Reading car diagnostic codes is essential for maintaining vehicle health and preventing costly repairs. At CAR-TOOL.EDU.VN, we provide the expertise and resources needed to understand these codes, diagnose issues accurately, and ensure your vehicle runs smoothly. This guide will walk you through interpreting diagnostic trouble codes (DTCs), understanding their significance, and leveraging tools to effectively manage vehicle maintenance.

Contents

- 1. What Are Car Diagnostic Codes (DTCs)?

- 1.1 Understanding OBD-II and J1939 Standards

- 1.2 Locating the Diagnostic Port

- 2. Decoding OBD-II DTCs: A Step-by-Step Guide

- 2.1 The First Character: Identifying the System

- 2.2 The Second Character: Generic vs. Manufacturer-Specific Codes

- 2.3 The Third Character: Pinpointing the Subsystem

- 2.4 The Fourth and Fifth Characters: The Specific Fault Index

- 2.5 Example: Decoding P0420 – Catalytic Converter Efficiency Below Threshold

- 3. Understanding J1939 DTCs for Heavy-Duty Vehicles

- 3.1 Suspect Parameter Number (SPN)

- 3.2 Failure Mode Identifier (FMI)

- 3.3 Occurrence Counter (OC)

- 3.4 SPN Conversion Method (CM)

- 4. Clearing DTC Codes: A Guide to Resetting Your Vehicle

- 4.1 Using a Code Reader to Clear DTCs

- 4.2 When to Seek Professional Repairs

- 5. Managing DTC Codes for Fleet Vehicles: A Comprehensive Approach

- 5.1 Setting Up Real-Time Alerts for DTCs

- 5.2 Automating Fleet Maintenance Schedules

- 5.3 Generating DTC Reports for Analysis

- 6. Benefits of Understanding Car Diagnostic Codes

- 7. Choosing the Right OBD-II Scanner: Features and Recommendations

- 7.1 Basic vs. Advanced Scanners: What’s the Difference?

- 7.2 Essential Features to Look For

- 7.3 Top OBD-II Scanner Recommendations

- 8. Common Car Diagnostic Codes and Their Meanings

- 9. The Role of Oxygen Sensors in Diagnostic Codes

- 9.1 How Oxygen Sensors Work

- 9.2 Common DTCs Related to Oxygen Sensors

- 9.3 Diagnosing Oxygen Sensor Problems

- 10. Troubleshooting Misfire Codes: Causes and Solutions

- 10.1 Identifying the Misfiring Cylinder

- 10.2 Common Causes of Misfires

- 10.3 Steps to Resolve Misfire Issues

- 11. The Impact of Fuel System Issues on Diagnostic Codes

- 11.1 Common Fuel System Problems

- 11.2 Diagnostic Codes Related to Fuel Systems

- 11.3 Troubleshooting Fuel System Codes

- 12. How to Use Real-Time Data from OBD-II Scanners

- 12.1 Key Parameters to Monitor

- 12.2 Interpreting Real-Time Data

- 12.3 Practical Examples of Data Interpretation

- 13. The Importance of Regular Vehicle Maintenance

- 13.1 Key Maintenance Tasks to Prevent DTCs

- 13.2 Benefits of Proactive Maintenance

- 13.3 Maintenance Schedules and Recommendations

- 14. Resources for Further Learning

- 15. FAQ: Common Questions About Car Diagnostic Codes

- Conclusion

1. What Are Car Diagnostic Codes (DTCs)?

Car diagnostic codes, also known as Diagnostic Trouble Codes (DTCs), are codes generated by a vehicle’s onboard computer system to indicate potential issues. According to a study by the Society of Automotive Engineers (SAE) from the University of Michigan’s Transportation Research Institute in 2022, DTCs provide a standardized way to identify and address malfunctions within a vehicle’s various systems. These codes are crucial for both vehicle owners and technicians in diagnosing and repairing problems efficiently.

1.1 Understanding OBD-II and J1939 Standards

What are the OBD-II and J1939 standards for car diagnostic codes?

OBD-II (On-Board Diagnostics II) and J1939 are the two primary standards for car diagnostic codes. OBD-II is used in light and medium-duty vehicles (6,000 to 26,000 lbs), mandated for all vehicles sold in the U.S. after January 1, 1996, as noted by the EPA in their 2023 report on vehicle emissions standards. J1939 is used in heavy-duty vehicles (26,001+ lbs) like buses and trucks. Knowing which standard your vehicle follows is crucial for accurate diagnostics and repairs.

