Obd2 Wikipedia, along with related vehicle diagnostic tools, is essential for modern automotive repair. CAR-TOOL.EDU.VN offers detailed resources to help you understand and utilize OBD2 systems effectively, ensuring accurate diagnostics and efficient repairs. Explore our site for in-depth guides on scan tools, diagnostic procedures, and more to keep your vehicle running smoothly.

Contents

- 1. What is OBD2 According to Wikipedia?

- 2. How Does the OBD2 System Work?

- 3. What Are The Key Components of an OBD2 System?

- 4. What Are the Benefits of Using OBD2 Scanners?

- 5. What Are Common OBD2 Trouble Codes and Their Meanings?

- 6. How to Choose the Right OBD2 Scanner for Your Needs

- 7. What is the Difference Between OBD1 and OBD2?

- 8. What Are the Limitations of OBD2 Systems?

- 9. How to Perform an OBD2 Scan on Your Vehicle

- 10. What Are Advanced OBD2 Functions and How to Use Them?

- 11. What Are the Different Types of OBD2 Protocols?

- 12. What are the Legal and Regulatory Aspects of OBD2?

- 13. How Does OBD2 Help in Reducing Vehicle Emissions?

- 14. What is Mode 6 Data in OBD2 and How to Use It?

- 15. How to Interpret OBD2 Freeze Frame Data?

- 16. What Are OBD2 Readiness Monitors and Their Importance?

- 17. How Does OBD2 Relate to CAN Bus Systems?

- 18. What Are the Future Trends in OBD2 Technology?

- 19. How to Use OBD2 Data for Performance Tuning?

- 20. What Are Common Mistakes to Avoid When Using OBD2 Scanners?

- 21. How to Keep Your OBD2 Scanner Updated?

- 22. What Are the Ethical Considerations When Using OBD2 Data?

- 23. Where Can You Find Reliable OBD2 Resources and Information?

- 24. How to Troubleshoot Common OBD2 Scanner Problems?

- 25. What are the Alternatives to Using OBD2 Scanners?

- 26. How Can CAR-TOOL.EDU.VN Help You with Your OBD2 Needs?

- 27. OBD2 Connector Types and Compatibility

- 28. The Role of Oxygen Sensors in OBD2 Systems

- 29. Decoding VIN Numbers with OBD2 Tools

- 30. Understanding Fuel Trims with OBD2 Diagnostics

- 31. Using OBD2 to Diagnose Transmission Problems

- 32. How to Perform a Cylinder Balance Test with OBD2

- 33. OBD2 and Electric Vehicles (EVs)

- 34. The Importance of Regular OBD2 Inspections

- 35. Contact CAR-TOOL.EDU.VN for Expert OBD2 Assistance

- FAQ About OBD2 Wikipedia

1. What is OBD2 According to Wikipedia?

According to Wikipedia, OBD2 (On-Board Diagnostics II) is a set of standards for implementing a computer-based system to monitor emission-related components, engine, and other parts of a vehicle. But what does that really mean for you as a mechanic or car enthusiast? OBD2 provides a standardized way to access diagnostic data from any vehicle manufactured after 1996 in the United States, and later in other countries. This standardization simplifies diagnostics, making it easier to identify problems and perform necessary repairs.

OBD2 is crucial because it mandates a universal connector (SAE J1962) and a standardized set of diagnostic trouble codes (DTCs). This means any OBD2 scanner can read codes from any compatible vehicle, regardless of make or model. The system monitors various sensors and systems, reporting any issues that could affect emissions or engine performance. For example, if the oxygen sensor is malfunctioning, the OBD2 system will detect this and store a corresponding DTC, such as P0131 (Oxygen Sensor Circuit Low Voltage Bank 1 Sensor 1). This information is invaluable for diagnosing and resolving vehicle issues efficiently. According to the EPA (Environmental Protection Agency), OBD2 compliance is a requirement for all vehicles sold in the US since 1996, emphasizing its importance in maintaining air quality and vehicle performance.

2. How Does the OBD2 System Work?

The OBD2 system works by continuously monitoring various sensors and components throughout the vehicle. These sensors provide data to the Engine Control Unit (ECU), which analyzes the information to ensure everything is functioning within specified parameters. When a sensor reading falls outside the acceptable range, the ECU registers a diagnostic trouble code (DTC) and illuminates the Malfunction Indicator Lamp (MIL), commonly known as the check engine light.

For example, if the mass airflow (MAF) sensor detects an abnormal airflow reading, the ECU will store a DTC like P0101 (Mass Air Flow Circuit Range/Performance Problem). The mechanic can then use an OBD2 scanner to retrieve this code and begin diagnosing the issue. The OBD2 system covers a wide range of components, including the engine, transmission, fuel system, and emissions control system. The standardized nature of OBD2 means that regardless of the vehicle’s make or model, the diagnostic process remains consistent. According to a study by the National Institute for Automotive Service Excellence (ASE), technicians who effectively use OBD2 systems can diagnose and repair vehicles up to 40% faster.

