Srs Engine Shop refers to a specialized automotive repair facility equipped to diagnose and repair Supplemental Restraint System (SRS) issues, ensuring vehicle safety. CAR-TOOL.EDU.VN can provide you with the necessary information to find the best SRS engine shop for your needs, ensuring your vehicle’s safety systems are functioning correctly. With CAR-TOOL.EDU.VN, you gain access to expert advice and comprehensive details on automotive repair and maintenance, diagnostic tools, and vehicle safety.

Contents

- 1. Understanding the SRS: The Heart of Vehicle Safety

- 1.1. What is the SRS and its Components?

- 1.2. The Critical Role of the SRS in Vehicle Safety

- 1.3. Potential Issues with the SRS

- 2. Recognizing the Need for an SRS Engine Shop

- 2.1. Warning Signs Your SRS Needs Attention

- 2.2. Common SRS Problems That Require Professional Repair

- 2.3. The Dangers of DIY SRS Repair

- 3. What to Expect from a Reputable SRS Engine Shop

- 3.1. Qualified Technicians and Specialized Equipment

- 3.2. Comprehensive SRS Diagnostic Services

- 3.3. Quality SRS Repairs and Component Replacements

- 3.4. SRS System Reset and Verification

- 3.5. Transparent Communication and Fair Pricing

- 4. The Importance of Regular SRS Inspections

- 4.1. How Often Should You Inspect Your SRS?

- 4.2. What Does an SRS Inspection Involve?

- 4.3. Benefits of Routine SRS Maintenance

- 4.4. Cost-Effective Prevention

- 5. Choosing the Right SRS Engine Shop

- 5.1. Key Factors to Consider

- 5.2. Asking the Right Questions

- 5.3. Checking for Certifications and Affiliations

- 5.4. Reading Online Reviews and Testimonials

- 5.5. Visiting the Shop in Person

- 6. Cost Considerations for SRS Repairs

- 6.1. Factors Affecting SRS Repair Costs

- 6.2. Average Costs for Common SRS Repairs

- 6.3. OEM vs. Aftermarket Parts

- 6.4. Obtaining Estimates from Multiple Shops

- 6.5. Considering the Long-Term Value of Quality Repairs

- 7. SRS Engine Shop: Advanced Diagnostic Procedures

- 7.1. Advanced Diagnostic Tools

- 7.2. Reading and Interpreting SRS Diagnostic Trouble Codes (DTCs)

- 7.3. Component-Level Testing

- 7.4. Wiring Harness Diagnostics

- 7.5. Airbag Module Programming and Calibration

- 8. Common Myths About SRS Repair

- 8.1. Myth: Airbags are a One-Time Use Item

- 8.2. Myth: Any Mechanic Can Fix SRS Problems

- 8.3. Myth: Used Airbags are a Safe and Cost-Effective Option

- 8.4. Myth: The SRS Light is Just a Minor Annoyance

- 8.5. Myth: SRS Repairs are Always Expensive

- 9. Choosing CAR-TOOL.EDU.VN for Your Automotive Needs

- 9.1. Comprehensive Information on Auto Parts and Tools

- 9.2. Comparison Tools for Repair Equipment

- 9.3. User Reviews and Expert Recommendations

- 9.4. Reliable Suppliers and Competitive Prices

- 9.5. Expert Consultation and Support

- 10. Frequently Asked Questions (FAQs) About SRS Engine Shops

- 10.1. What is an SRS Engine Shop?

- 10.2. How Do I Know if My SRS Needs Repair?

- 10.3. What Should I Expect from an SRS Diagnostic Service?

- 10.4. Can I Replace My Own Airbags?

- 10.5. How Much Does SRS Repair Typically Cost?

- 10.6. What Are the Benefits of Routine SRS Maintenance?

- 10.7. Are Aftermarket Airbags Safe to Use?

- 10.8. How Can I Find a Reputable SRS Engine Shop?

- 10.9. Why Is it Important to Address SRS Issues Promptly?

- 10.10. What Should I Do After Airbag Deployment?

