the standardized format and using resources to identify the specific issue each code represents. DTCs are five-character codes that follow a specific structure, as defined by the Society of Automotive Engineers (SAE).

The first character indicates the system affected:

- P: Powertrain (engine, transmission)

- B: Body (interior, exterior)

- C: Chassis (brakes, suspension)

- U: Network (communication)

The second character specifies whether the code is generic (0) or manufacturer-specific (1). Generic codes are standardized across all vehicles, while manufacturer-specific codes provide more detailed information unique to a particular make or model. The third character indicates the subsystem affected, such as fuel and air metering, ignition system, or auxiliary emission controls. The last two characters provide further detail about the specific fault.

For example, the DTC P0300 indicates a generic powertrain code (P0) related to a random or multiple cylinder misfire (300). Once a DTC is retrieved, technicians can use various resources to determine its exact meaning. These resources include:

- OBD2 Code Scanners: Many advanced scan tools provide detailed descriptions and possible causes for each DTC.

- Online Databases: Websites like the National Highway Traffic Safety Administration (NHTSA) and automotive forums offer extensive databases of DTCs with explanations and troubleshooting tips.

- Service Manuals: Vehicle-specific service manuals provide detailed information on DTCs, including diagnostic procedures and component locations.

According to a study by Delphi Automotive, accurately interpreting DTCs is crucial for efficient diagnostics. Technicians should consider the context in which the code appears, including the vehicle’s symptoms, other stored DTCs, and freeze frame data. With this information, technicians can develop a targeted diagnostic strategy, perform the necessary tests, and repair the underlying issue. Therefore, the ability to interpret DTCs accurately is a fundamental skill for automotive technicians.

6. Common Emission-Related DTCs

What are some common emission-related Diagnostic Trouble Codes (DTCs) that technicians frequently encounter, and what do these codes typically indicate? Several emission-related DTCs are commonly encountered by automotive technicians, each pointing to specific issues within the vehicle’s emission control systems. Understanding these codes is essential for diagnosing and repairing emission-related problems effectively.

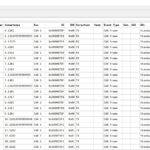

Here are some of the most common emission-related DTCs:

- P0420 – Catalyst System Efficiency Below Threshold (Bank 1): This code indicates that the catalytic converter is not functioning efficiently, meaning it is not effectively reducing pollutants in the exhaust. Common causes include a faulty catalytic converter, exhaust leaks, or issues with the oxygen sensors.

- P0171 – System Too Lean (Bank 1): This code suggests that the engine is running with too much air and not enough fuel. Possible causes include vacuum leaks, a faulty mass airflow (MAF) sensor, or a clogged fuel filter.

- P0174 – System Too Lean (Bank 2): Similar to P0171, this code indicates a lean condition on bank 2 of the engine.

- P0300 – Random/Multiple Cylinder Misfire Detected: This code indicates that the engine is experiencing misfires in one or more cylinders. Causes can range from faulty spark plugs and ignition coils to vacuum leaks and fuel delivery issues.

- P0401 – Exhaust Gas Recirculation (EGR) Flow Insufficient Detected: This code suggests that the EGR system is not allowing enough exhaust gas to recirculate into the engine. Common causes include a clogged EGR valve or a malfunctioning EGR sensor.

- P0440 – Evaporative Emission Control System Malfunction: This code indicates a problem with the evaporative emission control (EVAP) system, which prevents fuel vapors from escaping into the atmosphere. Common causes include a faulty gas cap, leaks in the EVAP system, or a malfunctioning EVAP sensor.

- P0135 – O2 Sensor Heater Circuit Malfunction (Bank 1, Sensor 1): This code indicates a problem with the heater circuit of the oxygen sensor located on bank 1, sensor 1. A faulty heater circuit can affect the sensor’s ability to accurately measure oxygen levels in the exhaust.

According to the EPA, addressing these and other emission-related DTCs promptly is crucial for maintaining vehicle compliance with environmental regulations and ensuring optimal engine performance. Technicians should use these codes as a starting point for a thorough diagnostic process, which may involve visual inspections, component testing, and the use of advanced diagnostic tools.

7. Tools and Equipment for Reading DTCs

What tools and equipment are essential for reading Diagnostic Trouble Codes (DTCs), and what features should technicians look for when selecting these tools? The primary tool for reading DTCs is a scan tool, also known as a code reader or diagnostic scanner. However, the capabilities and features of scan tools can vary widely, so it’s essential for technicians to choose tools that meet their specific needs.

