As a car repair specialist, understanding specific OBD2 codes and systems is crucial, and this article from CAR-TOOL.EDU.VN provides an in-depth look, helping you enhance diagnostic precision and efficiency. Dive in to master OBD2 diagnostics and keep your clients on the road.

Contents

- 1. Decoding OBD2: A Deep Dive for Automotive Specialists

- 1.1. The Evolution of On-Board Diagnostics

- 1.2. The Significance of Standardization

- 1.3. Benefits of Mastering OBD2 Diagnostics

- 1.4. Real-World Applications of OBD2 Knowledge

- 2. Understanding the Structure of OBD2 Codes

- 2.1. The Anatomy of an OBD2 Code

- 2.2. Decoding Common OBD2 Codes

- 2.3. Understanding Generic vs. Manufacturer-Specific Codes

- 2.4. Resources for Decoding OBD2 Codes

- 3. Specific OBD2 Codes and Systems

- 3.1. Powertrain Codes (P0xxx): Engine Performance

- 3.2. Transmission Codes (P07xx): Gearbox Issues

- 3.3. Emission Control System Codes (P04xx): Environmental Compliance

- 3.4. Body Codes (B0xxx) and Chassis Codes (C0xxx)

- 3.5. Network Communication Codes (U0xxx)

- 4. Essential Tools for Reading and Interpreting OBD2 Codes

- 4.1. Basic OBD2 Scanners

- 4.2. Advanced OBD2 Scanners

- 4.3. Software and Repair Databases

- 4.4. Multimeters and Other Diagnostic Tools

- 4.5. Choosing the Right Tools for Your Needs

- 5. Best Practices for Diagnosing OBD2 Codes

- 5.1. Verifying the Code

- 5.2. Researching the Code

- 5.3. Performing a Visual Inspection

- 5.4. Using Live Data

- 5.5. Performing Component Tests

- 5.6. Verifying the Repair

- 6. Advanced Diagnostic Techniques

- 6.1. Bidirectional Control

- 6.2. Relative Compression Tests

- 6.3. Smoke Machine Testing

- 6.4. Oscilloscope Analysis

- 6.5. Utilizing Technical Service Bulletins (TSBs)

- 7. Staying Updated with OBD2 Technology

- 7.1. Attending Industry Conferences and Training Seminars

- 7.2. Subscribing to Automotive Trade Publications and Online Forums

- 7.3. Investing in Updated Diagnostic Tools and Software

- 7.4. Continuous Practice and Refinement of Diagnostic Skills

- 7.5. Collaborating with Other Technicians

- 8. Frequently Asked Questions (FAQ)

- 8.1. What is the most common OBD2 code?

- 8.2. Can I drive my car with a “Check Engine” light on?

- 8.3. How do I reset the OBD2 system?

- 8.4. What does “OBD2 readiness monitors not ready” mean?

- 8.5. How often should I scan my car for OBD2 codes?

- 8.6. Can a faulty gas cap trigger an OBD2 code?

- 8.7. What is the difference between OBD1 and OBD2?

- 8.8. Are all OBD2 scanners compatible with all vehicles?

- 8.9. Can I use a smartphone app to read OBD2 codes?

- 8.10. How can CAR-TOOL.EDU.VN help me with OBD2 diagnostics?

1. Decoding OBD2: A Deep Dive for Automotive Specialists

What are OBD2 codes and why are they crucial for automotive diagnostics?

On-Board Diagnostics II (OBD2) codes are standardized alphanumeric codes that automotive specialists use to identify malfunctions in a vehicle’s systems. These codes are essential because they provide a standardized way to access a vehicle’s self-diagnostic data, allowing for faster and more accurate repairs. According to the Environmental Protection Agency (EPA), all cars and light trucks manufactured since 1996 are required to support OBD2 diagnostics.

1.1. The Evolution of On-Board Diagnostics

The history of OBD systems begins with the implementation of OBD-I in the late 1980s, which was primarily designed to monitor emissions-related components. However, OBD-I systems varied significantly between manufacturers, making it difficult for technicians to diagnose issues across different vehicle makes and models. This lack of standardization led to the development of OBD2, which provides a uniform diagnostic interface and a standardized set of diagnostic trouble codes (DTCs). According to SAE International, the standardization of OBD2 has greatly improved diagnostic accuracy and efficiency in the automotive industry.

1.2. The Significance of Standardization

The standardization of OBD2 means that a diagnostic tool can be used on any OBD2-compliant vehicle to retrieve the same basic information. This includes the ability to read diagnostic trouble codes (DTCs), monitor real-time data, and perform certain diagnostic tests. This standardization reduces the need for specialized tools and training for each vehicle manufacturer, making it easier for automotive specialists to work on a wide range of vehicles.