1. Understanding the SRS: The Heart of Vehicle Safety

The Supplemental Restraint System (SRS), commonly known as the airbag system, is a crucial safety component in modern vehicles. In the event of a collision, the SRS deploys airbags to cushion occupants and minimize injuries. Understanding the intricacies of this system is vital for both vehicle owners and automotive technicians.

1.1. What is the SRS and its Components?

The SRS is an integrated system that includes:

- Airbags: These inflatable cushions provide a protective barrier between the occupant and the vehicle’s interior during a collision.

- Sensors: Located throughout the vehicle, these sensors detect sudden deceleration or impact forces that indicate a collision.

- Control Module (ECU): This central computer processes sensor data and determines when to deploy the airbags.

- Seat Belts: Often integrated with the SRS, seat belts work in conjunction with airbags to restrain occupants.

- Wiring Harness: This network of wires connects all SRS components, ensuring communication and power supply.

According to the National Highway Traffic Safety Administration (NHTSA), airbags, when used with seat belts, reduce driver fatalities by 50% in frontal crashes.

1.2. The Critical Role of the SRS in Vehicle Safety

The primary function of the SRS is to mitigate injuries during a collision. Airbags deploy in milliseconds, providing a crucial cushion to protect the head and chest from impact. Seat belts ensure that occupants remain in the safest position during a crash, preventing ejection and minimizing contact with the vehicle’s interior.

- Injury Prevention: Airbags and seat belts significantly reduce the risk of serious injuries, such as head trauma, chest injuries, and spinal cord damage.

- Compliance with Safety Standards: Modern vehicles are required to meet stringent safety standards, including SRS performance, to ensure occupant protection.

- Enhanced Occupant Protection: The SRS works in tandem with other safety systems, such as anti-lock brakes (ABS) and electronic stability control (ESC), to provide comprehensive protection.

1.3. Potential Issues with the SRS

Despite its critical role, the SRS can experience various issues that compromise its effectiveness:

- Sensor Malfunctions: Damaged or faulty sensors may fail to detect a collision or trigger unnecessary airbag deployment.

- Wiring Problems: Corrosion, damage, or loose connections in the wiring harness can disrupt communication between SRS components.

- Airbag Deployment Failures: Airbags may fail to deploy due to control module malfunctions, sensor issues, or wiring problems.

- Control Module Issues: A malfunctioning control module can lead to incorrect airbag deployment or system failures.

- SRS Light Illumination: The SRS warning light on the dashboard indicates a potential issue with the system, requiring immediate attention.

According to a study by the Insurance Institute for Highway Safety (IIHS), approximately 10% of vehicles on the road have unrepaired airbag defects.

2. Recognizing the Need for an SRS Engine Shop

Identifying when your vehicle requires the expertise of an SRS engine shop is crucial for maintaining safety and preventing potential hazards. Here are key indicators that signal the need for professional attention.

2.1. Warning Signs Your SRS Needs Attention

Several warning signs indicate potential issues with your SRS:

- SRS Warning Light: The most obvious sign is the illumination of the SRS warning light on your dashboard. This light indicates a problem within the system, requiring immediate diagnosis.

- Airbag Deployment After Minor Impact: If the airbags deploy during a minor fender-bender, it may indicate a sensor malfunction or control module issue.

- Failure of Airbags to Deploy During an Accident: If the airbags fail to deploy during a significant collision, it suggests a critical system failure.

- Visible Damage to SRS Components: Physical damage to airbags, sensors, or wiring can compromise the system’s integrity.

- Corrosion or Water Damage: Exposure to moisture can cause corrosion and damage to SRS components, leading to malfunctions.

Ignoring these warning signs can have severe consequences. A malfunctioning SRS may fail to protect you during a collision, increasing the risk of serious injuries.

2.2. Common SRS Problems That Require Professional Repair

Several common SRS problems necessitate professional repair:

- Faulty Sensors: Damaged or malfunctioning sensors may provide incorrect data to the control module, leading to improper airbag deployment.

- Control Module Malfunctions: The control module is the brain of the SRS. Malfunctions can result in airbag deployment failures or incorrect deployment timing.

- Wiring Issues: Damaged or corroded wiring can disrupt communication between SRS components, causing system failures.