Here are some essential tools and equipment for reading DTCs:

- Basic OBD2 Code Reader: A basic OBD2 code reader is an entry-level tool that can read and clear DTCs. These tools are typically inexpensive and easy to use, making them suitable for DIY enthusiasts and small repair shops. However, basic code readers usually offer limited functionality beyond reading and clearing codes.

- Advanced Scan Tool: An advanced scan tool offers a broader range of features, including the ability to display live data, perform bidirectional tests, and access manufacturer-specific codes. These tools are essential for professional technicians who need to diagnose complex issues and perform advanced diagnostics.

- Laptop-Based Diagnostic Systems: Laptop-based diagnostic systems consist of software and an interface cable that connects the vehicle to a laptop. These systems offer powerful diagnostic capabilities, including access to a vast database of DTCs, wiring diagrams, and repair procedures. They often include advanced features like oscilloscope functions and data logging.

- Multimeter: A multimeter is a versatile tool used to measure voltage, current, and resistance. It can be used to test sensors, circuits, and components related to emission control systems.

- Smoke Machine: A smoke machine is used to detect leaks in the EVAP system, vacuum lines, and exhaust system. It works by injecting smoke into the system and identifying areas where smoke is escaping.

- Fuel Pressure Tester: A fuel pressure tester is used to measure the pressure of the fuel system. It can help diagnose issues related to fuel delivery, such as a faulty fuel pump or a clogged fuel filter.

When selecting a scan tool, technicians should consider the following features:

- Compatibility: Ensure the scan tool is compatible with the makes and models of vehicles you will be working on.

- Functionality: Choose a tool that offers the features you need, such as live data, bidirectional tests, and access to manufacturer-specific codes.

- Ease of Use: Select a tool with an intuitive interface and clear instructions.

- Updates: Ensure the tool can be updated with the latest software and DTC definitions.

According to a survey by Snap-on, professional technicians prefer scan tools with advanced features and comprehensive coverage. Investing in the right tools and equipment is crucial for accurate and efficient diagnostics.

8. Step-by-Step Guide to Diagnosing Issues Using Mode 03

How can technicians systematically diagnose automotive issues using Mode 03 and Diagnostic Trouble Codes (DTCs)? Diagnosing automotive issues using Mode 03 involves a structured approach that combines the information provided by DTCs with visual inspections, component testing, and logical reasoning.

Here is a step-by-step guide to diagnosing issues using Mode 03:

- Connect the Scan Tool: Begin by connecting the scan tool to the vehicle’s OBD2 port, typically located under the dashboard. Turn the ignition to the “on” position without starting the engine.

- Read DTCs: Use the scan tool to read the DTCs stored in the vehicle’s computer. Record all the DTCs present, along with any freeze frame data.

- Research DTCs: Consult a reliable source, such as a service manual or an online database, to understand the meaning of each DTC. Identify the possible causes and related components.

- Verify the Problem: Before proceeding with any repairs, verify that the problem is still present. Check for any obvious symptoms, such as a rough idle, poor performance, or unusual noises.

- Perform a Visual Inspection: Conduct a thorough visual inspection of the affected system and related components. Look for any signs of damage, such as broken wires, loose connections, or leaking fluids.

- Test Components: Use a multimeter, smoke machine, or other diagnostic tools to test the components identified as possible causes. Compare the test results to the manufacturer’s specifications.

- Isolate the Problem: Based on the test results, isolate the problem to a specific component or circuit.

- Repair the Problem: Repair or replace the faulty component or circuit. Ensure that all connections are secure and that any necessary adjustments are made.

- Clear DTCs: After completing the repair, use the scan tool to clear the DTCs from the vehicle’s computer.

- Verify the Repair: Start the engine and allow it to run for several minutes. Monitor the system for any signs of the problem recurring. Perform a test drive to ensure that the vehicle is operating normally.

- Recheck DTCs: Use the scan tool to recheck for DTCs. If no new codes appear, the repair was successful.

According to ASE, following a systematic diagnostic process is crucial for accurate and efficient repairs. Technicians should always verify the problem, perform a thorough inspection, and test components before replacing any parts.