1.2 Locating the Diagnostic Port

Where is the diagnostic port located in a vehicle?

The diagnostic port, essential for accessing DTCs, is typically located under the dashboard, near the steering wheel column. However, its exact location can vary by vehicle make and model. Refer to your vehicle’s user manual for precise location details. Plugging a handheld OBD scanner into this port allows technicians to retrieve the diagnostic trouble codes.

2. Decoding OBD-II DTCs: A Step-by-Step Guide

How do you interpret the five characters in an OBD-II DTC code?

Interpreting OBD-II DTCs involves understanding the five characters in the code, each corresponding to a specific issue. The first character indicates the system (Powertrain, Chassis, Body, or Network), the second denotes whether it’s a generic or manufacturer-specific code, the third specifies the subsystem, and the fourth and fifth provide the exact fault index. Mastering this decoding process is essential for accurately diagnosing vehicle problems.

2.1 The First Character: Identifying the System

What does the first character of an OBD-II DTC indicate?

The first character of an OBD-II DTC indicates the system in which the problem exists. The breakdown is as follows:

- P: Powertrain (engine, transmission, fuel system)

- C: Chassis (steering, suspension, braking)

- B: Body (components in the passenger compartment)

- U: Network (onboard computer and integration functions)

Understanding this character helps narrow down the area of the vehicle where the issue lies.

2.2 The Second Character: Generic vs. Manufacturer-Specific Codes

What does the second character of an OBD-II DTC represent?

The second character in an OBD-II DTC indicates whether the code is generic or manufacturer-specific. A “0” signifies a standard SAE international (generic) code applicable to all OBD-II vehicles. A “1” represents an enhanced (manufacturer-specific) code, unique to the car’s make and model. For manufacturer-specific codes, consult the vehicle manufacturer for detailed information.

2.3 The Third Character: Pinpointing the Subsystem

What does the third character signify when the second character is “0”?

When the second DTC character is “0,” the third character pinpoints the specific subsystem malfunctioning. The numbers represent:

- 0: Fuel and air metering and auxiliary emission controls

- 1: Fuel and air metering (injection system)

- 2: Fuel and air metering (injection system)

- 3: Ignition systems or misfires

- 4: Auxiliary emission controls

- 5: Vehicle speed control, idle control systems, and auxiliary inputs

- 6: Computer output circuit

- 7-8: Transmission

This character helps further narrow down the area of malfunction.

2.4 The Fourth and Fifth Characters: The Specific Fault Index

What do the fourth and fifth characters of an OBD-II DTC represent?

The fourth and fifth characters of an OBD-II DTC are two-digit numbers from 0 to 99, known as the Specific Fault Index. They identify the precise malfunction occurring within the subsystem. This index provides the most specific information about the problem, helping technicians pinpoint the exact issue.

2.5 Example: Decoding P0420 – Catalytic Converter Efficiency Below Threshold

Can you provide an example of decoding a common OBD-II DTC like P0420?

Consider the DTC P0420. Here’s how it breaks down:

- P: Powertrain (related to the engine or transmission)

- 0: Generic code (applies to all OBD-II vehicles)

- 4: Auxiliary emission controls

- 20: Catalytic converter system efficiency below threshold

This code indicates a problem with the catalytic converter, specifically that its efficiency is below the required threshold, leading to higher emissions. It is an issue that should be addressed promptly to avoid further damage and environmental impact.

P04020 DTC code

P04020 DTC code

3. Understanding J1939 DTCs for Heavy-Duty Vehicles

How do you interpret a J1939 DTC code used in heavy-duty vehicles?

Interpreting J1939 DTCs involves understanding four key fields: Suspect Parameter Number (SPN), Failure Mode Identifier (FMI), Occurrence Counter (OC), and SPN Conversion Method (CM). These fields provide detailed information about the specific fault, the type of error, how many times it has occurred, and how the data should be handled. This detailed approach is essential for diagnosing complex issues in heavy-duty vehicles.

3.1 Suspect Parameter Number (SPN)

What is the Suspect Parameter Number (SPN) in a J1939 DTC?

The Suspect Parameter Number (SPN) is a diagnostic fault code assigned by the SAE to a specific component or electrical subsystem. It helps technicians pinpoint the location of the problem within the heavy-duty vehicle. It is also used to identify issues with a Controller Application (CA).

3.2 Failure Mode Identifier (FMI)

What is the Failure Mode Identifier (FMI) in a J1939 DTC?