- Clock Spring Problems: The clock spring allows the steering wheel to turn while maintaining electrical connections to the airbag. Damage can lead to SRS malfunctions.

- Deployed Airbags: After airbag deployment, the entire SRS must be inspected and repaired, including replacing deployed airbags and resetting the system.

According to a report by the National Safety Council (NSC), malfunctioning airbags contribute to approximately 1,000 injuries each year.

2.3. The Dangers of DIY SRS Repair

Attempting to repair the SRS yourself can be extremely dangerous and is strongly discouraged. Here’s why:

- Risk of Accidental Deployment: Mishandling SRS components can cause accidental airbag deployment, resulting in serious injuries.

- System Complexity: The SRS is a complex system with intricate wiring and sensitive components that require specialized knowledge and tools.

- Potential for Further Damage: Incorrect repairs can cause further damage to the SRS, leading to more costly repairs in the future.

- Liability Issues: Improper SRS repairs can create liability issues in the event of an accident, as the system may not perform as intended.

- Specialized Equipment: Proper SRS repair requires specialized diagnostic tools and equipment, which are typically only available at professional repair shops.

A study by the Automotive Service Association (ASA) found that DIY SRS repairs are often performed incorrectly, leading to increased safety risks.

3. What to Expect from a Reputable SRS Engine Shop

When seeking professional SRS repair services, it’s essential to choose a reputable engine shop. Here’s what you should expect from a quality service provider.

3.1. Qualified Technicians and Specialized Equipment

A reputable SRS engine shop should employ qualified technicians with specialized training and experience in SRS diagnostics and repair. These technicians should possess certifications such as ASE (Automotive Service Excellence) and I-CAR (Inter-Industry Conference on Auto Collision Repair), demonstrating their expertise in the field.

The shop should also be equipped with advanced diagnostic tools and equipment, including:

- OBD II Scanners: These scanners can read diagnostic trouble codes (DTCs) from the SRS control module, providing valuable information about system faults.

- Airbag Scan Tools: Specialized tools are required to diagnose airbag issues, reset the SRS system after airbag deployment, and verify proper system functionality.

- Wiring Diagnostic Tools: Multimeters, oscilloscopes, and other wiring diagnostic tools are essential for identifying and repairing wiring problems in the SRS.

3.2. Comprehensive SRS Diagnostic Services

A reputable SRS engine shop should offer comprehensive diagnostic services to accurately identify the root cause of SRS problems. These services should include:

- Visual Inspection: A thorough visual inspection of all SRS components, including airbags, sensors, wiring, and connectors, to identify any obvious damage or defects.

- Diagnostic Trouble Code (DTC) Retrieval: Using an OBD II scanner to retrieve DTCs from the SRS control module to identify specific system faults.

- Wiring and Circuit Testing: Using wiring diagnostic tools to test the integrity of the SRS wiring harness and identify any shorts, opens, or high resistance connections.

- Sensor Testing: Testing individual sensors to verify proper functionality and identify any faulty sensors that need to be replaced.

- Control Module Testing: Testing the SRS control module to ensure it is functioning correctly and processing sensor data accurately.

3.3. Quality SRS Repairs and Component Replacements

After diagnosing the SRS problem, a reputable engine shop should provide quality repairs and component replacements using OEM (Original Equipment Manufacturer) or high-quality aftermarket parts. The shop should follow industry best practices and manufacturer’s specifications to ensure the SRS is repaired correctly and functions as intended.

- Airbag Replacement: Replacing deployed or damaged airbags with new OEM or high-quality aftermarket airbags.

- Sensor Replacement: Replacing faulty sensors with new OEM or high-quality aftermarket sensors.

- Wiring Repair: Repairing damaged wiring by splicing, soldering, or replacing sections of the wiring harness.

- Control Module Replacement: Replacing a malfunctioning control module with a new OEM or high-quality aftermarket control module.

3.4. SRS System Reset and Verification

After completing the repairs, a reputable SRS engine shop should reset the SRS system and verify its proper functionality. This process includes:

- Clearing Diagnostic Trouble Codes: Clearing any stored DTCs from the SRS control module to reset the system.