9. Advanced Diagnostic Techniques with Mode 03

What advanced diagnostic techniques can technicians employ using Mode 03 in conjunction with other diagnostic tools and data? While Mode 03 primarily provides Diagnostic Trouble Codes (DTCs), advanced diagnostic techniques can leverage this information in combination with other tools and data to pinpoint complex issues.

Here are some advanced diagnostic techniques using Mode 03:

- Using Freeze Frame Data: Freeze frame data captures the operating conditions of the vehicle at the moment a DTC was set. This data can include parameters such as engine speed, engine load, fuel trim, and coolant temperature. By analyzing freeze frame data, technicians can gain valuable insights into the conditions that triggered the DTC and narrow down the possible causes.

- Analyzing Live Data: Live data, also known as streaming data, provides real-time information about the vehicle’s sensors and systems. By monitoring live data while the engine is running, technicians can identify anomalies and inconsistencies that may not be apparent from DTCs alone. For example, a faulty oxygen sensor may produce erratic readings in live data, even if it hasn’t set a DTC.

- Performing Bidirectional Tests: Bidirectional tests allow technicians to control certain components and systems using the scan tool. This can be useful for testing the functionality of actuators, solenoids, and other components. For example, technicians can use a bidirectional test to activate the EGR valve and verify that it is opening and closing properly.

- Using a Lab Scope: A lab scope, also known as an oscilloscope, is a powerful tool for analyzing electrical signals. It can be used to diagnose issues with sensors, actuators, and circuits by displaying the waveform of the electrical signal. For example, a lab scope can be used to diagnose a faulty crankshaft position sensor by analyzing the waveform of its output signal.

- Performing Relative Compression Tests: A relative compression test measures the compression of each cylinder relative to the others. This test can be performed using a scan tool or a lab scope. By comparing the compression of each cylinder, technicians can identify cylinders with low compression, which may indicate issues such as worn piston rings or leaky valves.

- Utilizing Vehicle-Specific Diagnostic Procedures: Vehicle manufacturers often provide detailed diagnostic procedures for specific DTCs. These procedures may involve a series of tests and inspections to pinpoint the root cause of the problem. Technicians should consult the vehicle’s service manual or online resources to access these procedures.

According to a study by Autodata, the use of advanced diagnostic techniques can significantly reduce diagnostic time and improve the accuracy of repairs. Technicians who master these techniques are better equipped to tackle complex automotive issues.

10. Limitations and Challenges of Using Mode 03

What limitations and challenges might technicians encounter when using Mode 03 for diagnosing automotive problems? While Mode 03 is a valuable tool for diagnosing automotive problems, it is not without its limitations and challenges. Technicians should be aware of these issues to effectively use Mode 03 in conjunction with other diagnostic methods.

Here are some common limitations and challenges of using Mode 03:

- Limited Information: DTCs provide a starting point for diagnostics, but they do not always pinpoint the exact cause of the problem. A DTC may indicate a general area of concern, but further testing and inspection are often necessary to isolate the root cause.

- False Positives: DTCs can sometimes be triggered by factors other than a genuine fault. For example, a loose gas cap can trigger an EVAP system DTC, even if there is nothing wrong with the EVAP system itself.

- Intermittent Problems: Intermittent problems can be difficult to diagnose using Mode 03 because the DTC may not be present when the vehicle is being tested. In these cases, technicians may need to rely on freeze frame data or live data to capture the conditions that trigger the DTC.

- Multiple DTCs: When multiple DTCs are present, it can be difficult to determine which code is the primary cause of the problem. Technicians may need to prioritize the codes based on their severity and the symptoms of the vehicle.

- Manufacturer-Specific Codes: While many DTCs are standardized across all vehicles, some codes are manufacturer-specific. These codes can be difficult to interpret without access to the manufacturer’s service information.

- OBD2 System Limitations: The OBD2 system is primarily designed to monitor emissions-related components and systems. It may not provide information about other issues, such as problems with the braking system or the suspension.

- Tool Limitations: The capabilities of scan tools can vary widely. Some scan tools may offer limited functionality or lack the ability to access certain types of data.

According to a survey byidentifix, technicians often encounter challenges when diagnosing complex automotive problems, even with the use of Mode 03 and other diagnostic tools. Therefore, it’s essential for technicians to have a thorough understanding of automotive systems and to use a combination of diagnostic methods to accurately diagnose and repair problems.

