OBD2 plug, your car’s gateway to vital data, allows mechanics and car enthusiasts to diagnose issues and monitor performance. CAR-TOOL.EDU.VN provides a comprehensive understanding of OBD2, from its history and standards to practical applications and future trends. Explore the benefits of using OBD2 for vehicle maintenance, performance tracking, and more with CAR-TOOL.EDU.VN, and unlock a wealth of information related to automotive diagnostics, vehicle telematics, and engine performance monitoring.

Contents

- 1. Understanding the Basics of OBD2

- 1.1 History and Evolution of OBD2

- 1.2 Key Components of an OBD2 System

- 1.3 Identifying OBD2 Compliance in Your Vehicle

- 2. Decoding the OBD2 Plug: Standards and Protocols

- 2.1 The SAE J1962 Standard: OBD2 Connector Explained

- 2.2 CAN Bus and OBD2: ISO 15765-4 Standard

- 2.3 ISO 15765-2: Transporting OBD2 Messages via ISO-TP

- 3. Interpreting OBD2 Data: Modes and PIDs

- 3.1 The 10 OBD2 Diagnostic Services (Modes) Explained

- 3.2 OBD2 Parameter IDs (PIDs): Unlocking Real-Time Data

- 3.3 Using OBD2 PID Overview Tools for Efficient Diagnostics

- 4. Practical Applications: Logging and Decoding OBD2 Data

- 4.1 Step-by-Step Guide to Logging OBD2 Data

- 4.2 DBC Decoding: Converting Raw Data to Physical Values

- 4.3 Hardware and Software Tools for OBD2 Data Logging

- 5. Advanced OBD2 Applications: Multi-Frame Communication

- 5.1 Extracting the Vehicle Identification Number (VIN) via OBD2

- 5.2 Multi-PID Requests: Collecting Data Efficiently

- 5.3 Retrieving Diagnostic Trouble Codes (DTCs) with OBD2

- 6. Practical Use Cases for OBD2 Data Logging

- 6.1 Enhancing Vehicle Performance through OBD2 Monitoring

- 6.2 Optimizing Fleet Management with OBD2 Data

- 6.3 Predictive Maintenance: Leveraging OBD2 Data for Proactive Vehicle Care

- 7. The Future of OBD2: Trends and Innovations

- 7.1 OBD3: Integrating Telematics for Enhanced Diagnostics

- 7.2 WWH-OBD and OBDonUDS: Modern Alternatives to OBD2

- 7.3 OBD2 in Electric Vehicles: Challenges and Solutions

- 8. Expert Insights and Recommendations

- 9. Common Issues and Troubleshooting with OBD2 Plugs

- 10. Frequently Asked Questions (FAQ) about OBD2 Plugs

1. Understanding the Basics of OBD2

What is an OBD2 plug? An OBD2 plug, short for On-Board Diagnostics version 2, is a standardized interface in vehicles that allows access to the vehicle’s self-diagnostic system. The OBD2 system provides valuable insights into a vehicle’s health, performance, and emissions. This standard has revolutionized vehicle diagnostics by offering a universal way to retrieve diagnostic trouble codes (DTCs) and real-time data, making troubleshooting faster and more efficient. The OBD2 plug is a crucial component for both professional mechanics and car enthusiasts, enabling them to monitor and maintain their vehicles effectively.

OBD2, as explained by the Society of Automotive Engineers (SAE), is a standardized system that provides a wealth of data about your vehicle’s operation. It’s like having a direct line to your car’s computer, allowing you to see what’s happening under the hood in real-time. This capability is invaluable for diagnosing issues, optimizing performance, and ensuring your vehicle is running efficiently.