3. What Are The Key Components of an OBD2 System?

Key components of an OBD2 system include:

- Engine Control Unit (ECU): The brain of the system, processing data from sensors and controlling engine functions.

- Malfunction Indicator Lamp (MIL): The check engine light that illuminates when a problem is detected.

- Diagnostic Trouble Codes (DTCs): Standardized codes that identify specific problems.

- Oxygen Sensors: Monitor the oxygen levels in the exhaust to ensure optimal combustion.

- Mass Airflow (MAF) Sensor: Measures the amount of air entering the engine.

- Throttle Position Sensor (TPS): Monitors the position of the throttle plate.

- Vehicle Speed Sensor (VSS): Measures the speed of the vehicle.

Understanding these components and how they interact is crucial for effective diagnostics. For example, the ECU uses data from the MAF sensor and TPS to calculate the correct amount of fuel to inject into the engine. If the MAF sensor is faulty, the ECU may not be able to accurately determine the air-fuel mixture, leading to performance issues and potentially triggering a DTC. According to Bosch Automotive Handbook, the accuracy and reliability of these sensors directly impact the overall performance and efficiency of the OBD2 system.

4. What Are the Benefits of Using OBD2 Scanners?

Using OBD2 scanners provides numerous benefits, including:

- Accurate Diagnostics: Quickly identify the source of problems with specific DTCs.

- Time Savings: Reduce diagnostic time by pinpointing issues efficiently.

- Cost Savings: Avoid unnecessary repairs by accurately diagnosing the problem the first time.

- Improved Performance: Ensure your vehicle runs optimally by addressing issues promptly.

- Emissions Compliance: Maintain emissions compliance by identifying and resolving issues that could lead to increased emissions.

For instance, consider a scenario where a vehicle is experiencing poor fuel economy. Without an OBD2 scanner, diagnosing the cause could involve a time-consuming process of elimination, checking various components such as spark plugs, fuel injectors, and oxygen sensors. However, with an OBD2 scanner, a mechanic can quickly retrieve DTCs that indicate a faulty oxygen sensor or a malfunctioning fuel injector. This allows for a targeted repair, saving both time and money. A study by AAA found that using OBD2 scanners can reduce diagnostic time by an average of one hour per repair, translating to significant cost savings for both mechanics and vehicle owners.

5. What Are Common OBD2 Trouble Codes and Their Meanings?

Common OBD2 trouble codes and their meanings include:

| DTC | Description | Possible Causes |

|---|---|---|

| P0101 | Mass Air Flow Circuit Range/Performance Problem | Dirty or faulty MAF sensor, vacuum leak, faulty wiring |

| P0113 | Intake Air Temperature Sensor Circuit High Input | Faulty IAT sensor, open circuit in wiring |

| P0171 | System Too Lean (Bank 1) | Vacuum leak, faulty oxygen sensor, low fuel pressure |

| P0300 | Random/Multiple Cylinder Misfire Detected | Faulty spark plugs, ignition coils, fuel injectors, vacuum leaks, low compression |

| P0420 | Catalyst System Efficiency Below Threshold (Bank 1) | Faulty catalytic converter, exhaust leaks, faulty oxygen sensors |

Understanding these codes helps mechanics quickly identify and address common issues. For example, a P0171 code (System Too Lean) indicates that the engine is receiving too much air or not enough fuel. This could be caused by a vacuum leak, a faulty oxygen sensor, or low fuel pressure. By knowing the possible causes, the mechanic can perform targeted tests to pinpoint the exact issue and implement the appropriate repair. According to data from RepairPal, P0420 (Catalyst System Efficiency Below Threshold) is one of the most common OBD2 codes, often requiring replacement of the catalytic converter.

6. How to Choose the Right OBD2 Scanner for Your Needs

Choosing the right OBD2 scanner depends on your specific needs and budget. Here are some factors to consider:

- Functionality: Basic scanners read and clear DTCs, while advanced scanners offer features like live data streaming, bidirectional control, and advanced diagnostics.

- Compatibility: Ensure the scanner is compatible with the vehicles you’ll be working on.

- Ease of Use: Look for a scanner with a user-friendly interface and clear instructions.

- Updateability: Choose a scanner that can be updated with the latest vehicle information and diagnostic capabilities.

- Price: Scanners range in price from basic models under $50 to professional-grade tools costing several thousand dollars.

