Maf Sensor Connectors are essential components in your vehicle’s engine management system. CAR-TOOL.EDU.VN provides a comprehensive overview to help you understand, diagnose, and maintain your MAF sensor connector, ensuring optimal engine performance and efficiency. This guide delves into MAF sensor connectors, mass airflow sensor functionality, and relevant diagnostic procedures, promoting smoother vehicle operation and superior results.

Contents

- 1. What is a MAF Sensor Connector?

- 1.1. What is the Primary Function of the MAF Sensor Connector?

- 1.2. What are the Key Components of a MAF Sensor Connector?

- 1.3. What are the Different Types of MAF Sensor Connectors Available?

- 1.4. Why is the MAF Sensor Connector Important for Engine Performance?

- 1.5. Where is the MAF Sensor Connector Located in a Vehicle?

- 2. How to Diagnose a Faulty MAF Sensor Connector

- 2.1. What are the Common Symptoms of a Bad MAF Sensor Connector?

- 2.2. What Tools are Needed to Diagnose a MAF Sensor Connector?

- 2.3. How to Perform a Visual Inspection of the MAF Sensor Connector?

- 2.4. How to Use a Multimeter to Test the MAF Sensor Connector?

- 2.5. What Diagnostic Trouble Codes (DTCs) are Associated with a Bad MAF Sensor Connector?

- 2.6. How to Use a Scan Tool to Read MAF Sensor Data?

- 2.7. How to Test the Wiring Harness Connected to the MAF Sensor Connector?

- 3. How to Replace a MAF Sensor Connector

- 3.1. What Tools are Needed to Replace a MAF Sensor Connector?

- 3.2. Step-by-Step Guide to Replacing the MAF Sensor Connector

- 3.3. How to Ensure Proper Wiring When Replacing the Connector?

- 3.4. What are the Potential Pitfalls to Avoid When Replacing a MAF Sensor Connector?

- 3.5. How to Troubleshoot Issues After Replacing the MAF Sensor Connector?

- 4. Maintaining Your MAF Sensor Connector

- 4.1. What are the Best Practices for Maintaining a MAF Sensor Connector?

- 4.2. How Often Should You Inspect Your MAF Sensor Connector?

- 4.3. How to Clean a MAF Sensor Connector?

- 4.4. What Type of Contact Cleaner Should You Use?

- 4.5. How to Protect the MAF Sensor Connector from Corrosion?

- 4.6. When Should You Consider Replacing Your MAF Sensor Connector?

- 5. Advanced Tips for Working with MAF Sensor Connectors

- 5.1. How to Diagnose Intermittent MAF Sensor Connector Issues?

- 5.2. How to Repair a Damaged Wiring Harness Near the MAF Sensor Connector?

- 5.3. How to Use an Oscilloscope to Analyze MAF Sensor Signals?

- 5.4. What are the Aftermarket Upgrades for MAF Sensor Connectors?

- 5.5. How to Properly Ground the MAF Sensor Connector for Optimal Performance?

- 6. MAF Sensor Connector FAQs

- 6.1. What Causes a MAF Sensor Connector to Fail?

- 6.2. Can I Drive with a Bad MAF Sensor Connector?

- 6.3. How Much Does it Cost to Replace a MAF Sensor Connector?

- 6.4. Is it Possible to Repair a MAF Sensor Connector Instead of Replacing It?

- 6.5. Will a Bad MAF Sensor Connector Affect My Car’s Emissions?

- 6.6. How Do I Know if My MAF Sensor is Bad or if it’s Just the Connector?

- 6.7. Can a Dirty Air Filter Affect the MAF Sensor Connector?

- 6.8. What is the Lifespan of a MAF Sensor Connector?

- 6.9. How to Test a MAF Sensor Connector with an LED Test Light?

- 6.10. What is the Difference Between a MAF Sensor and a MAP Sensor?

- 7. Conclusion

1. What is a MAF Sensor Connector?

A MAF (Mass Air Flow) sensor connector is an electrical connector that links the MAF sensor to the vehicle’s engine control unit (ECU). It facilitates communication between the MAF sensor, which measures the amount of air entering the engine, and the ECU, which uses this information to optimize fuel delivery and ignition timing.