1.3. Benefits of Mastering OBD2 Diagnostics

Mastering OBD2 diagnostics offers several benefits for automotive specialists:

- Improved Diagnostic Accuracy: OBD2 codes provide specific information about the nature and location of a fault, reducing the time spent on manual inspection and guesswork.

- Faster Repair Times: By quickly identifying the problem, technicians can focus on the necessary repairs, reducing the overall repair time.

- Enhanced Customer Satisfaction: Accurate and efficient repairs lead to happier customers and a stronger reputation for your shop.

- Compliance with Regulations: Understanding OBD2 systems helps ensure that vehicles meet emissions standards, avoiding potential fines and penalties.

1.4. Real-World Applications of OBD2 Knowledge

Consider a scenario where a customer brings in a vehicle with the “Check Engine” light illuminated. Without OBD2 knowledge, a technician might spend hours trying to diagnose the problem through manual inspection. However, with a quick scan using an OBD2 tool, the technician can retrieve a code such as P0301, indicating a misfire in cylinder 1. This information allows the technician to focus directly on the ignition system, fuel injector, or other components related to that cylinder, saving time and improving the accuracy of the repair.

2. Understanding the Structure of OBD2 Codes

How are OBD2 codes structured, and what does each component signify?

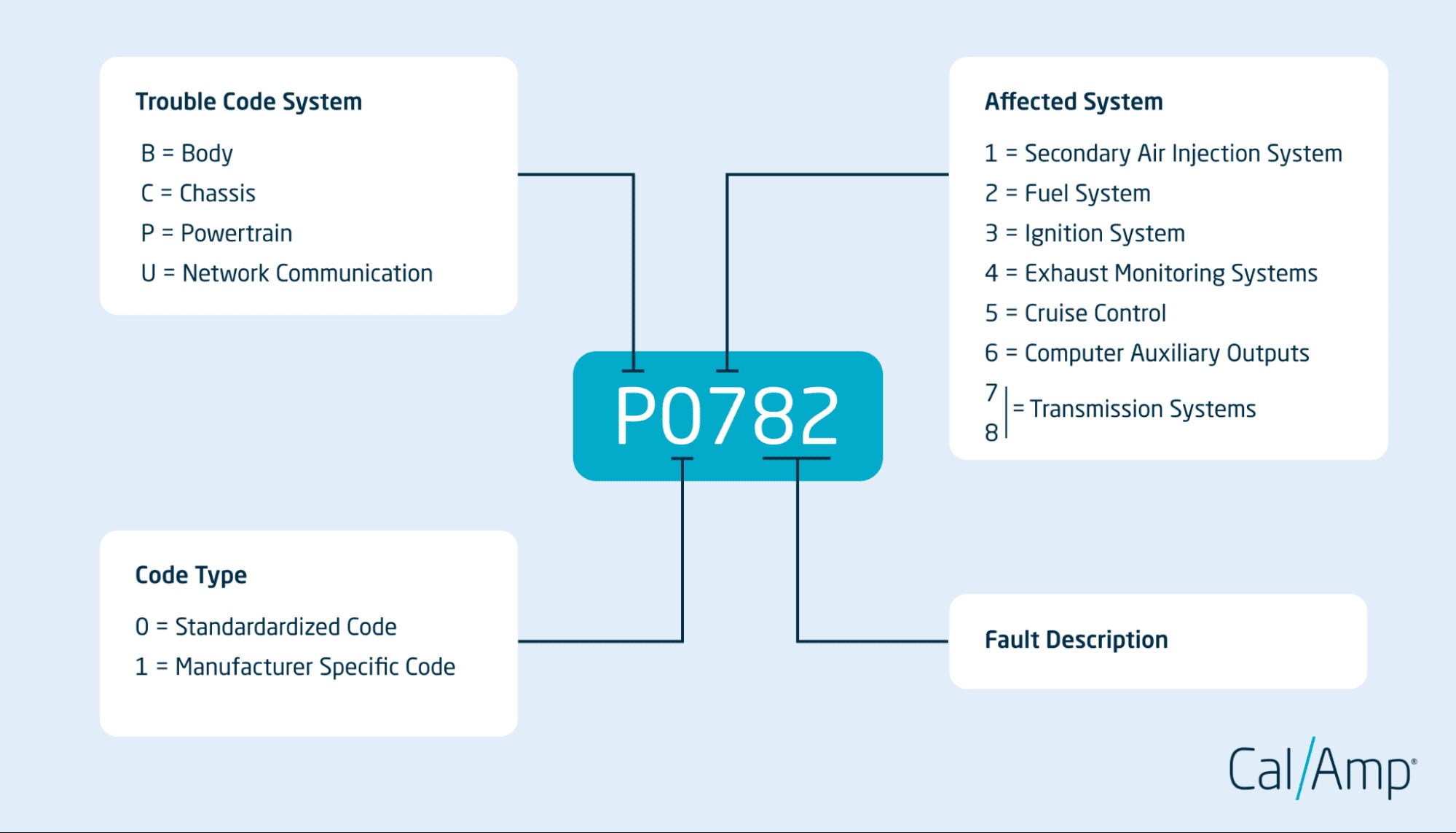

OBD2 codes are composed of five characters: a letter followed by four digits. The letter indicates the system, the first digit specifies whether the code is generic or manufacturer-specific, and the remaining three digits provide further detail about the fault. Knowing how to interpret these codes is essential for accurate diagnosis.

2.1. The Anatomy of an OBD2 Code

Each character in an OBD2 code provides specific information:

- First Character (Letter): Indicates the primary system affected:

- P: Powertrain (engine, transmission, fuel system)

- B: Body (airbags, climate control, lighting)

- C: Chassis (brakes, suspension, steering)

- U: Network Communication (communication between control modules)

- Second Character (Digit): Specifies whether the code is generic or manufacturer-specific:

- 0: Generic (SAE) code, common to all vehicles

- 1: Manufacturer-specific code

- Third Character (Digit): Indicates the subsystem affected:

- 0: Fuel and air metering and auxiliary emission controls

- 1: Fuel and air metering

- 2: Fuel and air metering (injector circuit)

- 3: Ignition system or misfire

- 4: Auxiliary emission controls

- 5: Vehicle speed controls and idle control system

- 6: Computer output system

- 7: Transmission

- 8: Transmission

- Fourth and Fifth Characters (Digits): Provide a specific fault number within the subsystem.

2.2. Decoding Common OBD2 Codes

Let’s break down some common OBD2 codes to illustrate how this structure works:

- P0300: Random/Multiple Cylinder Misfire Detected

- P: Powertrain

- 0: Generic code

- 3: Ignition system or misfire

- 00: Specific fault number (random/multiple cylinder misfire)

- P0171: System Too Lean (Bank 1)

- P: Powertrain

- 0: Generic code

- 1: Fuel and air metering

- 71: Specific fault number (system too lean, bank 1)

- B0001: Driver Frontal Airbag Deployment Loop Open

- B: Body

- 0: Generic code

- 0: Fuel and air metering and auxiliary emission controls

- 01: Specific fault number (driver frontal airbag deployment loop open)

2.3. Understanding Generic vs. Manufacturer-Specific Codes

Generic codes are standardized across all vehicle makes and models, providing a common starting point for diagnostics. Manufacturer-specific codes, on the other hand, offer more detailed information about issues specific to a particular vehicle brand or model. For example, a generic code might indicate a problem with the oxygen sensor, while a manufacturer-specific code could specify the exact location and circuit of the faulty sensor.

2.4. Resources for Decoding OBD2 Codes

Several resources can help automotive specialists decode OBD2 codes:

- Online Databases: Websites like OBD-Codes.com and FreeOBD.com offer comprehensive databases of OBD2 codes and their meanings.

- Diagnostic Tools: Advanced diagnostic tools often include built-in code readers and diagnostic information, providing real-time assistance.

- Service Manuals: Vehicle-specific service manuals provide detailed information about manufacturer-specific codes and diagnostic procedures.

- Professional Training: Automotive training programs offer in-depth instruction on OBD2 diagnostics and troubleshooting.

3. Specific OBD2 Codes and Systems

Which specific OBD2 codes and systems are most critical for automotive experts to understand?

Focus on powertrain codes (P0xxx), especially those related to engine misfires (P03xx), fuel and air metering (P01xx), and oxygen sensors (P013x, P014x). Additionally, familiarize yourself with codes related to transmission (P07xx) and emission control systems (P04xx).

3.1. Powertrain Codes (P0xxx): Engine Performance

Powertrain codes are critical because they address issues that directly impact engine performance, fuel efficiency, and emissions. Some of the most common and important powertrain codes include:

- P0300 – P0304: Misfire Codes

- These codes indicate that one or more cylinders are not firing correctly.

- Causes: Faulty spark plugs, ignition coils, fuel injectors, vacuum leaks, or low compression.

- Symptoms: Rough idling, reduced power, poor fuel economy, and a flashing “Check Engine” light.

- Diagnostic Steps: Check spark plugs and ignition coils, perform a compression test, inspect fuel injectors, and look for vacuum leaks.

- P0171 and P0174: System Too Lean

- These codes indicate that the engine is receiving too much air or not enough fuel.

- Causes: Vacuum leaks, faulty MAF sensor, low fuel pressure, or a clogged fuel filter.