1.1 History and Evolution of OBD2

How did the OBD2 plug become the standard? The OBD2 system originated in California, driven by the California Air Resources Board (CARB), which mandated on-board diagnostics for emission control in all new cars from 1991 onward. The Society of Automotive Engineers (SAE) recommended the OBD2 standard, leading to standardized DTCs and OBD connectors across manufacturers through SAE J1962. This standardization made it easier for mechanics and vehicle owners to diagnose and address issues, fostering better vehicle maintenance and performance.

| Year | Milestone |

|---|---|

| 1991 | CARB required OBD in all new cars for emission control purposes. |

| 1996 | OBD2 became mandatory in the USA for cars and light trucks. |

| 2001 | Required in the EU for gasoline cars. |

| 2003 | Required in the EU for diesel cars (EOBD). |

| 2005 | OBD2 was required in the US for medium-duty vehicles. |

| 2008 | US cars must use ISO 15765-4 (CAN) as the OBD2 basis. |

| 2010 | OBD2 was required in US heavy-duty vehicles. |

1.2 Key Components of an OBD2 System

What are the main parts of an OBD2 system connected by the OBD2 plug? The OBD2 system comprises several key components, including the OBD2 connector, sensors, and the vehicle’s engine control unit (ECU). The OBD2 plug serves as the physical interface for accessing data, while various sensors throughout the vehicle collect real-time information. The ECU processes this data, detects issues, and stores diagnostic trouble codes (DTCs). Together, these components provide a comprehensive diagnostic system accessible via the OBD2 plug.

| Component | Function |

|---|---|

| OBD2 Connector | Provides a standardized interface for accessing vehicle data. |

| Sensors | Collect real-time data from various parts of the vehicle. |

| Engine Control Unit | Processes data from sensors, detects issues, and stores diagnostic trouble codes (DTCs). |

| Diagnostic Scan Tool | Reads data from the OBD2 connector to diagnose and troubleshoot vehicle issues. |

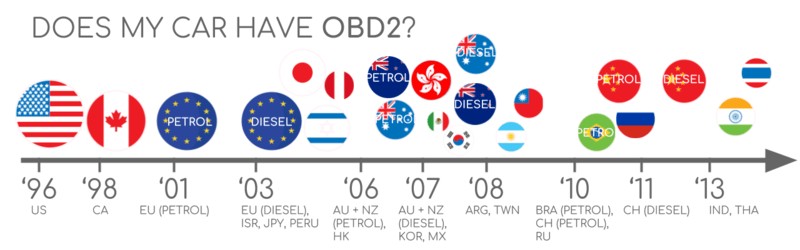

1.3 Identifying OBD2 Compliance in Your Vehicle

How can I determine if my car has an OBD2 plug and is OBD2 compliant? Nearly all new non-electric cars support OBD2, typically running on a CAN bus. For older cars, even with a 16-pin OBD2 connector, OBD2 support may not be present. Compliance can often be determined by the vehicle’s purchase location and date. In the USA, OBD2 has been mandatory for cars and light trucks since 1996. In the EU, it became required for gasoline cars in 2001 and diesel cars in 2003. Checking your vehicle’s manual or consulting a local mechanic can confirm OBD2 compliance.

2. Decoding the OBD2 Plug: Standards and Protocols

What are the communication standards and protocols used with the OBD2 plug? The OBD2 system relies on several standards and protocols to ensure effective communication between diagnostic tools and the vehicle. These standards specify the OBD2 connector, lower-layer protocols, and OBD2 parameter IDs (PIDs). Key protocols include ISO 15765 (CAN bus), ISO 14230 (KWP2000), ISO 9141, SAE J1850 VPW, and SAE J1850 PWM. Understanding these standards is essential for interpreting the data retrieved from the OBD2 plug accurately.

| Protocol | Description |

|---|---|

| ISO 15765 (CAN) | Mandatory in US cars since 2008; the most common protocol today. |

| ISO 14230 (KWP2000) | Common in 2003+ cars, especially in Asia. |

| ISO 9141 | Used in EU, Chrysler, and Asian cars in 2000-2004. |

| SAE J1850 VPW | Primarily used in older GM cars. |

| SAE J1850 PWM | Primarily used in older Ford cars. |

2.1 The SAE J1962 Standard: OBD2 Connector Explained

What is the SAE J1962 standard, and how does it define the OBD2 connector? The SAE J1962 standard defines the physical attributes and pinout configurations of the OBD2 connector, ensuring a standardized interface for accessing vehicle data. This 16-pin connector facilitates easy access to data, with specific pins designated for power supply, ground, and communication protocols. The standard specifies both Type A (cars) and Type B (medium and heavy-duty vehicles) connectors, differing mainly in power supply outputs (12V vs. 24V).