1.1. What is the Primary Function of the MAF Sensor Connector?

The primary function of the MAF sensor connector is to provide a reliable electrical connection between the MAF sensor and the vehicle’s ECU. This connection allows the MAF sensor to send accurate airflow data to the ECU, which then uses this data to calculate the correct amount of fuel to inject into the engine. Proper functioning of the MAF sensor connector is crucial for maintaining optimal engine performance, fuel efficiency, and emissions control. A faulty connector can result in inaccurate readings, leading to a variety of engine problems.

1.2. What are the Key Components of a MAF Sensor Connector?

A typical MAF sensor connector consists of several key components that ensure a secure and reliable electrical connection. These include:

- Housing: The housing is the outer casing of the connector, typically made of durable plastic. It provides physical protection to the internal components and helps secure the connector to the MAF sensor and the wiring harness.

- Terminals: These are the metal contacts inside the connector that make the electrical connection between the wires and the sensor. Terminals are usually made of a conductive material like brass or copper alloy to ensure good conductivity and prevent corrosion.

- Seals: Seals are used to protect the electrical connections from moisture, dirt, and other contaminants. They are typically made of rubber or silicone and are located around the terminals and the housing to provide a watertight seal.

- Locking Mechanism: This feature ensures that the connector stays securely attached to the MAF sensor. It may include clips, latches, or other mechanisms that prevent the connector from vibrating loose or becoming disconnected due to movement or environmental factors.

- Wiring: The wiring consists of the individual wires that connect to the terminals inside the connector. These wires transmit the electrical signals from the MAF sensor to the vehicle’s ECU. They are typically color-coded for easy identification and proper connection.

1.3. What are the Different Types of MAF Sensor Connectors Available?

MAF sensor connectors vary based on vehicle make, model, and year. Common types include:

- 3-Wire MAF Sensor Connector: Often used in older vehicles, these connectors have three wires: one for power, one for ground, and one for the signal to the ECU.

- 4-Wire MAF Sensor Connector: Commonly found in many modern vehicles, these connectors include power, ground, signal, and an intake air temperature (IAT) sensor wire.

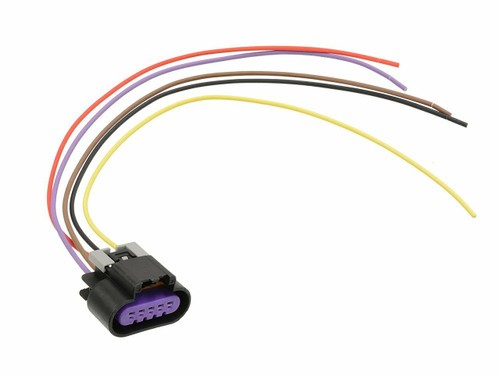

- 5-Wire MAF Sensor Connector: Used in some advanced systems, these connectors may include additional wires for enhanced diagnostics or control features.

1.4. Why is the MAF Sensor Connector Important for Engine Performance?

The MAF sensor connector is vital because it ensures that accurate airflow data reaches the ECU. The ECU uses this information to regulate fuel injection, ignition timing, and other critical engine parameters. A malfunctioning connector can lead to:

- Poor Fuel Economy: Inaccurate airflow readings can cause the ECU to inject too much or too little fuel, reducing fuel efficiency. According to a study by the U.S. Department of Energy, proper maintenance of engine sensors, including the MAF sensor, can improve fuel economy by up to 40% (U.S. Department of Energy, FuelEconomy.gov, 2023).

- Rough Idling: Incorrect fuel-air mixtures can result in unstable idling.

- Reduced Power: The engine may not produce its rated power if the fuel-air mixture is not optimized.

- Increased Emissions: An imbalanced mixture can increase harmful emissions, potentially causing the vehicle to fail emissions tests.

- Check Engine Light: A faulty MAF sensor connector can trigger the check engine light and store diagnostic trouble codes (DTCs).

1.5. Where is the MAF Sensor Connector Located in a Vehicle?

The MAF sensor is typically located in the intake air duct between the air filter and the throttle body. The MAF sensor connector is attached directly to the MAF sensor and connects to the vehicle’s wiring harness. The exact location may vary depending on the vehicle’s make and model, but it is generally accessible under the hood. Consulting the vehicle’s service manual or repair database can provide precise information for locating the MAF sensor connector.