- Symptoms: Rough idling, hesitation during acceleration, and poor fuel economy.

- Diagnostic Steps: Check for vacuum leaks, inspect the MAF sensor, test fuel pressure, and replace the fuel filter if necessary.

- P0101: Mass Air Flow (MAF) Sensor Range/Performance

- This code indicates that the MAF sensor is not providing accurate readings.

- Causes: Dirty or damaged MAF sensor, vacuum leaks, or a faulty wiring harness.

- Symptoms: Poor fuel economy, rough idling, and hesitation during acceleration.

- Diagnostic Steps: Clean or replace the MAF sensor, check for vacuum leaks, and inspect the wiring harness.

- P0130 and P0131: Oxygen Sensor Circuit Malfunction (Bank 1, Sensor 1)

- These codes indicate a problem with the oxygen sensor, which monitors the amount of oxygen in the exhaust.

- Causes: Faulty oxygen sensor, exhaust leaks, or a wiring issue.

- Symptoms: Poor fuel economy, increased emissions, and a rough-running engine.

- Diagnostic Steps: Test the oxygen sensor, check for exhaust leaks, and inspect the wiring.

3.2. Transmission Codes (P07xx): Gearbox Issues

Transmission codes are crucial for identifying issues within the vehicle’s transmission system. Understanding these codes can help prevent costly transmission repairs. Key transmission codes include:

- P0700: Transmission Control System Malfunction

- This code indicates a general problem within the transmission control system.

- Causes: Faulty sensors, solenoids, or a problem with the transmission control module (TCM).

- Symptoms: Erratic shifting, transmission slipping, or a complete loss of transmission function.

- Diagnostic Steps: Scan the TCM for additional codes, test the transmission sensors and solenoids, and inspect the wiring.

- P0715: Input/Turbine Speed Sensor Circuit Malfunction

- This code indicates a problem with the input speed sensor, which monitors the speed of the transmission’s input shaft.

- Causes: Faulty input speed sensor, damaged wiring, or a problem with the TCM.

- Symptoms: Erratic shifting, transmission slipping, or a complete loss of transmission function.

- Diagnostic Steps: Test the input speed sensor, inspect the wiring, and scan the TCM for additional codes.

- P0730: Incorrect Gear Ratio

- This code indicates that the transmission is not shifting into the correct gear.

- Causes: Low transmission fluid, faulty solenoids, or internal transmission damage.

- Symptoms: Erratic shifting, transmission slipping, or a complete loss of transmission function.

- Diagnostic Steps: Check the transmission fluid level, test the solenoids, and inspect the transmission for damage.

3.3. Emission Control System Codes (P04xx): Environmental Compliance

Emission control system codes are important for ensuring that vehicles meet environmental regulations and for maintaining optimal fuel efficiency. Common emission control system codes include:

- P0420: Catalyst System Efficiency Below Threshold (Bank 1)

- This code indicates that the catalytic converter is not functioning correctly.

- Causes: Faulty catalytic converter, exhaust leaks, or a problem with the oxygen sensors.

- Symptoms: Increased emissions, poor fuel economy, and a rough-running engine.

- Diagnostic Steps: Test the catalytic converter, check for exhaust leaks, and inspect the oxygen sensors.

- P0440: Evaporative Emission Control System Malfunction

- This code indicates a problem with the evaporative emission control system, which prevents fuel vapors from escaping into the atmosphere.

- Causes: Loose or damaged fuel cap, vacuum leaks in the EVAP system, or a faulty purge valve.

- Symptoms: Fuel odor, poor fuel economy, and a rough-running engine.

- Diagnostic Steps: Check the fuel cap, inspect the EVAP system for leaks, and test the purge valve.

- P0401: Exhaust Gas Recirculation (EGR) Flow Insufficient Detected

- This code indicates that the EGR system is not functioning correctly.

- Causes: Clogged EGR valve, vacuum leaks, or a faulty EGR sensor.

- Symptoms: Rough idling, poor fuel economy, and increased emissions.

- Diagnostic Steps: Clean or replace the EGR valve, check for vacuum leaks, and test the EGR sensor.

3.4. Body Codes (B0xxx) and Chassis Codes (C0xxx)

While powertrain codes are often the primary focus, body and chassis codes can also provide valuable information about vehicle issues. Examples include:

- B0001: Driver Frontal Airbag Deployment Loop Open

- Indicates a problem with the driver’s side airbag circuit.

- Diagnostic Steps: Check the airbag wiring, inspect the airbag module, and ensure proper connections.

- C0035: Right Front Wheel Speed Sensor Circuit

- Indicates a problem with the right front wheel speed sensor, affecting ABS and traction control systems.