| Pin | Function |

|---|---|

| 4 | Chassis Ground |

| 5 | Signal Ground |

| 6 | CAN High (ISO 15765-4 & SAE J2284) |

| 7 | K-Line (ISO 9141-2 & ISO 14230-4) |

| 10 | J1850 Bus – (SAE J1850 VPW) |

| 14 | CAN Low (ISO 15765-4 & SAE J2284) |

| 15 | L-Line (ISO 9141-2 & ISO 14230-4) |

| 16 | Battery Power |

2.2 CAN Bus and OBD2: ISO 15765-4 Standard

How does the CAN bus protocol relate to OBD2, and what does the ISO 15765-4 standard specify? Since 2008, CAN bus (Controller Area Network) has been the mandatory lower-layer protocol for OBD2 in all cars sold in the US, as defined by ISO 15765-4, also known as Diagnostics over CAN (DoCAN). This standard outlines specific restrictions and requirements for the CAN interface, including bit-rate (250K or 500K), CAN ID length (11-bit or 29-bit), specific CAN IDs for OBD requests/responses, a CAN frame data length of 8 bytes, and a maximum OBD2 adapter cable length of 5 meters.

| Specification | Value |

|---|---|

| CAN Bus Bit-Rate | 250K or 500K |

| CAN ID Length | 11-bit or 29-bit |

| Data Length | 8 bytes |

| Adapter Cable Length | Max 5 meters |

2.3 ISO 15765-2: Transporting OBD2 Messages via ISO-TP

What is ISO-TP (ISO 15765-2), and how does it facilitate OBD2 communication? ISO-TP, or ISO 15765-2, is the transport protocol used to communicate OBD2 data over the CAN bus. It enables the transmission of payloads exceeding 8 bytes, necessary for extracting vehicle identification numbers (VIN) and diagnostic trouble codes (DTCs). ISO-TP provides segmentation, flow control, and reassembly capabilities, ensuring efficient and reliable communication.

3. Interpreting OBD2 Data: Modes and PIDs

What are OBD2 modes and PIDs, and how are they used to interpret vehicle data? OBD2 diagnostic services are categorized into modes, each serving a specific function, such as showing real-time data (Mode 0x01), displaying/clearing diagnostic trouble codes (DTCs), and showing freeze-frame data. Each mode contains parameter IDs (PIDs) that represent specific data points, such as speed, RPM, and fuel level. Interpreting OBD2 data requires understanding these modes and PIDs, allowing users to extract meaningful information about their vehicle’s condition.

| OBD2 Service (Mode) | Description |

|---|---|

| 0x01 | Shows current real-time data. |

| 0x02 | Displays freeze frame data. |

| 0x03 | Shows stored Diagnostic Trouble Codes (DTCs). |

| 0x04 | Clears Diagnostic Trouble Codes (DTCs). |

| 0x09 | Requests vehicle information (e.g., VIN). |

3.1 The 10 OBD2 Diagnostic Services (Modes) Explained

What are the functions of the 10 standardized OBD2 diagnostic services or modes? There are 10 standardized OBD2 diagnostic services, each designed for a specific diagnostic function. Mode 0x01 provides current real-time data, while other modes are used to display and clear diagnostic trouble codes (DTCs) or show freeze frame data. Although vehicles aren’t required to support all OBD2 modes, understanding these services is vital for comprehensive vehicle diagnostics.