2. How to Diagnose a Faulty MAF Sensor Connector

Diagnosing a faulty MAF sensor connector involves several steps to identify whether the connector is the source of the problem.

2.1. What are the Common Symptoms of a Bad MAF Sensor Connector?

Common symptoms of a bad MAF sensor connector include:

- Check Engine Light: Illumination of the check engine light is a primary indicator, often accompanied by diagnostic trouble codes (DTCs) related to the MAF sensor.

- Rough or Erratic Idling: The engine may idle roughly or stall, especially when cold.

- Poor Acceleration: Hesitation or lack of power during acceleration can occur.

- Reduced Fuel Economy: Noticeable decrease in miles per gallon (MPG).

- Stalling: The engine may stall unexpectedly, especially at low speeds or when stopping.

2.2. What Tools are Needed to Diagnose a MAF Sensor Connector?

To diagnose a MAF sensor connector, you will need:

- Multimeter: To check for voltage, continuity, and resistance.

- Scan Tool: To read diagnostic trouble codes (DTCs) from the ECU.

- Wiring Diagram: To understand the wiring configuration and identify correct pinouts.

- Contact Cleaner: To clean corroded or dirty connectors.

- Terminal Test Kit: To test the terminals’ fit and tension.

- Needle-Nose Pliers: For removing and installing connectors.

- Visual Inspection Tools: Flashlight and magnifying glass to inspect for physical damage.

2.3. How to Perform a Visual Inspection of the MAF Sensor Connector?

A thorough visual inspection is the first step in diagnosing a MAF sensor connector. Look for:

- Physical Damage: Check for cracks, breaks, or melted plastic on the connector housing.

- Corrosion: Examine the terminals for signs of rust or corrosion.

- Loose Wires: Ensure that the wires are securely attached to the connector and not frayed or broken.

- Damaged Seals: Inspect the seals for tears or deterioration.

- Proper Connection: Verify that the connector is fully seated and locked onto the MAF sensor.

2.4. How to Use a Multimeter to Test the MAF Sensor Connector?

Using a multimeter is essential for verifying the electrical integrity of the MAF sensor connector. Follow these steps:

- Check for Power: Use the multimeter to ensure that the MAF sensor is receiving the correct voltage. Consult the vehicle’s wiring diagram to identify the power wire and the specified voltage (typically 12V or 5V).

- Check for Ground: Verify that the ground wire is properly grounded. Use the multimeter to check for continuity between the ground terminal and the vehicle’s chassis.

- Check for Continuity: With the ignition off, check the continuity of each wire between the MAF sensor connector and the ECU. This ensures that there are no breaks or shorts in the wiring.

- Check for Voltage Drop: With the engine running, measure the voltage drop across the connector. Excessive voltage drop indicates a poor connection, which can affect the accuracy of the MAF sensor readings.

2.5. What Diagnostic Trouble Codes (DTCs) are Associated with a Bad MAF Sensor Connector?

Several DTCs may indicate a problem with the MAF sensor connector. Common codes include:

- P0100: Mass Air Flow Circuit Malfunction

- P0101: Mass Air Flow Circuit Range/Performance Problem

- P0102: Mass Air Flow Circuit Low Input

- P0103: Mass Air Flow Circuit High Input

- P0104: Mass Air Flow Circuit Intermittent

2.6. How to Use a Scan Tool to Read MAF Sensor Data?

A scan tool can provide valuable information about the MAF sensor’s performance.

- Connect the Scan Tool: Plug the scan tool into the vehicle’s OBD-II port.

- Read DTCs: Retrieve any stored DTCs related to the MAF sensor.

- View Live Data: Access live data to monitor the MAF sensor readings while the engine is running. Look for abnormal values or fluctuations.

- Compare to Specifications: Compare the MAF sensor readings to the manufacturer’s specifications. Significant deviations indicate a problem.

2.7. How to Test the Wiring Harness Connected to the MAF Sensor Connector?

Testing the wiring harness involves checking for continuity, shorts, and proper voltage.

- Continuity Test: Use a multimeter to check the continuity of each wire in the harness. Disconnect the harness from both the MAF sensor and the ECU before testing.

