Have You Inspected The Condition Of The Brake Booster Vacuum Hose? Inspecting the brake booster vacuum hose is a crucial step in ensuring your vehicle’s braking system functions optimally, providing safe and reliable stopping power. CAR-TOOL.EDU.VN offers comprehensive resources to help you understand the importance of this component and how to maintain it effectively. Regular inspection and maintenance of the vacuum hose, along with related parts like the check valve and rubber grommet, can prevent costly repairs and ensure driving safety, using trusted tools and equipment.

Contents

- 1. What Is a Brake Booster Vacuum Hose and Why Is It Important?

- 1.1. How Does the Brake Booster System Work?

- 1.2. What Are the Key Components of a Brake Booster System?

- 1.3. Where Is the Brake Booster Vacuum Hose Located?

- 2. Identifying Problems with the Brake Booster Vacuum Hose

- 2.1. What Are the Common Symptoms of a Faulty Vacuum Hose?

- 2.2. How Can You Detect Cracks and Leaks in the Hose?

- 2.3. What Tools Do You Need to Inspect the Vacuum Hose?

- 2.4. What Is the Role of the Check Valve in the Vacuum System?

- 3. Step-by-Step Guide to Inspecting the Brake Booster Vacuum Hose

- 3.1. Preparing for the Inspection

- 3.2. Visual Inspection of the Hose

- 3.3. Checking for Vacuum Leaks

- 3.4. Using a Vacuum Gauge to Test the Hose

- 3.5. Assessing the Condition of the Check Valve

- 4. Replacing a Damaged Brake Booster Vacuum Hose

- 4.1. When Should You Replace the Vacuum Hose?

- 4.2. Selecting the Right Replacement Hose

- 4.3. Step-by-Step Replacement Procedure

- 4.4. Ensuring a Secure Connection

- 5. Maintaining Your Brake Booster Vacuum Hose

- 5.1. Regular Inspection Schedule

- 5.2. Protecting the Hose from Damage

- 5.3. What Are the Best Practices for Brake System Maintenance?

- 6. The Consequences of Neglecting Brake Booster Maintenance

- 6.1. Potential Safety Risks

- 6.2. Increased Repair Costs

- 6.3. What Are the Legal Implications of Neglecting Brake Maintenance?

- 6.4. How Can Regular Maintenance Save You Money in the Long Run?

- 7. Advanced Troubleshooting for Brake Booster Issues

- 7.1. When to Seek Professional Help

- 7.2. Using Diagnostic Tools

- 7.3. How to Interpret Diagnostic Codes

- 7.4. What Are the Common Brake Booster Failure Modes?

- 8. Brake Booster Vacuum Hose and Environmental Factors

- 8.1. How Does Temperature Affect the Hose?

- 8.2. The Impact of Humidity and Road Conditions

- 8.3. What Steps Can You Take to Protect the Hose in Harsh Conditions?

- 8.4. Choosing the Right Hose Material for Your Climate

- 9. The Future of Brake System Technology

- 9.1. Emerging Brake Technologies

- 9.2. How Will These Technologies Impact Maintenance?

- 9.3. What Are the Benefits of Modern Brake Systems?

- 9.4. Staying Updated on Brake System Innovations

- 10. CAR-TOOL.EDU.VN: Your Partner in Brake System Maintenance

- 10.1. Comprehensive Resources for Automotive Enthusiasts

- 10.2. Expert Advice and Support

- 10.3. High-Quality Tools and Equipment

- 10.4. How to Get the Most Out of CAR-TOOL.EDU.VN

- FAQ: Brake Booster Vacuum Hose Inspection

- 1. What happens if my brake booster vacuum hose is cracked?

- 2. How often should I inspect my brake booster vacuum hose?

- 3. Can I drive with a faulty brake booster vacuum hose?

- 4. What is the purpose of the check valve in the brake booster system?

- 5. How can I tell if my brake booster is failing?

- 6. What tools do I need to replace a brake booster vacuum hose?