| Mode | Description |

|---|---|

| 0x01 | Show current data |

| 0x02 | Show freeze frame data |

| 0x03 | Show stored DTCs |

| 0x04 | Clear DTCs and reset emission-related systems |

| 0x05 | Test oxygen sensors |

| 0x06 | Show results of on-board monitoring tests |

| 0x07 | Show pending DTCs detected during current drive cycle |

| 0x08 | Control operation of on-board system, test, or component |

| 0x09 | Request vehicle information |

| 0x0A | Show permanent DTCs |

3.2 OBD2 Parameter IDs (PIDs): Unlocking Real-Time Data

What are OBD2 parameter IDs (PIDs), and how do they provide real-time data? Each OBD2 mode contains parameter IDs (PIDs) that correspond to specific data points, such as speed, RPM, and fuel level. For example, mode 0x01 includes approximately 200 standardized PIDs that offer real-time data. Vehicles don’t have to support all PIDs, but understanding them allows users to access a wealth of real-time information about their vehicle’s performance. If an emissions-related ECU supports any OBD2 services, it must support mode 0x01 PID 0x00, which indicates support for PIDs 0x01-0x20.

3.3 Using OBD2 PID Overview Tools for Efficient Diagnostics

Where can I find resources to help me understand and use OBD2 PIDs effectively? To efficiently decode data, resources like SAE J1979 and ISO 15031-5 provide scaling information for standard OBD2 PIDs, enabling conversion of data into physical values. For quick access to mode 0x01 PIDs, the OBD2 PID overview tool by CAR-TOOL.EDU.VN aids in constructing OBD2 request frames and dynamically decoding OBD2 responses. This tool helps simplify the diagnostic process, saving time and improving accuracy.

4. Practical Applications: Logging and Decoding OBD2 Data

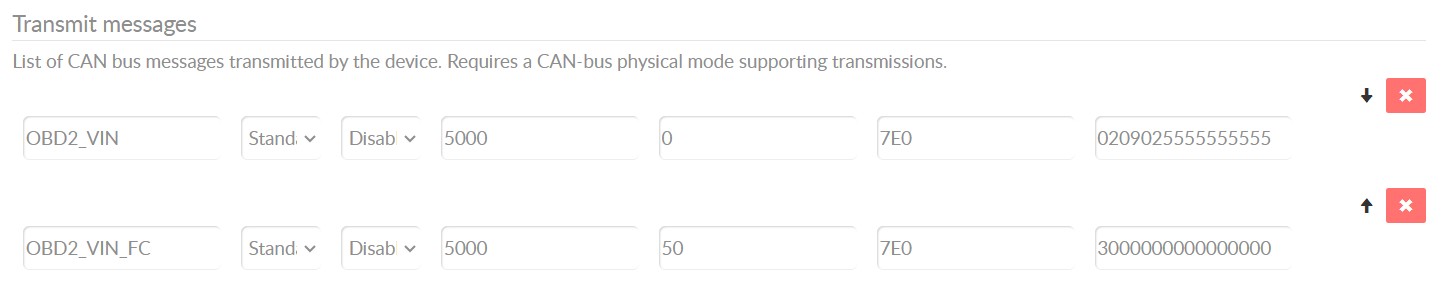

How can I practically use the OBD2 plug to log and decode vehicle data? To log and decode OBD2 data, tools like the CANedge CAN bus data logger can be utilized. The CANedge allows configuration of custom CAN frames for OBD2 logging and connects to the vehicle via an OBD2-DB9 adapter cable. The process involves testing bit-rates, IDs, and supported PIDs, configuring OBD2 PID requests, and DBC decoding raw OBD2 data into physical values.

| Step | Description |

|---|---|

| Test Bit-Rate, IDs, & PIDs | Determine the correct bit-rate and IDs used by the vehicle. |

| Configure OBD2 PID Requests | Set up transmit lists with PIDs of interest, considering CAN IDs, spacing, battery drain, and filters. |

| DBC Decode Raw OBD2 Data | Use DBC files to decode raw OBD2 data into physical values for analysis and visualization. |

4.1 Step-by-Step Guide to Logging OBD2 Data

What steps are involved in logging OBD2 data effectively? The process of logging OBD2 data involves several key steps:

- Test the bit-rate, IDs, and supported PIDs using tools like CANedge.

- Configure transmit lists with the PIDs of interest.