- Short to Ground Test: Check for shorts to ground by measuring the resistance between each wire and the vehicle’s chassis. Low resistance indicates a short.

- Voltage Test: With the ignition on, check for proper voltage at the appropriate wires in the harness. Refer to the wiring diagram for the correct voltage specifications.

3. How to Replace a MAF Sensor Connector

Replacing a MAF sensor connector is a straightforward process that can resolve many common MAF sensor issues.

3.1. What Tools are Needed to Replace a MAF Sensor Connector?

To replace a MAF sensor connector, you will need:

- New MAF Sensor Connector: Ensure it is compatible with your vehicle’s make and model.

- Wire Strippers: To strip the ends of the wires.

- Wire Crimpers: To crimp new terminals onto the wires.

- Soldering Iron and Solder: For soldering the wires (if necessary).

- Heat Shrink Tubing: To protect the soldered connections.

- Heat Gun: To shrink the heat shrink tubing.

- Electrical Tape: To insulate the connections.

- Screwdrivers: To remove any mounting hardware.

- Pliers: To grip and manipulate the wires and connectors.

3.2. Step-by-Step Guide to Replacing the MAF Sensor Connector

Follow these steps to replace the MAF sensor connector:

- Disconnect the Battery: Disconnect the negative terminal of the battery to prevent electrical shock.

- Remove the Old Connector: Disconnect the old MAF sensor connector from the MAF sensor.

- Inspect the Wires: Examine the wires connected to the old connector for any damage or corrosion.

- Cut the Wires: Cut the wires close to the old connector, leaving enough length to work with.

- Strip the Wires: Use wire strippers to remove the insulation from the ends of the wires.

- Attach New Terminals: Crimp new terminals onto the ends of the wires using wire crimpers.

- Insert Wires into New Connector: Insert the wires into the new connector, ensuring they are in the correct positions according to the wiring diagram.

- Secure the Connector: Secure the wires in the new connector by locking the terminals in place.

- Connect the New Connector: Connect the new MAF sensor connector to the MAF sensor.

- Reconnect the Battery: Reconnect the negative terminal of the battery.

- Test the Connection: Start the engine and use a scan tool to check for any DTCs related to the MAF sensor. Monitor the MAF sensor readings to ensure they are within the correct range.

3.3. How to Ensure Proper Wiring When Replacing the Connector?

Ensuring proper wiring is critical to avoid damaging the MAF sensor or the ECU.

- Use a Wiring Diagram: Always refer to the vehicle’s wiring diagram to identify the correct wire positions in the connector.

- Match Wire Colors: Match the wire colors from the old connector to the new connector.

- Double-Check Connections: Double-check all connections before securing the connector.

- Use a Terminal Test Kit: Use a terminal test kit to ensure that the terminals are properly seated and making good contact.

3.4. What are the Potential Pitfalls to Avoid When Replacing a MAF Sensor Connector?

Avoid these common pitfalls when replacing a MAF sensor connector:

- Incorrect Wiring: Incorrect wiring can damage the MAF sensor or the ECU.

- Poor Connections: Loose or corroded connections can cause inaccurate readings.

- Damaged Wires: Damaged wires can lead to intermittent problems.

- Incompatible Connector: Using an incompatible connector can result in poor performance or damage.

3.5. How to Troubleshoot Issues After Replacing the MAF Sensor Connector?

If you encounter issues after replacing the MAF sensor connector, follow these troubleshooting steps:

- Check DTCs: Use a scan tool to check for any new DTCs.

- Verify Wiring: Double-check the wiring to ensure it is correct.

- Inspect Connections: Inspect the connections for looseness or corrosion.

- Monitor MAF Sensor Readings: Use a scan tool to monitor the MAF sensor readings and compare them to the manufacturer’s specifications.

- Test the MAF Sensor: If the problem persists, test the MAF sensor itself to rule out any issues with the sensor.

4. Maintaining Your MAF Sensor Connector

Proper maintenance can extend the life of your MAF sensor connector and prevent future problems.

4.1. What are the Best Practices for Maintaining a MAF Sensor Connector?

- Regular Inspections: Inspect the MAF sensor connector regularly for any signs of damage or corrosion.