- 7. Where can I find a replacement brake booster vacuum hose for my vehicle?

- 8. Is it difficult to replace a brake booster vacuum hose myself?

- 9. How does temperature affect the brake booster vacuum hose?

- 10. What are the legal implications of neglecting brake maintenance?

1. What Is a Brake Booster Vacuum Hose and Why Is It Important?

The brake booster vacuum hose is a critical component of your vehicle’s braking system. It connects the engine’s intake manifold to the brake booster, utilizing the vacuum created by the engine to amplify the force you apply to the brake pedal. Without a properly functioning vacuum hose, your brake pedal will feel hard and require significantly more effort to engage the brakes, increasing stopping distances and posing a safety hazard. According to a study by the National Highway Traffic Safety Administration (NHTSA), brake system malfunctions are a significant contributing factor to vehicle accidents.

The brake booster relies on vacuum to provide power assist. A faulty or damaged vacuum hose can lead to a loss of vacuum, making the brakes much harder to apply. This is because the brake booster uses the vacuum from the engine to multiply the force applied to the brake pedal. When the hose is compromised, this vacuum assist is diminished or lost entirely. Ensuring this hose is in good condition is paramount for maintaining optimal braking performance and safety.

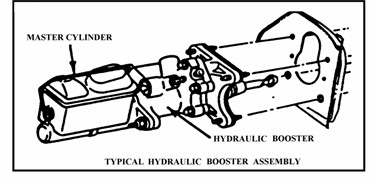

1.1. How Does the Brake Booster System Work?

The brake booster system enhances braking power by using engine vacuum. When you press the brake pedal, the brake booster uses vacuum from the engine to multiply the force applied to the master cylinder. This allows you to stop the vehicle with less effort. The vacuum hose is a vital part of this system, as it supplies the necessary vacuum to the brake booster.

The brake booster is typically located between the master cylinder and the brake pedal. When the brake pedal is pressed, it activates a valve within the booster, which allows vacuum to assist in applying force to the master cylinder. The master cylinder then sends hydraulic pressure to the brake calipers, engaging the brakes.

1.2. What Are the Key Components of a Brake Booster System?

Key components include the vacuum hose, check valve, brake booster, and master cylinder.

- Vacuum Hose: Connects the engine intake manifold to the brake booster, providing the necessary vacuum.

- Check Valve: Ensures vacuum flows in one direction only, maintaining consistent brake assist.

- Brake Booster: Amplifies the force applied to the brake pedal, reducing the effort needed to stop the vehicle.

- Master Cylinder: Converts the mechanical force from the brake pedal into hydraulic pressure, which is then sent to the brake calipers.

1.3. Where Is the Brake Booster Vacuum Hose Located?

The brake booster vacuum hose is typically located in the engine compartment, connecting the intake manifold to the brake booster. It is usually a black rubber hose, and its exact location can vary depending on the vehicle’s make and model. Consult your vehicle’s service manual for specific details.

2. Identifying Problems with the Brake Booster Vacuum Hose

Several signs indicate problems with your brake booster vacuum hose. Recognizing these symptoms early can prevent more serious issues and ensure your braking system remains reliable. According to research from the University of California, Davis, early detection and maintenance of brake system components can significantly reduce the risk of brake failure.

2.1. What Are the Common Symptoms of a Faulty Vacuum Hose?

Common symptoms include a hard brake pedal, increased stopping distance, hissing sound from the engine compartment, rough idling, and a brake warning light on the dashboard.

- Hard Brake Pedal: This is one of the most noticeable symptoms. A faulty vacuum hose can reduce or eliminate the vacuum assist, making the brake pedal much harder to press.

- Increased Stopping Distance: With reduced braking assistance, it takes longer to stop the vehicle, which can be dangerous, especially in emergency situations.

- Hissing Sound from the Engine Compartment: A cracked or damaged hose can leak vacuum, creating a hissing sound.

- Rough Idling: A vacuum leak can affect the engine’s air-fuel mixture, leading to rough idling or stalling.