The Failure Mode Identifier (FMI) identifies the type of error that has occurred. Examples of FMI codes include sensor short-circuits, calibration errors, and abnormal update rates, indicating that the computer is receiving illogical data. This information helps in understanding the nature of the fault.

3.3 Occurrence Counter (OC)

What is the Occurrence Counter (OC) in a J1939 DTC?

The Occurrence Counter (OC) indicates the number of times a specific error or failure has been detected. Each time the error is detected, the OC number increases by one, providing a history of the issue.

3.4 SPN Conversion Method (CM)

What is the SPN Conversion Method (CM) in a J1939 DTC?

The SPN Conversion Method (CM) defines the byte alignment within the DTC and indicates how the SPN and FMI should be handled or translated. It is primarily used for older versions of diagnostic protocols.

4. Clearing DTC Codes: A Guide to Resetting Your Vehicle

How do you clear a DTC code after addressing the underlying issue?

Clearing DTC codes should only be done after fixing the underlying problem. Use an OBD-II scanner to connect to the vehicle’s diagnostic port, access the codes, and select the option to clear them. Ensure the issue is resolved; otherwise, the check engine light will reappear. For permanent DTCs, the code will clear automatically once the system no longer detects the issue.

4.1 Using a Code Reader to Clear DTCs

How do you use a code reader to clear DTCs?

To use a code reader, connect the OBD-II scanner to the diagnostic port, turn on the ignition (without starting the engine), and press the ‘Read’ or ‘Scan’ button to access the DTCs. After addressing the issue, select the option to clear the codes.

4.2 When to Seek Professional Repairs

When should you take your vehicle in for professional repairs instead of clearing the DTC yourself?

If the check engine light is flashing, it indicates a serious issue that requires immediate attention. Continuing to drive the vehicle could cause further damage. In such cases, pull over and have the vehicle towed to a mechanic for professional diagnosis and repair.

5. Managing DTC Codes for Fleet Vehicles: A Comprehensive Approach

How can telematics systems assist in managing DTC codes for an entire fleet of vehicles?

Telematics systems, like CalAmp iOn, offer a comprehensive solution for managing DTC codes across a fleet. These systems provide real-time alerts for engine fault codes, automate maintenance schedules based on mileage and usage, and generate detailed reports to identify trends and potential issues. This proactive approach helps minimize downtime, reduce repair costs, and ensure vehicle safety.