11. Best Practices for Using Mode 03 in Automotive Repair

What are the best practices for using Mode 03 effectively in automotive repair to ensure accurate and efficient diagnostics? To ensure accurate and efficient diagnostics, technicians should follow best practices when using Mode 03 in automotive repair.

Here are some key best practices:

- Verify the Complaint: Always start by verifying the customer’s complaint. Ask detailed questions about the symptoms the vehicle is exhibiting and when they occur.

- Perform a Visual Inspection: Conduct a thorough visual inspection of the vehicle, looking for any obvious signs of damage, such as broken wires, loose connections, or leaking fluids.

- Connect the Scan Tool Properly: Ensure the scan tool is properly connected to the vehicle’s OBD2 port and that the ignition is in the “on” position without starting the engine.

- Record All DTCs: Record all DTCs present, along with any freeze frame data. This information can be valuable for diagnosing intermittent problems.

- Research DTCs: Consult a reliable source, such as a service manual or an online database, to understand the meaning of each DTC. Identify the possible causes and related components.

- Prioritize DTCs: If multiple DTCs are present, prioritize them based on their severity and the symptoms of the vehicle.

- Test Components Systematically: Test components in a logical and systematic manner, using a multimeter, smoke machine, or other diagnostic tools.

- Analyze Live Data: Monitor live data while the engine is running to identify anomalies and inconsistencies that may not be apparent from DTCs alone.

- Use Advanced Diagnostic Techniques: Employ advanced diagnostic techniques, such as bidirectional tests and lab scope analysis, to pinpoint complex issues.

- Consult Vehicle-Specific Information: Consult vehicle-specific service information for detailed diagnostic procedures and component locations.

- Verify Repairs: After completing the repair, clear the DTCs from the vehicle’s computer and verify that the problem has been resolved. Perform a test drive to ensure the vehicle is operating normally.

- Document Findings: Document all findings, test results, and repairs performed. This information can be valuable for future diagnostics.

According to a study by the Automotive Management Institute (AMI), technicians who follow best practices are more likely to accurately diagnose and repair automotive problems. Therefore, following these best practices can improve diagnostic efficiency and customer satisfaction.

12. The Future of OBD2 and Diagnostic Technologies

How might OBD2 and related diagnostic technologies evolve in the future to meet the increasing complexity of modern vehicles? The future of OBD2 and diagnostic technologies is likely to involve significant advancements to keep pace with the increasing complexity of modern vehicles. These advancements will focus on enhancing diagnostic capabilities, improving data accuracy, and facilitating remote diagnostics.

Here are some potential developments in the future of OBD2 and diagnostic technologies:

- Enhanced Data Logging: Future OBD systems may incorporate more sophisticated data logging capabilities, allowing technicians to capture a wider range of data over longer periods. This could be particularly useful for diagnosing intermittent problems that are difficult to replicate.

- Wireless Connectivity: Wireless connectivity, such as Bluetooth and Wi-Fi, is likely to become more prevalent in diagnostic tools, allowing technicians to access vehicle data from a greater distance. This could also enable remote diagnostics, where technicians can diagnose problems without physically being present with the vehicle.

- Cloud-Based Diagnostics: Cloud-based diagnostic systems could provide technicians with access to a vast database of diagnostic information, including DTC definitions, wiring diagrams, and repair procedures. These systems could also use artificial intelligence (AI) to analyze vehicle data and provide diagnostic recommendations.

- Integration with ADAS: As Advanced Driver Assistance Systems (ADAS) become more common, future OBD systems may need to integrate with these systems to provide diagnostic information about their performance. This could involve monitoring the sensors, cameras, and other components that make up ADAS.

- Cybersecurity Enhancements: With the increasing connectivity of modern vehicles, cybersecurity is becoming a growing concern. Future OBD systems may need to incorporate security features to protect against unauthorized access and tampering.

- Standardization of Diagnostic Protocols: Efforts to standardize diagnostic protocols are likely to continue, making it easier for technicians to diagnose vehicles from different manufacturers. This could involve the adoption of common diagnostic interfaces and data formats.

- Predictive Diagnostics: Predictive diagnostics uses data analytics to identify potential problems before they occur. This could involve monitoring vehicle data for patterns that indicate impending failures and alerting the driver or technician.

According to a report by McKinsey & Company, the automotive industry is undergoing a period of rapid technological change, and diagnostic technologies will need to evolve to keep pace. These advancements are likely to improve diagnostic accuracy, reduce repair times, and enhance the overall customer experience.