For example, a DIY enthusiast who only needs to read and clear codes on their personal vehicles might opt for a basic scanner. On the other hand, a professional mechanic working on a variety of vehicles would benefit from an advanced scanner with features like live data streaming and bidirectional control. According to a survey by the Equipment & Tool Institute (ETI), professional mechanics prefer scanners with robust diagnostic capabilities and frequent software updates to stay current with the latest vehicle technologies.

7. What is the Difference Between OBD1 and OBD2?

The main differences between OBD1 and OBD2 are standardization and functionality. OBD1, used in vehicles before 1996, lacked a standardized connector and diagnostic protocol. This meant each manufacturer had their own diagnostic system, making it difficult to diagnose vehicles without specialized tools and knowledge. OBD2, introduced in 1996, standardized the diagnostic process with a universal connector (SAE J1962) and a set of common diagnostic trouble codes (DTCs).

Additionally, OBD2 offers enhanced diagnostic capabilities compared to OBD1. OBD2 systems monitor a wider range of components and provide more detailed data, allowing for more accurate and efficient diagnostics. For example, OBD2 systems monitor oxygen sensors, mass airflow sensors, and other critical components in real-time, providing valuable information for troubleshooting performance issues. According to the Society of Automotive Engineers (SAE), the standardization of OBD2 has significantly improved the efficiency and accuracy of vehicle diagnostics.

8. What Are the Limitations of OBD2 Systems?

While OBD2 systems offer numerous benefits, they also have limitations:

- Limited Scope: OBD2 primarily focuses on emissions-related issues, so it may not detect all mechanical problems.

- Misleading Codes: Sometimes, the DTC may not directly indicate the root cause of the problem, requiring further investigation.

- False Positives: Sensor readings can be affected by factors like temperature and humidity, leading to false positives.

- Complexity: Interpreting live data and advanced diagnostic features can be complex and require specialized knowledge.

For example, a P0300 code (Random/Multiple Cylinder Misfire Detected) could be caused by a variety of issues, including faulty spark plugs, ignition coils, fuel injectors, or vacuum leaks. The OBD2 system only indicates that a misfire is occurring but doesn’t pinpoint the exact cause. This requires the mechanic to perform additional tests to identify the specific problem. According to ASE, experienced technicians understand the limitations of OBD2 and use their knowledge and expertise to interpret diagnostic data accurately.

9. How to Perform an OBD2 Scan on Your Vehicle

To perform an OBD2 scan on your vehicle:

- Locate the OBD2 port (usually under the dashboard on the driver’s side).

- Plug the OBD2 scanner into the port.

- Turn the ignition key to the “on” position (without starting the engine).

- Follow the scanner’s instructions to read the diagnostic trouble codes (DTCs).

- Record the DTCs and research their meanings.

- Clear the codes after addressing the underlying issue (optional).

For example, if the scanner displays a P0171 code (System Too Lean), you would then investigate potential causes such as vacuum leaks or a faulty oxygen sensor. After repairing the issue, you can clear the code using the scanner. It’s important to note that clearing codes without addressing the underlying problem will only result in the code reappearing. According to Popular Mechanics, performing regular OBD2 scans can help identify potential issues early, preventing more serious problems down the road.

10. What Are Advanced OBD2 Functions and How to Use Them?

Advanced OBD2 functions include:

- Live Data Streaming: View real-time data from sensors and components.

- Bidirectional Control: Activate and test certain components, such as fuel injectors and solenoids.

- Freeze Frame Data: Capture data from when a DTC was triggered.

- Oxygen Sensor Testing: Monitor the performance of oxygen sensors.

- EVAP System Testing: Test the evaporative emissions control system.

Using these functions requires a more advanced scanner and a thorough understanding of vehicle systems. For example, live data streaming can be used to monitor the voltage output of an oxygen sensor. By observing how the voltage changes under different driving conditions, a mechanic can determine if the sensor is functioning correctly. Bidirectional control allows a mechanic to activate a fuel injector and listen for the characteristic clicking sound, confirming that the injector is firing. According to a training manual by Delphi Technologies, mastering these advanced OBD2 functions can significantly improve diagnostic accuracy and efficiency.

11. What Are the Different Types of OBD2 Protocols?

Different types of OBD2 protocols include:

- SAE J1850 PWM: Used by Ford vehicles.

- SAE J1850 VPW: Used by GM vehicles.

- ISO 9141-2: Used by Chrysler, European, and Asian vehicles.

- ISO 14230-4 (KWP2000): Used by Chrysler, European, and Asian vehicles.

- CAN (Controller Area Network): Used by all vehicles sold in the US since 2008.

Understanding these protocols is important for ensuring compatibility between the scanner and the vehicle. While most modern scanners support all five protocols, older scanners may only support a limited number. CAN (Controller Area Network) is the most modern and widely used protocol, offering faster communication speeds and more advanced diagnostic capabilities. According to a technical bulletin from Actron, using the correct protocol is essential for accurate and reliable OBD2 communication.