- Diagnostic Steps: Test the wheel speed sensor, inspect the wiring, and check for proper installation.

OBD2 Scanner

OBD2 Scanner

3.5. Network Communication Codes (U0xxx)

Network communication codes highlight issues with the communication between various modules in the vehicle. A common code is:

- U0100: Lost Communication With ECM/PCM

- Indicates a loss of communication with the engine control module (ECM) or powertrain control module (PCM).

- Diagnostic Steps: Check the wiring and connections to the ECM/PCM, inspect the CAN bus network, and ensure proper power and ground to the module.

4. Essential Tools for Reading and Interpreting OBD2 Codes

What tools are necessary for effectively reading and interpreting OBD2 codes?

A quality OBD2 scanner is the most important tool. Basic scanners can read and clear codes, while advanced models offer enhanced features like live data streaming, freeze frame data, and bidirectional control. Additionally, access to repair databases and wiring diagrams is invaluable.

4.1. Basic OBD2 Scanners

Basic OBD2 scanners are essential tools for reading and clearing diagnostic trouble codes (DTCs) from a vehicle’s computer. These scanners are user-friendly and affordable, making them a great starting point for automotive specialists.

- Functionality:

- Read Codes: Retrieves stored and pending DTCs.

- Clear Codes: Erases DTCs and resets the “Check Engine” light.

- Live Data: Displays real-time data from various sensors, such as engine speed, coolant temperature, and oxygen sensor readings.

- Freeze Frame: Captures data at the moment a DTC is triggered, providing a snapshot of the conditions that led to the fault.

- Examples:

- Autel AutoLink AL319: A popular entry-level scanner known for its ease of use and comprehensive code definitions.

- Innova 3100j: Offers basic code reading and clearing capabilities, as well as battery and charging system testing.

- Benefits:

- Affordability: Basic scanners are relatively inexpensive, making them accessible to a wide range of users.

- Ease of Use: Simple interfaces and straightforward functionality make these scanners easy to use, even for beginners.

- Portability: Compact and lightweight, basic scanners are easy to carry and use in various locations.

4.2. Advanced OBD2 Scanners

Advanced OBD2 scanners offer more sophisticated features and capabilities, making them ideal for professional automotive specialists who need to perform in-depth diagnostics and repairs.

- Functionality:

- Bidirectional Control: Allows technicians to send commands to the vehicle’s computer to test specific components, such as fuel injectors, solenoids, and relays.

- Enhanced Code Definitions: Provides detailed descriptions of DTCs, including possible causes and troubleshooting steps.

- Live Data Streaming: Displays real-time data from a wide range of sensors, allowing technicians to monitor vehicle performance under various conditions.

- Special Functions: Supports advanced functions such as key programming, ABS bleeding, and throttle body adjustments.

- Graphing Capabilities: Visualizes live data in graphical format, making it easier to identify trends and anomalies.

- Examples:

- Autel MaxiSys MS906BT: A high-end scanner with advanced diagnostic capabilities, including bidirectional control and special functions.

- Snap-on Solus Edge: A professional-grade scanner known for its comprehensive coverage and advanced features.

- Benefits:

- Comprehensive Diagnostics: Advanced scanners offer a wide range of diagnostic capabilities, allowing technicians to perform in-depth troubleshooting and repairs.

- Time Savings: Bidirectional control and enhanced code definitions help technicians quickly identify and resolve issues.

- Versatility: Advanced scanners can be used on a wide range of vehicle makes and models, making them a valuable tool for any automotive shop.

4.3. Software and Repair Databases

In addition to OBD2 scanners, software and repair databases are essential resources for automotive specialists. These tools provide access to a wealth of information, including wiring diagrams, technical service bulletins (TSBs), and repair procedures.

- Examples:

- ALLDATA: A comprehensive online database with detailed repair information for a wide range of vehicles.

- Mitchell 1: Offers a suite of software solutions for automotive repair, including diagnostic tools, repair information, and shop management software.

- Identifix: Provides access to a database of confirmed fixes and diagnostic tips from experienced technicians.

- Benefits:

- Access to Information: Software and repair databases provide access to a wealth of information, including wiring diagrams, TSBs, and repair procedures.

- Diagnostic Assistance: These tools can help technicians quickly identify and resolve complex issues by providing step-by-step troubleshooting instructions.

- Time Savings: By providing access to the right information at the right time, software and repair databases can help technicians save time and improve efficiency.

4.4. Multimeters and Other Diagnostic Tools

While OBD2 scanners are essential for retrieving diagnostic trouble codes, multimeters and other diagnostic tools are also necessary for performing in-depth troubleshooting and repairs.

- Multimeters: Used to measure voltage, current, and resistance in electrical circuits.