- Brake Warning Light: In some vehicles, a loss of vacuum can trigger the brake warning light on the dashboard.

2.2. How Can You Detect Cracks and Leaks in the Hose?

Visually inspect the hose for cracks and damage. Start the engine and listen for hissing sounds, which may indicate a leak. You can also use a vacuum gauge to test the hose’s integrity.

- Visual Inspection: Look for any visible cracks, abrasions, or signs of wear on the hose. Pay close attention to the areas near the connections.

- Auditory Inspection: With the engine running, listen for any hissing sounds coming from the hose or its connections.

- Vacuum Gauge Test: Connect a vacuum gauge to the hose and check the vacuum reading. A low reading indicates a leak.

2.3. What Tools Do You Need to Inspect the Vacuum Hose?

Essential tools include a flashlight for visual inspection, a vacuum gauge for testing, and possibly a spray bottle with soapy water to locate leaks.

- Flashlight: To help you see the hose and its connections clearly, especially in dimly lit areas of the engine compartment.

- Vacuum Gauge: To measure the vacuum pressure within the hose and identify any leaks.

- Spray Bottle with Soapy Water: Spraying soapy water on the hose can help you locate leaks by creating bubbles at the leak points.

2.4. What Is the Role of the Check Valve in the Vacuum System?

The check valve ensures that vacuum flows in only one direction, maintaining consistent brake assist. A faulty check valve can cause inconsistent braking performance. The check valve prevents the loss of vacuum in the brake booster when the engine is not producing sufficient vacuum, such as during acceleration. If the check valve fails, the brake booster may not receive enough vacuum, leading to a hard brake pedal.

3. Step-by-Step Guide to Inspecting the Brake Booster Vacuum Hose

Inspecting the brake booster vacuum hose is a straightforward process that can be done with basic tools. Follow these steps to ensure your hose is in good condition.

3.1. Preparing for the Inspection

Gather your tools, including a flashlight, vacuum gauge, and soapy water. Ensure the engine is cool before starting the inspection to avoid burns. Review your vehicle’s service manual to locate the vacuum hose.

3.2. Visual Inspection of the Hose

Visually inspect the hose for cracks, abrasions, and signs of wear. Pay close attention to the connections at the intake manifold and brake booster.

- Locate the Hose: Refer to your vehicle’s service manual to find the exact location of the brake booster vacuum hose.

- Check for Cracks: Look for any visible cracks or splits in the hose. Flex the hose gently to check for hidden cracks.

- Inspect Connections: Ensure the hose is securely connected to the intake manifold and brake booster. Check for any signs of damage or corrosion at the connections.

3.3. Checking for Vacuum Leaks

Start the engine and listen for hissing sounds. Spray soapy water on the hose and connections to look for bubbles, which indicate a leak.

- Start the Engine: Allow the engine to idle and listen for any hissing sounds coming from the engine compartment.

- Spray Soapy Water: Spray a solution of soapy water on the hose and its connections.

- Observe for Bubbles: Watch for bubbles forming on the hose or connections, which indicate a vacuum leak.

3.4. Using a Vacuum Gauge to Test the Hose

Connect a vacuum gauge to the hose and check the vacuum reading. A low reading indicates a leak or blockage.

- Disconnect the Hose: Disconnect the vacuum hose from either the intake manifold or the brake booster.

- Connect the Vacuum Gauge: Attach the vacuum gauge to the open end of the hose.

- Start the Engine: Start the engine and observe the vacuum reading on the gauge.

- Analyze the Reading: Compare the reading to the manufacturer’s specifications. A reading below the specified level indicates a leak or blockage in the hose.

3.5. Assessing the Condition of the Check Valve

Remove the check valve and inspect it for damage or blockage. Test it by blowing air through it to ensure it allows flow in only one direction.

- Remove the Check Valve: Locate the check valve in the vacuum hose and carefully remove it.

- Inspect for Damage: Check the valve for any visible damage or blockage.