- Cleaning: Clean the connector with contact cleaner to remove dirt and debris.

- Secure Connections: Ensure that the connector is securely attached to the MAF sensor and the wiring harness.

- Protect from Moisture: Protect the connector from moisture by using dielectric grease or silicone sealant.

- Avoid Harsh Chemicals: Avoid using harsh chemicals or solvents that can damage the connector.

4.2. How Often Should You Inspect Your MAF Sensor Connector?

You should inspect your MAF sensor connector at least every 12 months or during routine maintenance checks. More frequent inspections may be necessary in harsh environments or if you experience any symptoms of a faulty connector.

4.3. How to Clean a MAF Sensor Connector?

Cleaning a MAF sensor connector is a simple process that can improve its performance.

- Disconnect the Connector: Disconnect the MAF sensor connector from the MAF sensor.

- Inspect the Terminals: Inspect the terminals for any signs of corrosion or dirt.

- Apply Contact Cleaner: Spray contact cleaner onto the terminals and into the connector housing.

- Use a Brush: Use a small brush or cotton swab to gently clean the terminals.

- Dry the Connector: Allow the connector to air dry or use compressed air to dry it.

- Apply Dielectric Grease: Apply a small amount of dielectric grease to the terminals to protect them from moisture and corrosion.

- Reconnect the Connector: Reconnect the MAF sensor connector to the MAF sensor.

4.4. What Type of Contact Cleaner Should You Use?

Use a contact cleaner specifically designed for electronic components. These cleaners are typically non-residue and safe for use on plastics and metals. Avoid using harsh chemicals or solvents that can damage the connector.

4.5. How to Protect the MAF Sensor Connector from Corrosion?

Protecting the MAF sensor connector from corrosion is essential for maintaining its performance and reliability.

- Use Dielectric Grease: Apply dielectric grease to the terminals to protect them from moisture and corrosion.

- Seal the Connector: Use silicone sealant or electrical tape to seal the connector and prevent moisture from entering.

- Avoid Water Exposure: Avoid exposing the connector to water or other liquids.

- Regular Cleaning: Clean the connector regularly to remove any dirt or debris that can contribute to corrosion.

4.6. When Should You Consider Replacing Your MAF Sensor Connector?

Consider replacing your MAF sensor connector if:

- It is Damaged: If the connector is physically damaged, such as cracked, broken, or melted.

- It is Corroded: If the terminals are heavily corroded and cannot be cleaned.

- It is Causing Problems: If you are experiencing persistent MAF sensor-related issues that cannot be resolved by cleaning or other maintenance.

- It is Old: If the connector is old and showing signs of wear and tear.

5. Advanced Tips for Working with MAF Sensor Connectors

For experienced technicians, here are some advanced tips for working with MAF sensor connectors.

5.1. How to Diagnose Intermittent MAF Sensor Connector Issues?

Intermittent MAF sensor connector issues can be challenging to diagnose. These tips can help:

- Check Wiring Harness: Inspect the entire wiring harness for any signs of damage, chafing, or loose connections.

- Perform a Wiggle Test: With the engine running, wiggle the wiring harness and the connector to see if this causes the engine to stumble or the MAF sensor readings to fluctuate.

- Use a Data Logger: Use a data logger to record the MAF sensor readings over time. This can help identify intermittent problems that may not be apparent during a static test.

- Check for Electrical Interference: Check for sources of electrical interference that may be affecting the MAF sensor signal.

5.2. How to Repair a Damaged Wiring Harness Near the MAF Sensor Connector?

Repairing a damaged wiring harness requires careful attention to detail.

- Identify the Damage: Locate the damaged section of the wiring harness.

- Disconnect the Battery: Disconnect the negative terminal of the battery.

- Cut the Wires: Cut the wires on either side of the damaged section.

- Strip the Wires: Strip the insulation from the ends of the wires.

- Splice the Wires: Splice the wires together using butt connectors or soldering.

- Insulate the Connections: Insulate the connections with heat shrink tubing or electrical tape.

- Protect the Harness: Protect the repaired section of the wiring harness with wire loom or tape.

- Reconnect the Battery: Reconnect the negative terminal of the battery.