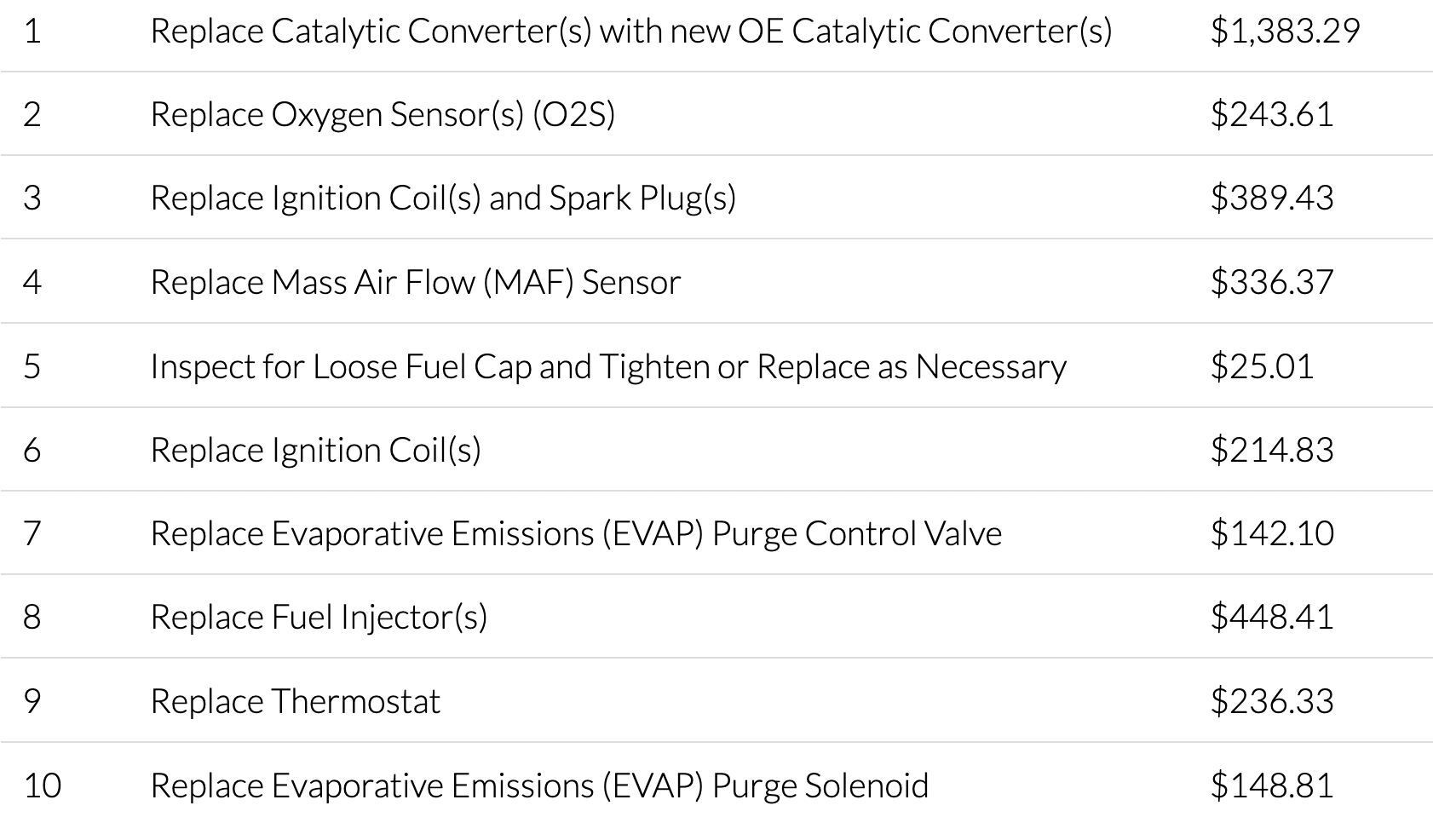

Most common check engine vehicle repairs in the US

Most common check engine vehicle repairs in the US

5.1 Setting Up Real-Time Alerts for DTCs

How can you set up real-time alerts for DTCs in a fleet management system?

Setting up real-time alerts in a telematics system involves configuring the system to notify you immediately when a vehicle triggers a DTC. These alerts include the code and a description of the issue, enabling quick response and minimizing potential damage or downtime. The fleet manager can then direct the driver to a service station or provide instructions based on the severity of the issue.

5.2 Automating Fleet Maintenance Schedules

How do telematics systems help automate fleet maintenance schedules?

Telematics systems automate fleet maintenance by scheduling reminders based on mileage and hours of use. This ensures that vehicles receive regular maintenance checks, such as oil changes and tire replacements, which helps extend the lifespan of the fleet and prevents costly repairs.

5.3 Generating DTC Reports for Analysis

How can DTC reports help in optimizing fleet efficiency and maintenance?

DTC reports provide valuable data for optimizing fleet efficiency and maintenance. By generating on-demand reports across the entire fleet, maintenance managers can identify trends, such as which parts wear out faster, and schedule repairs accordingly. This proactive approach can address issues before they become major problems, reducing downtime and costs.

6. Benefits of Understanding Car Diagnostic Codes

What are the key benefits of understanding and effectively managing car diagnostic codes?

Understanding and managing car diagnostic codes offers several key benefits, including:

- Early Issue Detection: Identifying problems early can prevent minor issues from escalating into major, costly repairs.

- Improved Vehicle Performance: Addressing DTCs promptly ensures that the vehicle operates at its optimal performance level.

- Increased Safety: Resolving issues related to DTCs enhances the safety of the vehicle for both the driver and others on the road.

- Cost Savings: Regular maintenance and quick repairs based on DTCs can save significant money in the long run by avoiding major breakdowns.

- Better Fuel Efficiency: Addressing engine-related DTCs can help maintain or improve fuel efficiency, saving on fuel costs.

By understanding these codes, vehicle owners and fleet managers can make informed decisions about maintenance and repairs, leading to more efficient and reliable vehicle operation.

7. Choosing the Right OBD-II Scanner: Features and Recommendations

What factors should you consider when choosing an OBD-II scanner for reading car diagnostic codes?

Choosing the right OBD-II scanner involves considering factors such as compatibility with your vehicle, ease of use, features like real-time data and graphing, and the ability to read and clear codes. According to a 2023 review by Consumer Reports, a good scanner should also offer a comprehensive database of DTC definitions and be updateable to support newer vehicles.

7.1 Basic vs. Advanced Scanners: What’s the Difference?

What are the key differences between basic and advanced OBD-II scanners?