12. What are the Legal and Regulatory Aspects of OBD2?

The legal and regulatory aspects of OBD2 are primarily focused on emissions control. In the United States, the Environmental Protection Agency (EPA) mandates that all vehicles sold since 1996 must be OBD2 compliant. This means that vehicles must have a functioning OBD2 system that monitors emissions-related components and alerts the driver to any issues that could increase emissions.

Additionally, many states require vehicles to pass an OBD2 emissions test as part of their annual inspection. During this test, a technician connects an OBD2 scanner to the vehicle and checks for any stored diagnostic trouble codes (DTCs). If any emissions-related DTCs are present, the vehicle will fail the test and require repairs. According to the EPA, OBD2 compliance has significantly reduced vehicle emissions, contributing to cleaner air quality.

13. How Does OBD2 Help in Reducing Vehicle Emissions?

OBD2 helps in reducing vehicle emissions by:

- Monitoring Emissions-Related Components: OBD2 systems continuously monitor components such as oxygen sensors, catalytic converters, and fuel injectors to ensure they are functioning correctly.

- Detecting Malfunctions: When a component malfunctions and could cause increased emissions, the OBD2 system stores a diagnostic trouble code (DTC) and illuminates the check engine light.

- Alerting Drivers: The check engine light alerts drivers to potential emissions issues, prompting them to seek repairs.

- Enabling Accurate Repairs: The DTCs provide mechanics with valuable information for diagnosing and repairing the underlying problem, reducing emissions.

For example, if a catalytic converter is not functioning efficiently, the OBD2 system will detect this and store a P0420 code (Catalyst System Efficiency Below Threshold). This alerts the driver to a potential emissions issue and allows a mechanic to replace the catalytic converter, restoring its ability to reduce harmful emissions. According to a report by the California Air Resources Board (CARB), OBD2 systems have played a crucial role in reducing vehicle emissions in California.

14. What is Mode 6 Data in OBD2 and How to Use It?

Mode 6 data in OBD2 provides detailed information about the performance of various vehicle systems and components. Unlike standard diagnostic trouble codes (DTCs), which only indicate that a problem exists, Mode 6 data provides specific test results and performance thresholds. This can be invaluable for diagnosing intermittent issues and fine-tuning vehicle performance.

Using Mode 6 data requires an advanced OBD2 scanner and a thorough understanding of vehicle systems. For example, Mode 6 data can be used to monitor the misfire rate of individual cylinders. By comparing the misfire rate to the manufacturer’s specifications, a mechanic can determine if a particular cylinder is experiencing excessive misfires, even if a DTC has not been triggered. According to a training manual by Snap-on, Mode 6 data is a powerful tool for advanced diagnostics and performance tuning.

15. How to Interpret OBD2 Freeze Frame Data?

Freeze frame data captures a snapshot of vehicle sensor data at the moment a diagnostic trouble code (DTC) was triggered. This data can provide valuable insights into the conditions that led to the problem, helping mechanics diagnose the underlying cause. Freeze frame data typically includes parameters such as engine speed, engine load, coolant temperature, and fuel trim.

To interpret freeze frame data:

- Record the DTC and associated freeze frame data.

- Analyze the data to identify any abnormal readings.

- Compare the data to the manufacturer’s specifications.

- Use the data to guide your diagnostic process.

For example, if a P0171 code (System Too Lean) is accompanied by freeze frame data showing high engine load and low fuel trim, this suggests that the engine is not receiving enough fuel under heavy load. This could be caused by a clogged fuel filter or a failing fuel pump. According to a guide by Autel, freeze frame data is an essential tool for diagnosing intermittent issues and complex problems.

16. What Are OBD2 Readiness Monitors and Their Importance?

OBD2 readiness monitors are internal tests that the OBD2 system performs to verify the functionality of various emissions-related components. These monitors run automatically during normal driving conditions and indicate whether a particular system is ready for an emissions test. Common readiness monitors include the oxygen sensor monitor, the catalyst monitor, and the evaporative system monitor.

The importance of readiness monitors lies in their ability to ensure that all emissions-related systems are functioning correctly before an emissions test. If any readiness monitors are not set (i.e., the tests have not been completed), the vehicle may fail the emissions test, even if no diagnostic trouble codes (DTCs) are present. According to the EPA, readiness monitors help to ensure that vehicles meet emissions standards and contribute to cleaner air quality.

17. How Does OBD2 Relate to CAN Bus Systems?

OBD2 and CAN (Controller Area Network) bus systems are closely related. CAN bus is a communication protocol used by modern vehicles to allow various electronic control units (ECUs) to communicate with each other. OBD2 systems utilize the CAN bus to access diagnostic data from these ECUs.