- Test the Connection: Start the engine and check for any DTCs related to the MAF sensor.

5.3. How to Use an Oscilloscope to Analyze MAF Sensor Signals?

An oscilloscope can provide a detailed view of the MAF sensor signal.

- Connect the Oscilloscope: Connect the oscilloscope to the MAF sensor signal wire and the ground wire.

- Set the Time and Voltage Scales: Set the time and voltage scales on the oscilloscope to capture the MAF sensor signal.

- Monitor the Signal: Monitor the MAF sensor signal while the engine is running. Look for any abnormalities, such as dropouts, spikes, or noise.

- Compare to Known Good Signal: Compare the MAF sensor signal to a known good signal to identify any deviations.

5.4. What are the Aftermarket Upgrades for MAF Sensor Connectors?

Several aftermarket upgrades are available for MAF sensor connectors.

- High-Performance Connectors: These connectors are designed to provide a more reliable and durable connection.

- Gold-Plated Terminals: Gold-plated terminals offer improved conductivity and corrosion resistance.

- Weatherproof Connectors: Weatherproof connectors provide enhanced protection against moisture and other environmental factors.

- Extension Harnesses: Extension harnesses allow you to relocate the MAF sensor to a different location.

5.5. How to Properly Ground the MAF Sensor Connector for Optimal Performance?

Proper grounding is essential for optimal MAF sensor performance.

- Check Ground Connection: Ensure that the MAF sensor ground wire is properly connected to the vehicle’s chassis.

- Clean Grounding Point: Clean the grounding point to remove any dirt or corrosion.

- Use Star Washers: Use star washers to ensure a good electrical connection.

- Add Additional Ground Wire: Add an additional ground wire from the MAF sensor to the chassis for improved grounding.

6. MAF Sensor Connector FAQs

6.1. What Causes a MAF Sensor Connector to Fail?

MAF sensor connectors fail due to physical damage, corrosion, loose connections, and electrical issues. Regular inspections and maintenance can help prevent these failures.

6.2. Can I Drive with a Bad MAF Sensor Connector?

Driving with a bad MAF sensor connector can cause poor engine performance, reduced fuel economy, and increased emissions. It is best to diagnose and repair the issue as soon as possible.

6.3. How Much Does it Cost to Replace a MAF Sensor Connector?

The cost to replace a MAF sensor connector can vary depending on the vehicle’s make and model and the labor costs in your area. Generally, the part itself costs between $10 and $50, while labor can range from $50 to $150.

6.4. Is it Possible to Repair a MAF Sensor Connector Instead of Replacing It?

In some cases, it may be possible to repair a MAF sensor connector by cleaning the terminals, tightening the connections, or repairing damaged wires. However, if the connector is severely damaged or corroded, it is best to replace it.

6.5. Will a Bad MAF Sensor Connector Affect My Car’s Emissions?

Yes, a bad MAF sensor connector can affect your car’s emissions by causing an imbalanced fuel-air mixture. This can lead to increased levels of harmful pollutants, such as hydrocarbons, carbon monoxide, and nitrogen oxides.

6.6. How Do I Know if My MAF Sensor is Bad or if it’s Just the Connector?

To determine if the MAF sensor is bad or if it’s just the connector, perform a thorough diagnosis, including a visual inspection of the connector, testing the wiring harness, and monitoring the MAF sensor readings with a scan tool. If the connector is in good condition and the MAF sensor readings are still abnormal, the sensor may be bad.

6.7. Can a Dirty Air Filter Affect the MAF Sensor Connector?

Yes, a dirty air filter can affect the MAF sensor connector by allowing dirt and debris to enter the engine and contaminate the connector. This can lead to corrosion and poor connections.

6.8. What is the Lifespan of a MAF Sensor Connector?

The lifespan of a MAF sensor connector can vary depending on the vehicle’s operating conditions and maintenance practices. Generally, a MAF sensor connector can last for several years, but it may need to be replaced sooner if it is exposed to harsh environments or neglected.

6.9. How to Test a MAF Sensor Connector with an LED Test Light?

Testing a MAF sensor connector with an LED test light involves checking for power and ground at the connector.

- Connect the Test Light: Connect the clip of the test light to a known good ground.