- Utilize filters to record only OBD2 responses.

- Log the data and decode it using appropriate software tools.

- Continuously monitor and adjust configurations for optimal data collection.

By following these steps, users can efficiently log OBD2 data for diagnostic and performance monitoring purposes.

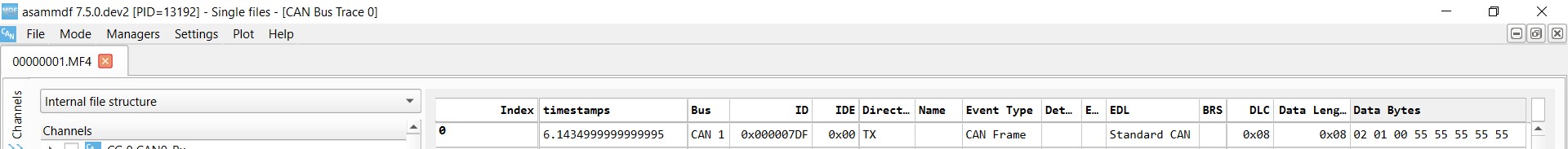

4.2 DBC Decoding: Converting Raw Data to Physical Values

How can I convert the raw OBD2 data from the OBD2 plug into meaningful physical values? Decoding raw OBD2 data into physical values involves using DBC files, which translate the data into readable metrics like km/h or degC. The decoding information is typically found in ISO 15031-5/SAE J1979. Tools like the free OBD2 DBC file provided by CAR-TOOL.EDU.VN simplifies the DBC decoding process, allowing users to interpret OBD2 data in most CAN bus software tools. This step is essential for understanding and analyzing vehicle data effectively.

OBD2 data decoded visual plot asammdf CAN bus DBC file

OBD2 data decoded visual plot asammdf CAN bus DBC file

4.3 Hardware and Software Tools for OBD2 Data Logging

What hardware and software tools are recommended for logging and interpreting OBD2 data? Several hardware and software tools are available for logging and interpreting OBD2 data. The CANedge data logger is a popular option for recording OBD2 data directly to an SD card. Software tools like asammdf, along with the free OBD2 DBC file from CAR-TOOL.EDU.VN, can then be used to decode and visualize the data. These tools help streamline the process of collecting, analyzing, and understanding OBD2 data.

| Tool | Description |

|---|---|

| CANedge | Allows you to easily record OBD2 data to an 8-32 GB SD card. |

| asammdf | Lets you DBC decode and visualize OBD2 data. |

| OBD2 DBC file | Simplifies the DBC decoding process, allowing users to interpret OBD2 data in most CAN bus software. |

5. Advanced OBD2 Applications: Multi-Frame Communication

What is multi-frame communication in OBD2, and why is it necessary? Multi-frame communication in OBD2 becomes necessary when the data being transmitted exceeds the 8-byte limit of a single CAN frame. This method, governed by ISO-TP (ISO 15765-2), uses flow control frames to manage the transmission. Multi-frame communication is vital for extracting large datasets like the Vehicle Identification Number (VIN) or multiple Diagnostic Trouble Codes (DTCs).

OBD2-multi-frame-request-message-vehicle-identification-number

OBD2-multi-frame-request-message-vehicle-identification-number

5.1 Extracting the Vehicle Identification Number (VIN) via OBD2

How can I use OBD2 multi-frame communication to extract the Vehicle Identification Number (VIN)? To extract the Vehicle Identification Number (VIN) using OBD2, multi-frame communication is essential. This process involves sending a request using mode 0x09 and PID 0x02. The vehicle responds with a First Frame that includes the PCI, length, mode, and PID, followed by the byte 0x01 indicating the Number Of Data Items (NODI). The remaining 17 bytes contain the VIN, which can be translated from HEX to ASC.

| Step | Description |

|---|---|

| Send Request | Use mode 0x09 and PID 0x02 to request the VIN. |

| Receive First Frame | Vehicle responds with PCI, length, mode (0x49), and PID (0x02). |

| Extract VIN | The remaining 17 bytes after the NODI (0x01) contain the VIN data in hexadecimal. |

| Translate | Translate the hexadecimal VIN data to ASCII characters to get the VIN. |

5.2 Multi-PID Requests: Collecting Data Efficiently

What are multi-PID requests in OBD2, and how do they improve data collection efficiency? Multi-PID requests allow external tools to request up to 6 mode 0x01 OBD2 PIDs in a single frame, enabling more efficient data collection. The ECU responds with data for supported PIDs, potentially using multiple frames if necessary. While this method can increase data collection frequency, it requires careful management of signal encoding and may not be suitable for generic OBD2 DBC files.