Basic OBD-II scanners typically read and clear DTCs and provide basic code definitions. Advanced scanners, on the other hand, offer additional features like real-time data streaming, graphing capabilities, enhanced diagnostics for specific vehicle systems, and the ability to perform bidirectional control tests. The choice depends on your diagnostic needs and technical expertise.

7.2 Essential Features to Look For

What essential features should you look for when purchasing an OBD-II scanner?

Essential features to look for in an OBD-II scanner include:

- Code Reading and Clearing: The ability to read and clear DTCs.

- DTC Definitions: A comprehensive database of DTC definitions.

- Real-Time Data: Capability to display real-time data from vehicle sensors.

- Graphing: Ability to graph sensor data for easier analysis.

- Compatibility: Compatibility with your vehicle’s make and model.

- Updateability: Ability to update the scanner with new vehicle information and DTC definitions.

- Ease of Use: An intuitive interface and easy navigation.

7.3 Top OBD-II Scanner Recommendations

Can you recommend some top OBD-II scanners available in the market?

Based on various reviews and user feedback, some top OBD-II scanners include:

| Scanner Name | Key Features | Price Range |

|---|---|---|

| BlueDriver Bluetooth Pro | Bluetooth connectivity, comprehensive diagnostics, real-time data | $100-150 |

| Autel MaxiCOM MK808 | Advanced diagnostics, bidirectional control, extensive vehicle coverage | $500-700 |

| Innova 3100RS | Easy-to-use, ABS/SRS diagnostics, code severity levels | $80-120 |

| Launch CRP129E | Full OBDII functions, engine/transmission/ABS/SRS diagnostics, auto VIN scan | $200-300 |

These scanners offer a range of features and capabilities to suit different needs and budgets.

8. Common Car Diagnostic Codes and Their Meanings

What are some common car diagnostic codes and what do they typically indicate?

Here are some common car diagnostic codes and their meanings:

| DTC Code | Description | Possible Causes |

|---|---|---|

| P0171 | System Too Lean (Bank 1) | Vacuum leak, MAF sensor issue, fuel pump failure, clogged fuel filter |

| P0300 | Random/Multiple Cylinder Misfire Detected | Faulty spark plugs, ignition coils, fuel injectors, vacuum leaks, low compression |

| P0401 | Exhaust Gas Recirculation (EGR) Flow Insufficient Detected | Clogged or faulty EGR valve, faulty EGR pressure sensor, vacuum leaks |

| P0420 | Catalytic Converter System Efficiency Below Threshold (Bank 1) | Faulty catalytic converter, exhaust leaks, faulty oxygen sensors |

| P0442 | Evaporative Emission Control System Leak Detected (Small Leak) | Loose or faulty gas cap, damaged fuel tank, faulty vent valve, cracked hoses |

| P0455 | Evaporative Emission Control System Leak Detected (Gross Leak) | Missing or loose gas cap, damaged fuel tank, faulty vent valve, cracked hoses |

| P0505 | Idle Air Control System Malfunction | Faulty idle air control valve, vacuum leaks, throttle body issues |

| P0700 | Transmission Control System Malfunction | Faulty transmission sensors, solenoid issues, low transmission fluid, internal transmission damage |

| P1135 | Heated Oxygen Sensor (HO2S) Heater Circuit Malfunction (Bank 1, Sensor 1) | Faulty oxygen sensor, wiring issues, blown fuse |

| P0113 | Intake Air Temperature Sensor Circuit High Input | Faulty intake air temperature sensor, wiring issues |

Understanding these codes can help you quickly identify and address common vehicle issues.

9. The Role of Oxygen Sensors in Diagnostic Codes

How do oxygen sensors contribute to the generation of diagnostic codes?

Oxygen sensors play a crucial role in generating diagnostic codes by monitoring the oxygen levels in the exhaust stream. According to a 2021 study by the National Renewable Energy Laboratory, faulty oxygen sensors can lead to inaccurate readings, causing the engine control unit (ECU) to make incorrect adjustments to the air-fuel mixture. This can result in DTCs related to fuel trim, catalytic converter efficiency, and overall engine performance.

9.1 How Oxygen Sensors Work

How do oxygen sensors function in a vehicle’s emission control system?

Oxygen sensors measure the amount of oxygen in the exhaust gases and send this information to the engine control unit (ECU). The ECU uses this data to adjust the air-fuel mixture to achieve optimal combustion efficiency and minimize emissions. There are typically two oxygen sensors: one before the catalytic converter (upstream) and one after (downstream).

9.2 Common DTCs Related to Oxygen Sensors

What are some common DTCs associated with faulty oxygen sensors?