In vehicles with CAN bus systems, the OBD2 port is connected to the CAN bus network. When an OBD2 scanner is plugged into the port, it can communicate with the various ECUs and retrieve diagnostic trouble codes (DTCs), live data, and other information. CAN bus systems offer faster communication speeds and more advanced diagnostic capabilities compared to older communication protocols. According to a technical document from Vector Informatik, CAN bus is the dominant communication protocol in modern automotive systems.

18. What Are the Future Trends in OBD2 Technology?

Future trends in OBD2 technology include:

- Wireless OBD2 Adapters: Wireless adapters that connect to smartphones and tablets via Bluetooth or Wi-Fi.

- Cloud-Based Diagnostics: Diagnostic systems that store data in the cloud, allowing for remote monitoring and analysis.

- Artificial Intelligence (AI): AI-powered diagnostic tools that can predict potential issues and provide more accurate diagnoses.

- Enhanced Cybersecurity: Improved security measures to protect against hacking and unauthorized access to vehicle systems.

These trends aim to make OBD2 diagnostics more convenient, accurate, and secure. Wireless OBD2 adapters allow users to perform scans and monitor vehicle data from their smartphones, while cloud-based diagnostics enable remote monitoring and analysis by mechanics. AI-powered tools can analyze vast amounts of data to identify patterns and predict potential issues, improving diagnostic accuracy. According to a report by MarketsandMarkets, the global automotive diagnostics market is expected to grow significantly in the coming years, driven by these technological advancements.

19. How to Use OBD2 Data for Performance Tuning?

OBD2 data can be used for performance tuning by monitoring various engine parameters and making adjustments to optimize performance. By using an advanced OBD2 scanner or a tuning software, you can monitor parameters such as air-fuel ratio, ignition timing, and boost pressure.

To use OBD2 data for performance tuning:

- Establish a baseline: Record data under normal driving conditions to establish a baseline.

- Make adjustments: Adjust engine parameters using a tuning software or a performance chip.

- Monitor changes: Monitor the changes in engine performance using OBD2 data.

- Fine-tune: Fine-tune the adjustments to achieve optimal performance.

For example, you can monitor the air-fuel ratio and adjust the fuel mixture to achieve optimal combustion. You can also adjust the ignition timing to improve engine responsiveness and power. According to a guide by HP Tuners, using OBD2 data for performance tuning requires a thorough understanding of engine management systems and tuning principles.

20. What Are Common Mistakes to Avoid When Using OBD2 Scanners?

Common mistakes to avoid when using OBD2 scanners include:

- Not Reading the Instructions: Failing to read the scanner’s instructions can lead to incorrect usage and inaccurate diagnoses.

- Clearing Codes Without Addressing the Issue: Clearing codes without addressing the underlying problem will only result in the code reappearing.

- Misinterpreting DTCs: Misinterpreting diagnostic trouble codes (DTCs) can lead to incorrect repairs.

- Ignoring Freeze Frame Data: Ignoring freeze frame data can result in a failure to diagnose the root cause of the problem.

- Using an Incompatible Scanner: Using an OBD2 scanner that is not compatible with the vehicle can result in communication errors and inaccurate data.

To avoid these mistakes, always read the scanner’s instructions carefully, research the meaning of DTCs, and analyze freeze frame data to gain a better understanding of the issue. Additionally, make sure to use an OBD2 scanner that is compatible with the vehicle you are working on. According to a training video by ScannerDanner, avoiding these common mistakes can significantly improve diagnostic accuracy and efficiency.

21. How to Keep Your OBD2 Scanner Updated?

Keeping your OBD2 scanner updated is essential for ensuring that it has the latest vehicle information and diagnostic capabilities. Scanner updates typically include new vehicle coverage, updated diagnostic trouble code (DTC) definitions, and bug fixes.

To keep your OBD2 scanner updated:

- Visit the manufacturer’s website.

- Download the latest update software.

- Connect the scanner to your computer.

- Follow the instructions to install the update.

Most scanner manufacturers provide free updates for a certain period after purchase, while others require a subscription fee. Keeping your scanner updated can help you diagnose a wider range of vehicles and ensure that you have the most accurate diagnostic information. According to a survey by Professional Tool & Equipment News (PTEN), mechanics who regularly update their scanners are more confident in their diagnostic abilities.

22. What Are the Ethical Considerations When Using OBD2 Data?

Ethical considerations when using OBD2 data include:

- Privacy: Protecting the privacy of vehicle owners by not sharing their diagnostic data without their consent.

- Security: Ensuring the security of OBD2 systems to prevent hacking and unauthorized access to vehicle data.

- Transparency: Being transparent with vehicle owners about how their diagnostic data is being used.