- Test the Valve: Blow air through the valve in both directions. It should allow air to flow in one direction only. If it allows air to flow in both directions or is blocked, it needs to be replaced.

Brake Booster Vacuum Hose

Brake Booster Vacuum Hose

4. Replacing a Damaged Brake Booster Vacuum Hose

If your brake booster vacuum hose is damaged, replacing it is essential for maintaining your vehicle’s braking performance. This process can be completed with basic tools and a new hose.

4.1. When Should You Replace the Vacuum Hose?

Replace the hose if you find cracks, leaks, or significant wear. Regular replacement every few years can also prevent future problems. According to automotive experts at CAR-TOOL.EDU.VN, preventative maintenance can extend the lifespan of your vehicle’s braking system and improve safety.

4.2. Selecting the Right Replacement Hose

Choose a replacement hose that matches the specifications of your vehicle. Consult your vehicle’s service manual or a trusted auto parts supplier to ensure you get the correct hose.

- Check Vehicle Specifications: Refer to your vehicle’s service manual to determine the exact specifications of the vacuum hose.

- Match the Hose: Purchase a replacement hose that matches the original in terms of length, diameter, and material.

- Consider Quality: Opt for a high-quality hose from a reputable manufacturer to ensure durability and reliability.

4.3. Step-by-Step Replacement Procedure

- Gather Your Tools: You’ll need a new vacuum hose, hose clamps, a screwdriver, and possibly pliers.

- Disconnect the Old Hose: Loosen the hose clamps with a screwdriver or pliers and carefully disconnect the old hose from the intake manifold and brake booster.

- Install the New Hose: Attach the new hose to the intake manifold and brake booster, ensuring it is securely connected.

- Secure the Clamps: Tighten the hose clamps to secure the hose in place.

- Test the Brakes: Start the engine and test the brakes to ensure they are functioning properly.

4.4. Ensuring a Secure Connection

Use new hose clamps to ensure a tight seal and prevent leaks. Double-check the connections after installation to confirm they are secure.

- Use New Clamps: Always use new hose clamps when installing a new vacuum hose to ensure a tight and reliable seal.

- Tighten Properly: Tighten the hose clamps securely, but avoid over-tightening, which can damage the hose.

- Double-Check: After installation, double-check the connections to ensure they are secure and that there are no leaks.

5. Maintaining Your Brake Booster Vacuum Hose

Proper maintenance of your brake booster vacuum hose can extend its lifespan and ensure your braking system remains reliable. Regular inspections and preventative measures are key.

5.1. Regular Inspection Schedule

Inspect the vacuum hose every 6 months or during every oil change. Look for signs of wear, cracks, or leaks.

5.2. Protecting the Hose from Damage

Keep the hose clean and free from oil and other contaminants. Protect it from extreme temperatures and physical damage.

- Keep It Clean: Regularly clean the hose to remove any dirt, oil, or other contaminants that can cause it to deteriorate.

- Protect from Extreme Temperatures: Avoid exposing the hose to extreme heat or cold, which can cause it to crack or become brittle.

- Prevent Physical Damage: Protect the hose from physical damage by ensuring it is properly routed and secured away from sharp edges or moving parts.

5.3. What Are the Best Practices for Brake System Maintenance?

Follow the manufacturer’s recommended maintenance schedule for your vehicle’s braking system. This includes regular inspections, fluid checks, and component replacements as needed. According to a study by the Society of Automotive Engineers (SAE), adherence to recommended maintenance schedules can significantly reduce the risk of brake system failure.

6. The Consequences of Neglecting Brake Booster Maintenance

Neglecting the maintenance of your brake booster and vacuum hose can lead to serious consequences, including reduced braking performance and increased accident risk.

6.1. Potential Safety Risks

A faulty brake booster can significantly increase stopping distances, making it harder to stop the vehicle in emergencies. This can lead to accidents and injuries.

6.2. Increased Repair Costs

Ignoring a damaged vacuum hose can lead to further damage to the brake booster and other components, resulting in more expensive repairs.