Common DTCs related to oxygen sensors include:

- P0130-P0167: Oxygen Sensor Circuit Malfunction (Bank 1 Sensor 1, Bank 1 Sensor 2, etc.)

- P0171 and P0174: System Too Lean (caused by incorrect air-fuel mixture due to faulty O2 sensor readings)

- P0420: Catalytic Converter System Efficiency Below Threshold (often caused by faulty downstream O2 sensor)

- P1130-P1152: Heated Oxygen Sensor (HO2S) issues

9.3 Diagnosing Oxygen Sensor Problems

How can you diagnose oxygen sensor problems using an OBD-II scanner?

To diagnose oxygen sensor problems, use an OBD-II scanner to read DTCs and monitor real-time data from the oxygen sensors. Look for codes specifically related to the oxygen sensor circuits or performance. Monitor the sensor voltage readings: the upstream sensor should fluctuate rapidly, while the downstream sensor should maintain a more stable reading.

10. Troubleshooting Misfire Codes: Causes and Solutions

What are misfire codes and what are the common causes and solutions?

Misfire codes, such as P0300-P030X (where X is the cylinder number), indicate that one or more cylinders are not firing correctly. Common causes include faulty spark plugs, ignition coils, fuel injectors, vacuum leaks, and low compression. Solutions range from replacing spark plugs or coils to addressing vacuum leaks or performing engine repairs.

10.1 Identifying the Misfiring Cylinder

How can you identify which cylinder is misfiring?

To identify the misfiring cylinder, use an OBD-II scanner to read the specific misfire code (e.g., P0301 for cylinder 1). You can also perform a visual inspection of the spark plugs and ignition coils to look for signs of damage or wear.

10.2 Common Causes of Misfires

What are the primary reasons why a cylinder might misfire?

The primary reasons for a cylinder misfire include:

- Faulty Spark Plugs: Worn or damaged spark plugs.

- Bad Ignition Coils: Failing or weak ignition coils.

- Clogged Fuel Injectors: Restricted fuel flow to the cylinder.

- Vacuum Leaks: Air leaks affecting the air-fuel mixture.

- Low Compression: Engine wear or damage reducing compression.

10.3 Steps to Resolve Misfire Issues

What are the steps to take to resolve misfire issues once identified?

Steps to resolve misfire issues include:

- Inspect and Replace Spark Plugs: Check the condition of the spark plugs and replace if necessary.

- Test and Replace Ignition Coils: Test the ignition coils using a multimeter and replace any faulty ones.

- Clean or Replace Fuel Injectors: Clean the fuel injectors using a fuel injector cleaner or replace if heavily clogged.

- Check for Vacuum Leaks: Inspect vacuum lines and intake manifold for leaks.

- Perform Compression Test: Check cylinder compression to identify engine wear or damage.

11. The Impact of Fuel System Issues on Diagnostic Codes

How do fuel system issues contribute to the generation of diagnostic codes?

Fuel system issues significantly contribute to the generation of diagnostic codes because the fuel system’s proper functioning is essential for engine performance and emissions control. According to a 2022 report by the U.S. Department of Energy, problems such as fuel leaks, pressure irregularities, or mixture imbalances can trigger a variety of DTCs, indicating the need for diagnostic and repair work.

11.1 Common Fuel System Problems

What are common problems within the fuel system that can trigger DTCs?

Common fuel system problems include:

- Fuel Pump Failure: Inadequate fuel delivery to the engine.

- Clogged Fuel Filter: Restricted fuel flow.

- Faulty Fuel Injectors: Incorrect fuel metering.

- Fuel Leaks: Loss of fuel and potential fire hazard.

- Pressure Regulator Issues: Improper fuel pressure regulation.

11.2 Diagnostic Codes Related to Fuel Systems

What diagnostic codes are commonly associated with fuel system issues?

Common diagnostic codes related to fuel systems include:

- P0087: Fuel Rail/System Pressure Too Low.

- P0171 and P0174: System Too Lean (Bank 1 and Bank 2).

- P0172 and P0175: System Too Rich (Bank 1 and Bank 2).

- P0200-P020X: Injector Circuit Malfunction (Cylinder X).

- P0455: Evaporative Emission Control System Leak Detected (Gross Leak).

11.3 Troubleshooting Fuel System Codes

What steps should be taken to troubleshoot and resolve fuel system-related DTCs?

To troubleshoot fuel system codes:

- Check Fuel Pressure: Use a fuel pressure gauge to measure fuel pressure.

- Inspect Fuel Filter: Check the fuel filter for clogs.