13. Mode 03 and Vehicle Inspection Programs

How is Mode 03 utilized in vehicle inspection programs, and what role does it play in ensuring vehicle compliance with emissions standards? Mode 03 plays a crucial role in vehicle inspection programs, particularly in states and regions that require regular emissions testing. During an inspection, technicians use Mode 03 to retrieve Diagnostic Trouble Codes (DTCs) from the vehicle’s computer, which provides a quick and standardized way to assess whether the vehicle is compliant with emissions standards.

Here’s how Mode 03 is typically used in vehicle inspection programs:

- Initial Scan: The inspection process begins with a scan of the vehicle’s OBD2 system using a scan tool. The tool retrieves any stored DTCs, which indicate potential issues with the vehicle’s emissions control systems.

- DTC Evaluation: The retrieved DTCs are then evaluated to determine whether the vehicle passes or fails the inspection. Some DTCs, particularly those related to critical emissions components, will automatically cause the vehicle to fail.

- Visual Inspection: In addition to the DTC scan, a visual inspection of the vehicle’s emissions components may be performed. This can include checking for damaged or missing components, such as the catalytic converter, oxygen sensors, and fuel cap.

- Functional Tests: Some inspection programs may also include functional tests of certain emissions components, such as the EGR valve and the EVAP system. These tests help to ensure that the components are operating properly.

- Pass/Fail Determination: Based on the results of the DTC scan, visual inspection, and functional tests, the vehicle is determined to have either passed or failed the inspection. If the vehicle fails, the owner is typically required to have the necessary repairs performed and then return for a re-inspection.

According to the EPA, vehicle inspection programs are an effective way to reduce air pollution and ensure that vehicles are operating within emissions standards. By using Mode 03 to quickly identify emissions-related issues, these programs can help to improve air quality and protect public health. Therefore, Mode 03 is an integral part of ensuring vehicles comply with environmental regulations.

14. Case Studies: Real-World Applications of Mode 03

Can you provide specific case studies illustrating how Mode 03 has been used to diagnose and resolve automotive issues in real-world scenarios? Several real-world case studies demonstrate how Mode 03, in conjunction with other diagnostic techniques, can be used to effectively diagnose and resolve automotive issues.

Here are a few examples:

Case Study 1: Catalytic Converter Efficiency

- Vehicle: 2010 Toyota Camry with 150,000 miles

- Complaint: Check engine light illuminated

- Diagnostic Steps:

- Technician connected a scan tool and retrieved DTC P0420 (Catalyst System Efficiency Below Threshold).

- Technician performed a visual inspection of the exhaust system, checking for leaks or damage.

- Technician monitored live data from the oxygen sensors to assess the performance of the catalytic converter.

- Technician used Mode 6 to access the on-board monitoring test results for the catalytic converter, confirming that it was not functioning efficiently.

- Resolution: Technician replaced the catalytic converter, cleared the DTC, and verified that the check engine light did not return.

Case Study 2: Vacuum Leak

- Vehicle: 2012 Honda Civic with 80,000 miles

- Complaint: Rough idle and poor fuel economy

- Diagnostic Steps:

- Technician connected a scan tool and retrieved DTC P0171 (System Too Lean).

- Technician performed a visual inspection of the engine compartment, checking for vacuum leaks.

- Technician used a smoke machine to identify a vacuum leak in the intake manifold gasket.

- Technician monitored live data from the mass airflow (MAF) sensor to confirm that it was operating properly.

- Resolution: Technician replaced the intake manifold gasket, cleared the DTC, and verified that the engine idled smoothly and fuel economy improved.

Case Study 3: Misfire

- Vehicle: 2015 Ford F-150 with 100,000 miles

- Complaint: Check engine light flashing and engine misfiring

- Diagnostic Steps:

- Technician connected a scan tool and retrieved DTC P0301 (Cylinder 1 Misfire).

- Technician performed a compression test on cylinder 1 to check for mechanical issues.

- Technician tested the spark plug, ignition coil, and fuel injector for cylinder 1.

- Technician used a lab scope to analyze the waveform of the ignition coil signal.

- Resolution: Technician replaced the faulty ignition coil on cylinder 1, cleared the DTC, and verified that the engine ran smoothly.

These case studies illustrate how Mode 03, in conjunction with other diagnostic techniques and tools, can be used to effectively diagnose and resolve automotive issues in real-world scenarios.