- Test Lights: Used to check for power and ground in electrical circuits.

- Vacuum Gauges: Used to measure vacuum pressure in the engine and diagnose vacuum leaks.

- Compression Testers: Used to measure compression in the engine cylinders and diagnose compression-related issues.

- Fuel Pressure Testers: Used to measure fuel pressure in the fuel system and diagnose fuel-related issues.

4.5. Choosing the Right Tools for Your Needs

When selecting OBD2 scanners and diagnostic tools, it’s important to consider your specific needs and budget. Basic scanners are suitable for simple code reading and clearing, while advanced scanners are necessary for complex diagnostics and repairs. Software and repair databases provide access to valuable information, but they can be expensive. Multimeters and other diagnostic tools are essential for performing in-depth troubleshooting, but they require additional training and expertise.

5. Best Practices for Diagnosing OBD2 Codes

What are the best practices for diagnosing OBD2 codes effectively?

Start by verifying the code with a second scan to rule out transient issues. Research the code thoroughly using repair databases and service manuals. Perform a visual inspection of related components and wiring. Use live data to pinpoint the root cause, and always verify the repair after completion.

5.1. Verifying the Code

Before beginning any diagnostic work, it’s crucial to verify the OBD2 code. This involves using an OBD2 scanner to read the code and confirm that it is consistently present.

- Steps:

- Connect the OBD2 scanner to the vehicle’s diagnostic port.

- Read the stored codes and note any pending codes.

- Clear the codes and perform a test drive to see if the code returns.

- If the code returns, proceed with further diagnostics.

- Importance:

- Prevents unnecessary repairs based on transient issues.

- Ensures that the diagnostic efforts are focused on a genuine problem.

5.2. Researching the Code

Once the code has been verified, the next step is to research the code thoroughly. This involves using repair databases, service manuals, and online resources to gather information about the code’s possible causes, symptoms, and diagnostic procedures.

- Resources:

- ALLDATA: Provides detailed repair information, wiring diagrams, and technical service bulletins (TSBs).

- Mitchell 1: Offers a suite of software solutions for automotive repair, including diagnostic tools and repair information.

- Identifix: Provides access to a database of confirmed fixes and diagnostic tips from experienced technicians.

- Steps:

- Look up the code in a repair database or service manual.

- Review the possible causes and symptoms associated with the code.

- Identify any relevant TSBs that may provide additional information or guidance.

5.3. Performing a Visual Inspection

After researching the code, perform a visual inspection of the related components and wiring. This involves carefully examining the components for any signs of damage, wear, or corrosion.

- Steps:

- Inspect the wiring harness for any signs of damage, such as frayed wires, loose connections, or corrosion.

- Check the related components for any signs of wear, damage, or leaks.

- Look for any obvious issues that may be contributing to the problem.

- Importance:

- Helps identify obvious issues that may be easily corrected.

- Provides valuable clues about the root cause of the problem.

5.4. Using Live Data

Live data is real-time information from the vehicle’s sensors and modules. This data can be invaluable for pinpointing the root cause of an OBD2 code.

- Steps:

- Connect the OBD2 scanner and select the live data option.

- Monitor the data from the relevant sensors and modules.

- Look for any abnormal readings or patterns that may indicate a problem.

- Example:

- If diagnosing a P0171 code (System Too Lean), monitor the MAF sensor readings, oxygen sensor voltages, and fuel trim values to identify the cause of the lean condition.

5.5. Performing Component Tests

Component tests involve using diagnostic tools to test the functionality of specific components. This can help confirm whether a component is faulty and needs to be replaced.

- Examples:

- Testing a Fuel Injector: Use a multimeter to check the resistance of the fuel injector and verify that it is within the specified range.

- Testing an Oxygen Sensor: Use an OBD2 scanner to monitor the oxygen sensor voltage and verify that it is switching properly.

- Importance:

- Provides definitive confirmation of a component’s functionality.

- Helps avoid unnecessary replacements of good components.

5.6. Verifying the Repair

After completing the repair, it’s important to verify that the issue has been resolved and that the OBD2 code does not return.

- Steps:

- Clear the OBD2 codes and perform a test drive.

- Monitor the vehicle’s performance and check for any symptoms.

- Rescan the vehicle to ensure that the code does not return.

- Importance:

- Ensures that the repair has been effective.

- Prevents comebacks and customer dissatisfaction.

6. Advanced Diagnostic Techniques

What advanced diagnostic techniques can automotive experts employ for challenging OBD2 issues?

Utilize bidirectional control to activate components and observe their response. Perform relative compression tests to identify cylinder issues. Use a smoke machine to detect vacuum and EVAP leaks. Employ an oscilloscope to analyze sensor waveforms.