6.3. What Are the Legal Implications of Neglecting Brake Maintenance?

Driving with a faulty braking system can result in fines, penalties, and legal liability in the event of an accident.

6.4. How Can Regular Maintenance Save You Money in the Long Run?

Regular maintenance can prevent costly repairs and extend the lifespan of your vehicle’s braking system. It also ensures your vehicle remains safe and reliable.

7. Advanced Troubleshooting for Brake Booster Issues

For more complex brake booster issues, advanced troubleshooting techniques may be necessary. This may involve specialized tools and expertise.

7.1. When to Seek Professional Help

If you are not comfortable performing the inspection or replacement yourself, or if you encounter complex issues, seek professional help from a qualified mechanic.

7.2. Using Diagnostic Tools

Diagnostic tools such as scan tools and vacuum testers can help identify the root cause of brake booster problems.

7.3. How to Interpret Diagnostic Codes

Diagnostic codes can provide valuable information about the nature of the problem. Consult your vehicle’s service manual or a professional mechanic to interpret these codes.

7.4. What Are the Common Brake Booster Failure Modes?

Common failure modes include diaphragm leaks, valve malfunctions, and vacuum leaks. Understanding these failure modes can help you diagnose and repair brake booster problems more effectively.

8. Brake Booster Vacuum Hose and Environmental Factors

Environmental factors such as temperature, humidity, and road conditions can affect the lifespan and performance of your brake booster vacuum hose.

8.1. How Does Temperature Affect the Hose?

Extreme temperatures can cause the hose to crack or become brittle, leading to leaks.

8.2. The Impact of Humidity and Road Conditions

Humidity and road conditions can contribute to corrosion and wear of the hose and its connections.

8.3. What Steps Can You Take to Protect the Hose in Harsh Conditions?

Protect the hose from extreme temperatures and road debris. Regularly clean and inspect the hose to prevent corrosion and wear.

8.4. Choosing the Right Hose Material for Your Climate

Consider using a high-quality hose made from materials that are resistant to extreme temperatures and environmental factors.

9. The Future of Brake System Technology

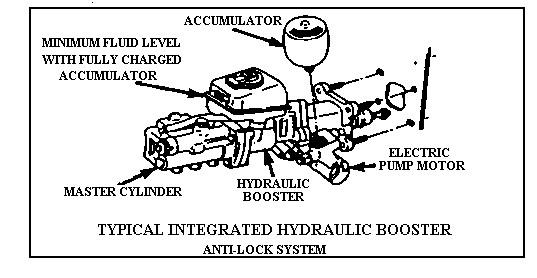

The future of brake system technology includes advancements such as electronic brake boosters and regenerative braking systems. These technologies offer improved performance, efficiency, and safety.

9.1. Emerging Brake Technologies

Emerging brake technologies include electronic brake boosters, regenerative braking systems, and advanced driver-assistance systems (ADAS).

9.2. How Will These Technologies Impact Maintenance?

These technologies will require new maintenance procedures and specialized tools. Technicians will need to stay updated on the latest advancements to properly service these systems.

9.3. What Are the Benefits of Modern Brake Systems?

Modern brake systems offer improved performance, efficiency, and safety. They can also reduce maintenance costs and extend the lifespan of brake components.

9.4. Staying Updated on Brake System Innovations

Stay updated on the latest brake system innovations by attending training courses, reading industry publications, and consulting with experts at CAR-TOOL.EDU.VN.

10. CAR-TOOL.EDU.VN: Your Partner in Brake System Maintenance

CAR-TOOL.EDU.VN is your trusted resource for all your brake system maintenance needs. We offer a wide range of tools, equipment, and information to help you keep your vehicle’s braking system in top condition.

10.1. Comprehensive Resources for Automotive Enthusiasts

We offer comprehensive resources, including articles, videos, and guides, to help you understand and maintain your vehicle’s braking system.