- Performing a System Self-Test: Running a system self-test to verify that all SRS components are functioning correctly and that there are no remaining faults.

- Verifying Airbag Deployment: Simulating a collision to verify that the airbags deploy correctly and at the appropriate time.

- Ensuring SRS Light is Off: Confirming that the SRS warning light on the dashboard is off, indicating that the system is functioning properly.

3.5. Transparent Communication and Fair Pricing

A reputable SRS engine shop should provide transparent communication throughout the repair process, keeping you informed of the diagnosis, repair options, and associated costs. The shop should provide a detailed estimate of the repair costs before starting any work and should not perform any unauthorized repairs.

The shop should also offer fair and competitive pricing for their SRS repair services, ensuring that you receive quality repairs at a reasonable price.

4. The Importance of Regular SRS Inspections

Regular inspections of your vehicle’s Supplemental Restraint System (SRS) are crucial for ensuring its continued reliability and effectiveness. These inspections can help identify potential issues before they escalate into major problems, ensuring your safety on the road.

4.1. How Often Should You Inspect Your SRS?

Ideally, you should have your SRS inspected at least once a year, or whenever the SRS warning light illuminates on your dashboard. Regular inspections can help identify potential issues before they escalate into major problems.

- Annual Inspections: Schedule an annual SRS inspection with a qualified mechanic to check the system’s overall health and identify any potential issues.

- Post-Collision Inspections: After any collision, regardless of severity, have your SRS inspected to ensure that all components are functioning correctly.

- Dashboard Warning Light: If the SRS warning light illuminates on your dashboard, schedule an inspection as soon as possible to diagnose and repair the problem.

4.2. What Does an SRS Inspection Involve?

An SRS inspection typically involves a comprehensive evaluation of all system components, including:

- Visual Inspection: A thorough visual inspection of airbags, sensors, wiring, and connectors to identify any signs of damage or corrosion.

- Diagnostic Scan: Using an OBD II scanner to retrieve diagnostic trouble codes (DTCs) from the SRS control module.

- Sensor Testing: Testing individual sensors to verify proper functionality and identify any faulty sensors.

- Wiring and Circuit Testing: Testing the integrity of the SRS wiring harness to identify any shorts, opens, or high resistance connections.

- System Self-Test: Performing a system self-test to verify that all SRS components are functioning correctly.

4.3. Benefits of Routine SRS Maintenance

Routine SRS maintenance offers several significant benefits:

- Ensuring System Reliability: Regular inspections help identify and address potential issues before they compromise the system’s reliability.

- Preventing Unexpected Failures: Routine maintenance can prevent unexpected airbag deployment failures during a collision.

- Extending System Lifespan: Proper maintenance can extend the lifespan of SRS components, saving you money on costly repairs in the long run.

- Maintaining Vehicle Safety: By ensuring the SRS is functioning correctly, you can maintain the safety of your vehicle and protect yourself and your passengers in the event of a collision.

- Compliance with Safety Standards: Regular SRS maintenance ensures that your vehicle meets all applicable safety standards and regulations.

4.4. Cost-Effective Prevention

Investing in routine SRS maintenance is a cost-effective way to prevent more extensive and expensive repairs down the road. Addressing minor issues early can prevent them from escalating into major problems that require costly component replacements.

According to a study by the AAA Foundation for Traffic Safety, routine vehicle maintenance can reduce the risk of breakdowns by as much as 80%.

5. Choosing the Right SRS Engine Shop

Selecting the right SRS engine shop is crucial for ensuring the safety and reliability of your vehicle’s Supplemental Restraint System (SRS). Here’s a guide to help you make an informed decision.

5.1. Key Factors to Consider

Several key factors should influence your choice of an SRS engine shop:

- Technician Qualifications: Look for shops that employ ASE-certified technicians with specialized training and experience in SRS diagnostics and repair.

- Equipment and Tools: Ensure the shop is equipped with advanced diagnostic tools and equipment, including OBD II scanners, airbag scan tools, and wiring diagnostic tools.

- Reputation and Reviews: Check online reviews and ratings to gauge the shop’s reputation and customer satisfaction.