5.3 Retrieving Diagnostic Trouble Codes (DTCs) with OBD2

How can I use OBD2 to retrieve Diagnostic Trouble Codes (DTCs) from my vehicle? Diagnostic Trouble Codes (DTCs) can be retrieved using OBD2 mode 0x03, which commands the system to “Show stored Diagnostic Trouble Codes”. The targeted ECU(s) respond with the number of stored DTCs, with each DTC taking up 2 data bytes. When more than 2 DTCs are stored, multi-frame responses are necessary. The 2-byte DTC value is split into a category and a 4-digit code, which can be looked up in OBD2 DTC lookup tools.

6. Practical Use Cases for OBD2 Data Logging

What are some common and practical applications of OBD2 data logging? OBD2 data logging offers numerous practical applications across various fields:

- Vehicle Diagnostics: Diagnose issues, monitor engine performance, and reduce maintenance costs.

- Fleet Management: Optimize fuel consumption, track driver behavior, and improve vehicle maintenance schedules.

- Automotive Research: Test prototype parts, collect real-world driving data, and develop new technologies.

- Insurance: Monitor driving habits, assess risk, and validate claims.

These use cases highlight the versatility and value of OBD2 data logging in enhancing vehicle performance, safety, and efficiency.

6.1 Enhancing Vehicle Performance through OBD2 Monitoring

How can OBD2 monitoring improve my vehicle’s performance and efficiency? By monitoring OBD2 data, you can gain insights into your vehicle’s performance and efficiency. This includes tracking parameters such as fuel consumption, engine temperature, and RPM. Real-time monitoring helps identify potential issues, optimize driving habits, and make informed maintenance decisions, ultimately improving vehicle performance and efficiency.

6.2 Optimizing Fleet Management with OBD2 Data

How can OBD2 data contribute to effective fleet management? OBD2 data provides valuable insights for optimizing fleet management. By tracking vehicle location, fuel consumption, and driver behavior, fleet managers can improve route planning, reduce fuel costs, and enhance driver safety. Additionally, predictive maintenance based on OBD2 data can minimize downtime and extend the lifespan of fleet vehicles.

6.3 Predictive Maintenance: Leveraging OBD2 Data for Proactive Vehicle Care

How does OBD2 data support predictive maintenance strategies? OBD2 data enables predictive maintenance by monitoring critical vehicle parameters and predicting potential failures before they occur. By tracking metrics such as engine temperature, oil pressure, and fault codes, maintenance teams can proactively address issues, reducing the risk of breakdowns and costly repairs. This proactive approach enhances vehicle reliability and minimizes downtime.

7. The Future of OBD2: Trends and Innovations

What are the future trends and innovations in OBD2 technology? The future of OBD2 includes significant trends such as:

- OBD3 with Telematics: Adding telematics for real-time emission monitoring and diagnostics.

- WWH-OBD and OBDonUDS: Streamlining and enhancing OBD communication by leveraging the UDS protocol.

- Electric Vehicle Integration Challenges: Addressing the limited OBD2 support in electric vehicles and exploring alternative communication methods.

These trends indicate a move toward more connected, efficient, and comprehensive vehicle diagnostic systems.

7.1 OBD3: Integrating Telematics for Enhanced Diagnostics

What is OBD3, and how will it enhance vehicle diagnostics through telematics? OBD3 aims to integrate telematics into all vehicles, adding a radio transponder for transmitting the vehicle identification number (VIN) and DTCs via WiFi to a central server. This allows for real-time emission checks and diagnostics, saving time and costs. However, it also raises privacy concerns due to potential surveillance.