6.1. Bidirectional Control

Bidirectional control is an advanced diagnostic technique that allows automotive specialists to send commands to the vehicle’s computer and activate specific components. This can be invaluable for testing the functionality of components and diagnosing complex issues.

- Functionality:

- Activating Components: Send commands to activate components such as fuel injectors, solenoids, and relays.

- Monitoring Response: Observe the response of the components and verify that they are functioning correctly.

- Examples:

- Activating a Fuel Injector: Use bidirectional control to activate a fuel injector and verify that it is spraying fuel properly.

- Testing an EGR Valve: Use bidirectional control to open and close the EGR valve and verify that it is functioning correctly.

- Benefits:

- Precise Testing: Allows for precise testing of individual components.

- Time Savings: Helps quickly identify faulty components and avoid unnecessary replacements.

6.2. Relative Compression Tests

Relative compression tests are used to identify cylinder issues without disassembling the engine. This technique involves using an OBD2 scanner to monitor the engine speed during cranking and comparing the compression of each cylinder.

- Steps:

- Connect the OBD2 scanner and select the relative compression test option.

- Crank the engine and monitor the engine speed.

- Compare the compression of each cylinder and identify any cylinders with low compression.

- Benefits:

- Non-Invasive: Does not require disassembling the engine.

- Quick and Easy: Can be performed quickly and easily with an OBD2 scanner.

6.3. Smoke Machine Testing

Smoke machine testing is used to detect vacuum and EVAP leaks. This technique involves using a smoke machine to introduce smoke into the vehicle’s vacuum or EVAP system and then looking for any leaks.

- Steps:

- Connect the smoke machine to the vehicle’s vacuum or EVAP system.

- Introduce smoke into the system and look for any leaks.

- Use a light to help identify the leaks.

- Benefits:

- Effective Leak Detection: Can detect even small leaks that are difficult to find with other methods.

- Versatile: Can be used to test a variety of systems, including the vacuum, EVAP, and exhaust systems.

6.4. Oscilloscope Analysis

Oscilloscope analysis involves using an oscilloscope to analyze sensor waveforms. This technique can provide valuable information about the functionality of sensors and help identify issues that may not be apparent with other diagnostic methods.

- Functionality:

- Waveform Analysis: Analyze the waveform of sensors such as oxygen sensors, MAF sensors, and crankshaft position sensors.

- Signal Integrity: Check the integrity of the sensor signals and identify any abnormalities.

- Benefits:

- Detailed Analysis: Provides a detailed analysis of sensor signals.

- Diagnostic Accuracy: Helps improve diagnostic accuracy and identify complex issues.

6.5. Utilizing Technical Service Bulletins (TSBs)

Technical Service Bulletins (TSBs) are issued by vehicle manufacturers to provide information about known issues and recommended repair procedures. Utilizing TSBs can help automotive specialists quickly identify and resolve common problems.

- Benefits:

- Efficient Diagnostics: Provides information about known issues and recommended repair procedures.

- Time Savings: Helps quickly identify and resolve common problems, saving time and improving efficiency.

7. Staying Updated with OBD2 Technology

How can automotive experts stay updated with the latest OBD2 technology and diagnostic techniques?

Attend industry conferences and training seminars. Subscribe to automotive trade publications and online forums. Invest in updated diagnostic tools and software. Continuously practice and refine diagnostic skills.

7.1. Attending Industry Conferences and Training Seminars

Attending industry conferences and training seminars is a great way to stay updated with the latest OBD2 technology and diagnostic techniques. These events provide opportunities to learn from experts, network with peers, and see the latest tools and equipment.

- Examples:

- SAE International: Offers a variety of conferences and training seminars on automotive technology and diagnostics.

- ASE Training Expo: Provides opportunities to attend training sessions and see the latest tools and equipment.

- Benefits:

- Learning from Experts: Learn from industry experts and gain valuable insights into the latest OBD2 technology and diagnostic techniques.

- Networking: Network with peers and share experiences and best practices.

7.2. Subscribing to Automotive Trade Publications and Online Forums

Subscribing to automotive trade publications and online forums is another great way to stay updated with the latest OBD2 technology and diagnostic techniques. These resources provide access to articles, news, and discussions about the latest trends and developments in the automotive industry.

- Examples:

- Motor Age: A trade publication that provides articles and news about automotive repair and maintenance.

- Automotive Service Association (ASA): An organization that provides resources and information for automotive service professionals.

- Benefits:

- Access to Information: Provides access to articles, news, and discussions about the latest OBD2 technology and diagnostic techniques.

- Staying Informed: Helps stay informed about the latest trends and developments in the automotive industry.