- Accuracy: Ensuring the accuracy of diagnostic data to avoid incorrect diagnoses and unnecessary repairs.

As OBD2 systems become more sophisticated and connected, it is important to address these ethical considerations to protect the privacy and security of vehicle owners. According to an article by the National Law Review, data privacy and cybersecurity are increasingly important issues in the automotive industry.

23. Where Can You Find Reliable OBD2 Resources and Information?

You can find reliable OBD2 resources and information at:

- CAR-TOOL.EDU.VN: Offers detailed guides, product reviews, and expert advice on OBD2 scanners and diagnostic procedures.

- Environmental Protection Agency (EPA): Provides information on OBD2 regulations and emissions standards.

- Society of Automotive Engineers (SAE): Publishes technical standards and resources related to OBD2 technology.

- National Institute for Automotive Service Excellence (ASE): Offers certification programs and training resources for automotive technicians.

- Online Forums and Communities: Participate in online forums and communities to share knowledge and learn from other technicians and enthusiasts.

CAR-TOOL.EDU.VN aims to be your go-to resource for all things OBD2, providing accurate and up-to-date information to help you diagnose and repair vehicles efficiently.

24. How to Troubleshoot Common OBD2 Scanner Problems?

Common OBD2 scanner problems and how to troubleshoot them:

| Problem | Possible Causes | Solutions |

|---|---|---|

| Scanner won’t connect | Loose connection, incompatible protocol, faulty scanner | Check the connection, verify protocol compatibility, try a different scanner |

| No DTCs found | No problems detected, DTCs cleared, scanner malfunction | Verify that the check engine light is on, check for pending codes, try a different scanner |

| Inaccurate data | Faulty sensor, incorrect scanner settings, scanner malfunction | Verify sensor readings with a different scanner, check scanner settings, update scanner software |

| Scanner freezes or crashes | Software bug, low battery, scanner malfunction | Restart the scanner, check the battery, update scanner software, contact the manufacturer for support |

| Can’t clear DTCs | Underlying problem not fixed, incompatible scanner, security lock | Fix the underlying problem, verify scanner compatibility, check for security locks preventing code clearing |

25. What are the Alternatives to Using OBD2 Scanners?

Alternatives to using OBD2 scanners include:

- Professional Diagnostic Services: Taking your vehicle to a professional mechanic for diagnostic services.

- Code Readers: Simple code readers that only read and clear diagnostic trouble codes (DTCs).

- Smartphone Apps: Using smartphone apps that connect to OBD2 adapters via Bluetooth or Wi-Fi.

- Manual Inspection: Performing a manual inspection of vehicle components to identify potential problems.

While these alternatives may be suitable for certain situations, OBD2 scanners offer the most comprehensive and accurate diagnostic capabilities. Professional diagnostic services can be expensive, while code readers and smartphone apps may not provide the same level of detail as a dedicated OBD2 scanner. Manual inspection can be time-consuming and may not identify all problems.

26. How Can CAR-TOOL.EDU.VN Help You with Your OBD2 Needs?

CAR-TOOL.EDU.VN can help you with your OBD2 needs by providing:

- Detailed Guides: Comprehensive guides on OBD2 systems, scanners, and diagnostic procedures.

- Product Reviews: Expert reviews of the latest OBD2 scanners and diagnostic tools.

- Troubleshooting Tips: Tips and tricks for troubleshooting common OBD2 problems.

- Expert Advice: Advice from experienced mechanics and automotive professionals.

- Product Comparisons: Detailed comparisons of different OBD2 scanners to help you choose the right tool for your needs.

At CAR-TOOL.EDU.VN, we are committed to providing you with the most accurate and up-to-date information on OBD2 technology. Our goal is to empower you with the knowledge and tools you need to diagnose and repair vehicles efficiently. Whether you’re a professional mechanic or a DIY enthusiast, CAR-TOOL.EDU.VN is your trusted resource for all things OBD2.

27. OBD2 Connector Types and Compatibility

OBD2 connectors are standardized, but understanding their types ensures compatibility. The standard OBD2 connector is a 16-pin (2×8) SAE J1962 female connector. However, there are two types:

- Type A: Used for 12V systems (most passenger vehicles).

- Type B: Used for 24V systems (heavy-duty vehicles). Type B has a different keying to prevent accidental connection to 12V systems.

While physical compatibility is usually straightforward, ensure your scan tool supports the vehicle’s communication protocol (CAN, ISO, etc.). Some older vehicles might require adapters for full functionality. Consulting your vehicle’s service manual or a compatibility chart from your scan tool manufacturer is always a good practice.

28. The Role of Oxygen Sensors in OBD2 Systems

Oxygen sensors are critical components in OBD2 systems, responsible for monitoring the oxygen content in the exhaust gas. This information is used by the Engine Control Unit (ECU) to adjust the air-fuel mixture for optimal combustion and emissions control.