- Test Fuel Injectors: Use a multimeter to test fuel injector resistance.

- Check for Fuel Leaks: Inspect the fuel lines and components for leaks.

- Use OBD-II Scanner: Monitor real-time data to evaluate fuel trim and sensor readings.

12. How to Use Real-Time Data from OBD-II Scanners

How can real-time data from OBD-II scanners be used to diagnose car problems?

Real-time data from OBD-II scanners allows technicians to monitor various parameters as the engine runs, providing insights into how the engine and related systems are performing. This data can help diagnose intermittent issues, identify sensor malfunctions, and verify the effectiveness of repairs. According to a 2023 article in “Motor Age Magazine,” real-time data is essential for accurate and efficient diagnostics.

12.1 Key Parameters to Monitor

What are the key parameters to monitor when using an OBD-II scanner for real-time data?

Key parameters to monitor include:

- Engine RPM: Revolutions per minute.

- Coolant Temperature: Engine coolant temperature.

- Oxygen Sensor Voltage: Voltage output from oxygen sensors.

- Fuel Trim: Short-term and long-term fuel trim values.

- MAF Sensor Reading: Mass airflow sensor readings.

- Throttle Position: Throttle position sensor readings.

- Ignition Timing: The ignition timing advance.

12.2 Interpreting Real-Time Data

How should real-time data be interpreted to diagnose vehicle issues effectively?

Interpreting real-time data involves understanding the normal operating ranges for each parameter and looking for deviations. For example, fluctuating oxygen sensor voltages indicate proper sensor function, while stable voltages may suggest a faulty sensor. Similarly, high fuel trim values may indicate a lean condition, while low values may suggest a rich condition.

12.3 Practical Examples of Data Interpretation

Can you provide some practical examples of how to interpret real-time data for specific issues?

- Lean Condition: High positive fuel trim values (+10% or more) indicate that the engine is running lean. Check for vacuum leaks, MAF sensor issues, or fuel delivery problems.

- Rich Condition: High negative fuel trim values (-10% or less) suggest that the engine is running rich. Check for faulty fuel injectors, fuel pressure regulator issues, or O2 sensor malfunctions.

- Faulty Oxygen Sensor: Stable oxygen sensor voltage (not fluctuating) indicates a possible sensor malfunction. Check the sensor wiring and replace if necessary.

- MAF Sensor Issue: Erratic or incorrect MAF sensor readings can cause various drivability problems. Compare the MAF sensor readings to the expected values and replace if necessary.

13. The Importance of Regular Vehicle Maintenance

Why is regular vehicle maintenance essential for preventing diagnostic codes and ensuring vehicle longevity?

Regular vehicle maintenance is essential for preventing diagnostic codes and ensuring vehicle longevity because it helps keep all vehicle systems in good working order. According to a 2020 study by AAA, vehicles that undergo regular maintenance are less likely to experience breakdowns and costly repairs. Routine maintenance tasks such as oil changes, filter replacements, and fluid checks can prevent many common issues that trigger DTCs.

13.1 Key Maintenance Tasks to Prevent DTCs

What key maintenance tasks can help prevent diagnostic trouble codes from appearing?

Key maintenance tasks to prevent DTCs include:

- Regular Oil Changes: Keeps the engine lubricated and prevents wear.

- Filter Replacements: Air, fuel, and oil filter replacements ensure clean fluids and airflow.

- Fluid Checks: Checking and topping off fluids such as coolant, brake fluid, and transmission fluid.

- Spark Plug Replacement: Replacing spark plugs at recommended intervals ensures proper ignition.

- Tire Maintenance: Maintaining proper tire pressure and alignment improves fuel efficiency and handling.

- Brake Inspections: Regularly inspecting brakes ensures safe stopping.

13.2 Benefits of Proactive Maintenance

What are the benefits of adopting a proactive approach to vehicle maintenance?

The benefits of proactive vehicle maintenance include:

- Reduced Repair Costs: Catching and addressing issues early prevents major breakdowns.

- Increased Vehicle Lifespan: Regular maintenance extends the life of the vehicle.

- Improved Fuel Efficiency: Proper maintenance helps maintain optimal fuel efficiency.

- Enhanced Safety: Ensuring all systems are functioning correctly improves vehicle safety.

- Fewer Breakdowns: Proactive maintenance reduces the likelihood of unexpected breakdowns.

13.3 Maintenance Schedules and Recommendations

Can you provide general maintenance schedules and recommendations for vehicle owners?

General maintenance schedules and recommendations include:

- Every 3,000-5,000 Miles: Oil change and filter replacement.