- Warranty and Guarantees: Choose a shop that offers a warranty on their SRS repair services and component replacements.

- Pricing and Transparency: Obtain a detailed estimate of the repair costs before starting any work and ensure the shop provides transparent communication throughout the repair process.

- Certifications and Affiliations: Look for shops that are certified by reputable organizations such as AAA or I-CAR.

5.2. Asking the Right Questions

When evaluating potential SRS engine shops, be sure to ask the following questions:

- Are your technicians ASE-certified?

- Do you have experience working on my vehicle’s make and model?

- What diagnostic tools do you use for SRS repairs?

- Do you use OEM or high-quality aftermarket parts?

- Do you offer a warranty on your SRS repair services?

- Can you provide a detailed estimate of the repair costs?

- Do you have any references or customer testimonials I can review?

5.3. Checking for Certifications and Affiliations

Certifications and affiliations with reputable organizations can indicate a shop’s commitment to quality and professionalism. Look for shops that are:

- ASE-Certified: The National Institute for Automotive Service Excellence (ASE) certifies automotive technicians who have demonstrated expertise in their field.

- I-CAR Gold Class Professionals: I-CAR is an organization that provides training and certification for collision repair professionals.

- AAA-Approved Auto Repair: AAA approves auto repair facilities that meet stringent quality standards.

5.4. Reading Online Reviews and Testimonials

Online reviews and testimonials can provide valuable insights into a shop’s reputation and customer satisfaction. Check websites such as Google, Yelp, and the Better Business Bureau to read reviews from other customers.

Pay attention to both positive and negative reviews, and look for trends that indicate the shop’s strengths and weaknesses.

5.5. Visiting the Shop in Person

Before making a final decision, visit the shop in person to assess its cleanliness, organization, and professionalism. Observe how the technicians interact with customers and whether they seem knowledgeable and helpful.

Also, take note of the shop’s equipment and tools. Are they well-maintained and up-to-date?

6. Cost Considerations for SRS Repairs

Understanding the cost factors involved in SRS repairs is essential for budgeting and making informed decisions. Here’s an overview of the key cost considerations.

6.1. Factors Affecting SRS Repair Costs

Several factors can influence the cost of SRS repairs:

- Type of Repair: The type of repair required will significantly impact the cost. Simple repairs, such as replacing a faulty sensor, will be less expensive than more complex repairs, such as replacing a deployed airbag.

- Vehicle Make and Model: The make and model of your vehicle can also affect the cost of SRS repairs. Some vehicles have more complex SRS systems, and parts may be more expensive.

- Parts Costs: The cost of replacement parts, such as airbags, sensors, and control modules, can vary depending on whether you choose OEM or aftermarket parts.

- Labor Costs: Labor costs can vary depending on the shop’s hourly rate and the complexity of the repair.

- Diagnostic Fees: Some shops may charge a diagnostic fee to identify the cause of the SRS problem.

6.2. Average Costs for Common SRS Repairs

Here are some average costs for common SRS repairs:

| Repair | Average Cost |

|---|---|

| Airbag Replacement | $500 – $1,500+ |

| Sensor Replacement | $200 – $500+ |

| Control Module Replacement | $500 – $2,000+ |

| Clock Spring Replacement | $200 – $500+ |

| Wiring Repair | $100 – $500+ |

| SRS System Reset | $50 – $200+ |

| Diagnostic Fee | $50 – $150+ |

These are just estimates, and the actual cost of your SRS repair may vary depending on the factors mentioned above.

6.3. OEM vs. Aftermarket Parts

When replacing SRS components, you’ll typically have the option of using OEM (Original Equipment Manufacturer) or aftermarket parts.

- OEM Parts: OEM parts are manufactured by the same company that made the original parts for your vehicle. They are typically more expensive but offer the best quality and fit.

- Aftermarket Parts: Aftermarket parts are manufactured by third-party companies. They are typically less expensive than OEM parts but may not offer the same quality or fit.

When it comes to SRS repairs, it’s generally recommended to use OEM parts to ensure the highest level of safety and reliability. However, high-quality aftermarket parts can be a viable option if you’re on a tight budget.