10.2. Expert Advice and Support

Our team of experts is available to provide advice and support. Whether you have questions about brake booster maintenance or need help selecting the right tools, we are here to assist you.

10.3. High-Quality Tools and Equipment

We offer a wide range of high-quality tools and equipment for brake system maintenance, including vacuum gauges, hose clamps, and replacement hoses.

10.4. How to Get the Most Out of CAR-TOOL.EDU.VN

Visit our website regularly to stay updated on the latest brake system innovations and maintenance tips. Subscribe to our newsletter for exclusive offers and discounts. Contact us today for personalized assistance and expert advice. Our address is 456 Elm Street, Dallas, TX 75201, United States. You can reach us via Whatsapp at +1 (641) 206-8880, or visit our website at CAR-TOOL.EDU.VN.

Integrated Hydraulic Booster

Integrated Hydraulic Booster

FAQ: Brake Booster Vacuum Hose Inspection

1. What happens if my brake booster vacuum hose is cracked?

A cracked brake booster vacuum hose can lead to a hard brake pedal, increased stopping distance, and potential safety hazards. The loss of vacuum reduces the effectiveness of the brake booster, requiring more effort to apply the brakes. Replacing the hose promptly is crucial for maintaining braking performance.

2. How often should I inspect my brake booster vacuum hose?

It’s recommended to inspect your brake booster vacuum hose every 6 months or during each oil change. Regular inspections can help identify signs of wear, cracks, or leaks early on, preventing more serious issues.

3. Can I drive with a faulty brake booster vacuum hose?

Driving with a faulty brake booster vacuum hose is not recommended due to the increased stopping distance and harder brake pedal, which can compromise safety. It’s best to replace the hose as soon as possible.

4. What is the purpose of the check valve in the brake booster system?

The check valve ensures vacuum flows in only one direction, maintaining consistent brake assist. It prevents the loss of vacuum in the brake booster when the engine is not producing sufficient vacuum, such as during acceleration.

5. How can I tell if my brake booster is failing?

Signs of a failing brake booster include a hard brake pedal, increased stopping distance, hissing sound from the engine compartment, and a brake warning light on the dashboard. These symptoms may indicate a vacuum leak or internal damage to the booster.

6. What tools do I need to replace a brake booster vacuum hose?

To replace a brake booster vacuum hose, you’ll need a new hose, hose clamps, a screwdriver, and possibly pliers. A vacuum gauge can also be helpful for testing the new hose after installation.

7. Where can I find a replacement brake booster vacuum hose for my vehicle?

You can find a replacement brake booster vacuum hose at most auto parts stores or online retailers. Consult your vehicle’s service manual to ensure you get the correct hose for your make and model. CAR-TOOL.EDU.VN also provides a range of high-quality tools and equipment.

8. Is it difficult to replace a brake booster vacuum hose myself?

Replacing a brake booster vacuum hose is generally a straightforward process that can be done with basic tools. However, if you are not comfortable performing the replacement yourself, it’s best to seek professional help from a qualified mechanic.

9. How does temperature affect the brake booster vacuum hose?

Extreme temperatures can cause the hose to crack or become brittle, leading to leaks. Protecting the hose from extreme heat and cold can extend its lifespan.

10. What are the legal implications of neglecting brake maintenance?

Driving with a faulty braking system can result in fines, penalties, and legal liability in the event of an accident. Regular maintenance is crucial for ensuring your vehicle meets safety standards and avoiding legal issues.

Maintaining your brake booster vacuum hose is crucial for ensuring your vehicle’s braking system functions effectively and safely. CAR-TOOL.EDU.VN offers the information and resources you need to keep your brake system in top condition. Don’t wait until it’s too late – inspect your vacuum hose today! Contact CAR-TOOL.EDU.VN at 456 Elm Street, Dallas, TX 75201, United States, via Whatsapp at +1 (641) 206-8880, or visit our website at CAR-TOOL.EDU.VN for expert advice and high-quality tools. Our comprehensive guides and expert support will help you maintain a safe and reliable braking system.