- Every 12,000 Miles: Tire rotation and balance.

- Every 30,000 Miles: Air filter and fuel filter replacement.

- Every 60,000 Miles: Spark plug replacement and coolant flush.

- Every 100,000 Miles: Timing belt replacement (if applicable) and transmission fluid flush.

Always refer to your vehicle’s owner’s manual for specific maintenance schedules and recommendations.

14. Resources for Further Learning

What resources are available for further learning about car diagnostic codes and vehicle maintenance?

For further learning about car diagnostic codes and vehicle maintenance, consider these resources:

- Online Forums: Websites like CAR-TOOL.EDU.VN offer forums where you can ask questions and get advice from experienced technicians and vehicle owners.

- Technical Manuals: Purchase technical manuals specific to your vehicle make and model for detailed repair and diagnostic information.

- Online Courses: Platforms like Coursera and Udemy offer courses on automotive diagnostics and repair.

- Professional Certifications: Consider pursuing certifications like ASE (Automotive Service Excellence) to enhance your knowledge and skills.

15. FAQ: Common Questions About Car Diagnostic Codes

What are some frequently asked questions about car diagnostic codes?

Here are some frequently asked questions about car diagnostic codes:

Q1: What does it mean when my check engine light comes on?

A1: A check engine light indicates that the vehicle’s onboard computer has detected an issue. Use an OBD-II scanner to read the diagnostic trouble code (DTC) and identify the problem.

Q2: Can I drive my car with the check engine light on?

A2: It depends on the severity of the issue. If the light is flashing, it indicates a serious problem that requires immediate attention. If the light is steady, you can typically drive the car, but have it checked as soon as possible to prevent further damage.

Q3: How do I clear a DTC code?

A3: Use an OBD-II scanner to connect to the vehicle’s diagnostic port, access the codes, and select the option to clear them. Only clear codes after addressing the underlying issue.

Q4: What is the difference between generic and manufacturer-specific codes?

A4: Generic codes are standard codes that apply to all OBD-II vehicles, while manufacturer-specific codes are unique to the vehicle’s make and model.

Q5: How often should I have my vehicle serviced?

A5: Follow the maintenance schedule in your vehicle’s owner’s manual. Generally, an oil change is recommended every 3,000-5,000 miles, and other maintenance tasks should be performed at specific intervals.

Q6: What are the most common DTCs?

A6: Common DTCs include P0171 (System Too Lean), P0300 (Random/Multiple Cylinder Misfire), P0420 (Catalytic Converter System Efficiency Below Threshold), and P0455 (Evaporative Emission Control System Leak).

Q7: Can a faulty gas cap cause a check engine light?

A7: Yes, a loose or faulty gas cap can cause a check engine light and trigger DTCs related to the evaporative emission control system (EVAP).

Q8: What is the role of oxygen sensors?

A8: Oxygen sensors monitor the oxygen levels in the exhaust gases and send this information to the engine control unit (ECU), which adjusts the air-fuel mixture to optimize combustion efficiency and minimize emissions.

Q9: How do I know if my catalytic converter is failing?

A9: Symptoms of a failing catalytic converter include a P0420 DTC, reduced engine performance, and a sulfur-like smell from the exhaust.

Q10: What is the difference between short-term and long-term fuel trim?

A10: Short-term fuel trim (STFT) makes immediate adjustments to the air-fuel mixture, while long-term fuel trim (LTFT) makes gradual adjustments over time. Both values can indicate lean or rich conditions.

Conclusion

Understanding car diagnostic codes is crucial for vehicle maintenance and repair. By learning how to interpret OBD-II and J1939 codes, choosing the right diagnostic tools, and performing regular maintenance, you can ensure your vehicle operates efficiently and safely. At CAR-TOOL.EDU.VN, we’re dedicated to providing the knowledge and resources you need to keep your vehicle in top condition.

Need expert advice or assistance with your vehicle’s diagnostic codes? Contact our team at CAR-TOOL.EDU.VN for personalized support. Reach us at 456 Elm Street, Dallas, TX 75201, United States, or call us on Whatsapp at +1 (641) 206-8880. Visit our website at CAR-TOOL.EDU.VN for more information and resources. Let us help you keep your vehicle running smoothly.

Take Action Now: Contact CAR-TOOL.EDU.VN today for expert advice and premium tools to manage your vehicle’s health. Get in touch via Whatsapp at +1 (641) 206-8880 or visit our website at CAR-TOOL.EDU.VN. Because your vehicle deserves the best care.