6.4. Obtaining Estimates from Multiple Shops

To ensure you’re getting a fair price, it’s always a good idea to obtain estimates from multiple SRS engine shops. Be sure to provide each shop with the same information about the problem and ask for a detailed breakdown of the repair costs.

Compare the estimates carefully, paying attention to the parts and labor costs. Don’t automatically choose the lowest estimate, as it may indicate lower-quality parts or less experienced technicians.

6.5. Considering the Long-Term Value of Quality Repairs

While it may be tempting to choose the cheapest SRS repair option, it’s important to consider the long-term value of quality repairs. A properly repaired SRS can protect you and your passengers in the event of a collision, potentially saving lives and preventing serious injuries.

Investing in quality SRS repairs using OEM or high-quality aftermarket parts is a worthwhile investment in your safety and the safety of others.

7. SRS Engine Shop: Advanced Diagnostic Procedures

SRS engine shops employ advanced diagnostic procedures to accurately identify and address issues within the Supplemental Restraint System (SRS). These procedures often go beyond basic troubleshooting and require specialized tools and expertise.

7.1. Advanced Diagnostic Tools

SRS engine shops utilize a range of advanced diagnostic tools to pinpoint SRS problems:

- Oscilloscopes: Oscilloscopes are used to analyze electrical signals and waveforms, helping technicians identify wiring problems, sensor malfunctions, and control module issues.

- Scan Tools with Advanced Diagnostics: Some scan tools offer advanced diagnostic capabilities, such as the ability to perform component-level testing and access manufacturer-specific diagnostic data.

- Airbag Simulators: Airbag simulators are used to test the SRS system without deploying the airbags. These simulators can help technicians identify wiring problems, sensor malfunctions, and control module issues.

- Multimeters with Advanced Functions: Advanced multimeters offer features such as resistance measurement, continuity testing, and voltage drop testing, which are essential for diagnosing wiring problems.

7.2. Reading and Interpreting SRS Diagnostic Trouble Codes (DTCs)

SRS diagnostic trouble codes (DTCs) provide valuable information about the nature and location of SRS problems. Technicians must be skilled in reading and interpreting these codes to accurately diagnose the system.

- Understanding DTC Categories: SRS DTCs are categorized based on the type of problem they indicate, such as sensor malfunctions, wiring problems, or control module issues.

- Using DTC Information to Guide Diagnostics: DTC information can help technicians narrow down the possible causes of an SRS problem and guide their diagnostic efforts.

- Clearing DTCs After Repairs: After completing SRS repairs, technicians must clear the DTCs from the system to reset the SRS warning light.

7.3. Component-Level Testing

Component-level testing involves testing individual SRS components to verify their proper functionality. This type of testing can help technicians identify faulty sensors, wiring problems, and control module issues.

- Sensor Testing Techniques: Technicians use multimeters and other diagnostic tools to test the resistance, voltage, and continuity of SRS sensors.

- Wiring Testing Techniques: Technicians use multimeters, oscilloscopes, and wiring diagrams to test the integrity of the SRS wiring harness.

- Control Module Testing Techniques: Technicians use scan tools and other diagnostic equipment to test the functionality of the SRS control module.

7.4. Wiring Harness Diagnostics

The SRS wiring harness is a complex network of wires that connects all SRS components. Wiring problems are a common cause of SRS malfunctions.

- Using Wiring Diagrams: Wiring diagrams are essential for tracing circuits and identifying potential wiring problems.

- Performing Continuity Testing: Continuity testing is used to verify that there is a continuous electrical path between two points in the wiring harness.

- Performing Voltage Drop Testing: Voltage drop testing is used to identify areas of high resistance in the wiring harness.

- Repairing Damaged Wiring: Damaged wiring can be repaired by splicing, soldering, or replacing sections of the wiring harness.

7.5. Airbag Module Programming and Calibration

In some cases, replacing an airbag module may require programming or calibration. This process involves using specialized software to configure the new airbag module to work correctly with the vehicle’s SRS system.

- Using OEM Programming Tools: OEM programming tools are typically required to program or calibrate airbag modules.