There are typically two types of oxygen sensors:

- Upstream (Pre-Catalytic Converter): Measures the oxygen content before the catalytic converter.

- Downstream (Post-Catalytic Converter): Measures the oxygen content after the catalytic converter to monitor its efficiency.

Faulty oxygen sensors can cause a variety of issues, including poor fuel economy, increased emissions, and engine performance problems. The OBD2 system monitors the performance of the oxygen sensors and will store a diagnostic trouble code (DTC) if a problem is detected.

29. Decoding VIN Numbers with OBD2 Tools

Many advanced OBD2 scan tools offer VIN (Vehicle Identification Number) decoding functionality. This feature allows you to quickly retrieve vehicle-specific information, such as make, model, year, engine type, and factory-installed options.

Decoding the VIN can be useful for:

- Identifying the correct parts for repairs.

- Accessing vehicle-specific diagnostic information.

- Determining the vehicle’s original configuration.

To decode a VIN using an OBD2 scan tool, simply enter the VIN into the tool and follow the instructions. The tool will then retrieve the vehicle information from a database and display it on the screen.

30. Understanding Fuel Trims with OBD2 Diagnostics

Fuel trims are adjustments made by the Engine Control Unit (ECU) to compensate for deviations in the air-fuel mixture. OBD2 systems provide access to both short-term and long-term fuel trim data, which can be valuable for diagnosing fuel-related issues.

- Short-Term Fuel Trim (STFT): Immediate adjustments to the fuel mixture.

- Long-Term Fuel Trim (LTFT): Learned adjustments based on STFT values over time.

High positive fuel trim values indicate that the ECU is adding fuel to compensate for a lean condition (too much air or not enough fuel). High negative fuel trim values indicate that the ECU is reducing fuel to compensate for a rich condition (too much fuel or not enough air). By analyzing fuel trim data, mechanics can identify potential problems such as vacuum leaks, faulty oxygen sensors, or clogged fuel injectors.

31. Using OBD2 to Diagnose Transmission Problems

While OBD2 systems primarily focus on engine and emissions-related issues, they can also provide valuable information for diagnosing transmission problems. Many modern vehicles have transmission control modules (TCMs) that communicate with the Engine Control Unit (ECU) via the CAN bus.

OBD2 scan tools can access diagnostic trouble codes (DTCs) stored in the TCM, as well as live data such as transmission temperature, gear position, and torque converter lockup status. This information can be used to diagnose a variety of transmission problems, including slipping gears, harsh shifting, and torque converter issues.

32. How to Perform a Cylinder Balance Test with OBD2

A cylinder balance test is a diagnostic procedure used to assess the performance of individual cylinders in an engine. This test can help identify problems such as faulty spark plugs, fuel injectors, or compression issues.

Many advanced OBD2 scan tools have the ability to perform a cylinder balance test. This test typically involves disabling each cylinder one at a time and monitoring the change in engine speed. A cylinder that is not contributing to engine power will cause a significant drop in engine speed when disabled.

33. OBD2 and Electric Vehicles (EVs)

While OBD2 was initially designed for internal combustion engine (ICE) vehicles, it also plays a role in electric vehicles (EVs). Although EVs don’t have traditional engines or emissions systems, they still have a variety of electronic control units (ECUs) that monitor and control various systems.

OBD2 scan tools can access diagnostic information from these ECUs, including battery voltage, motor temperature, and charging status. This information can be used to diagnose problems with the EV’s battery, motor, or charging system.

34. The Importance of Regular OBD2 Inspections

Regular OBD2 inspections are important for maintaining the health and performance of your vehicle. By performing regular scans, you can identify potential problems early, before they lead to more serious and costly repairs.

Regular OBD2 inspections can also help you:

- Improve fuel economy.

- Reduce emissions.

- Extend the life of your vehicle.

- Ensure that your vehicle is running safely.

Whether you’re a professional mechanic or a DIY enthusiast, investing in a good OBD2 scan tool and performing regular inspections is a smart way to keep your vehicle running smoothly.

35. Contact CAR-TOOL.EDU.VN for Expert OBD2 Assistance

Are you struggling to find the right parts or tools for your automotive repairs? Do you need reliable information and expert advice? Don’t waste time comparing prices and features – let CAR-TOOL.EDU.VN help you!

Our team of experienced professionals can provide detailed information about various auto parts, compare repair tools, and offer valuable recommendations. We understand the challenges you face and are dedicated to helping you find the best solutions for your needs.