7.2 WWH-OBD and OBDonUDS: Modern Alternatives to OBD2

What are WWH-OBD and OBDonUDS, and how do they improve OBD communication? WWH-OBD (World Wide Harmonized OBD) and OBDonUDS (OBD on UDS) are modern alternatives designed to streamline and enhance OBD communication. They leverage the UDS protocol as a basis, improving data richness and lower-layer protocols. These alternatives aim to provide more efficient and comprehensive vehicle diagnostics.

7.3 OBD2 in Electric Vehicles: Challenges and Solutions

What are the challenges and potential solutions for OBD2 integration in electric vehicles? Electric vehicles (EVs) present challenges for OBD2 integration, as they are not required to support OBD2 in the same way as internal combustion engine vehicles. Many modern EVs utilize OEM-specific UDS communication, making it difficult to decode data using standard OBD2 protocols. Solutions involve reverse engineering and developing new standards to ensure comprehensive EV diagnostics.

8. Expert Insights and Recommendations

What expert insights and recommendations can help me maximize the benefits of using an OBD2 plug?

- Choose the Right Tools: Select high-quality OBD2 scanners and data loggers for accurate and reliable data collection.

- Stay Updated: Keep abreast of the latest OBD2 standards, protocols, and diagnostic techniques.

- Utilize Reliable Resources: Refer to trusted sources like CAR-TOOL.EDU.VN for accurate information and support.

- Prioritize Data Security: Protect your vehicle data and privacy by using secure OBD2 devices and software.

These recommendations will help you leverage the full potential of OBD2 technology for vehicle maintenance, diagnostics, and performance monitoring.

9. Common Issues and Troubleshooting with OBD2 Plugs

What are some common issues and troubleshooting tips when working with OBD2 plugs?

- Connector Problems: Inspect the OBD2 connector for damage or debris, ensuring a secure connection.

- Communication Errors: Verify compatibility between the OBD2 scanner and vehicle, checking for protocol mismatches.

- Data Accuracy: Ensure the OBD2 tool is calibrated correctly and that you are using the correct PIDs for accurate data interpretation.

- Software Issues: Keep the OBD2 scanner software updated to resolve bugs and improve performance.

Addressing these common issues will help ensure a smooth and effective OBD2 diagnostic experience.

10. Frequently Asked Questions (FAQ) about OBD2 Plugs

Here are some frequently asked questions about OBD2 plugs:

- What type of OBD2 plug do I need for my car? Check your vehicle’s make, model, and year to determine the correct OBD2 protocol and connector type (Type A or Type B).

- Can I use an OBD2 scanner on any car? Most cars manufactured after 1996 are OBD2 compliant, but always verify compatibility before use.

- How do I interpret OBD2 codes? Use a reliable OBD2 code lookup tool or consult a mechanic to accurately interpret diagnostic trouble codes (DTCs).

- Is it safe to leave an OBD2 scanner plugged in? Leaving an OBD2 scanner plugged in can drain the battery, so it’s best to unplug it when not in use.

- Where can I find a reliable OBD2 plug and scanner? Visit CAR-TOOL.EDU.VN for a wide range of high-quality OBD2 plugs, scanners, and diagnostic tools.

By addressing these common questions, users can gain a better understanding of OBD2 technology and its practical applications.

Do you have questions or need assistance with your OBD2 plug or diagnostics? Contact CAR-TOOL.EDU.VN today for expert support and solutions. Our team is ready to help you get the most out of your vehicle’s diagnostic system.

Address: 456 Elm Street, Dallas, TX 75201, United States

WhatsApp: +1 (641) 206-8880

Website: CAR-TOOL.EDU.VN

Contact CAR-TOOL.EDU.VN now for personalized advice on selecting the right OBD2 tools and accessories for your needs. Let us help you unlock the full potential of your vehicle’s diagnostic capabilities.

OBD2 bit rate test

OBD2 bit rate test