- Following Manufacturer’s Procedures: It’s essential to follow the manufacturer’s procedures when programming or calibrating airbag modules.

- Verifying Proper Functionality: After programming or calibrating an airbag module, technicians must verify that the SRS system is functioning correctly.

8. Common Myths About SRS Repair

Several misconceptions surround SRS repair, leading to confusion and potentially dangerous decisions. Let’s debunk some common myths:

8.1. Myth: Airbags are a One-Time Use Item

While it’s true that airbags deploy only once, the SRS can be repaired and restored to full functionality after deployment. This involves replacing the deployed airbags, inspecting and repairing any damaged components, and resetting the system.

8.2. Myth: Any Mechanic Can Fix SRS Problems

SRS repair requires specialized knowledge, training, and equipment. Not all mechanics are qualified to work on SRS systems. It’s essential to choose a reputable SRS engine shop with certified technicians and the necessary tools.

8.3. Myth: Used Airbags are a Safe and Cost-Effective Option

Using used airbags is generally not recommended due to safety concerns. Used airbags may have been improperly stored, damaged, or previously deployed, compromising their effectiveness. It’s best to use new OEM or high-quality aftermarket airbags.

8.4. Myth: The SRS Light is Just a Minor Annoyance

The SRS warning light indicates a potential problem with the system, which could compromise its ability to protect you in a collision. Ignoring the SRS light can have serious consequences.

8.5. Myth: SRS Repairs are Always Expensive

While some SRS repairs can be costly, others are relatively affordable. The cost of SRS repair depends on the type of repair required, the vehicle make and model, and the parts and labor costs.

9. Choosing CAR-TOOL.EDU.VN for Your Automotive Needs

When it comes to automotive repair and maintenance, choosing the right source for information and services is crucial. CAR-TOOL.EDU.VN stands out as a reliable and comprehensive resource for all your automotive needs.

9.1. Comprehensive Information on Auto Parts and Tools

CAR-TOOL.EDU.VN provides a wealth of detailed information about various auto parts and tools. Whether you’re looking for specifications, brands, or durability ratings, you’ll find the information you need to make informed decisions.

9.2. Comparison Tools for Repair Equipment

Comparing different repair tools can be time-consuming and confusing. CAR-TOOL.EDU.VN simplifies this process by offering comparison tools that allow you to evaluate features, benefits, and prices side-by-side.

9.3. User Reviews and Expert Recommendations

Benefit from the experiences of other users and the recommendations of industry experts. CAR-TOOL.EDU.VN aggregates reviews and insights to help you choose the best products for your needs.

9.4. Reliable Suppliers and Competitive Prices

CAR-TOOL.EDU.VN connects you with trusted suppliers offering competitive prices. You can be confident that you’re getting high-quality products at the best possible value.

9.5. Expert Consultation and Support

Need personalized advice or have specific questions? CAR-TOOL.EDU.VN offers expert consultation and support to guide you through your automotive repair and maintenance journey.

10. Frequently Asked Questions (FAQs) About SRS Engine Shops

Here are some frequently asked questions about SRS engine shops to help you better understand the topic:

10.1. What is an SRS Engine Shop?

An SRS engine shop is a specialized automotive repair facility equipped to diagnose and repair Supplemental Restraint System (SRS) issues, ensuring vehicle safety.

10.2. How Do I Know if My SRS Needs Repair?

The most common sign is the SRS warning light on your dashboard. Other signs include airbag deployment after minor impact and failure of airbags to deploy during an accident.

10.3. What Should I Expect from an SRS Diagnostic Service?

Expect a thorough visual inspection, diagnostic trouble code retrieval, wiring and circuit testing, sensor testing, and control module testing.

10.4. Can I Replace My Own Airbags?

No, DIY SRS repair is extremely dangerous. Mishandling SRS components can cause accidental airbag deployment and serious injuries.

10.5. How Much Does SRS Repair Typically Cost?

The cost varies depending on the type of repair needed. Airbag replacement can range from $500 to $1,500+, while sensor replacement is typically between $200 and $500+.

10.6. What Are the Benefits of Routine SRS Maintenance?

Routine maintenance ensures system reliability, prevents unexpected failures, extends system lifespan, and maintains vehicle safety.