Contact us today for personalized assistance:

- Address: 456 Elm Street, Dallas, TX 75201, United States

- WhatsApp: +1 (641) 206-8880

- Website: CAR-TOOL.EDU.VN

Let CAR-TOOL.EDU.VN be your trusted partner in automotive repairs. We are here to answer your questions and provide the support you need. Reach out now and experience the difference!

FAQ About OBD2 Wikipedia

Q: What does OBD2 stand for?

A: OBD2 stands for On-Board Diagnostics II. It is a standardized system for monitoring a vehicle’s engine, emissions, and other systems.

Q: When did OBD2 become mandatory in the United States?

A: OBD2 became mandatory for all cars sold in the United States in 1996.

Q: Where is the OBD2 port located in my car?

A: The OBD2 port is typically located under the dashboard on the driver’s side.

Q: Can I use any OBD2 scanner on my car?

A: Yes, all OBD2 scanners should be compatible with any car manufactured after 1996 in the United States.

Q: What is a DTC?

A: DTC stands for Diagnostic Trouble Code. It is a code stored by the OBD2 system when a problem is detected.

Q: Can I clear DTCs myself?

A: Yes, you can clear DTCs using an OBD2 scanner. However, it is important to address the underlying problem first.

Q: What is live data?

A: Live data is real-time data from the vehicle’s sensors, which can be viewed using an OBD2 scanner.

Q: What is freeze frame data?

A: Freeze frame data is a snapshot of vehicle sensor data at the moment a DTC was triggered.

Q: What are readiness monitors?

A: Readiness monitors are internal tests that the OBD2 system performs to verify the functionality of emissions-related components.

Q: How often should I perform an OBD2 scan on my vehicle?

A: You should perform an OBD2 scan whenever the check engine light comes on, or at least once a year as part of regular maintenance.

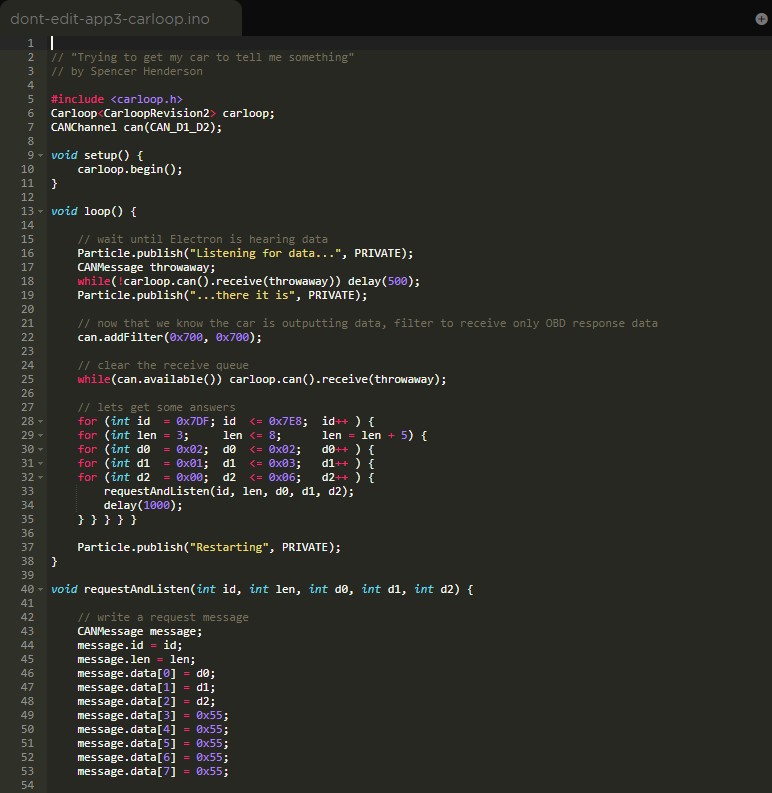

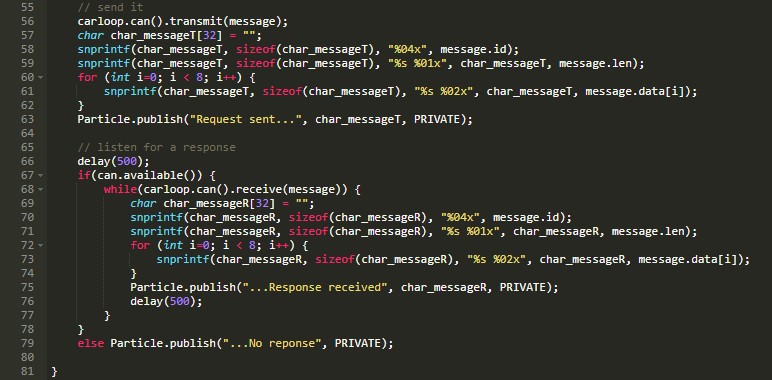

Carloop Setup

Carloop Setup