15. FAQ: Frequently Asked Questions About Mode 03

What are some frequently asked questions (FAQs) about Mode 03 that can help clarify its use and importance in automotive diagnostics? Here are some frequently asked questions about Mode 03 to help clarify its use and importance:

Q: What is Mode 03 in OBD2?

A: Mode 03 in OBD2 is the function that allows a scan tool to request and retrieve emissions-related Diagnostic Trouble Codes (DTCs) from the vehicle’s computer system.

Q: Why is Mode 03 important?

A: Mode 03 is important because it provides technicians with a standardized way to access DTCs, which are essential for diagnosing and repairing issues that could affect vehicle emissions and performance.

Q: How do I access Mode 03 data?

A: To access Mode 03 data, connect a scan tool to the vehicle’s OBD2 port, turn the ignition to the “on” position without starting the engine, and navigate the scan tool’s menu to find the “Read Codes” or “Diagnostic Codes” option.

Q: What do DTCs tell me?

A: DTCs provide a standardized way to identify and address issues affecting vehicle performance and emissions. Each code corresponds to a specific fault, such as a misfire, a faulty sensor, or a malfunctioning component.

Q: Are all DTCs the same across different vehicles?

A: Most DTCs are standardized across all vehicles, but some codes are manufacturer-specific. These codes provide more detailed information unique to a particular make or model.

Q: Can I fix my car just by reading the DTC?

A: Reading the DTC is just the first step. While it helps identify the potential issue, further diagnostics, testing, and inspection are often necessary to isolate the root cause and perform the appropriate repairs.

Q: What tools do I need to read DTCs?

A: The primary tool for reading DTCs is a scan tool, also known as a code reader or diagnostic scanner. However, the capabilities and features of scan tools can vary widely.

Q: What are some common emission-related DTCs?

A: Some common emission-related DTCs include P0420 (Catalyst System Efficiency Below Threshold), P0171 (System Too Lean), and P0440 (Evaporative Emission Control System Malfunction).

Q: How can I use Mode 03 to diagnose intermittent problems?

A: For intermittent problems, you may need to rely on freeze frame data or live data to capture the conditions that trigger the DTC.

Q: Where can I find more information about DTCs?

A: You can find more information about DTCs in service manuals, online databases, and automotive forums.

16. CAR-TOOL.EDU.VN: Your Partner in Automotive Diagnostics

Looking for reliable information and tools for automotive diagnostics? CAR-TOOL.EDU.VN offers a comprehensive range of resources and products to assist technicians and vehicle owners in diagnosing and resolving automotive issues efficiently. At CAR-TOOL.EDU.VN, we understand the challenges of modern automotive repair and are committed to providing the tools and knowledge you need to succeed.

Here are some benefits of using CAR-TOOL.EDU.VN:

- Extensive Product Selection: We offer a wide range of scan tools, code readers, and diagnostic equipment from leading brands. Whether you’re a professional technician or a DIY enthusiast, we have the tools to meet your needs.

- Detailed Product Information: Our website provides detailed product information, including specifications, features, and customer reviews, to help you make informed purchasing decisions.

- Expert Advice: Our team of experienced automotive professionals is available to answer your questions and provide expert advice on diagnostic techniques and tool selection.

- Training Resources: We offer a variety of training resources, including articles, videos, and online courses, to help you improve your diagnostic skills.

- Competitive Pricing: We offer competitive pricing on all our products, ensuring you get the best value for your money.

CAR-TOOL.EDU.VN is your trusted partner in automotive diagnostics. Whether you’re looking for a basic code reader or an advanced scan tool, we have the resources and expertise to help you succeed. Visit our website today to explore our product selection and learn more about how we can assist you with your diagnostic needs.

Need assistance in finding the right tools and equipment for your automotive diagnostic needs? Contact us today for expert advice and personalized recommendations. Reach out to us at 456 Elm Street, Dallas, TX 75201, United States, or give us a call on Whatsapp at +1 (641) 206-8880. You can also visit our website at CAR-TOOL.EDU.VN for more information. Let CAR-TOOL.EDU.VN be your trusted partner in automotive diagnostics, helping you keep vehicles running smoothly and efficiently.

A professional OBD2 scanner displaying real-time diagnostic data during a vehicle inspection.

*Illustration showing the location of a vehicle’s OBD2