10.7. Are Aftermarket Airbags Safe to Use?

While OEM airbags are recommended, high-quality aftermarket airbags can be a viable option if they meet safety standards and are installed by a qualified technician.

10.8. How Can I Find a Reputable SRS Engine Shop?

Look for shops with ASE-certified technicians, advanced equipment, positive online reviews, and transparent pricing.

10.9. Why Is it Important to Address SRS Issues Promptly?

Ignoring SRS issues can compromise the system’s ability to protect you in a collision, increasing the risk of serious injuries.

10.10. What Should I Do After Airbag Deployment?

After airbag deployment, have your SRS inspected and repaired by a qualified SRS engine shop to ensure all components are functioning correctly.

If you’re facing issues with your vehicle’s SRS, don’t hesitate to contact CAR-TOOL.EDU.VN at 456 Elm Street, Dallas, TX 75201, United States, or reach out via WhatsApp at +1 (641) 206-8880. Our team is ready to provide expert consultation and support to address your automotive needs.

SRS Engine Diagnostics

SRS Engine Diagnostics

SRS Engine Diagnostics: Utilizing advanced OBDII/EOBD engine scan functions to ensure comprehensive vehicle safety checks.

Godiag GD202 Package Contents

Godiag GD202 Package Contents

Godiag GD202 Package: Complete with GD202 host, cipher paper, USB cable, test line, multilingual quick guide, and instruction manual for easy setup and use.

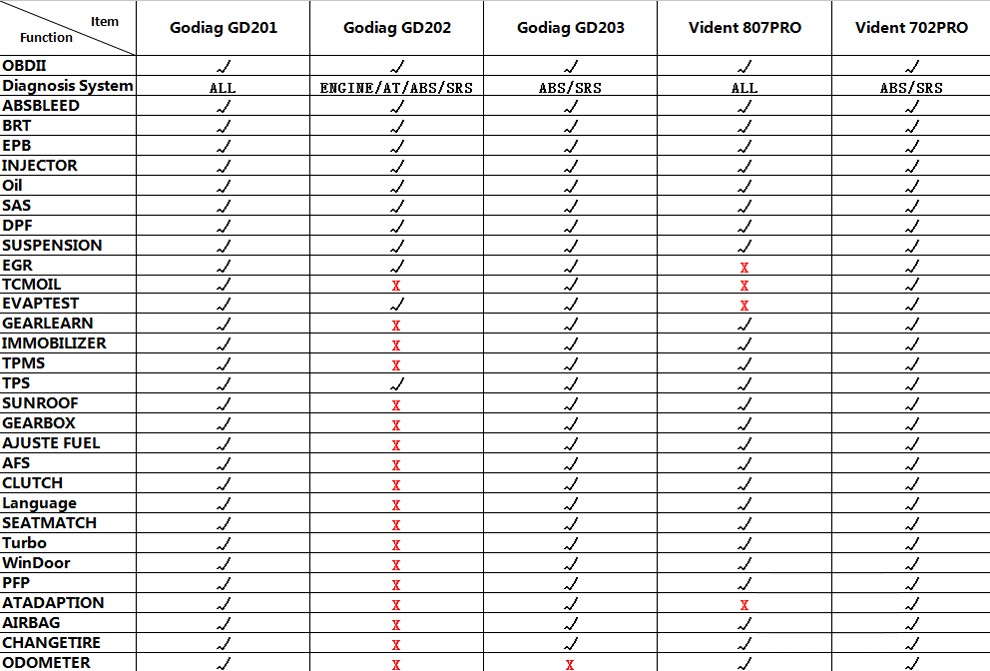

Comparing Diagnostic Scanners

Comparing Diagnostic Scanners

Diagnostic Scanner Comparison: A detailed comparison of Godiag GD201, GD202, GD203, Vident 807Pro, and Vident 702Pro scanners highlighting their features and capabilities.

CAR-TOOL.EDU.VN is your go-to resource for reliable information and expert advice on SRS engine shops and all your automotive needs. Contact us today to ensure your vehicle is in top condition.