- Check for Power: Probe the power terminal of the connector with the test light. The LED should light up if there is power.

- Check for Ground: Connect the clip of the test light to the positive terminal of the battery. Probe the ground terminal of the connector with the test light. The LED should light up if there is a good ground.

6.10. What is the Difference Between a MAF Sensor and a MAP Sensor?

A MAF (Mass Air Flow) sensor measures the amount of air entering the engine, while a MAP (Manifold Absolute Pressure) sensor measures the pressure in the intake manifold. Both sensors provide critical information to the ECU for fuel control, but they use different methods to measure airflow.

7. Conclusion

Understanding the MAF sensor connector is crucial for maintaining your vehicle’s engine performance and efficiency. By following the diagnostic and maintenance tips outlined in this guide, you can ensure that your MAF sensor connector remains in good condition and that your engine continues to run smoothly. Remember to consult CAR-TOOL.EDU.VN for all your automotive tool and information needs. Whether you are a seasoned technician or a DIY enthusiast, having access to reliable information and quality tools is essential for successful automotive repairs.

Are you having trouble finding reliable MAF sensor connectors or diagnostic tools? Contact us at CAR-TOOL.EDU.VN for expert advice and support. Our team can assist you in selecting the right parts and tools for your specific needs. Reach out to us at 456 Elm Street, Dallas, TX 75201, United States, or via WhatsApp at +1 (641) 206-8880. Visit our website at CAR-TOOL.EDU.VN for more information and to explore our wide range of automotive products. Let CAR-TOOL.EDU.VN be your trusted partner in automotive maintenance and repair. Optimize your vehicle’s functionality with our specialized diagnostic and repair assistance.

MAF sensor wiring extension

MAF sensor wiring extension

LS2 to LS3/LS7 MAF Adapter Harness Corvette GTO

LS2 to LS3/LS7 MAF Adapter Harness Corvette GTO

Gen 5 MAF Extension 2016-2019 LT Card Style LT1 L83 L86 LT4 48

Gen 5 MAF Extension 2016-2019 LT Card Style LT1 L83 L86 LT4 48

LS Gen 3 Mass Air Flow MAF Connector 3-Wire Sensor Pigtail Wiring LS1 5.7L

LS Gen 3 Mass Air Flow MAF Connector 3-Wire Sensor Pigtail Wiring LS1 5.7L

Mass Air Flow Sensor Connector MAF Fits 2007-2010 GM GMC Pontiac Saturn Buick PT2268, 19151506

Mass Air Flow Sensor Connector MAF Fits 2007-2010 GM GMC Pontiac Saturn Buick PT2268, 19151506

Mass Air Flow Wiring Adapter 05-10 Ford Mustang Conversion to 96-04 MAF Sensor

Mass Air Flow Wiring Adapter 05-10 Ford Mustang Conversion to 96-04 MAF Sensor

5 Wire Mass Air Flow Fits 85-89 Camaro Corvette TPI GM MAF Sensor Connector Pigtail

5 Wire Mass Air Flow Fits 85-89 Camaro Corvette TPI GM MAF Sensor Connector Pigtail

5 Wire Mass Air Flow Fits GM MAF Sensor Connector Pigtail LS2 LS1 LQ4 4.8 5.3 6.0

5 Wire Mass Air Flow Fits GM MAF Sensor Connector Pigtail LS2 LS1 LQ4 4.8 5.3 6.0

5 Wire VVT Cam Sensor Wire Harness Pigtail Fits: 4.8 5.3 6.0 6.2 Gen IV GM GMC Cadillac Hummer Chevy Buick SAAB Saturn

5 Wire VVT Cam Sensor Wire Harness Pigtail Fits: 4.8 5.3 6.0 6.2 Gen IV GM GMC Cadillac Hummer Chevy Buick SAAB Saturn

5 Wire Mass Air Flow GM MAF Extension – Sensor Connector LS2, LS1 LQ4 4.8 5.3 6.0 4.3 and 8.1 GM Truck

5 Wire Mass Air Flow GM MAF Extension – Sensor Connector LS2, LS1 LQ4 4.8 5.3 6.0 4.3 and 8.1 GM Truck

Mass Air Flow 24

Mass Air Flow 24