7.3. Investing in Updated Diagnostic Tools and Software

Investing in updated diagnostic tools and software is essential for staying current with the latest OBD2 technology. As vehicle technology evolves, new diagnostic tools and software are needed to properly diagnose and repair vehicles.

- Benefits:

- Access to New Features: Provides access to new features and capabilities that can improve diagnostic accuracy and efficiency.

- Compatibility: Ensures compatibility with the latest vehicle models and systems.

7.4. Continuous Practice and Refinement of Diagnostic Skills

Continuous practice and refinement of diagnostic skills are essential for becoming a proficient automotive specialist. The more you practice and refine your skills, the better you will become at diagnosing and repairing vehicles.

- Benefits:

- Improved Diagnostic Accuracy: Helps improve diagnostic accuracy and reduce the risk of misdiagnosis.

- Increased Efficiency: Helps increase efficiency and reduce the time it takes to diagnose and repair vehicles.

7.5. Collaborating with Other Technicians

Collaborating with other technicians can be a valuable way to enhance your diagnostic skills and stay updated with the latest OBD2 technology. Sharing experiences and insights with other technicians can help you learn new techniques and approaches.

- Benefits:

- Knowledge Sharing: Provides opportunities to share knowledge and learn from others.

- Problem Solving: Helps solve complex diagnostic problems more effectively.

By following these practices, automotive experts can stay updated with the latest OBD2 technology and diagnostic techniques and provide the best possible service to their customers.

CAR-TOOL.EDU.VN is dedicated to providing automotive professionals with the latest information and tools necessary to excel in the field. Contact us at 456 Elm Street, Dallas, TX 75201, United States, or reach out via Whatsapp at +1 (641) 206-8880. Visit our website, CAR-TOOL.EDU.VN, for more resources and to discover how we can help you elevate your expertise.

Contact CAR-TOOL.EDU.VN today for expert guidance and support!

8. Frequently Asked Questions (FAQ)

8.1. What is the most common OBD2 code?

The most common OBD2 code is P0300, indicating a random or multiple cylinder misfire. This code can be triggered by various issues, including faulty spark plugs, ignition coils, or fuel injectors.

8.2. Can I drive my car with a “Check Engine” light on?

It depends on the severity of the issue. If the “Check Engine” light is flashing, it indicates a serious problem that could damage the engine, and you should not drive the car. If the light is on but not flashing, it’s generally safe to drive, but you should have the car inspected as soon as possible.

8.3. How do I reset the OBD2 system?

You can reset the OBD2 system by using an OBD2 scanner to clear the diagnostic trouble codes. Alternatively, you can disconnect the negative battery cable for a few minutes to reset the system.

8.4. What does “OBD2 readiness monitors not ready” mean?

This means that the OBD2 system has not completed all of its self-tests. This can occur after clearing the codes or disconnecting the battery. You need to drive the car under specific conditions to allow the monitors to complete their tests.

8.5. How often should I scan my car for OBD2 codes?

You should scan your car for OBD2 codes whenever the “Check Engine” light comes on or if you notice any unusual symptoms, such as rough idling, poor fuel economy, or reduced power.

8.6. Can a faulty gas cap trigger an OBD2 code?

Yes, a faulty or loose gas cap can trigger an OBD2 code, specifically P0440, indicating an evaporative emission control system malfunction.

8.7. What is the difference between OBD1 and OBD2?

OBD1 is an earlier version of the on-board diagnostic system that was used in vehicles before 1996. OBD2 is a standardized system that provides more detailed diagnostic information and is required for all cars and light trucks manufactured since 1996.

8.8. Are all OBD2 scanners compatible with all vehicles?

Most OBD2 scanners are compatible with all vehicles manufactured since 1996. However, some advanced features may not be available on all vehicles.

8.9. Can I use a smartphone app to read OBD2 codes?

Yes, you can use a smartphone app to read OBD2 codes by purchasing a Bluetooth or Wi-Fi OBD2 adapter that plugs into the vehicle’s diagnostic port and connects to your smartphone.

8.10. How can CAR-TOOL.EDU.VN help me with OBD2 diagnostics?

CAR-TOOL.EDU.VN provides comprehensive resources and support for automotive professionals, including detailed information about OBD2 codes, diagnostic techniques, and the latest tools and equipment. Contact us for expert guidance and support.

Mastering specific OBD2 codes and systems is essential for automotive experts. By understanding the structure of OBD2 codes, utilizing essential tools, and following best practices for diagnostics, you can improve diagnostic accuracy, reduce repair times, and enhance customer satisfaction. Staying updated with the latest OBD2 technology and diagnostic techniques is crucial for providing the best possible service to your customers. CAR-TOOL.EDU.VN is here to support you with the resources and information you need to excel in the field.